Professional Documents

Culture Documents

A General Solution For The Stress Around Internally Pressurized Circular Hole in Symmetric Laminates

Uploaded by

Ioan-Lucian StanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A General Solution For The Stress Around Internally Pressurized Circular Hole in Symmetric Laminates

Uploaded by

Ioan-Lucian StanCopyright:

Available Formats

INSTITUTE OF TECHNOLOGY, NIRMA UNIVERSITY, AHMEDABAD 382 481, 08-10 DECEMBER, 2011

1

Abstract-- General solutions for determining the stress field

around circular hole in infinite orthotropic plate subjected to

internal pressure are obtained using Muskhelisvilis complex

variable formulation. The generalized formulation thus

obtained is coded and few numerical results are obtained

using MATLAB 7.6. The effect of fibre orientation and

material parameter on stress pattern around pressurized

circular hole is studied. Plane stress models are prepared in

ANSYS and results are compared with present method.

Index termsFibre orientation, orthotropic plate, stress

function, Pressurized Circular hole.

I. INTRODUCTION

oles and cut-outs are bound to be present in many

engineering structures, which cause serious problems of

stress concentrations. These hole/opening work as stress

raisers and may lead to the failure of the structure/machine

component. Many researchers have tried to find stress fields

around holes and cut-outs in isotropic /anisotropic media.

Ukadgaonker and Rao[1] found stress patterns around

different shaped holes using Muskhelisvilis [2] complex

variable approach. J.Rezaeepazhand and M.Jafari[3] found

the stress patterns around different central cut-outs in metallic

plates using Lekhnitskiis[4] approach. Ukadgaonker and

Rao[5] found resultant stresses on triangular hole boundary

due to uniform pressure.

Using Muskhelisvilis [2] complex variable approach, the

generalized solution for stress distribution around circular

hole in symmetric laminate subjected to internal uniform

pressure is obtained. The generalized solutions obtained are

coded in MATLAB 7.6 and the effect of stacking sequence,

fibre orientation and material property on stress pattern is

studied for isotropic steel and for Eglass/epoxy [E

1

=41GPa,

E

2

=10.4GPa, G

12

=4.3GPa, =0.28] with fibre orientation 0,

0/90. The results are compared with the results obtained in

ANSYS.

II. COMPLEX VARIABLE FORMULATION

A thin anisotropic plate is considered under generalized plane

stress condition (Figure 1). The plate is assumed to be loaded

in such a way that resultants lies in XOY plane. The stresses

on top and bottom surface of plate as well as

xz z

, and

yz

are zero everywhere within the plate.

Fig. 1 Plate with circular hole

The stress components for plane stress conditions can be

written in terms of Mushkhelishvilis complex function

) (

1

z and ) (

2

z as follows

[ ] ) ( ' ) ( ' Re 2

2

2

2 1

2

1

z s z s

x

+ =

[ ] ) ( ' ) ( ' Re 2

2 1

z z

y

+ =

[ ] ) ( ' ) ( ' Re 2

2 2 1 1

z s z s

xy

+ = (1)

Where, s

1

and s

2

are complex constants of anisotropy, which

are obtained from roots of characteristic equation arrived at

from Hookes law, Airys stress function and strain-

displacement compatibility condition.

The area external to a given circular hole, in Z-plane is

mapped conformably to the area outside the unit circle in

plane using following mapping function.

( )

(

+

|

|

\

|

= =

j j j j

b a

R

z

1

2

) (

( ), 1

j j

is a + = ( )

j j

is b = 1 ; j=1,2. (2)

III. GENERAL SOLUTION FOR UNIFORM

PRESSURE AROUND THE HOLE

For the case of uniform pressure p around hole, the

resultant stress X

n

, Y

n

on the hole boundary are given by

A General Solution for the Stresses around

Internally Pressurized Circular hole in

Symmetric Laminates

A. D S Sharma, B. Panchal Khushbu

*

, C. Patel Nirav

A. Professor, Mechanical Engg. Department, Institute of Technology,

Nirma University,Ahmedabad

B. Assistant Professor, Shri Sad Vidya Mandal Institute of Technology, Bharuch.

C. Assistant Professor, Gandhinagar Institute of Technology, Gandhinagar

H

INTERNATIONAL CONFERENCE ON CURRENT TRENDS IN TECHNOLOGY, NUiCONE 2011

2

ds

dy

p x n p X

n

= = ) , cos( ,

ds

dx

p y n p Y

n

= = ) , cos( (3)

Where n is the positive direction of the outward normal to the

hole boundary. The stress boundary conditions are given by

, .

