Professional Documents

Culture Documents

Delphi Pump Test Plans 4 Web

Uploaded by

Aspro Brazil Se IglesiasOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Delphi Pump Test Plans 4 Web

Uploaded by

Aspro Brazil Se IglesiasCopyright:

Available Formats

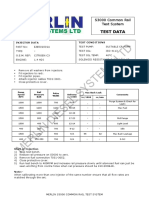

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

Pump Designation:-9042A0013A-014A

Type Designation:-0.6CC2

Manufacturer I.D.:- RENAULT

Engine:-

Testing Prerequisites

Inlet Feed Pressure - 0.2 BAR

Test Oil Specification- ISO4113

Test Oil Temperature- 40 deg C

Direction of Rotation - Clockwise

Remove injector pipes from test rail and blank off with T031-3005

Fit In line return temperature sensor to return line.

Fit Bosch type Pressure control valve to test rail (ie 0 281 200 872).

Connect Fuel Pump Cable T031-3001 to PCV in test rail.

Set S3000 Test Unit to PCV

1. LEAK TEST

2. RUNNING IN TEST

To be Carried out whenever rollers and shoes have been disturbed or replaced

Test

Bench Speed - RPM Rail Pressure - BAR Conditions Comments

1 350 250 15 Secs No Unusual noise

2 2000 1000 3 Mins No Leaks and

No abnormal

Temperature rise.

Test

Bench Speed - RPM Rail Pressure - BAR Time - Seconds Max Delta

T

1 400 400 60 5

2 800 400 60 5

3 1200 400 60 6

4 2000 800 60 8

5 2000 1200 60 9

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

MERLIN S3000 COMMON RAIL TEST SYSTEM

3. TRANSFER PRESSURE

3. PUMP PERFORMANCE

Fit Bosch type PCV to rail (ie 0281002872) and connect lead T031-3001.

Set S3000 Test Unit to PCV

4. SCV TEST

Connect pump lead T031-3001 to fuel pump SCV

Leave Bosch type PCV in rail (ie 0281002872)

Set S3000 test unit to SCV.

5. TEMP SENDER / SCV RESISTANCE CHECKS

Test

Bench Speed - RPM Rail Pressure - BAR Comments T.Pressure

BAR

1 400 230 4.5-5.5

2 1000 1600 5.8-6.2

3 2000 1600 6.5-7.0

Test

Bench Speed - RPM SCV DRV % Comments Delivery

CC/1000

1 1000

80

500-600

2 1000

60 0

3 1000

80

500-600

Test

Bench Speed - RPM Temp Sender

Resistance K

SCV Resistance

INLET FUEL

TEMP C

1

-

N/A 5.0-6.0 20

2

-

N/A 5.5-6.5 40

Test

Bench Speed - RPM Rail Pressure

BAR

Comments Delivery

CC/1000

1 2500 1600 440

2 2000 1600 475-525

3 1000 1200 475-525

4 1000 500 560 10%

5 1000 1000 Max 10% less 450-500

6 50 230 450+

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

MERLIN S3000 COMMON RAIL TEST SYSTEM

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

Pump Designation:-9042A021A-023A

Type Designation:-0.6CC2

Manufacturer I.D.:- PSA

Engine:- DV4 1.4HDi 90HP

Testing Prerequisites

Inlet Feed Pressure - 0.2 BAR

Test Oil Specification- ISO4113

Test Oil Temperature- 40 deg C

Direction of Rotation - Clockwise

Remove injector pipes from test rail and blank off with T031-3005

Fit In line return temperature sensor to return line.

Fit Bosch type Pressure control valve to test rail (ie 0 281 200 872).

Connect Fuel Pump Cable T031-3001 to PCV in test rail.

Set S3000 Test Unit to PCV

1. LEAK TEST

2. RUNNING IN TEST

To be Carried out whenever rollers and shoes have been disturbed or replaced

Test

Bench Speed - RPM Rail Pressure - BAR Conditions Comments

1 350 250 15 Secs No Unusual noise

2 2000 1000 3 Mins No Leaks and

No abnormal

Temperature rise.

