Professional Documents

Culture Documents

Challenges in Ore Characterization Home Project

Uploaded by

le_fridaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Challenges in Ore Characterization Home Project

Uploaded by

le_fridaCopyright:

Available Formats

Challenges in Ore Characterization The overall grade of many common ore types is gradually declining.

For example, copper ore bodies at Cu-grades >5% with bornite as the primary copper mineral species are no longer the rule but the exception. Much more common are copper ores of 1% copper grade, with a multitude of copper sulphides contributing to copper grade, such as chalcocite, chalcopyrite and covalite. As a result, plant operators are increasingly challenged to understand which minerals actually contribute to grade, as each mineral is likely to behave differently to comminution, flotation or leaching. Elemental deportment also entails the comprehensive understanding of minerals that do not contribute to grade, as well as penalty elements that can cause environmental concerns with tailings storage (e.g. Arsenicum), affect the efficiency of processing (e.g. hydrophobic gangue minerals such as talc), or affect the value of the final concentrate (e.g. bismuth in a copper sulphide concentrate, or chrome in a PGM concentrate). Traditional bulk geochemical analysis techniques such as AA, ICP or XRF do not offer a capability to measure elemental deportment -- XRD and automated mineralogy do. In addition, automated mineralogy also provides the textural context of elemental and mineral deportment.

A Portfolio of Automated Mineralogy Solutions

Leading mining companies such as Anglo Platinum, Freeport McMoran and Rio Tinto were among the early adaptors of automated mineralogy, collecting years of monthly or weekly composites of feed, concentrate and tailings samples. These vast databases of ore properties have been correlated to plant performance, which in each case has led to a revised insight of ore classification. This was historically done on the basis of input from geologists and mineralogists, yet some of the geological ore differences did not translate into different processing behaviors. Instead, automated mineralogy data coupled to plant data has led to revised insight of classifying ore types on the basis of metallurgical properties, i.e. processing domains that are metallurgically meaningful. In many documented instances, the enhanced understanding of ore properties has led to major investments with enormous returns in e.g. new grinding technologies or plant upgrades. In addition, the knowledge is stored in a database for future reference and to be used for comparative studies when plants experience high losses to tailings, which drives a key requirement for Automated Mineralogy, namely compatibility with historical data. FEI serves ore characterization requirements of the mining companies with a portfolio of automated mineralogy laboratory and field systems, both QEMSCAN and MLA, on four different SEM platforms, to provide tailored solutions to throughput requirements, turnkey solutions for certain ore types (e.g. low grade), basic analysis resolution, and ruggedness for fast turn-around on-site geometallurgical programs.

Mining Automated mineralogy delivers a particle-by-particle view of mining and mineral processing effectiveness

The outlook for the mining industry is both prosperous, as demand for both base and precious metals is expected to remain high, and challenging, due to declining ore grades, steeply increasing costs of production resources such as electricity and water, and investor pressure on operational efficiency. Mineralogy and ore texture are increasingly critical attributes that affect the ability of mining companies to extract base and precious elements from ores both economically and sustainably. A thorough understanding of ore mineralogy and texture will continue to play an increasingly important role, from upstream ore characterization, metallurgical testing and flow sheet design, to mineral processing. Textural properties of ores typically

feature microscopic, sometimes nanoscopic, attributes; hence ore characterization, metallurgical testing and mineral processing are prime use cases for FEIs natural resources imaging solutions.

QEMSCAN

QEMSCAN is a fully automated, non-destructive, micro-analysis system that provides rapid, statistically reliable and repeatable, mineralogical, petrographic and metallurgical data, from virtually any inorganic, and some organic, materials. It is used in the mining industry for mineral exploration, ore characterization, and mineral process optimization applications. The oil and gas industry utilizes QEMSCAN to reduce risk and improve extraction, based on knowledge derived from the micro-analysis of drill cuttings and cores. The coal industry is applying automated analysis of coal, pulverized fuel and coal combustion products, to better understand coal combustion and waste utilization.

