Professional Documents

Culture Documents

Fto1143 - CPX Counter Module - Final

Uploaded by

H.M. ShamsuzzamanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fto1143 - CPX Counter Module - Final

Uploaded by

H.M. ShamsuzzamanCopyright:

Available Formats

Press Information

Date

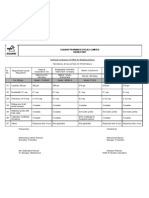

04.02.2014 New multi-featured Counter Module adds flexible counting capability to CPX systems Festo, the leaders in automation technology, introduces the latest addition to its wellestablished CPX Modular Automation Platform, the CPX-2ZE2DA-PI Counter Module. System builders can now incorporate counting capability simply by plugging a CPX Counter Module directly into their CPX system; this eliminates the need for an external counter and the associated costs it would present in terms of hardware and software integration effort, space requirement, cabling and installation time. Once installed, the Counter Modules high I/O, operational mode and parameterization flexibility allows engineers and machine builders to set up sophisticated counting applications with minimal effort. These can be implemented directly on the CPX system with a wide range of plant sensors and actuators far more rapidly than was previously possible. Festos CPX platform is a complete automation solution that integrates a wide choice of pneumatic and electrical, analogue and digital I/O. CPX systems configured for specific requirements are delivered pre-built, tested and ready for installation, enabling system integrators to meet tight timeframes and budgets. For additional flexibility, the CPX platform can operate as either a self-contained industrial PLC, or as a local unit on a Fieldbus or Industrial Ethernet-based distributed system. In addition, a wide choice of I/O and connector modules makes interfacing to process sensors and actuators easy. The CPX Counter Module has two channels, allowing compact and cost-effective solutions for applications with multiple sensors. Each channel accepts most 24 V and 5 V pulse and single-ended or differential incremental encoders, as well as SSI absolute types; this facilitates a wide range of length, position, speed and angular position measurement applications. A direction signal, or 90 phase shift inputs, on each channel allow extraction of direction information for incremental encoders. Count continuously, count once and periodic count modes at 24 V and 5 V levels are supported with pulse count frequencies to 1 MHz. Output functions are also well supported; these include configurable 24 V digital, pulse, pulse train, pulse-width modulation (PWM), On/Off control with delay and frequency output to 20 kHz. In addition, by pairing the Counter channels 24 V DC motors can be controlled.

Our reference

FTO1143

Festo Ltd. Technology House 1 Fleetwood Park Barley Way Fleet Hants. GU51 2QJ Tel: 01252 775000

The Counter Module has features to improve the quality of its results. These include hysteresis to overcome encoder fluctuations, and limit monitoring and diagnostics. For ease of use and added flexibility, parameterisation of each channel for its input and output connections and functionality can be managed via a laptop using Festos free to download FMT software, as are commissioning and diagnostics. IP-rated CPX systems using the Counter Module can be mounted directly onto the machine being controlled rather than relegated to a cabinet, as the module can achieve IP65-rated ingress protection with an optional cover. This allows engineers to design more compact, reliable and cost-effective systems with reduced cabling requirements. The module features Festos new push-in connection technology, which makes connection to the counters inputs and outputs quick and easy. The Counter Module is designed for applications within the packaging, drive engineering, process, food & drink, mechanical engineering and other industries. One example concerns rotary or in-line filling machines of up to 18 nozzles each with flowmeters for accurate volume dispensing. The Counter Module counts the flowmeter pulses and controls outputs to the nozzle shut-off valves. Other examples include fast, bus- and control-independent reactions for controlling fast-switching valves, valve opening times and direction changing for fast drives, and pulse-width modulation control for thermostat temperature settings, drive speed and lamp brightness. These Counter Modules add an easily-installed, compact and highly functional counting capability to CPX systems, comments Jacqui Hanbury, Product Manager at Festo GB. In line with the CPXs Functional Integration philosophy, the modules connect directly to encoders without need for A/D converters and associated wiring. Parameterisation is also performed simply and quickly. Overall, this means that CPX users in a wide variety of applications can start benefiting from the Counter Modules considerable flexibility with minimal disruption or delay. For further information on the CPX Counter Module please visit www.festo.co.uk/press/countermodule, or for more information about Festos pneumatic and electric automation solutions visit www.festo.co.uk or call 0800 626 422.

