Professional Documents

Culture Documents

Engeneering Desing Sistematic Aproach

Uploaded by

Felipe LopesCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Engeneering Desing Sistematic Aproach

Uploaded by

Felipe LopesCopyright:

Available Formats

G. Pahl and W. Beitz J. Feldhusen and K.-H.

Grote

Engineering Design

A Systematic Approach Third Edition

Ken Wallace and Lucienne Blessing Translators and Editors

fyA Springer

Contents

Introduction 1.1 The Engineering Designer 1.1.1 Tasks and Activities 1.1.2 Position of the Design Process within a Company 1.1.3 Trends 1.2 Necessity for Systematic Design 1.2.1 Requirements and the Need for Systematic Design 1.2.2 Historical Background 1.2.3 Current Methods 1.2.4 Aims and Objectives of this Book Fundamentals 2.1 Fundamentals of Technical Systems 2.1.1 Systems, Plant, Equipment, Machines, Assemblies and Components 2.1.2 Conversion of Energy, Material and Signals 2.1.3 Functional Interrelationship 2.1.4 Working Interrelationship 2.1.5 Constructional Interrelationship 2.1.6 System Interrelationship 2.1.7 Systematic Guideline 2.2 Fundamentals of the Systematic Approach 2.2.1 Problem Solving Process 2.2.2 Characteristics of Good Problem Solvers 2.2.3 Problem Solving as Information Processing . . . . 2.2.4 General Working Methodology 2.2.5 Generally Applicable Methods 2.2.6 Role of Computer Support Product Planning, Solution Finding and Evaluation 3.1 Product Planning 3.1.1 Degree of Novelty of a Product

1 1 1 6 6 9 9 10 14 19 27 27 27 29 31 38 42 42 43 45 45 49 51 53 58 62 63 63 64

Contents

3.2

3.3

3.1.2 Product Life Cycle 3.1.3 Company Goals and Their Effect 3.1.4 Product Planning Solution Finding Methods 3.2.1 Conventional Methods 3.2.2 Intuitive Methods 3.2.3 Discursive Methods 3.2.4 Methods for Combining Solutions Selection and Evaluation Methods 3.3.1 Selecting Solution Variants 3.3.2 Evaluating Solution Variants

64 65 66 77 78 82 89 103 106 106 109 125 125 128 128 134 136 138 138 141 145 145 146 146 147 149 151 152 153 153 153 156 157 157 159 159 161 161 162 164 169

Product Development Process 4.1 General Problem Solving Process 4.2 Flow of Work During the Process of Designing 4.2.1 Activity Planning 4.2.2 Timing and Scheduling 4.2.3 Planning Project and Product Costs 4.3 Effective Organisation Structures 4.3.1 Interdisciplinary Cooperation 4.3.2 Leadership and Team Behaviour Task Clarification 5.1 Importance of Task Clarification 5.2 Setting Up a Requirements List (Design Specification) 5.2.1 Contents 5.2.2 Format 5.2.3 Identifying the Requirements 5.2.4 Refining and Extending the Requirements 5.2.5 Compiling the Requirements List 5.2.6 Examples 5.3 Using Requirements Lists 5.3.1 Updating 5.3.2 Partial Requirements Lists 5.3.3 Further Uses 5.4 Practical Application of Requirements Lists Conceptual Design 6.1 Steps of Conceptual Design 6.2 Abstracting to Identify the Essential Problems 6.2.1 Aim of Abstraction 6.2.2 Broadening the Problem Formulation 6.2.3 Identifying the Essential Problems from the Requirements List 6.3 Establishing Function Structures

Contents

xix

6.4

6.5

6.6

6.3.1 Overall Function 6.3.2 Breaking a Function Down into Subfunctions .. 6.3.3 Practical Applications of Function Structures .. Developing Working Structures 6.4.1 Searching for Working Principles 6.4.2 Combining Working Principles 6.4.3 Selecting Working Structures 6.4.4 Practical Application of Working Structures Developing Concepts 6.5.1 Firming Up into Principle Solution Variants.... 6.5.2 Evaluating Principle Solution Variants 6.5.3 Practical Application of Developing Concepts .. Examples of Conceptual Design 6.6.1 One-Handed Household Water Mixing Tap 6.6.2 Impulse-Loading Test Rig

169 170 178 181 181 184 186 186 190 190 192 198 199 199 210 227 227 233 234 235 242 247 268 269 281 290 301 305 308 308 309 321 328 340 341 348 355 375 385 388 402 410 416 417 436