Product Models

QEMSCAN QEMSCAN 650F QEMSCAN Express QEMSCAN WellSite QEMSCAN 650

The MLA (an acronym for Mineral Liberation Analyzer) is an automated mineral analysis system that can identify minerals in polished sections of drill core, particulate, or lump materials, and quantify a wide range of mineral characteristics, such as mineral abundance, grain size, and liberation.

Mineral texture and degree of liberation are fundamental properties of ore and drive its economic treatment, making the data gathered by the MLA invaluable to geologists, mineralogists and metallurgists who engage in process optimization, mine feasibility studies, and ore characterization.

How Does a Scanning Electron Microscopes Work Its Magic?

In some ways, SEMs work in the same way key copying machines work. When you get a key copied at your local hardware store, a machine traces over the indentations of the original key while cutting an exact replica into a blank key. The copy isn't made all at once, but rather traced out from one end to the other. You might think of the specimen under examination as the original key. The SEM's job is to use an electron beam to trace over the object, creating an exact replica of the original object on amonitor. So rather than just tracing out a flat one-dimensional outline of the key, the SEM gives the viewer more of a living, breathing 3-D image, complete with grooves and engraving. As the electron beam traces over the object, it interacts with the surface of the object, dislodging secondary electrons from the surface of the specimen in unique patterns. A secondary electron detector attracts those scattered electrons and, depending on the number of electrons that reach the detector, registers different levels of brightness on a monitor. Additional sensors detect backscattered electrons (electrons that reflect off the specimen's surface) and X-rays (emitted from beneath the

specimen's surface). Dot by dot, row by row, an image of the original object is scanned onto a monitor for viewing (hence the "scanning" part of the machine's name). Of course, this entire process wouldn't be possible if the microscope couldn't control the movement of an electron beam. SEMs use scanning coils, which create a magnetic field using fluctuating voltage, to manipulate the electron beam. The scanning coils are able to move the beam precisely back and forth over a defined section of an object. If a researcher wants to increase the magnification of an image, he or she simply sets the electron beam to scan a smaller area of the sample. While it's nice to know how an SEM works in theory, operating one is even better.

The History of Scanning Electron Microscopes

The development of SEMs started with more of a whimper than a bang. When the technology was first unveiled in 1935, a group of marketing professionals was asked to evaluate the new instrument's potential in the marketplace. After polling the scientific community, the marketing experts weren't too optimistic. They estimated a need for, at most, 10 of the devices worldwide. As it turns out, the experts vastly underestimated the potential of SEMs, and thankfully, their dour outlook failed to deter further development of the technology. As a result, more than 50,000 SEMs fill laboratories and businesses across the globe [source: Breton]. So how did SEMs go from near obsolescence to the essential research tools that they are today? For one thing, scientists had pushed optical microscopes to their limits. Optical microscopes had been around for centuries, and while you can still find them in classrooms across the country, their dependence on light had become a problem. Light's tendency to diffract, or bend around the edges of optical lenses, limits the magnification capability and resolution of optical microscopes. As a result, scientists began to develop new ways to examine the microscopic world around them and, in 1932, produced the world's firsttransmission electron microscope (TEM). This instrument directs a beam of electrons through the sample under observation and then projects the resulting image on a fluorescent screen. TEMs, as you might guess, share a lot in common with SEMs, and it was only a matter of a few years before SEMs were developed. Since development of TEMs was well under way by the time SEMs came along, the latter were initially considered unnecessary. It took the unwavering resolution of C.W. Oatley, a professor of engineering at Cambridge University, to move the newer microscope forward. Working closely with several of his colleagues and graduate students, Oatley was able to demonstrate both the SEM's magnification potential and the astonishing 3-D quality of images it produced. Today, SEMs are routinely used in tasks like inspecting semiconductors for defects or exploring how insects work.

Scanning electron microscopes lord lots of advantages over optical microscopes, but they still can't produce color images (more on why later). One way to add color is to use photo-processing software. More recently, however, scientists have developed an electron microscope with the ability to detect energy signatures emitted during the magnification process. This information allows the microscope to assign colors to different elements, such as titanium and manganese, depending on the energy signatures they emit. With this technology, researchers can determine precisely where one material ends and another begins, all in glorious color.

