Professional Documents

Culture Documents

Standard Specs - Subbase, Road Base and Gravel

Uploaded by

Abinet MarsOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Standard Specs - Subbase, Road Base and Gravel

Uploaded by

Abinet MarsCopyright:

Available Formats

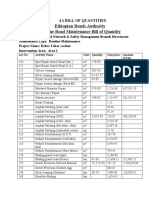

Standard Technical Specification - 2002

Series 5000: Subbase Road Base And Gravel Wearing Course Table of Content

SERIES 5000: SUBBASE ROAD BASE AND GRAVEL WEARING COURSE

TABLE OF CONTENT

TABLES AND FIGURES................................................................................................................. 6 DIVISION 5100: SUB-BASES ....................................................................................................... 7 5101 Scope..................................................................................................................................7 5102 Materials.............................................................................................................................7 5103 Material Sources for Sub-Bases.........................................................................................7 5104 Material Requirements For Gravel Sub-Base ..................................................................7 (a) General......................................................................................................................7 (b) Grading Limits..........................................................................................................7 (c) Grading Modulus......................................................................................................8 (d) Plasticity Index .........................................................................................................8 (e) Californian Bearing Ratio (CBR) .............................................................................8 (f) Compaction requirements.........................................................................................8 (g) Los Angeles Abrasion ..............................................................................................9 5105 Material Requirements For Crushed Stone Sub-Base........................................................9 (a) General......................................................................................................................9 (b) Grading Limits..........................................................................................................9 (c) Grading Modulus....................................................................................................10 (d) Plasticity Index (PI) ................................................................................................10 (e) Compaction Requirements .....................................................................................10 (f) Los Angeles Abrasion ............................................................................................10 (g) Particle shape; Flakiness Index ..............................................................................10 5106 Construction Requirements For Sub-Bases Using Recycled Material ............................10 (a) General....................................................................................................................10 (b) Milling/Scarifying ..................................................................................................10 (c) Placing, Spreading and Compacting.......................................................................11 5107 Construction Requirements..............................................................................................11 (a) General....................................................................................................................11 (b) Stabilization............................................................................................................11 (c) Trial Areas ..............................................................................................................11 (d) Traffic on Sub-base ................................................................................................11 5108 Protection and Maintenance.............................................................................................12 5109 Sub-Base as a Filter or Separating Layer.........................................................................12 5110 Classification of Layers for Payment Purposes ...............................................................12 5111 Construction Tolerances ..................................................................................................12 (a) Levels .....................................................................................................................12 (b) Width ......................................................................................................................13 (c) Thickness ................................................................................................................13

Ethiopian Roads Authority

Page 5000-1

Series 5000: Subbase Road Base And Gravel Wearing Course Table of Content

Standard Technical Specification -2002

(d) Cross Section.......................................................................................................... 13 5112 Testing ............................................................................................................................. 13 (a) Process Control ...................................................................................................... 13 (b) Routine Inspection and Testing.............................................................................. 13 5113 Measurement And Payment ............................................................................................ 14 Item 51.01 Sub-base layer constructed from gravel or Crushed stone:.......................... 14 Item 51.02 Extra over Pay item 51.01 for excavation of material in: ............................ 15 Item 51.03 Sub-base layer constructed from gravel or crushed stone obtained from existing pavement layers:....................................................................................... 15 Item 51.04 In situ reconstruction of existing Sub-base layer as:.................................... 16 Item 51.05 Sub-base layer constructed Extra over Pay item 51.03 (a),(b),(c)&(d) and Pay item 51.04 (a),(b)&(c) from recovered pavement material mixed with existing bituminous surfacing material................................................................................ 17 Item 51.06 Extra over Pay item 51.04 for adding extra material ................................... 17 Item 51.07 Extra over Pay item 51.04 for blading the material to windrow.................. 18 Item 51.08 Extra over Pay item 51.03 for excavating material in existing pavement layers in restricted areas ......................................................................................... 18 Item 51.09 Compacting the floors of pavement excavations ......................................... 18 Item 51.10 Watering the pavement excavation floor ..................................................... 19 Item 51.11 Variations in the number of roller passes applicable to pay item 51.09 ...... 19 Item 51.12 Extra over Pay item 51.09 for compacting pavement excavation floor in restricted areas........................................................................................................ 19 DIVISION 5200: ROAD BASES ...................................................................................................20 5201 Scope ............................................................................................................................... 20 5202 Dimensions ...................................................................................................................... 20 5203 Materials .......................................................................................................................... 20 (a) Sources of Material ................................................................................................ 20 (b) Road Base Material Types ..................................................................................... 20 5204 Material Requirements For Crushed Rock Or Stone....................................................... 20 (a) General ................................................................................................................... 20 (b) Grading................................................................................................................... 20 (c) Plasticity Index....................................................................................................... 21 (d) Californian Bearing Ratio (CBR) .......................................................................... 21 (e) Aggregate Crushing Value (ACV)......................................................................... 21 (f) Mechanical Strength Requirements(TFVT)........................................................... 21 (g) Flakiness Index ...................................................................................................... 22 5205 Material Requirements for Naturally Occurring Granular Materials .............................. 22 (a) General ................................................................................................................... 22 (b) Grading................................................................................................................... 22 (c) Plasticity Index....................................................................................................... 23 (d) Californian Bearing Ratio (CBR) .......................................................................... 23 (e) Aggregate Crushing Value (ACV)......................................................................... 23 (f) Abrasion ................................................................................................................. 23 (g) Flakiness Index ...................................................................................................... 23 (h) Crushed Ratio......................................................................................................... 24 (i) Grading Modulus ................................................................................................... 24 5206 Material Requirements for Dense Bitumen Macadam .................................................... 24 (a) Coarse Aggregates ................................................................................................. 24

Page5000-2

Ethiopian Roads Authority

Standard Technical Specification - 2002

Series 5000: Subbase Road Base And Gravel Wearing Course Table of Content

(b) Fine Aggregate .......................................................................................................25 (c) Filler .......................................................................................................................25 (d) Binder .....................................................................................................................25 5207 Material Requirements For Mixed Bitumen Macadam ...................................................25 (a) Combined Aggregate Grading................................................................................25 (b) Mix Design Parameters for Dense Bitumen Macadam ..........................................26 5208 Construction Requirements For Crushed Rock And Crushed Boulder Road Bases........27 (a) Equipment...............................................................................................................27 (b) Placing and Compaction.........................................................................................27 (c) Stabilization............................................................................................................28 (d) Trial Sections..........................................................................................................28 (e) Traffic on Road base...............................................................................................28 5209 Construction Requirements For Crushed Gravel Road Base...........................................29 (a) Equipment...............................................................................................................29 (b) Placing and Compaction.........................................................................................29 (c) Stabilization............................................................................................................30 (d) Trial Sections..........................................................................................................30 (e) Traffic on Road Base..............................................................................................30 5210 Construction Requirements For Dense Bitumen Macadam Road Base ..........................30 (a) Equipment...............................................................................................................30 (b) Placing and Compaction.........................................................................................31 (c) Trial Sections..........................................................................................................32 (d) Traffic on Road Base..............................................................................................32 (e) Weather Limitations ...............................................................................................33 5211 Construction Tolerances ..................................................................................................33 (a) Level and Grade......................................................................................................33 (b) Width ......................................................................................................................33 (c) Thickness ................................................................................................................33 (d) Cross Section ..........................................................................................................34 5212 Measurement And Payment .............................................................................................34 Item 52.01 Base layer construction.................................................................................34 Item 52.02 Extra over Pay Item 52.1 for excavation of material....................................35 Item 52.03 Base layer constructed from from existing pavement layers........................35 Item 52.04 In situ reconstruction of existing base layer ................................................37 Item 52.05 Extra over Pay item 52.04 for adding extra material....................................38 Item 52.06 Extra over Pay item 52.04 for t blading the material to windrow ................39 Item 52.07 Extra over Pay item 52.03 for excavating material in existing pavement layers in restricted areas: ........................................................................................39 Item 52.08 Compacting the floors of pavement excavations..........................................39 Item 52.09 Watering the pavement excavation floor......................................................40 Item 52.10 Variations in the number of roller passes applicable to pay item 52.08.......40 Item 52.11 Extra over Pay item 52.08 for compacting pavement excavation floor in restricted areas ........................................................................................................40 Item 52.12 Trial Sections..............................................................................................40 Note on additional Pay Items....................................................................................................41 DIVISION 5300: BREAKING UP EXISTING PAVEMENT LAYERS ............................................... 42 5301 Scope................................................................................................................................42 5302 Selecting The Material .....................................................................................................42