0

0

1

px const ds Y f

s

n

= + =

, .

0

0

2

py const ds X f

s

n

= + =

(4)

The stress functions are obtained using these boundary

conditions ) , (

0

2

0

1

f f into Schwarz formula:

)

`

t

dt

t

t

f f s

s s

i

) (

) ( 4

) (

0

2

0

1 1

2 1

)

`

t

dt

t

t

f f s

s s

i

) (

) ( 4

) (

0

2

0

1 2

2 1

The stress functions and their derivatives obtained are given

bellow,

(

2

2 1

) ( 2

) (

a

s s

ipR

,

(

1

2 1

) ( 2

) (

a

s s

ipR

(

=

2

2

2 1

) ( 2

) ( '

a

s s

ipR

, ( )

( )

(

=

2

1

2 1

2

'

a

s s

ipR

(5)

IV. RESULTS AND DISCUSSION

The stress functions obtained above are the generalized

solutions. Using these functions stress field around circular

hole under internal uniform pressure condition is presented.

The basic procedure for the numerical solution is as follows:

Take the value of elastic constants according to the material

properties.

a. Calculate the compliance co-efficient, a

ij

from generalized Hookes Law.

b. Calculate the value of complex parameters

of anisotropy s

1

and s

2

from the

characteristic equation.

c. Calculate the constants: a

1

,b

1

,a

2

,b

2

etc.

d. Evaluate the stress functions and their

derivatives.

e. Evaluate stresses.

Figure [2] and [3] shows the stress distribution

around the circular hole subjected to internal pressure in

isotropic steel plate. Figure [3] shows the tangential and

radial stress near the vicinity of hole. Radial stress varies

from -1.00 to 0 and tangential stress varies from 0 to 1.00.

Figure [4], [5] and [6] shows the stress distribution

around the circular hole subjected to internal pressure in

glass/epoxy plate with 0 fibre orientation. The effect of

anisotropy leads to increment in value of stresses. Stresses are

comparatively higher in glass/epoxy than isotropic steel. The

comparison of results are also seen in Figure [4], [5] and [6].

To understand the effect of fibre orientation and

stacking sequence in the multilayered plate, the glass/epoxy

plate with fibre orientation 0/90 is taken. Figure [7], [8] and

[9] shows the stress distribution around the circular hole

subjected to internal pressure in anisotropic glass/epoxy plate

with 0/90 fibre orientation. The plane stress model has

prepared using ANSYS and the results are obtained. In all

cases the present methods results are in good agreement with

the ANSYSs results.

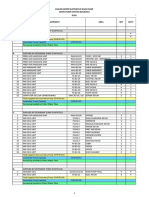

The comparison of results obtained for different

material parameter from present method and ANSYS is

tabulated in Table [I].

F

ig. 2(a) Present Method

Fig. 2(b) ANSYS

Fig. 2 Shear stresses for Isotropic material

INSTITUTE OF TECHNOLOGY, NIRMA UNIVERSITY, AHMEDABAD 382 481, 08-10 DECEMBER, 2011

3

Fig. 3(a) Radial stress( Present Method)

Fig. 3(b) Tangential stress (Present Method)

Fig. 3 Stresses in Radial and Tangential direction for Isotropic material

Fig. 4(a) Present Method

Fig. 4(b) ANSYS

Fig. 4 Stresses in X direction for Glass/Epoxy with 0 fiber orientation

Fig. 5(a) Present Method

Fig. 5(b) ANSYS

Fig. 5 Stresses in Y direction for Glass/Epoxy with 0 fiber orientation

Fig. 6(a) Present Method

Fig. 6(b) ANSYS

Fig. 6 Shear Stresses for Glass/Epoxy with 0 fiber orientation

Fig. 7(a)