Test

Bench Speed - RPM Rail Pressure - BAR Time - Seconds Max Delta

T

1 400 400 60 5

2 800 400 60 5

3 1200 400 60 6

4 2000 800 60 8

5 2000 1200 60 9

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

MERLIN S3000 COMMON RAIL TEST SYSTEM

3. TRANSFER PRESSURE

3. PUMP PERFORMANCE

Fit Bosch type PCV to rail (ie 0281002872) and connect lead T031-3001.

Set S3000 Test Unit to PCV

4. SCV TEST

Connect pump lead T031-3001 to fuel pump SCV

Leave Bosch type PCV in rail (ie 0281002872)

Set S3000 test unit to SCV.

5. TEMP SENDER / SCV RESISTANCE CHECKS

Test

Bench Speed - RPM Rail Pressure - BAR Comments T.Pressure

BAR

1 400 230 4.5-5.5

2 1000 1600 5.8-6.2

3 2000 1600 6.5-7.0

Test

Bench Speed - RPM SCV DRV % Comments Delivery

CC/1000

1 1000

80

500-600

2 1000

60 0

3 1000

80

500-600

Test

Bench Speed - RPM Temp Sender

Resistance K

SCV Resistance

INLET FUEL

TEMP C

1

-

N/A 5.0-6.0 20

2

-

N/A 5.5-6.5 40

Test

Bench Speed - RPM Rail Pressure

BAR

Comments Delivery

CC/1000

1 2500 1600 440

2 2000 1600 475-525

3 1000 1200 475-525

4 1000 500 560 10%

5 1000 1000 Max 10% less 450-500

6 50 230 450+

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

MERLIN S3000 COMMON RAIL TEST SYSTEM

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

Pump Designation:-9042A041A

Type Designation:-0.6CC2

Manufacturer I.D.:- RENAULT

Engine:-

Testing Prerequisites

Inlet Feed Pressure - 0.2 BAR

Test Oil Specification- ISO4113

Test Oil Temperature- 40 deg C

Direction of Rotation - Clockwise

Remove injector pipes from test rail and blank off with T031-3005

Fit In line return temperature sensor to return line.

Fit Bosch type Pressure control valve to test rail (ie 0 281 200 872).

Connect Fuel Pump Cable T031-3001 to PCV in test rail.

Set S3000 Test Unit to PCV

1. LEAK TEST

2. RUNNING IN TEST

To be Carried out whenever rollers and shoes have been disturbed or replaced

Test

Bench Speed - RPM Rail Pressure - BAR Conditions Comments

1 350 250 15 Secs No Unusual noise

2 2000 1000 3 Mins No Leaks and

No abnormal

Temperature rise.

Test

Bench Speed - RPM Rail Pressure - BAR Time - Seconds Max Delta

T

1 400 400 60 5

2 800 400 60 5

3 1200 400 60 6

4 2000 800 60 8

5 2000 1200 60 9

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

MERLIN S3000 COMMON RAIL TEST SYSTEM

3. TRANSFER PRESSURE

3. PUMP PERFORMANCE

Fit Bosch type PCV to rail (ie 0281002872) and connect lead T031-3001.

Set S3000 Test Unit to PCV

4. SCV TEST

Connect pump lead T031-3001 to fuel pump SCV

Leave Bosch type PCV in rail (ie 0281002872)

Set S3000 test unit to SCV.