The Key Components of a Scanning Electron Microscope

We've begun to get an idea of what SEMs are capable of. Now we're ready to take a look at the various components of one and how they work together to form an image. While the variations from one model to the next are seemingly endless, all SEMs share the same basic parts. Electron gun: Electron guns aren't some futuristic weapon used in the newest Vin Diesel movie. Instead, they produce the steady stream of electrons necessary for SEMs to operate. Electron guns are typically one of two types.Thermionic guns, which are the most common type, apply thermal energy to a filament (usually made of tungsten, which has a high melting point) to coax electrons away from the gun and toward the specimen under examination. Field emission guns, on the other hand, create a strong electrical field to pull electrons away from the atoms they're associated with. Electron guns are located either at the very top or at the very bottom of an SEM and fire a beam of electrons at the object under examination. These electrons don't naturally go where they need to, however, which gets us to the next component of SEMs. Lenses: Just like optical microscopes, SEMs use lenses to produce clear and detailed images. The lenses in these devices, however, work differently. For one thing, they aren't made of glass. Instead, the lenses are made of magnets capable of bending the path of electrons. By doing so, the lenses focus and control the electron beam, ensuring that the electrons end up precisely where they need to go. Sample chamber: The sample chamber of an SEM is where researchers place the specimen that they are examining. Because the specimen must be kept extremely still for the microscope to produce

clear images, the sample chamber must be very sturdy and insulated from vibration. In fact, SEMs are so sensitive to vibrations that they're often installed on the ground floor of a building. The sample chambers of an SEM do more than keep a specimen still. They also manipulate the specimen, placing it at different angles and moving it so that researchers don't have to constantly remount the object to take different images. Detectors: You might think of an SEM's various types of detectors as the eyes of the microscope. These devices detect the various ways that the electron beam interacts with the sample object. For instance, Everhart-Thornley detectors register secondary electrons, which are electrons dislodged from the outer surface of a specimen. These detectors are capable of producing the most detailed images of an object's surface. Other detectors, such as backscattered electron detectors and Xray detectors, can tell researchers about the composition of a substance. Vacuum chamber: SEMs require a vacuum to operate. Without a vacuum, the electron beam generated by the electron gun would encounter constant interference from air particles in the atmosphere. Not only would these particles block the path of the electron beam, they would also be knocked out of the air and onto the specimen, which would distort the surface of the specimen. As with many things, an SEM is more than the sum of its parts. Read on to see how all of these components work together to create astounding images of very, very tiny things.

How Does a Scanning Electron Microscopes Work Its Magic?

In some ways, SEMs work in the same way key copying machines work. When you get a key copied at your local hardware store, a machine traces over the indentations of the original key while cutting an exact replica into a blank key. The copy isn't made all at once, but rather traced out from one end to the other. You might think of the specimen under examination as the original key. The SEM's job is to use an electron beam to trace over the object, creating an exact replica of the original object on amonitor. So rather than just tracing out a flat one-dimensional outline of the key, the SEM gives the viewer more of a living, breathing 3-D image, complete with grooves and engraving. As the electron beam traces over the object, it interacts with the surface of the object, dislodging secondary electrons from the surface of the specimen in unique patterns. A secondary electron detector attracts those scattered electrons and, depending on the number of electrons that reach the detector, registers different levels of brightness on a monitor. Additional sensors detect backscattered electrons (electrons that reflect off the specimen's surface) and X-rays (emitted from beneath the specimen's surface). Dot by dot, row by row, an image of the original object is scanned onto a monitor for viewing (hence the "scanning" part of the machine's name). Of course, this entire process wouldn't be possible if the microscope couldn't control the movement of an electron beam. SEMs use scanning coils, which create a magnetic field using fluctuating voltage, to manipulate the electron beam. The scanning coils are able to move the beam precisely back and forth over a defined section of an object. If a researcher wants to increase the magnification of an image, he or she simply sets the electron beam to scan a smaller area of the sample. While it's nice to know how an SEM works in theory, operating one is even better.