Present

Method

INTERNATIONAL CONFERENCE ON CURRENT TRENDS IN TECHNOLOGY, NUiCONE 2011

4

Fig. 7(b) ANSYS

Fig. 7 Stresses in X direction for Glass/Epoxy with 0/90 fiber orientation

Fig. 8(a) Present Method

Fig. 8(b) ANSYS

Fig. 8 Stresses in Y direction for Glass/Epoxy with 0/90 fiber orientation

Fig. 9(a) Present

Method

Fig. 9(b) ANSYS

Fig. 9 Shear stresses direction for Glass/Epoxy with 0/90 fiber orientation

TABLE I.

COMPARISON OF RESULTS OF PRESENT METHOD WITH ANSYS

RESULTS FOR CIRCULAR HOLE

Material Stress Present

Method

ANSYS

Max

X

1.00 1.001

Max

Y

1.00 1.001

Isotropic

Max

XY

1.00 0.9955

Max

X

1.6521 1.555

Max

Y

1.3085 1.209

Glass/Epoxy

Fiber orientation =0 Max

XY

0.8537 0.8554

Max

X

1.7916 1.611

Max

Y

1.7916 1.599

Glass/Epoxy

Fiber orientation

=0/90

Max

XY

0.7164 0.7942

V. CONCLUSION

The generalized solution for infinite plate having

circular hole subjected to internal pressure loading is obtained

using Mushkhelisvilis complex variable method. The effect

of various parameters on stress concentration around holes is

studied. It is found that the fibre orientation, stacking

sequence and material property has significant effect on stress

distribution around hole. The formulation presented here, is a

good tool for the designer to predict stress pattern around

internally pressurized hole and to predict failure pattern of

mechanical component and structures.

VI. REFERENCES

[1] V.G. Ukadgaonker, D.K.N. Rao, A general solution for

stresses around holes in symmetric laminates under in

plane loading, Journal of Composite Structures 49,

2000, pp.339-354.

[2] N.I. Muskhelishvili, Some basic problems of the

mathematical theory of elasticity, P. Noordhooff Ltd.,

Groningen, The Netherlands, 1963.

[3] J. Rezaeepazhand, M. Jafari,, Stress concentration in

metallic plates with special shaped cut-out, Composite

structure 52, 2010,pp.96-102

INSTITUTE OF TECHNOLOGY, NIRMA UNIVERSITY, AHMEDABAD 382 481, 08-10 DECEMBER, 2011

5

[4] S.G. Lekhnitskii,, Anisotropic plates,. New York:

Gordon and Breach, 1968.

[5] V.G. Ukadgaonker, D.K.N. Rao Stress distribution

around triangular holes in anisotropic plates, Journal of

Composite Structures 45, 1999, pp.171-183.

You might also like

- Residual Stress Distributions and Their Influence On Fatigue LifetimesDocument9 pagesResidual Stress Distributions and Their Influence On Fatigue LifetimesPandhari Sanap100% (1)

- Scope of Work Technical Condition For Mechanical Works R2-CILDocument33 pagesScope of Work Technical Condition For Mechanical Works R2-CILgullipalli srinivasa raoNo ratings yet

- Drilled Glass BearingDocument11 pagesDrilled Glass BearingRichard GreenNo ratings yet

- Stress InStress Intensity Factors For Threaded ConnectionstensityDocument23 pagesStress InStress Intensity Factors For Threaded ConnectionstensityCorrado AnelliNo ratings yet

- Chilled Water Supply and Pressure DropDocument10 pagesChilled Water Supply and Pressure DropgothdaddeeNo ratings yet

- Analysis of Stress Distribution Around Pin Loaded Holes in Orthotropic PlatesDocument6 pagesAnalysis of Stress Distribution Around Pin Loaded Holes in Orthotropic Plateskhudhayer1970No ratings yet