Embodiment Design 7.1 Steps of Embodiment Design 7.2 Checklist for Embodiment Design 7.3 Basic Rules of Embodiment Design 7.3.1 Clarity 7.3.2 Simplicity 7.3.3 Safety 7.4 Principles of Embodiment Design 7.4.1 Principles of Force Transmission 7.4.2 Principle of the Division of Tasks 7.4.3 Principle of Self-Help 7.4.4 Principles of Stability and Bi-Stability 7.4.5 Principles for Fault-Free Design 7.5 Guidelines for Embodiment Design 7.5.1 General Considerations 7.5.2 Design to Allow for Expansion 7.5.3 Design to Allow for Creep and Relaxation 7.5.4 Design Against Corrosion 7.5.5 Design to Minimise Wear 7.5.6 Design for Ergonomics 7.5.7 Design for Aesthetics 7.5.8 Design for Production 7.5.9 Design for Assembly 7.5.10 Design for Maintenance 7.5.11 Design for Recycling 7.5.12 Design for Minimum Risk 7.5.13 Design to Standards 7.6 Evaluating Embodiment Designs 7.7 Example of Embodiment Design 7.8 Detail Design

xx

Contents

Mechanical Connections, Mechatronics and Adaptronics 8.1 Mechanical Connections 8.1.1 Generic Functions and General Behaviour 8.1.2 Material Connections 8.1.3 Form Connections 8.1.4 Force Connections 8.1.5 Applications 8.2 Mechatronics 8.2.1 General Architecture and Terminology 8.2.2 Goals and Limitations 8.2.3 Development of Mechatronic Solutions 8.2.4 Examples 8.3 Adaptronics 8.3.1 Fundamentals and Terminology 8.3.2 Goals and Limitations 8.3.3 Development of Adaptronic Solutions 8.3.4 Examples

439 439 440 440 441 443 447 448 448 450 450 451 458 458 459 460 461

Size Ranges and Modular Products 465 9.1 Size Ranges 465 9.1.1 Similarity Laws 466 9.1.2 Decimal-Geometric Preferred Number Series ..469 9.1.3 Representation and Selection of Step Sizes 472 9.1.4 Geometrically Similar Size Ranges 476 9.1.5 Semi-Similar Size Ranges 481 9.1.6 Development of Size Ranges 493 9.2 Modular Products 495 9.2.1 Modular Product Systematics 496 9.2.2 Modular Product Development 499 9.2.3 Advantages and Limitations of Modular Systems 508 9.2.4 Examples 510 9.3 Recent Rationalisation Approaches 514 9.3.1 Modularisation and Product Architecture 514 9.3.2 Platform Construction 515 517 517 521 522 529 531

10 Design for Quality 10.1 Applying a Systematic Approach 10.2 Faults and Disturbing Factors 10.3 Fault-Tree Analysis 10.4 Failure Mode and Effect Analysis (FMEA) 10.5 Quality Function Deployment (QFD)

Contents

xxi

11 Design for Minimum Cost 11.1 Cost Factors 11.2 Fundamentals of Cost Calculations 11.3 Methods for Estimating Costs 11.3.1 Comparing with Relative Costs 11.3.2 Estimating Using Share of Material Costs 11.3.3 Estimating Using Regression Analysis 11.3.4 Extrapolating Using Similarity Relations 11.3.5 Cost Structures 11.4 Target Costing 11.5 Rules for Minimising Costs 12 Summary 12.1 The Systematic Approach 12.2 Experiences of Applying the Systematic Approach in Practice References English Bibliography Index

535 535 537 539 539 544 545 547 558 560 561 563 563 567 571 603 609

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Nais Control 1131 FP0FP1FPM Instruction SetDocument613 pagesNais Control 1131 FP0FP1FPM Instruction SettlilinouraNo ratings yet

- Fabricación de Insertos de Carburo de TungstenoDocument5 pagesFabricación de Insertos de Carburo de TungstenoRolando Nuñez MonrroyNo ratings yet

- A Design and Analysis of A Morphing Hyper-Elliptic Cambered Span (HECS) WingDocument10 pagesA Design and Analysis of A Morphing Hyper-Elliptic Cambered Span (HECS) WingJEORJENo ratings yet

- RE 1 (BAB 8 DAN BAB 9) - Halaman-9-18Document10 pagesRE 1 (BAB 8 DAN BAB 9) - Halaman-9-18Yesi Indri HeryaniNo ratings yet

- MVC Project Jarvis DatabaseDocument30 pagesMVC Project Jarvis DatabaseSravan SaiNo ratings yet