THIS SEM BUSINESS IS ALL WET Since SEMs operate in a vacuum, researchers always assumed samples observed using an SEM would need to be moisture-free. This requirement kept them from observing biological specimens like living cells. Fortunately, the newest generation of SEMs has overcome these limitations. For instance, some SEMs now require only a moderately strong vacuum for operation. While these microscopes sacrifice resolution in the process, they're much more flexible in terms of the samples they can view. Other companies have devised a method of observing samples in solution. By separating the samples from the vacuum chamber using a high-strength film, these SEMs can observe objects never before subject to such high levels of magnification.

Operating a Scanning Electron Microscope

Before researchers can take their first SEM image of, say, a mosquito, they have to prepare the specimen. Because SEMs, unlike optical microscopes, operate in a vacuum and rely on electric fields to work, sample preparation can be a complicated process. Researchers start by cleaning it of any dust or debris. Once clean, it's ready to be mounted in the SEM if the specimen is fairly conductive. Otherwise, it's coated in a conductive material like gold or platinum through a process called sputter coatingbefore it's ready for viewing. Sputter coating allows a sample to be grounded, preventing it from being damaged by the electron beam. Since specimens placed in the microscopes also are subject to a vacuum, they sometimes undergo additional preparation to ensure that they hold up under such extreme conditions. Biological samples, for instance, are typically dehydrated before being placed in an SEM. Otherwise, the low atmospheric pressure of a vacuum would cause the water in biological samples to evaporate quickly, destroying the sample in the process. Other specimens are frozen before they are examined, and still others are chemically treated so that they survive the magnification process. Researchers, like photographers, have a variety of controls over the images they produce. The magnification, focus, contrast and brightness of an image are all at the fingertips of the operator of an SEM. While some models have dedicated hardware for these settings, the more recent integration of computerized controls has both lowered the cost of SEMs and simplified their operation. Finally, make sure to observe some safety precautions when operating the instrument. In the process of scanning specimens, SEMs generate small levels of radiation in the form of X-rays as electrons beneath the surface of a specimen are dislodged and replaced by other electrons. While X-rays are inherently dangerous to humans, you shouldn't be too worried about operating an SEM. Most of the instruments have a highly isolated specimen chamber, designed to keep out electrical and magnetic interference, so any X-rays generated in the magnification process shouldn't pose a threat to the operator. Still, researchers should make sure to observe any safety precautions concerning the operation of the SEMs at their institution.

N\B

Not all microscopes use lenses. If you're like most people, the microscope you used in high school was a light-based microscope. Electron microscopes work using completely different principles. Electron microscopes are important for the depth of detail they show, which has led to a variety of important discoveries. Understanding their importance requires an understanding of how they work, and how this has led to further discovery.

Strength

The reasons these microscopes are so important is the sheer level of detail that can be seen with them. Standard, light-based microscopes are limited by the inherent

limitations of light, and as such can only magnify to 500 or 1000 times. Electron microscopes can exceed this by far, showing details as small as the molecular level. This means electron microscopes can be used to examine things only theoretically known before 1943, when the electron microscope was invented.

Use

These microscopes are used in a variety of studies, including physics, chemistry and biology. Because of the incredible amount of detail these microscopes allow for, they've led to advances in the fields of medicine, and are widely used in the field of forensics.

who invented the electron microscope? The electron microscope was invented in 1931 by Germans Ernst Ruska and Max Knoll. Ernst Ruska later received Nobel Prize for his work in 1986. Look here for more information: http:

http://answers.ask.com/Science/Physics/who_invente...

What is a Electron Microscope? The electron microscope is the granddaddy of all microscopes because it can magnify things up to two million times its size! Scientists use electron microscopes to study microorganisms

http://answers.ask.com/Science/Physics/what_is_a_e...

What is a Scanning Electron Microscope? A scanning electron microscope is a microscope that scan something with an electron beam. These microscopes are very powerful and can show different properties of samples, such as

http://answers.ask.com/Science/Physics/what_is_a_s...

How does An Electron Microscope Work? An electron microscope works by passing electrons through an object to get a clear picture of it. There are two types of electron microcscopes one is the transmission electron microscope

http://answers.ask.com/Science/Physics/how_does_an...