Ethiopian Roads Authority

Page 5000-3

Series 5000: Subbase Road Base And Gravel Wearing Course Table of Content

Standard Technical Specification -2002

5303 Classifying The Material ................................................................................................. 42 (a) Existing bituminous material ................................................................................. 42 (b) Non-cemented material .......................................................................................... 42 (c) Cemented material ................................................................................................. 42 5304 Plant And Equipment ...................................................................................................... 42 (a) General ................................................................................................................... 42 (b) Milling equipment.................................................................................................. 43 5305 Construction .................................................................................................................... 43 (a) General ................................................................................................................... 43 (b) Milling.................................................................................................................... 44 5306 Storing Recovered Pavement Material ............................................................................ 45 5307 Measurement And Payment ............................................................................................ 46 General ............................................................................................................................ 46 Item 53.01 Excavating and removing existing bituminous material.............................. 47 Item 53.02 Milling out existing bituminous material..................................................... 47 Item 53.03 Excavating and spoiling material from an existing pavement and/or the underlying fill......................................................................................................... 48 Item 53.04 Sawing or cutting asphalt or cemented pavement layers ............................. 48 Item 53.05 Removing the remaining asphalt from the underlying layer........................ 48 Item 53.06 Preparing stockpile sites............................................................................... 49 DIVISION 5400: GRAVEL WEARING COURSE AND GRAVEL SHOULDERS ................................50 5401 Scope ............................................................................................................................... 50 5402 Sources of Material.......................................................................................................... 50 5403 Material Requirements for Gravel Wearing Course........................................................ 50 (a) General ................................................................................................................... 50 (b) Grading................................................................................................................... 50 (c) Gravel Wearing Course Material Specification ..................................................... 51 5404 Construction Requirements For Gravel Wearing Course................................................ 52 (a) Equipment .............................................................................................................. 52 (b) Crushing and Screening ......................................................................................... 52 (c) Transport, Placing and Spreading .......................................................................... 53 (d) Compaction ............................................................................................................ 53 (e) Trial Areas.............................................................................................................. 53 5405 Construction Tolerances .................................................................................................. 53 5406 Testing ............................................................................................................................. 54 5407 Measurement And Payment ............................................................................................ 55 Item 54.01 Gravel Wearing course and Shoulder .......................................................... 55 Item 54.02 Extra over Pay item 54.01 for excavation of material in ............................. 55 Item 54.03 Gravel Wearing course and Shoulder constructed from gravel obtained from existing pavement layers ........................................................................................ 56 Item 54.04 In situ reconstruction of existing gravel wearing course and shoulder....... 57 Item 54.05 Extra over Pay item 54.04 for adding extra material .................................. 57 Item 54.06 Extra over Pay item 54.04 for blading the material to windrow.................. 58 Item 54.07 Extra over Pay item 54.03 for excavating material in existing pavement layers in restricted areas ......................................................................................... 58 Item 54.08 Compacting the floors of pavement excavations ......................................... 58 Item 54.09 Watering the pavement excavation floor ..................................................... 59 Item 54.10 Variations in the number of roller passes applicable to pay item 54.08 ...... 59

Page5000-4

Ethiopian Roads Authority

Standard Technical Specification - 2002

Series 5000: Subbase Road Base And Gravel Wearing Course Table of Content

Item 54.11 Extra over Pay item 54.08 for compacting pavement excavation floor in restricted areas ........................................................................................................59

Ethiopian Roads Authority

Page 5000-5

Series 5000: Subbase Road Base And Gravel Wearing Course List of Tables and Figures

Standard Technical Specification -2002

LIST OF TABLES AND FIGURES

Table 5104/1 Grading Requirements for Sub-base Material: ................................................... 8 Table 5105/1 Grading Requirements for Crushed Stone Sub-base Material............................ 9 Table 5112/1 Testing Frequency............................................................................................. 13 Table 5112/2 Density requirements: ....................................................................................... 14 Table 5200/1 Grading Limits for Graded Crushed Stone Base Course Materials (GB1)....... 21 Table 5200/2 Mechanical Strength Requirements for the Aggregate Fraction of Crushed Stone Base Course Materials (GB1) as Defined by the Ten Percent Fines Test 22 Table 5203/3 Recommended Particle Size Distributions for Mechanically Stable Natural Gravels and Weathered Rocks for Use as Base Course Material (GB2, GB3) . 23 Table 5200/4 Combined Aggregate Grading Limits for Dense Bitumen Macadam .............. 26 Table 5200/5 Mix Design Parameters for Dense Bitumen Macadam .................................... 26 Table 5403/1 Grading Requirements for Gravel Wearing Course and Gravel Shoulder ....... 51 Table 5404/1 Longitudinal grade tolerance ............................................................................ 54 Table 5405/2 Density requirements: ....................................................................................... 55

Page5000-6

Ethiopian Roads Authority

Standard Technical Specification - 2002

Series 5000: Subbase Road Base And Gravel Wearing Course Division 5100: Sub-Bases

DIVISION 5100: SUB-BASES

5101 SCOPE

This Division covers the specification of materials for, and the construction of, sub-base pavement layers including the in-situ recycling of existing pavements.

5102 MATERIALS

Sub-base material shall be obtained from sources located by the Contractor and approved by the Engineer or from existing pavement layers. The Contractor is required to obtain suitable sources, which are closest to the area where subbase is being placed.

5103 MATERIAL SOURCES FOR SUB-BASES

The materials used for the construction of sub-base layers shall be either: 1. Natural Gravel; 2. Scoria (Cinder Gravel); 3. Weathered Rock; 4. Crushed Gravel; 5. Crushed Rock or crushed Boulders; 6. Recycled Pavement Material. Any other granular material complying with the requirements of this clause.

5104 MATERIAL REQUIREMENTS FOR GRAVEL SUB-BASE

(a) General Gravel material to be used for sub-base shall be obtained from approved sources in borrow areas, cuts or existing pavement layers. The complete sub-base shall contain no material having a maximum dimension exceeding two-thirds of the completed layer thickness. Gravel Sub-base material shall, unless otherwise stated, conform to the following requirements. (b) Grading Limits The sub-base material shall comply with one of the gradings shown in Table 5104/1 as described in the Contract. The material shall have a smooth continuous grading within the limits for grading A, B or C given below.