- BS Standard For Cable LayingDocument2 pagesBS Standard For Cable Layingmurali50% (2)

- Isotropic Linear Elastic Stress ConcentrationDocument19 pagesIsotropic Linear Elastic Stress ConcentrationIoan-Lucian StanNo ratings yet

- Isotropic Linear Elastic Stress ConcentrationDocument19 pagesIsotropic Linear Elastic Stress ConcentrationIoan-Lucian StanNo ratings yet

- Daikin AG 31-004 LR School HVAC Design GuideDocument54 pagesDaikin AG 31-004 LR School HVAC Design GuideShawn Melville100% (1)

- Static Analysis of Isotropic & Orthotropic Plates With Central CutoutDocument7 pagesStatic Analysis of Isotropic & Orthotropic Plates With Central CutoutKanak_KalitaNo ratings yet

- Plate Heat Exchanger Pre-Commissioning ChecklistDocument1 pagePlate Heat Exchanger Pre-Commissioning ChecklistHoang Nam100% (1)

- ISTAM - Stress Concentration Factor Convergence Study of A Thin PlateDocument7 pagesISTAM - Stress Concentration Factor Convergence Study of A Thin PlateKanak_KalitaNo ratings yet

- Ijems 15 (6) 452-458Document7 pagesIjems 15 (6) 452-458Rahul GoswamiNo ratings yet

- TIMOSHENKO Strength of Materials Vol2Document587 pagesTIMOSHENKO Strength of Materials Vol2Pinaki MohantyNo ratings yet

- Demolition of Post-Tensioned ConcreteDocument5 pagesDemolition of Post-Tensioned ConcreteIoan-Lucian Stan100% (1)

- Finite Element Analysis and Reliability Assessment of Spherical LPG ...Document6 pagesFinite Element Analysis and Reliability Assessment of Spherical LPG ...Suleyman HaliciogluNo ratings yet

- Innovative Adhesive For Sandwich SystemsDocument20 pagesInnovative Adhesive For Sandwich SystemsTravis WoodNo ratings yet

- Assess Pipeline Girth Weld DefectsDocument3 pagesAssess Pipeline Girth Weld Defectsbumoh1No ratings yet

- v60 74Document7 pagesv60 74Vijaya KumarNo ratings yet

- 11.7 States of Matter PhET LabDocument2 pages11.7 States of Matter PhET LabCoacytTucumanNo ratings yet

- Nanoparticle Synthesis MethodsDocument18 pagesNanoparticle Synthesis Methodssunil ugadiNo ratings yet

- Tcsq11304r0 Precast ConcreteDocument24 pagesTcsq11304r0 Precast Concreteazeemmet9924No ratings yet

- Economiser & DrumDocument75 pagesEconomiser & DrumGaurav ChauhanNo ratings yet

- Tubular Film Blowing Process ExplainedDocument9 pagesTubular Film Blowing Process ExplainedAlmir MachadoNo ratings yet

- 10 1 1 193 4173 PDFDocument7 pages10 1 1 193 4173 PDFRohit GadekarNo ratings yet

- Photoelastic and Numerical Analysis of A Sphere/plan Contact ProblemDocument7 pagesPhotoelastic and Numerical Analysis of A Sphere/plan Contact ProblemfjNo ratings yet

- Pure Bending Analysis of Thin Rectangular Flat Plates Using Ordinary Finite Difference MethodDocument4 pagesPure Bending Analysis of Thin Rectangular Flat Plates Using Ordinary Finite Difference MethodsyammohansNo ratings yet

- Materials Science and Engineering ADocument10 pagesMaterials Science and Engineering Akhudhayer1970No ratings yet

- Elastic-Plastic Stress Distribution in A Plastically Anisotropic Rotating DiskDocument8 pagesElastic-Plastic Stress Distribution in A Plastically Anisotropic Rotating DiskAnonymous UoHUagNo ratings yet