Ends

Image number 1, caption: Festo introduces the latest addition to its well-established CPX Modular Automation Platform, the CPX-2ZE2DA-PI Counter Module Image number 2, caption: The multi-featured Counter Module adds flexible counting capability to Festos CPX systems

News about Festos CPX Counter Module can be downloaded from

www.festo.co.uk/press/countermodule

Or, for Festos latest news go to www.festo.co.uk/gbpress. Ref: FTO1143 About Festo Festo is a leading international supplier of automation technology with a turnover in 2012 of over 2.24 billion. Festo employs more than 16,000 people worldwide and is a proven innovator and problem solver in the field of pneumatic and electrical automation where it has established itself as the performance leader. Festo Industrial Automations innovative strength is demonstrated through the introduction of around 100 new products being launched every year. The company invests 9% of its turnover in R&D resulting in over 2,900 patents held worldwide. For more information about the companys products and services, please visit: www.festo.co.uk. Festo Training & Consulting specialises in the development of people, organisations and technology skills. Offering a range of open courses, structured development programmes and tailor-made, customer-specific projects, Festo trains over 42,000 delegates worldwide every year. More information on the training and consulting services can be found at www.festo-didactic.co.uk. Festos Bionic Learning Network encapsulates the innovative nature of Festo, raising awareness and attracting talent to the company. Exploring the links between nature and technology opens up new areas of innovation and demonstrates complex ideas in a stimulating and enjoyable way. Festo works with an alliance of internal R&D, external educational establishments and specialist companies, to advance the development of bionic solutions for automation applications of the future. For more information about Festos Bionic Learning Network, please visit: www.festo.com/gb/bionics For more information please visit www.festo.com

Telephone number for publication: - 01252 775000 Journalist contact: Dulcie Elliot, Technical Publicity Tel: 01582 390984 Email: delliot@technical-group.com

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Guideline S7 PB eDocument26 pagesGuideline S7 PB eH.M. ShamsuzzamanNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Technical Comprsion (Int. Tester)Document3 pagesTechnical Comprsion (Int. Tester)H.M. ShamsuzzamanNo ratings yet

- Technical Comprsion (Int. Tester)Document3 pagesTechnical Comprsion (Int. Tester)H.M. ShamsuzzamanNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Technical Comparison (Balance) MDI.Document1 pageTechnical Comparison (Balance) MDI.H.M. ShamsuzzamanNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- AcknowledgeDocument3 pagesAcknowledgeH.M. ShamsuzzamanNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Switched Mode Power SupplyDocument153 pagesSwitched Mode Power SupplyIvan222244No ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Backwards Design - Jessica W Maddison CDocument20 pagesBackwards Design - Jessica W Maddison Capi-451306299100% (1)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- CAREDocument11 pagesCARELuis SementeNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Microfinance Ass 1Document15 pagesMicrofinance Ass 1Willard MusengeyiNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Openvpn ReadmeDocument7 pagesOpenvpn Readmefzfzfz2014No ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Zimbabwe - Medical - CPIN - v2.0 - GOV - UKDocument39 pagesZimbabwe - Medical - CPIN - v2.0 - GOV - UKsammy redganjiNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Introducing The Thinkcentre M70A. A Desktop You DefineDocument3 pagesIntroducing The Thinkcentre M70A. A Desktop You DefineSiti RohayatiNo ratings yet