Ethiopian Roads Authority

Page 5000-7

Series 5000: Subbase Road Base And Gravel Wearing Course Division 5100: Sub-Bases

Standard Technical Specification -2002

Table 5104/1 Grading Requirements for Sub-base Material: Sieve Size (mm) 63.0 50.0 37.5 25.0 20 9.5 5 4.75 2.0 1.18 0.425 0.3 0.075 A 100 90 - 100 51 - 80 35 - 70 5 - 15 Mass Percent Passing B C 100 100 80-100 55 - 85 60-100 40 - 70 30-100 30 - 60 20 - 51 17-75 10 - 30 9-50 5 - 15 5-25

D 100 51 - 85 35 - 65 25 - 51 15 - 30 5 - 15

The complete sub-base shall contain no material having a maximum dimension exceeding two-thirds of the compacted layer thickness. Sub-base material shall, unless otherwise authorized, conform to the following requirements when finally placed: (c) Grading Modulus The minimum Grading Modulus shall be 1.5 except where a material, having a lower Grading Modulus but not less than 1.2, is approved for use by the Engineer. (d) Plasticity Index All sub-base materials shall have a maximum Plasticity Index of 6 or 12, as described in the Contract, and when determined in accordance with AASHTO T-90. The plasticity product (PP = PI x percentage passing the 0.075mm sieve) shall not be greater than 75. (e) Californian Bearing Ratio (CBR) The minimum soaked Californian Bearing Ratio (CBR) shall be 30% when determined in accordance with the requirements of AASHTO T-193. The Californian Bearing Ratio (CBR) shall be determined at a density of 95% of the maximum dry density when determined in accordance with the requirements of AASHTO T-180 method D. (f) Compaction requirements The minimum in- situ dry density of sub-base material shall be as specified hereinafter for the layers in terms of a percentage of modified AASHTO density. (i) (ii) 95% or 97% as required for material not chemically stabilized. 95% or 96 % as required for chemically stabilized material.

Page5000-8

Ethiopian Roads Authority

Standard Technical Specification - 2002

Series 5000: Subbase Road Base And Gravel Wearing Course Division 5100: Sub-Bases

(g) Los Angeles Abrasion The Los Angeles abrasion value shall not exceed 51% when determined in accordance with the requirements of AASHTO T-96.

5105 MATERIAL REQUIREMENTS FOR CRUSHED STONE SUB-BASE

(a) General The aggregate used for crushed stone sub-base shall be derived from a parent rock that is hard, sound, durable, and unweathered. It shall be obtained from sound rock from an approved quarry or clean sound boulders. It shall contain no deleterious material such as decomposed rock, clay, shale, or mica. The crushed aggregate shall comply with the following requirements: (b) Grading Limits The grading of the crushed stone sub-base shall comply with one of the gradings shown in Table 5105/1 as described in the Contract, or as approved or directed by the Engineer. The grading shall follow a smooth curve without any marked gaps or excessive quantities at a particular size, unless specified otherwise. Table 5105/1 Grading Requirements for Crushed Stone Sub-base Material. Sieve Size (mm) Percentage Passing by weight A B C Nominal size Nominal size Nominal size 37.5 mm 28 mm 20 mm 100 95-100 100 100 60-80 70-85 90-100 40-60 50-65 60-75 25-40 35-55 40-60 15-30 25-40 30-45 7-19 12-24 13-27 5 - 12 5 - 12 5-12

50.0 37.5 28 20 10 5 2.36 0.425 0.075

Tests to determine whether the crushed stone material complies with the specified grading requirements shall be conducted after the material has been mixed on the road and spread out. The aggregate shall be produced entirely by the crushing of rock or boulders. Single stage crushing will not be allowed and the crusher installation shall be capable of producing material complying with the specified requirements. If, however, the nature of the parent rock is such that despite every effort made the material remains deficient in the finer fractions, the Engineer may allow the addition of approved soil fines, crusher fines or sand in controlled quantities not exceeding 15% by mass of the aggregate. Fines shall be introduced at the crushing plant.

Ethiopian Roads Authority

Page 5000-9

Series 5000: Subbase Road Base And Gravel Wearing Course Division 5100: Sub-Bases

Standard Technical Specification -2002

(c) Grading Modulus The minimum Grading Modulus shall be 1.5 except where a material, having a lower Grading Modulus but not less than 1.2, is approved for use by the Engineer. (d) Plasticity Index (PI) The Plasticity Index shall not exceed 6. (e) Compaction Requirements The minimum dry density to which the material shall be compacted shall be 95% unless specified otherwise, shown on the drawings or ordered by the Engineer, of the maximum dry density as determined by AASHTO T 180. Field dry densities shall be determined by the sand replacement method as specified in AASHTO T 191 or nuclear method as specified in AASHTO T 238. (f) Los Angeles Abrasion The Los Angeles abrasion value shall not exceed 45% when determined in accordance with the requirements of AASHTO T-96. (g) Particle shape; Flakiness Index The flakiness index, determined by testing in accordance with BS812, Part 105 or ASTM D 3398, shall not exceed 35. The crushed aggregate portion, which is retained on the 5 mm sieve, shall have at least 75 percent by weight of particles with at least two fractured faces and 100 percent with at least one fractured face. The area of each face shall be equal to at least 75 percent of the smallest midsection area of the piece. When two fractured faces are contiguous, the angle between the planes of fractures shall be at least 30 degrees to count as two fractured faces.

5106 CONSTRUCTION REQUIREMENTS FOR SUB-BASES USING RECYCLED (INSITU) PAVEMENT MATERIAL

(a) General Construction of sub-bases using recycled (in-situ) existing pavement materials shall comply with the requirements of Clause 5105 and with the requirements of this Clause. (b) Milling/Scarifying (i) Before scarification or milling is commenced, the surface of the existing pavement shall be clean and free from soil and other deleterious matter. (ii) The existing pavement shall be broken up to the depth described in the Contract either by scarifying or by the use of an approved milling machine.

Page5000-10

Ethiopian Roads Authority

Standard Technical Specification - 2002

Series 5000: Subbase Road Base And Gravel Wearing Course Division 5100: Sub-Bases

(c) Placing, Spreading and Compacting Any material which is required to be added, to either supplement or modify the scarified milled material, shall be evenly spread and thoroughly mixed into the scarified/milled material to form a homogeneous material prior to compaction. The material shall be placed, spread and compacted in accordance with the requirements of Clause 5105.

5107 CONSTRUCTION REQUIREMENTS

(a) General. Sub-base material shall be spread on the approved sub-grade by mechanical means without segregation. The material shall be loosely spread in layers to give a compacted thickness not exceeding 200mm and not less than 100mm. The final compacted layer shall be free from concentrations of coarse or fine materials. 1. The surface of each completed layer shall be moistened prior to the construction of the succeeding layer. Determine the optimum moisture content according to AASHTO T 180 method D. Mix the aggregate and adjust the moisture content to obtain a uniform mixture with moisture content within 2 percent of the optimum moisture content. Spread and shape the mixture on the prepared surface in a uniform layer. 2. The material shall be compacted by the use of approved rollers progressing gradually from the outside towards the centre of the layer, except on superelevated curves, where the rolling shall begin at the low side and progress to the high side. Compact each layer full width. Roll from the sides to the center, parallel to the centerline of the road. Along curbs, headers, walls, and all places not accessible to the roller, compact the material with approved tampers or compactors. Each succeeding pass shall overlap the previous pass by at least one third of the roller width. Rolling shall continue until the entire thickness of each layer is thoroughly and uniformly compacted to the specified density. Compact each layer to at least 95 percent of maximum density. Determine the in place density and moisture content according to AASHTO T 238 and AASHTO T 239 or other approved test procedures. (b) Stabilization When specified in the contract or required by the engineer, sub-base layers shall be stabilized as specified in Division 4600. (c) Trial Areas Prior to the commencement of normal working the Contractor shall construct a trial area of not less than 1000 square metres using the materials and equipment proposed for the work to demonstrate compliance with the requirements of this Clause. (d) Traffic on Sub-base The completed sub-base layer may be used by construction and public traffic subject to the approval of the Engineer. Any such approval shall not relieve the Contractor of his responsibility to maintain and repair any damage caused to the layer.