- 113 418 2 PBDocument7 pages113 418 2 PBTanu RdNo ratings yet

- MECHANICS RESEARCH COMMUNICATIONSDocument9 pagesMECHANICS RESEARCH COMMUNICATIONSkhudhayer1970No ratings yet

- Effect of Fiber Orientation On Stress Concentration Factor in A Laminate With Central Circular Hole Under Transverse Static LoadingDocument7 pagesEffect of Fiber Orientation On Stress Concentration Factor in A Laminate With Central Circular Hole Under Transverse Static LoadingSiva BhaskarNo ratings yet

- Stresses in Finite Anisotropic Plate Weakened by Rectangular HoleDocument8 pagesStresses in Finite Anisotropic Plate Weakened by Rectangular Holemihir.chauhanNo ratings yet

- Composite Structures: D.K. Nageswara Rao, M. Ramesh Babu, K. Raja Narender Reddy, D. SunilDocument15 pagesComposite Structures: D.K. Nageswara Rao, M. Ramesh Babu, K. Raja Narender Reddy, D. SunilDr.D.K.Nageswara RaoNo ratings yet

- Brazilian Test Stress Field and Tensile Strength of Anisotropic Rocks Using An Analytical SolutioDocument14 pagesBrazilian Test Stress Field and Tensile Strength of Anisotropic Rocks Using An Analytical Solutiovinayak_katkarNo ratings yet

- Static Analysis of Rectangular Plate With Internal Cut-Out Using Finite Element MethodDocument6 pagesStatic Analysis of Rectangular Plate With Internal Cut-Out Using Finite Element MethodKanak_KalitaNo ratings yet

- Approx Deflection Function for Simply Supported Quadrilateral Thin PlateDocument8 pagesApprox Deflection Function for Simply Supported Quadrilateral Thin PlateDurukan Burak DilekNo ratings yet

- Foundation_design_taking_into_account_non-linear_sDocument8 pagesFoundation_design_taking_into_account_non-linear_sKafui KluNo ratings yet

- 1VECF1 - Analysis of Crack-Tip Constraint Due To V - and U - Side Grooves in C (T) SpecimensDocument11 pages1VECF1 - Analysis of Crack-Tip Constraint Due To V - and U - Side Grooves in C (T) SpecimensslvjayaprakashNo ratings yet

- Kang 2015Document7 pagesKang 2015ahmet ergüveNo ratings yet

- SCF in Isotopic & Orthotropic Plates Part I: Uniaxial LoadDocument7 pagesSCF in Isotopic & Orthotropic Plates Part I: Uniaxial LoadNandit JadvaniNo ratings yet

- Effect of Hole Shape On Stress Concentration in Graphite/epoxy Laminates Under Uniaxial LoadingDocument18 pagesEffect of Hole Shape On Stress Concentration in Graphite/epoxy Laminates Under Uniaxial LoadingDr.D.K.Nageswara RaoNo ratings yet

- Residual Stresses of Plate With Holes by ANSYS Analysis - Hani Aziz AmeenDocument14 pagesResidual Stresses of Plate With Holes by ANSYS Analysis - Hani Aziz AmeenHani Aziz AmeenNo ratings yet

- Stress Concentrations For Slotted Plates in Bi-Axial Stress: D. W. A. Rees, H. Bahai, S. TaylorDocument7 pagesStress Concentrations For Slotted Plates in Bi-Axial Stress: D. W. A. Rees, H. Bahai, S. TaylorYasser BahaaNo ratings yet

- Shear Stresses Around Circular Cylindrical OpeningsDocument14 pagesShear Stresses Around Circular Cylindrical OpeningsBeny AbdouNo ratings yet

- Muh 29 6 4 0506 7Document8 pagesMuh 29 6 4 0506 7Sneh YadavNo ratings yet

- Nitin Eng Journal PDFDocument16 pagesNitin Eng Journal PDFpdhurveyNo ratings yet

- G6206029035 PDFDocument7 pagesG6206029035 PDFShilpa Dheeraj GunwantNo ratings yet