5. TEMP SENDER / SCV RESISTANCE CHECKS

Test

Bench Speed - RPM Rail Pressure - BAR Comments T.Pressure

BAR

1 400 230 4.5-5.5

2 1000 1600 5.8-6.2

3 2000 1600 6.5-7.0

Test

Bench Speed - RPM SCV DRV % Comments Delivery

CC/1000

1 1000

80

500-600

2 1000

60 0

3 1000

80

500-600

Test

Bench Speed - RPM Temp Sender

Resistance K

SCV Resistance

INLET FUEL

TEMP C

1

-

N/A 5.0-6.0 20

2

-

N/A 5.5-6.5 40

Test

Bench Speed - RPM Rail Pressure

BAR

Comments Delivery

CC/1000

1 2500 1600 440

2 2000 1600 475-525

3 1000 1200 475-525

4 1000 500 560 10%

5 1000 1000 Max 10% less 450-500

6 50 230 450+

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

MERLIN S3000 COMMON RAIL TEST SYSTEM

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

Pump Designation:-9044A070A

Type Designation:-1.2CC2

Manufacturer I.D.:- KIA/HYUNDAI

Engine:- 2.9L

Testing Prerequisites

Inlet Feed Pressure - 0.2 BAR

Test Oil Specification- ISO4113

Test Oil Temperature- 40 deg C

Direction of Rotation - Clockwise

Remove injector pipes from test rail and blank off with T031-3005

Fit Transfer pressure adaptor T016-697 in place of Temperature sender and

re-connect temperature sender to T.P.adaptor. Connect test bench pressure gauge.

Fit Bosch type Pressure control valve to test rail (ie 0 281 200 872).

Connect Fuel Pump Cable T031-3001 to PCV in test rail.

Set S3000 Test Unit to PCV

1. LEAK TEST

2. RUNNING IN TEST

To be Carried out whenever rollers and shoes have been disturbed or replaced

Test

Bench Speed - RPM Rail Pressure - BAR Conditions Comments

1 350 250 15 Secs No Unusual noise

2 2000 1000 3 Mins No Leaks and

No abnormal

Temperature rise.

Test

Bench Speed - RPM Rail Pressure - BAR Time - Seconds Max Delta

T

1 400 400 60 5

2 800 400 60 5

3 1200 400 60 6

4 2000 800 60 8

5 2000 1200 60 9

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

MERLIN S3000 COMMON RAIL TEST SYSTEM

3. TRANSFER PRESSURE

3. PUMP PERFORMANCE

Fit Bosch type PCV to rail (ie 0281002872) and connect lead T031-3001.

Set S3000 Test Unit to PCV

4. SCV TEST

Connect pump lead T031-3001 to fuel pump SCV

Leave Bosch type PCV in rail (ie 0281002872)

Set S3000 test unit to SCV.

5. TEMP SENDER / SCV RESISTANCE CHECKS

Test

Bench Speed - RPM Rail Pressure - BAR Comments T.Pressure

BAR

1 400 230 4.5-5.5

2 1000 1600 5.8-6.2

3 2000 1600 6.5-7.0

Test

Bench Speed - RPM SCV DRV % Comments Delivery

CC/1000

1 1000

80

130 BAR 1150-1250

2 1000

60 0

3 1000

80

1150-1250

Test

Bench Speed - RPM Temp Sender

Resistance K

SCV Resistance

INLET FUEL

TEMP C

1

-

2.5-4.0 5.0-6.0 20

2

-

0.9-1.5 5.5-6.5 40

Test

Bench Speed - RPM Rail Pressure

BAR

Comments Delivery

CC/1000

1 2000 1600 760-840

2 1000 1200

3 1000 500 980 10%

4 1000 1000 Max 10% less >900

5 50 230 >1000

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

Pump Designation:-9044A071A

Type Designation:-1.2CC2

Manufacturer I.D.:- KIA/HYUNDAI

Engine:- 2.9L

Testing Prerequisites

Inlet Feed Pressure - 0.2 BAR

Test Oil Specification- ISO4113

Test Oil Temperature- 40 deg C

Direction of Rotation - Clockwise

Remove injector pipes from test rail and blank off with T031-3005

Fit Transfer pressure adaptor T016-697 in place of Temperature sender and

re-connect temperature sender to T.P.adaptor. Connect test bench pressure gauge.

Fit Bosch type Pressure control valve to test rail (ie 0 281 200 872).

Connect Fuel Pump Cable T031-3001 to PCV in test rail.

Set S3000 Test Unit to PCV

1. LEAK TEST

2. RUNNING IN TEST

To be Carried out whenever rollers and shoes have been disturbed or replaced

Test

Bench Speed - RPM Rail Pressure - BAR Conditions Comments

1 350 250 15 Secs No Unusual noise

2 2000 1000 3 Mins No Leaks and

No abnormal

Temperature rise.