Ethiopian Roads Authority

Page 5000-11

Series 5000: Subbase Road Base And Gravel Wearing Course Division 5100: Sub-Bases

Standard Technical Specification -2002

5108 PROTECTION AND MAINTENANCE

The Contractor shall protect and maintain the completed sub-base at his own expense. Maintenance shall include immediate repairs of any damage or defects, which may occur and shall be repeated as often as is necessary to keep the subbase continuously intact. Repairs shall be made in a manner that will ensure restoration to an even and uniform surface.

5109 SUB-BASE AS A FILTER OR SEPARATING LAYER

This may be required to protect a drainage layer from blockage by a finer material or to prevent migration of fines and the mixing of two layers. The two functions are similar except that for use as a filter the material needs to be capable of allowing drainage to take place and therefore the amount of material passing the 0.075 mm sieve must be restricted. The following criteria should be used to evaluate a sub-base as a separating or filter layer: a) The ratio D15(coarse layer) should be less than 5 D85(fine layer)

where D15 is the sieve size through which 15% by weight of the material passes and D85 is the sieve size through which 85% passes. b) The ratio D50(coarse layer) should be less than 25 D50(fine layer) The ratio D15(coarse layer) should lie between 5 and 40 D15(fine layer)

For a filter to possess the required drainage characteristics a further requirement is: c)

These criteria shall be applied to the materials at both the base course/sub-base and the subbase/subgrade interfaces.

5110 CLASSIFICATION OF LAYERS FOR PAYMENT PURPOSES

Payment for sub-base layers constructed from gravel material shall distinguish between layers constructed with material from borrow pits, cuts or existing pavement layers, and in-situ recompacted layers with or without the use of additional material. Sub-base layers constructed from crushed-stone material recovered from existing crushedstone pavement layers shall be placed and paid for as gravel material, unless otherwise determined by the Engineer. Where the Engineer determines, in writing, which the material shall be processed and placed as crushed stone.

5111 CONSTRUCTION TOLERANCES

The completed subbase shall conform to the dimensional tolerances stated below: (a) Levels The lot shall be deemed to comply with the requirements specified for surface levels if, before any repair work is undertaken, at least 90% of the level measurements are within + 25 mm of the specified levels. Isolated spots , where the surface levels deviate by more than 33 mm of the specified levels shall be repaired to bring the deviation to within the + 25 mm tolerance.

Page5000-12

Ethiopian Roads Authority

Standard Technical Specification - 2002

Series 5000: Subbase Road Base And Gravel Wearing Course Division 5100: Sub-Bases

(b) Width The average width of the sub-base shall not be less than the specified width and nowhere shall the outer edge of the sub-base be more than 75 mm inside the lines shown on the Drawings. (c) Thickness The lot will be considered to comply with the requirements for layer thicknesses if: At least 90 % of all the thickness measurements taken before any thickness repairs are made is equal to or greater than the specified thickness minus 27 mm; and The mean layer thickness of the lot is not less than the specified thickness minus 5 mm Isolated spots where the actual thickness is less than the specified thickness less 35 mm shall be repaired so as to fall within the 27 mm tolerance. (d) Cross Section At any transverse section the difference in level between any two points shall not vary by more than 20 mm from their difference in level as computed from the cross sections as shown on the Drawings.

5112 TESTING

(a) Process Control The minimum testing frequency that will be required from the Contractor in terms of Clause 1202, for the purpose of process control, shall be as shown on Table 5112/1 below. Table 5112/1 Testing Frequency Test Materials Field density and OMC Atterberg limits and gradings Construction Tolerances Surface levels Thickness Width Cross section Testing Frequency One test Minimum number of tests per lot every 2 510 m2 2 510 m2 20 m 20 m 20 m 20 m 4 4 (3 points per cross section) (3 points per cross section) -

(b) Routine Inspection and Testing. Routine inspection and testing will be carried out by the Engineer to test the quality of materials and workmanship for compliance with the requirements of this Division.

Ethiopian Roads Authority

Page 5000-13

Series 5000: Subbase Road Base And Gravel Wearing Course Division 5100: Sub-Bases

Standard Technical Specification -2002

The density requirements specified in Clause 5105 for compaction of subbase shall be deemed to have been complied with if the minimum dry densities as shown in Table 5112/2 are equaled or exceeded. In calculating the mean, density values differing by more than 5 percentage points from the mean shall be disregarded and a new mean calculated. Any material or workmanship that does not comply with the specified requirements shall be removed and replaced with materials and workmanship complying with the specified requirements, or if the Engineer permits, be repaired as specified in Clause 1208 so that after being repaired it will comply with the specified requirements. Table 5112/2 Density requirements Specified density (% of Number of tests AASHTO T 180 MDD) per lot Minimum mean density (% of AASHTO T 180 MDD) 95. 6 95. 8 95. 9 Minimum density for any single test (% of AASHTO T 180 MDD) 92. 0 91. 8 91. 6

95 (unstabilized)

3&4 5 6

Note: The determination of field dry density expressed as a percentage of AASHTO T 180 MDD implies an AASHTO T 180 density determination for each field density. Where material is homogeneous, this ratio can be decreased to one laboratory determination for up to four field densities.

5113 MEASUREMENT AND PAYMENT

Items 51.08, 51.09 and 51.012 are applicable solely to work that has to be executed in a restricted area of which the width is less than 3.0 m or the length is less than 150.0 m. Item 51.01 Sub-base layer constructed from gravel or Crushed stone: a) Gravel sub-base (unstabilized gravel) compacted to: (i) (ii) b) 95% of modified AASHTO density 97% of modified AASHTO density (specify compacted layer thickness) ....................................................cubic metre (m3) (specify compacted layer thickness) ...................................................cubic metre (m3) Gravel sub-base (chemically stabilized material) compacted to: (i) (ii) 95% of modified AASHTO density 96% of modified AASHTO density (specify compacted layer thickness) ....................................................cubic metre (m3) (specify compacted layer thickness) ...................................................cubic metre (m3) (c) Crushed stone Sub-base 95% of modified AASHTO density (specify compacted layer thickness) .................................................................................................cubic metre (m3)

Page5000-14

Ethiopian Roads Authority

Standard Technical Specification - 2002

Series 5000: Subbase Road Base And Gravel Wearing Course Division 5100: Sub-Bases

The unit of measurement shall be the cubic metre of compacted pavement layer, and the quantity shall be calculated from the authorized dimensions of the completed layer. The tendered rates shall include full compensation for procuring, crushing or soft excavation or pits, breaking down, placing and compacting the material, including transporting the material for a distance of 1.0 km and its removal, disposal and transporting for a distance of 1.0 km, of up to 5% by volume of oversize material, and the protection and maintenance of the layer and the conducting of control tests, all as specified. Item 51.02 Extra over Pay item 51.01 for excavation of material in: (a) (b) Intermediate excavation ..................................................................... cubic metre (m3) Hard excavation................................................................................... cubic metre (m3)