- Comp 12Document36 pagesComp 12Tanu RdNo ratings yet

- Eshelby Tensors and Overall Properties of Nano-Composites Considering Both Interface Stretching and Bending EffectsDocument34 pagesEshelby Tensors and Overall Properties of Nano-Composites Considering Both Interface Stretching and Bending EffectsM Mohsin RazaNo ratings yet

- MECH3310 Mechanics of Solids 2: The University of SydneyDocument8 pagesMECH3310 Mechanics of Solids 2: The University of SydneyJim LettermanNo ratings yet

- Nonlinear Kinematic Hardening Model for Anisotropic AlloysDocument4 pagesNonlinear Kinematic Hardening Model for Anisotropic AlloysNugraha BintangNo ratings yet

- Analysis of Stress and Strain in A Rotating Disk Mounte PDFDocument26 pagesAnalysis of Stress and Strain in A Rotating Disk Mounte PDFJigneshNo ratings yet

- Modeling and Stress Analysis of Nozzle ConnectionsDocument14 pagesModeling and Stress Analysis of Nozzle ConnectionsvijayanmksNo ratings yet

- Physical Modeling of Extrusion ProcessDocument9 pagesPhysical Modeling of Extrusion ProcessGeoffrey ArmstrongNo ratings yet

- Experimental and Numerical Studies To The Contact Stresses in AsymmetricDocument6 pagesExperimental and Numerical Studies To The Contact Stresses in AsymmetricHassan AlaaNo ratings yet

- Failure Analysis of Composites Plate With Central Opening Hole Subject To Arbitrary Tension LoadDocument12 pagesFailure Analysis of Composites Plate With Central Opening Hole Subject To Arbitrary Tension LoadSajjid Hasan Asif PanthoNo ratings yet

- Use of Strain Gauge Rosette To Investigate Stress Concentration in Isotropic and Orthotropic Plate With Circular HoleDocument5 pagesUse of Strain Gauge Rosette To Investigate Stress Concentration in Isotropic and Orthotropic Plate With Circular HoleHako KhechaiNo ratings yet

- 1 s2.0 S1365160997800731 MainDocument8 pages1 s2.0 S1365160997800731 MainNeha RaniNo ratings yet

- Estimation of Stress Intensity Factors With Considering Crack Surface ContactDocument8 pagesEstimation of Stress Intensity Factors With Considering Crack Surface Contact_Asylum_No ratings yet

- A More Generalized Approach For Analyzing Eccentrically Loaded ConnectionsDocument6 pagesA More Generalized Approach For Analyzing Eccentrically Loaded ConnectionsNacho ReyesNo ratings yet

- MECH3310 Mechanics of Solids 2: The University of SydneyDocument8 pagesMECH3310 Mechanics of Solids 2: The University of SydneyJim LettermanNo ratings yet

- Closed Form Solutions For Small Deformations Superimposed Upon The Symmetrical Expansion of A Spherical ShellDocument12 pagesClosed Form Solutions For Small Deformations Superimposed Upon The Symmetrical Expansion of A Spherical ShellBensingh DhasNo ratings yet

- Simulation of Plate With Crack Using Extended Finite Element MethodDocument4 pagesSimulation of Plate With Crack Using Extended Finite Element MethodVirender RawalNo ratings yet

- Stresses and Deformation of Compressed Elastomeric O-Ring SealsDocument13 pagesStresses and Deformation of Compressed Elastomeric O-Ring SealsCarlosIkedaNo ratings yet

- FulltextDocument15 pagesFulltextjinshadNo ratings yet

- Experimental Stress Analysis of Composite Circular Disc: T.Lalitha and Dr.A.PurushothamDocument5 pagesExperimental Stress Analysis of Composite Circular Disc: T.Lalitha and Dr.A.PurushothamIOSRjournalNo ratings yet

- SIF For Cracks in Notched Plates in Biaxial LoadingDocument24 pagesSIF For Cracks in Notched Plates in Biaxial LoadingArun KumarNo ratings yet