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- ListDocument4 pagesListgeralda pierrelusNo ratings yet

- Barker-Choucalas, Vida PDFDocument176 pagesBarker-Choucalas, Vida PDFAnn GarbinNo ratings yet

- Guidelines To MAS Notice 626 April 2015Document62 pagesGuidelines To MAS Notice 626 April 2015Wr OngNo ratings yet

- Sss PDFDocument1 pageSss PDFROVI ROSE MAILOMNo ratings yet

- Long Standoff Demolition Warheads For Armor, Masonry and Concrete TargetsDocument27 pagesLong Standoff Demolition Warheads For Armor, Masonry and Concrete Targetsahky7No ratings yet

- Numerical Solution of Ordinary Differential EquationsDocument31 pagesNumerical Solution of Ordinary Differential Equationschandu3072002100% (1)

- Case NoDocument13 pagesCase NoLaurente JessicaNo ratings yet

- Chapter 4 and 5 - For StudentsDocument6 pagesChapter 4 and 5 - For Studentsdesada testNo ratings yet

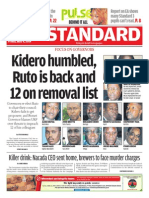

- The Standard 09.05.2014Document96 pagesThe Standard 09.05.2014Zachary Monroe100% (1)

- 8510C - 15, - 50, - 100 Piezoresistive Pressure Transducer: Features DescriptionDocument3 pages8510C - 15, - 50, - 100 Piezoresistive Pressure Transducer: Features Descriptionedward3600No ratings yet

- DesignWS P1 PDFDocument673 pagesDesignWS P1 PDFcaubehamchoi6328No ratings yet

- Amino AcidsDocument17 pagesAmino AcidsANAND sNo ratings yet

- Adjectives Weekly Plan1Document10 pagesAdjectives Weekly Plan1RItta MariaNo ratings yet

- Mass ELA Releases ORQs Grade 8Document24 pagesMass ELA Releases ORQs Grade 8scmsliteracyNo ratings yet

- Big Data, Consumer Analytics, and The Transformation of MarketingDocument17 pagesBig Data, Consumer Analytics, and The Transformation of MarketingPeyush NeneNo ratings yet

- #1Document7 pages#1Ramírez OmarNo ratings yet

- Living in a digital age unit review and digital toolsDocument1 pageLiving in a digital age unit review and digital toolsLulaNo ratings yet

- Teaching and Learning in the Multigrade ClassroomDocument18 pagesTeaching and Learning in the Multigrade ClassroomMasitah Binti TaibNo ratings yet

- Anna University CTDocument3 pagesAnna University CTprayog8No ratings yet

- Declarative and Procedural Knowledge (Lêda's Final Paper) 2010 01Document13 pagesDeclarative and Procedural Knowledge (Lêda's Final Paper) 2010 01Jair Luiz S. FilhoNo ratings yet

- Chiller Carrier - 30gn-9siDocument28 pagesChiller Carrier - 30gn-9siZJ Limited (ZJLimited)No ratings yet

- Import Sample 2Document63 pagesImport Sample 2akkyNo ratings yet

- Test Engleza 8Document6 pagesTest Engleza 8Adriana SanduNo ratings yet

- Megneto TherapyDocument15 pagesMegneto TherapyedcanalNo ratings yet

- Vestax VCI-380 Midi Mapping v3.4Document23 pagesVestax VCI-380 Midi Mapping v3.4Matthieu TabNo ratings yet

- On-Chip ESD Protection Design For IcsDocument14 pagesOn-Chip ESD Protection Design For IcsMK BricksNo ratings yet

- As 91435Document3 pagesAs 91435api-271057641No ratings yet

- The Act of Proclamation of The Independence of The Filipino PeopleDocument33 pagesThe Act of Proclamation of The Independence of The Filipino PeopleJULIANA RAE CONTRERASNo ratings yet

- KEC115/6/7x: Ac Generator Short Circuit and Over Current GuardDocument4 pagesKEC115/6/7x: Ac Generator Short Circuit and Over Current GuardRN NNo ratings yet

- 2016-08-03 Iot Global Forecast Analysis 2015-2025Document65 pages2016-08-03 Iot Global Forecast Analysis 2015-2025Hoang ThanhhNo ratings yet