The unit of measurement shall be the cubic metre of material obtained from intermediate or hard excavation. The tendered rates shall include full compensation for the additional costs involved for taking material from classes of material harder than soft excavation and for the additional costs, if any, for processing such material in the pavement layers. Item 51.03 Sub-base layer constructed from gravel or crushed stone obtained from existing pavement layers: (a) Gravel sub-base (unstabilized gravel) compacted to 95% of modified AASHTO density, using: (i) (ii) Non-cemented material (specify compacted layer thickness) ... cubic metre (m3) Cemented material (specify compacted layer thickness)........... cubic metre (m3)

(b) Gravel sub-base (unstabilized gravel) compacted to 97% of modified AASHTO density using: (i) (ii) Non-cemented material (specify compacted layer thickness) ... cubic metre (m3) Cemented material (specify compacted layer thickness)........... cubic metre (m3)

(c) Gravel sub-base (chemically stabilized material) compacted to 95% of modified AASHTO density, using: (i) (ii) Non-cemented material (specify compacted layer thickness) ... cubic metre (m3) Cemented material (specify compacted layer thickness)........... cubic metre (m3)

(d) Gravel sub-base (chemically stabilized material) compacted to 96% of modified AASHTO density, using: (i) (ii) Non-cemented material (specify compacted layer thickness) ... cubic metre (m3) Cemented material (specify compacted layer thickness)........... cubic metre (m3)

(e) Crushed Stone sub-base (unstabilized) compacted to 95% of modified AASHTO density using: (i) Non-cemented material (specify compacted layer thickness) ... cubic metre (m3)

Ethiopian Roads Authority

Page 5000-15

Series 5000: Subbase Road Base And Gravel Wearing Course Division 5100: Sub-Bases

Standard Technical Specification -2002

(ii)

Cemented material (specify compacted layer thickness) ...........cubic metre (m3)

(f) Crushed Stone sub-base (chemically stabilized material) compacted to 95% of modified AASHTO density, using: (i) (ii) Non-cemented material (specify compacted layer thickness)....cubic metre (m3) Cemented material (specify compacted layer thickness) ...........cubic metre (m3)

The unit of measurement shall be the cubic metre of compacted pavement layer, the quantity of which shall be calculated in accordance with the authorized dimensions of the completed layer if the underlying layer has also been reconstructed or reworked. Where the underlying layer has not been reconstructed or reworked but only rolled, or where no work has been done on it, quantities shall be calculated with the aid of cross-sections taken of the layer before and after construction. Where the material consist of recovered pavement material in part and imported material in part the quantity of imported material obtained from cut or borrow shall be paid for under pay item 51.01, calculated in accordance with the volume relation of the respective materials. The tendered rate shall include full compensation for breaking up the existing pavement layer, excavating the material in the existing pavement, procuring, breaking down, placing and compacting the material, including haul for a free-haul distance of 1.0 km, and for the protection and maintenance of the layer as well as for the performance of control tests, all as specified. Where excavation is executed over sections of the road payment shall also include compensation for the proper measuring and marking-off of the excavation, and the protection of the adjacent existing pavement and its repair should it be damaged. The tendered rate for cemented material shall include full compensation of breaking down the material to comply with the specified grading requirements. Item 51.04 In situ reconstruction of existing Sub-base layer as: (a) Gravel sub-base (unstabilized gravel) compacted to 95% of modified AASHTO density, using: (i) (ii) Non-cemented material (specify compacted layer thickness)....cubic metre (m3) Cemented material (specify compacted layer thickness) ...........cubic metre (m3)

(b) Gravel sub-base (chemically stabilized material) compacted to 95% of modified AASHTO density using: (i) (ii) Non-cemented material (specify compacted layer thickness)....cubic metre (m3) Cemented material (specify compacted layer thickness) ...........cubic metre (m3)

(c) Gravel sub-base (chemically stabilized material) compacted to 96% of modified AASHTO density, using: (i) (ii) Non-cemented material (specify compacted layer thickness)....cubic metre (m3) Cemented material (specify compacted layer thickness) ..........cubic metre (m3)

Page5000-16

Ethiopian Roads Authority

Standard Technical Specification - 2002

Series 5000: Subbase Road Base And Gravel Wearing Course Division 5100: Sub-Bases

(d) Crushed stone Sub-base (unstabilized) compacted to 95% of modified AASHTO density, using: (i) (ii) Non-cemented material (specify compacted layer thickness) ... cubic metre (m3) Cemented material (specify compacted layer thickness) ......... cubic metre (m3)

(e) Crushed stone Sub-base (chemically stabilized) compacted to 95% of modified AASHTO density using: (i) (ii) Non-cemented material (specify compacted layer thickness) ... cubic metre (m3) Cemented material (specify compacted layer thickness)........... cubic metre (m3)

The unit of measurement shall be the cubic metre of compacted pavement layer reworked in situ, the quantity of which shall be calculated in accordance with the authorized dimensions of the completed layer. The tendered rate shall include full compensation for breaking up the existing pavement layer to the specified depth, breaking down and preparing the material, placing and compacting the material as well as the protection and maintenance of the layer, conducting control tests, measuring and demarcating the work where layers are reprocessed partly, protecting the adjacent pavement and its repair should it be damaged. The tendered rate shall also include full compensation for spreading and mixing in any additional material should the existing layer thickness be inadequate and it be specified or instructed by the engineer that the thickness be increased. Material which is temporarily bladed to windrow for the removal of an underlying layer and then bladed back and compacted, will be classed as in situ reconstruction and paid for under this item. The temporary blading of the material to windrow will be paid for under Pay item 51.07. The tendered rate for cemented material shall include full compensation for breaking down the material to comply with the specified grading requirements. Item 51.05 Sub-base layer constructed Extra over Pay item 51.03 (a),(b),(c)&(d) and Pay item 51.04 (a),(b)&(c) from recovered pavement material mixed with existing bituminous surfacing material The unit of measurement shall be in cubic metre (m3). The tendered extra-over rate for constructing the pavement layers from material recovered from existing pavements and mixed with existing bituminous surfacing material shall include full compensation for breaking down the surfacing material into fragments not exceeding 37.5 mm in size, uniformly mixing it with the other material, manually removing any over-sized fragments, and for any other incidentals. Item 51.06 Extra over Pay item 51.04 for adding extra material as specified below: (a) (b) Gravel sub-base ................................................................................... cubic metre (m3) Crushed stone Sub-base....................................................................... cubic metre (m3)

Where the thickness of any existing pavement layer requires to be supplemented and the thickness of the added material after compaction will be less than 100 mm, the existing layer shall be scarified to a depth that will give a layer thickness of at least 100 mm after

Ethiopian Roads Authority

Page 5000-17

Series 5000: Subbase Road Base And Gravel Wearing Course Division 5100: Sub-Bases

Standard Technical Specification -2002

compacting together the loosened existing and added material. In the case of gravel or crushed-stone sub-bases the engineer may direct the existing layer to be broken down to its full depth. The composite layer shall be watered mixed and compacted as determined in the clause for placing and compaction. Payment for adding the material will be made as per this pay item. The unit of measurement shall be a cubic metre of material added on the instruction of the engineer, which quantity shall be taken as 70% of the loose volume measured in trucks, unless instructed by the engineer that the quantity be determined by way of cross-sections. The tendered rate shall include full compensation for procuring and adding the material to the in situ broken- down pavement layer and for haul over a free-haul distance of 1.0 km. Item 51.07 Extra over Pay item 51.04 for temporarily blading the material to windrow The unit of measurement shall be a cubic metre (m3) of material from an existing pavement layer, temporarily bladed to windrow and measured in its original position before removal. The tendered rate shall include full compensation for all additional costs involved in temporarily blading the material to windrow and later blading back and also for all clearingup work which may be necessary after the material has been bladed back. Only material bladed to windrow on the instruction of the engineer in order to expose the underlying layer shall be measured and paid for. Material bladed or cut from restricted areas to windrow, and material temporarily stockpiled, will not be paid for under this item. Item 51.08 Extra over Pay item 51.03 for excavating material in existing pavement layers in restricted areas: (a) (b) Non-cemented material........................................................................cubic metre (m3) Cemented material ...............................................................................cubic metre (m3)