- RESIDUAL ELASTO-PLASTIC STRESSES ANALYSIS OF POLYMERIC THICK - WALLED PRESSURIZED CYLINDER - Hani Aziz AmeenDocument14 pagesRESIDUAL ELASTO-PLASTIC STRESSES ANALYSIS OF POLYMERIC THICK - WALLED PRESSURIZED CYLINDER - Hani Aziz AmeenHani Aziz AmeenNo ratings yet

- Theme 5Document36 pagesTheme 5Hermann MeierNo ratings yet

- Bending of Thin Circular RingsDocument14 pagesBending of Thin Circular RingsozkanhasanNo ratings yet

- New Concepts On Caustics and ApplicationsDocument5 pagesNew Concepts On Caustics and ApplicationsSEP-PublisherNo ratings yet

- Oneplus-3t-User Manual Android NDocument43 pagesOneplus-3t-User Manual Android NJC RivNo ratings yet

- CO PY: Camera User GuideDocument0 pagesCO PY: Camera User GuideDiogo MartinhoNo ratings yet

- CO PY: The "Software Start Guide" and "Quick Reference Guide" Are Provided at End of This ManualDocument324 pagesCO PY: The "Software Start Guide" and "Quick Reference Guide" Are Provided at End of This ManualDir MaheeNo ratings yet

- WisDOT Manual PDFDocument166 pagesWisDOT Manual PDFIoan-Lucian StanNo ratings yet

- Telecomanda ORIONDocument28 pagesTelecomanda ORIONIoan-Lucian StanNo ratings yet

- Rezistente Termice in Camp CurentDocument12 pagesRezistente Termice in Camp CurentIoan-Lucian StanNo ratings yet

- Stress Around Mine Openings in Some Simple Geologic Structures - R. D. CAUDLE, G. B. CLARKDocument50 pagesStress Around Mine Openings in Some Simple Geologic Structures - R. D. CAUDLE, G. B. CLARKIoan-Lucian StanNo ratings yet

- Thick Walled CylindersDocument9 pagesThick Walled CylinderskabangiNo ratings yet

- Analytic Solutions of Elastic Tuneling ProblemsDocument116 pagesAnalytic Solutions of Elastic Tuneling ProblemsAlessandro Lugli NascimentoNo ratings yet

- Analysis of The Radial and Tangential Stress Distribution Between Two Neighbouring Circular Holes Internal Pressure by Numerical Modelling - Sh. ARSHADNEJAD, K. GOSHTASBIDocument8 pagesAnalysis of The Radial and Tangential Stress Distribution Between Two Neighbouring Circular Holes Internal Pressure by Numerical Modelling - Sh. ARSHADNEJAD, K. GOSHTASBIIoan-Lucian StanNo ratings yet

- Livro - Resistência Dos Materiais - Stephen P. Timoshenko - Vol. 1 - Parte 2Document25 pagesLivro - Resistência Dos Materiais - Stephen P. Timoshenko - Vol. 1 - Parte 2Raphael Da Silva Carinhanha50% (2)

- Interacion of Circular Holes in An Infinite Elastic Medium - C.B. KOII, A. VERRUIJTDocument4 pagesInteracion of Circular Holes in An Infinite Elastic Medium - C.B. KOII, A. VERRUIJTIoan-Lucian Stan100% (1)

- The Influence of Friction On The Theoretical Strenght of Pin-Loaded Holes Orthotropic Plates - Th. de JONGDocument46 pagesThe Influence of Friction On The Theoretical Strenght of Pin-Loaded Holes Orthotropic Plates - Th. de JONGIoan-Lucian StanNo ratings yet

- Stress and Strain Concentration at A Circular Hole in A Infinite Plate - Elbridge Z. STOWELLDocument15 pagesStress and Strain Concentration at A Circular Hole in A Infinite Plate - Elbridge Z. STOWELLIoan-Lucian StanNo ratings yet

- The Distribution of Stress Round A Circular Hole in A Plate - W. G. BICKLEYDocument34 pagesThe Distribution of Stress Round A Circular Hole in A Plate - W. G. BICKLEYIoan-Lucian StanNo ratings yet