- Manual Bristol 3808 Multivariable Transmitters en 133322 PDFDocument174 pagesManual Bristol 3808 Multivariable Transmitters en 133322 PDFROBERTO MARTINEZNo ratings yet

- Determine Floating Body StabilityDocument11 pagesDetermine Floating Body StabilityDember Paul100% (1)

- Solid Mechanics: Amit Sir (M-Tech (STRUCTURE), BE, Diploma in Civil), 7020059691/7385990691Document9 pagesSolid Mechanics: Amit Sir (M-Tech (STRUCTURE), BE, Diploma in Civil), 7020059691/7385990691Nikita GonnadeNo ratings yet

- Equipment Schedule HVACDocument7 pagesEquipment Schedule HVACHussainShabbirNo ratings yet

- Hazardous Area ClassificationDocument15 pagesHazardous Area ClassificationpmnasimNo ratings yet

- Astm c243 Withdrawn.31346Document4 pagesAstm c243 Withdrawn.31346SilvioCarrilloNo ratings yet

- ACSEW Cast Control Centers: Explosionproof, Dust-IgnitionproofDocument24 pagesACSEW Cast Control Centers: Explosionproof, Dust-IgnitionproofDennis MendozaNo ratings yet

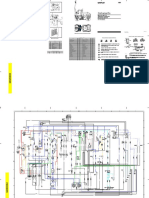

- Electric Schematic CB113 114 QENR2003 PDFDocument2 pagesElectric Schematic CB113 114 QENR2003 PDFHipac TapicuNo ratings yet

- Type 3025 Sizes P462, P460-200 and P900 Diaphragm Actuator: Bulletin 61.1:3025Document8 pagesType 3025 Sizes P462, P460-200 and P900 Diaphragm Actuator: Bulletin 61.1:3025Datt NguyenNo ratings yet

- Estimate of Cycle Stand Extension Situated at Bhagat Singh College Jaora, Dist. RatlamDocument5 pagesEstimate of Cycle Stand Extension Situated at Bhagat Singh College Jaora, Dist. RatlamaasifahNo ratings yet

- Jacoby TarboxDocument7 pagesJacoby TarboxBayu Permana RydhaNo ratings yet

- Checklist for Training Cleaning StaffDocument1 pageChecklist for Training Cleaning StaffharrydrivesucrazyNo ratings yet

- DBMS Lab ExperimentsDocument45 pagesDBMS Lab ExperimentsMad Man100% (1)

- Datasheet CONTI SILENTSYNC ENDocument1 pageDatasheet CONTI SILENTSYNC ENViniciusNo ratings yet

- Loop Back DSP Audio AppDocument12 pagesLoop Back DSP Audio AppGytis BernotasNo ratings yet

- A320-25-1BPK R01 Dt. 25.05.21Document39 pagesA320-25-1BPK R01 Dt. 25.05.21Pradeep K sNo ratings yet

- Max 223C Pipeline Welding InverterDocument2 pagesMax 223C Pipeline Welding InvertermtonellyNo ratings yet

- Driver Control Master NXT Service Manual 092137-8Document53 pagesDriver Control Master NXT Service Manual 092137-8Piero Capretti0% (1)

- Bernard D. Marquez Eduardo M. Axalan Engr. William A.L.T. NGDocument1 pageBernard D. Marquez Eduardo M. Axalan Engr. William A.L.T. NGRhon Nem KhoNo ratings yet

- RDSO Guidelines - Bs 112 - Planning of Road Over BridgesDocument9 pagesRDSO Guidelines - Bs 112 - Planning of Road Over BridgesAnkur MundraNo ratings yet

- Nidek ARK 730 Autorefractometer Service Manual PDFDocument83 pagesNidek ARK 730 Autorefractometer Service Manual PDFPetrica DascaluNo ratings yet

- UOP046-85 Wax Content in Petroleum OilsDocument6 pagesUOP046-85 Wax Content in Petroleum OilsZiauddeen Noor100% (1)

- Tiny House MovementDocument51 pagesTiny House MovementAngelique Lucille PumanesNo ratings yet

- 20 Things To Know About The Jeepney Modernization ProgramDocument2 pages20 Things To Know About The Jeepney Modernization ProgramMark Julius MaravilloNo ratings yet

- Voltage Divider Bias Stabilizes BJT Transistor OutputDocument5 pagesVoltage Divider Bias Stabilizes BJT Transistor OutputMalikAlrahabiNo ratings yet