The unit of measurement shall be a cubic metre of material excavated in a restricted area, the quantity of which shall be calculated in accordance with the area and the average thickness of the layers excavated. The tendered rate shall include full compensation for all additional costs for excavating the material in restricted areas. Item 51.09 Compacting the floors of pavement excavations (5 roller passes) with: (a) (b) (c) (d) (e) Vibratory rollers ................................................................................. square metre (m2) Oscillatory rollers .............................................................................. square metre (m2) Grid rollers ......................................................................................... square metre (m2) Flat-wheeled rollers ........................................................................... square metre (m2) Pneumatic-tyred rollers...................................................................... square metre (m2)

The unit of measurement shall be a square metre of floor of pavement excavations compacted by 5 roller passes. Payment will differentiate between the above types of rollers. The tendered rate shall include full compensation for supplying the roller, applying 5 roller passes, and removing the roller after completion of the compacting process. The engineer may

Page5000-18

Ethiopian Roads Authority

Standard Technical Specification - 2002

Series 5000: Subbase Road Base And Gravel Wearing Course Division 5100: Sub-Bases

increase or decrease the number of roller passes, in which case payment will be adjusted in accordance with pay item 51.11. Item 51.10 Watering the pavement excavation floor. The unit of measurement shall be kilolitre (kl) of water applied to the floor of the excavation to be compacted on the instruction of the engineer. The tendered rate shall include full compensation for procuring and applying the water, including all hauls. Item 51.11 Variations in the number of roller passes applicable to pay item 51.09: (a) (b) (c) (d) (e) Vibratory rollers ............................................................. square metre- pass (m2 -pass) Oscillatory rollers ............................................................ square metre- pass (m2 -pass) Grid rollers ...................................................................... square metre- pass (m2 -pass) Flat-wheeled rollers......................................................... square metre- pass (m2 -pass) Pneumatic-tyred rollers ................................................... square metre- pass (m2 -pass)

Item 51.12 Extra over Pay item 51.09 for compacting pavement excavation floor in restricted areas The unit of measurement shall be a square metre (m2) of pavement excavation floor compacted in restricted areas. The tendered rate shall include full compensation for all additional costs for compacting the pavement excavation floor in a restricted area irrespective of the compaction plant used.

Ethiopian Roads Authority

Page 5000-19

Series 5000: Subbase Road Base And Gravel Wearing Course Division 5200: Road Bases

Standard Technical Specification -2002

DIVISION 5200: ROAD BASES

5201 SCOPE

This Division covers the specifications of materials for, and the construction of road base pavement layers from approved base materials. It includes the use of crushed, screened or crushed and screened stones or gravels, natural gravels, and stabilized base materials.

5202 DIMENSIONS

The road base layer shall be constructed to the dimensions and cross sectional profiles shown in the Contract.

5203 MATERIALS

(a) Sources of Material Road base material shall be obtained from sources located by the Contractor and approved by the Engineer. (b) Road Base Material Types The materials used for the construction of road base layers shall be one of the following as described in the Contract: Crushed Rock or Stone; Naturally occurring Granular Materials, Boulders, Weathered Rock; Dense Bitumen Macadam.

5204 MATERIAL REQUIREMENTS FOR CRUSHED ROCK OR STONE

(a) General Graded crushed stone (GB1): This material is produced by crushing fresh, quarried rock (GB1) and may be an all-in product, usually termed a 'crusher-run', or alternatively the material may be separated by screening and recombined to produce a desired particle size distribution, as per the specifications. The material shall be clean and free from organic matter, lumps of clay or other deleterious substances. The material shall be of such a nature that it can be readily transported, spread and compacted without segregation. (b) Grading The combined grading of the material shall be a smooth continuous curve falling within the grading limits shown in Table 5200/1 when determined in accordance with the requirements of AASHTO T-27. The mass of material passing the 0.075mm sieve shall be determined in accordance with the requirements of AASHTO T-11.

Page5000-20

Ethiopian Roads Authority

Standard Technical Specification - 2002

Series 5000: Subbase Road Base And Gravel Wearing Course Division 5200: Road Bases

Table 5200/1: Grading Limits for Graded Crushed Stone Base Course Materials (GB1) Test sieve (mm) Percentage by mass of total aggregate passing test sieve Nominal maximum particle size 37.5 mm 28 mm 20 mm 100 95 100 100 100 60 80 70 - 85 90 100 40 60 50 - 65 60 75 25 - 40 35 - 55 40 60 15 30 25 - 40 30 45 7 19 12 - 24 13 27 5 12 5 - 12 5 12

50 37.5 28 20 10 5 2.36 0.425 0.075(1)

Note 1. For paver-laid materials a lower fine content may be accepted. (c) Plasticity Index The fine fraction of a GB1 material shall be non-plastic or shall have a maximum Plasticity Index of 6 when determined in accordance with AASHTO T-90. (d) Californian Bearing Ratio (CBR) The in- situ dry density of the placed material should be a minimum of 98% of the maximum dry density obtained in the ASTM Test Method D 1557 (Heavy Compaction). The compacted thickness of each layer should not exceed 200 mm. Crushed stone base courses constructed with proper care with GB1 materials described above should have CBR values in excess of 100 per cent. (e) Aggregate Crushing Value (ACV) Requirements expressed in terms of the results of the Aggregate Crushing Value (ACV) (British Standard 812, Part 110) may be used: the ACV should preferably be less than 25 and in any case less than 29. Other simpler tests e.g. the Aggregate Impact Test (British Standard 812, Part 112, 1990) may be used in quality control testing provided a relationship between the results of the chosen test and the Ten percent Fines Value (TFV) has been determined. (f) Mechanical Strength Requirements (TFVT) To ensure that the materials are sufficiently durable, they should satisfy the criteria given in Table 5200/2. These are a minimum Ten Per Cent Fines Value (TFV) (British Standard 812, Part 111) and limits on the maximum loss in strength following a period of 24 hours of soaking in water. The likely moisture conditions in the pavement are taken into account in broad terms based on annual rainfall.

Ethiopian Roads Authority

Page 5000-21

Series 5000: Subbase Road Base And Gravel Wearing Course Division 5200: Road Bases

Standard Technical Specification -2002

Table 5200/2: Mechanical Strength Requirements for the Aggregate Fraction of Crushed Stone Base Course Materials (GB1) as Defined by the Ten Percent Fines Test Typical Annual Rainfall (mm) >500 <500 (g) Flakiness Index The flakiness index shall not exceed 30% when determined in accordance with BS 812 Part 105-1990. Minimum 10% Fines Values (kN) 110 110 Minimum Ratio Wet/Dry Test (%) 75 60

5205 MATERIAL REQUIREMENTS FOR NATURALLY OCCURRING GRANULAR MATERIALS, BOULDERS, WEATHERED ROCK

(a) General Graded Natural Gravel (GB2, GB3): A wide range of materials including lateritic, calcareous and quartzitic gravels, river gravels, boulders and other transported gravels, or granular materials resulting from the weathering of rocks can be used successfully as base course materials. The material shall be of such a nature that it can be readily transported, spread and compacted without segregation. (b) Grading The particle size distribution should be approximately parallel with the grading envelope, to ensure that the material has maximum mechanical stability, in the grading limits shown in Table 5203/3 when determined in accordance with the requirements of AASHTO T-27. The mass of material passing the 0.075mm sieve shall be determined in accordance with the requirements of AASHTO T-11. Table 5200/3 contains two recommended particle size distributions for suitable materials corresponding to maximum nominal sizes of 37.5 mm and 20 mm.