- Chapter 03 Two Dimensional Problems in Elasticity - Ugural, FensterDocument50 pagesChapter 03 Two Dimensional Problems in Elasticity - Ugural, Fensteracanerk100% (6)

- The Stress Distribution Round An Infinte Row of Circular Holes in An Orthotropic Plate - Th. de JONGDocument58 pagesThe Stress Distribution Round An Infinte Row of Circular Holes in An Orthotropic Plate - Th. de JONGIoan-Lucian StanNo ratings yet

- Numerical Methods For Stress Analysis Using Known Elasticity Solution - A. R. CHARMICHAELDocument234 pagesNumerical Methods For Stress Analysis Using Known Elasticity Solution - A. R. CHARMICHAELIoan-Lucian StanNo ratings yet

- On The Stress Distribution Round A Circular Hole in A Infinite Elastic Plate - B. K. AGABWALA, S. K. BAHLDocument15 pagesOn The Stress Distribution Round A Circular Hole in A Infinite Elastic Plate - B. K. AGABWALA, S. K. BAHLIoan-Lucian StanNo ratings yet

- Baymak Electric Storage Water Heaters BrochureDocument2 pagesBaymak Electric Storage Water Heaters Brochureolesia gundjakNo ratings yet

- Brochure NEMAG Quick Release Links and Rope Pear SocketsDocument12 pagesBrochure NEMAG Quick Release Links and Rope Pear Socketsfabo_amdNo ratings yet

- SM05Document70 pagesSM05Izyan Mastura100% (3)

- The Materials and Processes Behind the Gerber Serrated Clip Point Gator KnifeDocument12 pagesThe Materials and Processes Behind the Gerber Serrated Clip Point Gator KnifeCh M AamirNo ratings yet

- DoorknobDocument8 pagesDoorknobBurn-Man Hiruma VillanuevaNo ratings yet

- Cutting Tool Materials - Properties and List of MaterialsDocument3 pagesCutting Tool Materials - Properties and List of MaterialsarulsivagiriNo ratings yet

- HEAT TRANSFER - Conduction - HandoutDocument21 pagesHEAT TRANSFER - Conduction - HandoutTrong PhatNo ratings yet

- Thermomechanical Characterization of Basalt Fiber Reinforced Biodegradable PolymersDocument11 pagesThermomechanical Characterization of Basalt Fiber Reinforced Biodegradable Polymerssedat kumartaşlıNo ratings yet

- Duratomic TP Brochure GT15-214 PDFDocument24 pagesDuratomic TP Brochure GT15-214 PDFDeysi CardenasNo ratings yet

- 442 Adoc QDocument172 pages442 Adoc QNitesh KadiyaNo ratings yet

- PistonDocument16 pagesPistonhilmy yusuf maulanaNo ratings yet

- ROADBED CONSTRUCTION (HIGHWAY ENGINEERINGDocument42 pagesROADBED CONSTRUCTION (HIGHWAY ENGINEERINGGrace Ann CabanbanNo ratings yet

- Concrete Tech 1 Sample Questions AnsDocument18 pagesConcrete Tech 1 Sample Questions AnsJohn luckyNo ratings yet

- KEUMDUK KDW PumpDocument17 pagesKEUMDUK KDW PumpThairanil AbduljaleelNo ratings yet

- Electric Charges Physics SSS 1Document14 pagesElectric Charges Physics SSS 1aliutunde3495No ratings yet

- Fiberglass Bridge and Boardwalk Systems: Presented by Dustin TroutmanDocument36 pagesFiberglass Bridge and Boardwalk Systems: Presented by Dustin Troutmanaandueza_1No ratings yet

- T.9.2.7 Reinforcing For Shear - EUROCODE2: RAPT User ManualDocument16 pagesT.9.2.7 Reinforcing For Shear - EUROCODE2: RAPT User Manualtailieuxaydung2019No ratings yet

- Oceanic HW 443 Series: Key Benefits DescriptionDocument2 pagesOceanic HW 443 Series: Key Benefits Descriptions bNo ratings yet