- The Time Machine Was First Published in 1984 As A Story Under The Name The Time Traveller in The National ObserverDocument1 pageThe Time Machine Was First Published in 1984 As A Story Under The Name The Time Traveller in The National ObservermarceNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Enrico Fermi Pioneer of The at Ted GottfriedDocument156 pagesEnrico Fermi Pioneer of The at Ted GottfriedRobert Pérez MartinezNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- 1500 Series: Pull Force Range: 10-12 Lbs (44-53 N) Hold Force Range: 19-28 Lbs (85-125 N)Document2 pages1500 Series: Pull Force Range: 10-12 Lbs (44-53 N) Hold Force Range: 19-28 Lbs (85-125 N)Mario FloresNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Persuasive Speech 2016 - Whole Person ParadigmDocument4 pagesPersuasive Speech 2016 - Whole Person Paradigmapi-311375616No ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Directorate of Technical Education, Admission Committee For Professional Courses (ACPC), GujaratDocument2 pagesDirectorate of Technical Education, Admission Committee For Professional Courses (ACPC), GujaratgamailkabaaaapNo ratings yet

- Generalized Class of Sakaguchi Functions in Conic Region: Saritha. G. P, Fuad. S. Al Sarari, S. LathaDocument5 pagesGeneralized Class of Sakaguchi Functions in Conic Region: Saritha. G. P, Fuad. S. Al Sarari, S. LathaerpublicationNo ratings yet

- Liquitex Soft Body BookletDocument12 pagesLiquitex Soft Body Booklethello belloNo ratings yet

- KundaliniDocument3 pagesKundaliniAlfred IDunnoNo ratings yet

- Albert Roussel, Paul LandormyDocument18 pagesAlbert Roussel, Paul Landormymmarriuss7No ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Introduction To Password Cracking Part 1Document8 pagesIntroduction To Password Cracking Part 1Tibyan MuhammedNo ratings yet

- Dessler HRM12e PPT 01Document30 pagesDessler HRM12e PPT 01harryjohnlyallNo ratings yet

- 32 Hyderabad HITEC City BisleriDocument23 pages32 Hyderabad HITEC City BisleriSridhar ViswanathanNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Strategic Marketing: The University of Lahore (Islamabad Campus)Document3 pagesStrategic Marketing: The University of Lahore (Islamabad Campus)Sumaira IrshadNo ratings yet

- Java Complete Collection FrameworkDocument28 pagesJava Complete Collection FrameworkkhushivanshNo ratings yet

- Paul Wade - The Ultimate Isometrics Manual - Building Maximum Strength and Conditioning With Static Training-Dragon Door Publications (2020) - 120-146Document27 pagesPaul Wade - The Ultimate Isometrics Manual - Building Maximum Strength and Conditioning With Static Training-Dragon Door Publications (2020) - 120-146usman azharNo ratings yet

- Changed Report 2015 PDFDocument298 pagesChanged Report 2015 PDFAnonymous FKjeRG6AFnNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Lesser Known Homoeopathic Medicines of Alopecia Areata.20200718115446Document9 pagesLesser Known Homoeopathic Medicines of Alopecia Areata.20200718115446BruntNo ratings yet

- Spring 2010 - CS604 - 1 - SolutionDocument2 pagesSpring 2010 - CS604 - 1 - SolutionPower GirlsNo ratings yet

- The Body Shop Case Analysis. The Challenges of Managing Business As Holistic ConfigurationDocument28 pagesThe Body Shop Case Analysis. The Challenges of Managing Business As Holistic ConfigurationHanna AbejoNo ratings yet

- EP001 LifeCoachSchoolTranscriptDocument13 pagesEP001 LifeCoachSchoolTranscriptVan GuedesNo ratings yet

- Term Paper Inorganic PolymersDocument24 pagesTerm Paper Inorganic PolymersCasey Karua0% (1)

- Sheltered 2 Item Recycle ListDocument5 pagesSheltered 2 Item Recycle ListRachel GNo ratings yet

- On Animal Language in The Medieval Classification of Signs PDFDocument24 pagesOn Animal Language in The Medieval Classification of Signs PDFDearNoodlesNo ratings yet

- Group 2 ITI Consensus Report: Prosthodontics and Implant DentistryDocument9 pagesGroup 2 ITI Consensus Report: Prosthodontics and Implant DentistryEsme ValenciaNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)