Page5000-22

Ethiopian Roads Authority

Standard Technical Specification - 2002

Series 5000: Subbase Road Base And Gravel Wearing Course Division 5200: Road Bases

Table 5200/3: Recommended Particle Size Distributions for Mechanically Stable Natural Gravels and Weathered Rocks for Use as Base Course Material (GB2, GB3) Test sieve (mm) Percentage by mass of total aggregate passing test sieve Nominal maximum particle size 37.5 mm 20 mm 100 80 100 100 60 80 80 100 45 65 55 80 30 50 40 60 20 40 30 50 10 25 12 27 5 15 5 15

50 37.5 20 10 5 2.36 0.425 0.075

(c) Plasticity Index The fine fraction of a GB1 material shall be non-plastic or shall have a maximum Plasticity Index of 6 when determined in accordance with AASHTO T-90. If the PI approaches the upper limit of 6, it is desirable that the fines content be restricted to the lower end of the range. To ensure this, a maximum PP of 60 is recommended or alternatively a maximum Plasticity Modulus (PM) of 90 where: PM = PI x (percentage passing the 0.425 mm sieve) If difficulties are encountered in meeting the plasticity criteria, consideration should be given to modifying the material by the addition of a low percentage of hydrated lime or cement. (d) Californian Bearing Ratio (CBR) When used as a base course, the material should be compacted to a density equal to or greater than 98 per cent of the maximum dry density achieved in the ASTM Test Method D 1557 (Heavy Compaction). When compacted to this density in the laboratory, the material should have a minimum CBR of 80% after four days immersion in water (ASTM D 1883). (e) Aggregate Crushing Value (ACV) Minimum soaked Ten percent Fines Value (TFV) Value (BS 812, Part 111) shall be 50 KN. (f) Abrasion The Los Angeles Abrasion value, determined by testing in accordance with AASHTO T96 shall not exceed 45 at 500 revolutions unless otherwise specified in the Project Specifications. (g) Flakiness Index The flakiness index shall not exceed 30% when determined in accordance with BS 812 Part 105-1990.

Ethiopian Roads Authority

Page 5000-23

Series 5000: Subbase Road Base And Gravel Wearing Course Division 5200: Road Bases

Standard Technical Specification -2002

(h) Crushed Ratio The crushed ratio shall be a minimum of 60%. (i) Grading Modulus The minimum Grading Modulus for material once placed and compacted on the road shall be: For natural material. . . . . . . . . . . . . . . . . . . . 2.00 For material to be chemically stabilized. . . . . . . . . . 1.75

5206 MATERIAL REQUIREMENTS FOR DENSE BITUMEN MACADAM

(a) Coarse Aggregates The material shall consist of hard durable particles produced by crushing rock or boulders and shall be clean and free from organic matter, lumps of clay or other deleterious substances and complying with the requirements of AASHTO M-80. Crushed rock or crushed boulders shall be produced from one or more of the following rock types; Basalt; Gabbro; Granite; Gritstone; Hornfels; Limestone; Porphyry or Quartzite. Aggregate Crushing Value The aggregate crushing value of the coarse aggregate shall not exceed 25 when determined in accordance with BS 812 Part 3. (i) Los Angeles Abrasion

The Los Angeles Abrasion value shall not exceed 35% when determined in accordance with the requirements of AASHTO T-96. (ii) Soundness

The loss of soundness of the coarse aggregate shall not be greater than 12% when tested in accordance with AASHTO T-104. (iii) Flakiness index

The flakiness index, shall not exceed 45% when determined in accordance with the requirements of BS 812 Part 105-1990. (iv) Crushed Ratio

The crushed ratio shall be a minimum of 100%.

Page5000-24

Ethiopian Roads Authority

Standard Technical Specification - 2002

Series 5000: Subbase Road Base And Gravel Wearing Course Division 5200: Road Bases

(v)

Water Absorption

The water absorption shall not exceed 2% when determined in accordance with the requirements of AASHTO T-85. (vi) Coating of Chippings

The coating of chippings with binder shall not be less than 60% when determined in accordance with the requirements of prEN 12697-11:1998E for compatibility between aggregate and bitumen. (b) Fine Aggregate Fine aggregate shall comply with the requirements of AASHTO M-6 and shall consist of one of the following: (i) (ii) Crushed rock or crushed boulders; Natural sand;

(iii) A blend of (i) and (ii) above. (c) Filler Where necessary to improve the combined grading or other properties of the mix, a filler of either hydrated lime, cement or crushed rock or crushed boulder dust may be added. Filler shall be material passing the 0.075mm sieve. If used as an anti-stripping agent, the quantity of hydrated lime shall be at least 1.5% by weight of total aggregates and in no case shall the quantity exceed 3% by weight of total aggregates. (d) Binder The binder shall be 60/70 penetration grade bitumen complying with the requirements of AASHTO M-20.

5207 MATERIAL REQUIREMENTS FOR MIXED BITUMEN MACADAM

(a) Combined Aggregate Grading The combined grading of the aggregates shall be a smooth continuous curve falling within the grading limits shown in Table 5200/4 when determined in accordance with AASHTO T-27. The mass of material passing the 0.075mm sieve shall be determined in accordance with AASHTO T-11.

Ethiopian Roads Authority

Page 5000-25

Series 5000: Subbase Road Base And Gravel Wearing Course Division 5200: Road Bases

Standard Technical Specification -2002

Table 5200/4 Combined Aggregate Grading Limits for Dense Bitumen Macadam Test sieve (mm) 28 20 14 10 6.3 3.35 1.18 0.3 0.075 (1) Notes: 1. When gravel other than limestone is used, the anti-stripping properties shall be improved by including 2% Portland cement or hydrated lime in the material passing the 0.075 mm sieve. 2. Limestone and gravel shall not be used for wearing courses where high skidding resistance is required. (b) Mix Design Parameters for Dense Bitumen Macadam The parameters for dense bitumen macadam shall comply with the requirements as shown in Table 5200/5. Table 5200/5 Mix Design Parameters for Dense Bitumen Macadam Property Bitumen content (1) (per cent by mass of total mix) Bitumen grade (2) Minimum Marshal Stability (Depending on Design traffic) Unit % pen kN Value 5.0 0.6 60/70 or 80/100 3.5-9 Percentage by mass of total aggregate passing test sieve 100 95 100 65 85 52 72 39 55 32 46 7 21 28

Flow mm 2-4 Air Voids % 4.0 - 8.0 Voids in Mineral Aggregate % 16.0 - 22.0 Voids Filled with Bitumen % 65.0 - 85.0 Filler/Bitumen Ratio* % 1.0 - 1.6 Compaction Level Number of blows 2x50, 2x75 - To refusal (Depending on Design traffic) Note : 1. For aggregate with fine microtexture e.g. limestone, the bitumen content should be reduced by 0.1 to 0.3%. 2. 60/70 grade bitumen is preferred.

Page5000-26

Ethiopian Roads Authority

Standard Technical Specification - 2002

Series 5000: Subbase Road Base And Gravel Wearing Course Division 5200: Road Bases

The mix proportions for each type of mixture to be used in the Works shall be determined initially in accordance with the requirements of the Asphalt Institute Mix Design Manual (MS2) using at least five binder contents. The Marshall specimens shall be compacted using 75 blows on each face. Trial mixes shall be carried out using various combined aggregate gradings within the limits stipulated within Table 5200/4 in order to determine the optimum design within the stipulated parameters in Table 5200/5 for the materials being used. Prior to final approval of the proposed job mix formula, mixes shall be compacted to refusal using the extended Marshall compaction method (in accordance with the requirements of BS 598 Part 104 (1989)) and the resulting air voids in the mix shall not be less than 3%.

5208 CONSTRUCTION REQUIREMENTS FOR CRUSHED ROCK AND CRUSHED BOULDER ROAD BASES

(a) Equipment The material shall be laid either by a self-propelled paving machine or by means of a grader, as described in the Contract. It shall be so designed and operated as to produce a mixture of laid material complying with the requirements of this Specification. The equipment used shall be of adequate rated capacity, in good working order, and subject to the approval of the Engineer. Obsolete or worn out equipment will not be permitted on the Site. The mixing plant shall be either a batch or a continuous type, as approved by the Engineer, and shall be equipped with satisfactory means of accurately controlling the proportions of all constituent materials. The crushing and screening plant shall be capable of crushing and screening the aggregates, to be used for crushed rock or crushed boulder road base material, into at least four different sized fractions. Compaction shall be carried out using self-propelled 8 10 tonnes deadweight smooth wheeled rollers having a width of roll not less than 450mm, or by multi-wheeled pneumatic tyred rollers of equivalent mass, or by vibratory rollers of equivalent compactive performance, or a combination of these. Rollers shall be equipped with adjustable scrapers for cleaning the drums and an efficient means of moistening the drums to prevent adhesion of asphalt. The rollers shall be fitted with a quick and smooth acting reversing mechanism. (b) Placing and Compaction The surface on which the crushed rock and crushed boulder road base is to be laid shall be free from loose or deleterious material. The crushed material shall be screened into at least four different aggregate fractions. The aggregate shall be recombined in a mixing plant in the proportions necessary to produce a smooth continuous combined grading curve complying with the requirements of Table 5200/1. The mixing plant shall be an approved type and shall be equipped with satisfactory means of controlling the mix proportions and the addition of the required quantity of water to achieve the optimum, which is required for compaction purposes.

Ethiopian Roads Authority

Page 5000-27

Series 5000: Subbase Road Base And Gravel Wearing Course Division 5200: Road Bases

Standard Technical Specification -2002

The mixed material shall be transported at the required moisture content and in such a way, that no segregation occurs. Unless otherwise described in the Contract, the material shall be laid by a self-propelled paving machine approved by the Engineer. The rate of travel of the paver and its method of operation shall be adjusted to produce an even and uniform flow of material across the full laying width free from dragging and without segregation. The material shall be spread in layers not exceeding 200mm and not less than 100mm compacted thickness. The material shall be compacted by the use of approved rollers progressing gradually from the outside towards the centre of the layer, except on superelevated curves, where the rolling shall begin at the low side and progress to the high side. Each succeeding pass shall overlap the previous pass by at least one third of the roller width. Rolling shall continue until the entire thickness of each layer is thoroughly and uniformly compacted to the specified density. Any area, which is inaccessible to rolling equipment, shall be compacted by means of mechanical tampers or other equipment approved by the Engineer. Upon completion of compaction, the surface of the completed layer shall be tightly bound, free from movement under the compaction plant, and free from laminations, ridges, cracks or loose or segregated material. The in-situ density of the completed layer shall not be less than 98% of the maximum dry density determined in accordance with the requirements of AASHTO T-180 method D. The in-situ density of the completed layer shall be determined in accordance with the requirements of AASHTO T-191. Alternatively, if approved by the Engineer, the dry density may be determined by use of a nuclear densometer in direct transmission mode in accordance with AASHTO T238-86 Method B or ASTM D 2992-96. The nuclear densometer shall be accurately calibrated before use, and at interval thereafter, and correlated against results obtained in accordance with AASHTO T-191. (c) Stabilization When specified in the contract or required by the engineer, base layers shall be stabilized as specified in Division 4600. (d) Trial Sections Prior to the commencement of normal working the Contractor shall construct a trial section of not less than 1000 square metres using the materials and equipment proposed for the work to demonstrate compliance with the requirements of this Clause. (e) Traffic on Road base The completed road base layer shall not be used by construction or public traffic prior to the application of the prime coat in accordance with the requirements of Division 6100 of these specifications and without the prior written approval of the Engineer. The approval by the Engineer shall not relieve the Contractor of his obligations to maintain the road base in a satisfactory condition and to undertake any repairs as instructed by the Engineer.

Page5000-28

Ethiopian Roads Authority

Standard Technical Specification - 2002

Series 5000: Subbase Road Base And Gravel Wearing Course Division 5200: Road Bases

5209 CONSTRUCTION REQUIREMENTS FOR CRUSHED GRAVEL ROAD BASE

(a) Equipment The material shall be laid either by a self-propelled paving machine or by means of a grader, as described in the Contract. It shall be so designed and operated as to produce a mixture of laid material complying with the requirements this Specification. The equipment used shall be of adequate rated capacity in good working order and subject to the approval of the Engineer. Obsolete or worn out equipment will not be permitted on the Site. Compaction shall be carried out using self-propelled 8 10 tonnes deadweight smooth wheeled rollers having a width of roll not less than 450mm, or by multi-wheeled pneumatic tyred rollers of equivalent mass, or by vibratory rollers of equivalent compactive performance, or a combination of these. Rollers shall be equipped with adjustable scrapers for cleaning the drums and an efficient means of moistening the drums to prevent adhesion of asphalt. The rollers shall be fitted with a quick and smooth acting reversing mechanism. (b) Placing and Compaction The surface on which the crushed gravel road base is to be laid shall be free from loose and deleterious material. Crushed gravel road base shall be spread on the sub-base material by mechanical means without segregation. The material shall be loosely spread in layers to give a compacted thickness not exceeding 200mm and not less than 100mm. The final compacted layer shall be free from concentrations of coarse or fine materials. The surface of each completed layer shall be moistened prior to the construction of the succeeding layer. Prior to compaction, the moisture content of the spread material shall be adjusted as necessary either by the uniform application of water or drying out, to achieve within -1% to +2% of the optimum moisture content when determined in accordance with AASHTO T-180. The material shall be compacted by the use of approved rollers progressing gradually from the outside towards the centre of the layer, except on superelevated curves, where the rolling shall begin at the low side and progress to the high side. Each succeeding pass shall overlap the previous pass by at least one third of the roller width. Rolling shall continue until the entire thickness of each layer is thoroughly and uniformly compacted to the specified density. Any area, which is inaccessible to rolling equipment, shall be compacted by means of mechanical tampers or other equipment approved by the Engineer. Upon completion of compaction, the surface of the completed layer shall be tightly bound, free from movement under the compaction plant, and free from laminations, ridges, cracks or loose or segregated material. The in-situ density of the completed layer shall not be less than 98% of the maximum dry density determined in accordance with the requirements of AASHTO T-180 method D.

Ethiopian Roads Authority

Page 5000-29

Series 5000: Subbase Road Base And Gravel Wearing Course Division 5200: Road Bases

Standard Technical Specification -2002