Test

Bench Speed - RPM Rail Pressure - BAR Time - Seconds Max Delta

T

1 400 400 60 5

2 800 400 60 5

3 1200 400 60 6

4 2000 800 60 8

5 2000 1200 60 9

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

MERLIN S3000 COMMON RAIL TEST SYSTEM

3. TRANSFER PRESSURE

3. PUMP PERFORMANCE

Fit Bosch type PCV to rail (ie 0281002872) and connect lead T031-3001.

Set S3000 Test Unit to PCV

4. SCV TEST

Connect pump lead T031-3001 to fuel pump SCV

Leave Bosch type PCV in rail (ie 0281002872)

Set S3000 test unit to SCV.

5. TEMP SENDER / SCV RESISTANCE CHECKS

Test

Bench Speed - RPM Rail Pressure - BAR Comments T.Pressure

BAR

1 400 230 4.5-5.5

2 1000 1600 5.8-6.2

3 2000 1600 6.5-7.0

Test

Bench Speed - RPM SCV DRV % Comments Delivery

CC/1000

1 1000

80

130 BAR 1150-1250

2 1000

60 0

3 1000

80

1150-1250

Test

Bench Speed - RPM Temp Sender

Resistance K

SCV Resistance

INLET FUEL

TEMP C

1

-

2.5-4.0 5.0-6.0 20

2

-

0.9-1.5 5.5-6.5 40

Test

Bench Speed - RPM Rail Pressure

BAR

Comments Delivery

CC/1000

1 2000 1600 760-840

2 1000 1200

3 1000 500 980 10%

4 1000 1000 Max 10% less >900

5 50 230 >1000

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

Pump Designation:-9044A072A

Type Designation:-1.2CC2

Manufacturer I.D.:- KIA/HYUNDAI

Engine:- 2.9L

Testing Prerequisites

Inlet Feed Pressure - 0.2 BAR

Test Oil Specification- ISO4113

Test Oil Temperature- 40 deg C

Direction of Rotation - Clockwise

Remove injector pipes from test rail and blank off with T031-3005

Fit Transfer pressure adaptor T016-697 in place of Temperature sender and

re-connect temperature sender to T.P.adaptor. Connect test bench pressure gauge.

Fit Bosch type Pressure control valve to test rail (ie 0 281 200 872).

Connect Fuel Pump Cable T031-3001 to PCV in test rail.

Set S3000 Test Unit to PCV

1. LEAK TEST

2. RUNNING IN TEST

To be Carried out whenever rollers and shoes have been disturbed or replaced

Test

Bench Speed - RPM Rail Pressure - BAR Conditions Comments

1 350 250 15 Secs No Unusual noise

2 2000 1000 3 Mins No Leaks and

No abnormal

Temperature rise.

Test

Bench Speed - RPM Rail Pressure - BAR Time - Seconds Max Delta

T

1 400 400 60 5

2 800 400 60 5

3 1200 400 60 6

4 2000 800 60 8

5 2000 1200 60 9

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

MERLIN S3000 COMMON RAIL TEST SYSTEM

3. TRANSFER PRESSURE

3. PUMP PERFORMANCE

Fit Bosch type PCV to rail (ie 0281002872) and connect lead T031-3001.

Set S3000 Test Unit to PCV

4. SCV TEST

Connect pump lead T031-3001 to fuel pump SCV

Leave Bosch type PCV in rail (ie 0281002872)

Set S3000 test unit to SCV.

5. TEMP SENDER / SCV RESISTANCE CHECKS

Test

Bench Speed - RPM Rail Pressure - BAR Comments T.Pressure

BAR

1 400 230 4.5-5.5

2 1000 1600 5.8-6.2

3 2000 1600 6.5-7.0

Test

Bench Speed - RPM SCV DRV % Comments Delivery

CC/1000

1 1000

80

130 BAR 1150-1250

2 1000

60 0

3 1000

80

1150-1250

Test

Bench Speed - RPM Temp Sender

Resistance K

SCV Resistance

INLET FUEL

TEMP C

1

-

2.5-4.0 5.0-6.0 20

2

-

0.9-1.5 5.5-6.5 40

Test

Bench Speed - RPM Rail Pressure

BAR

Comments Delivery

CC/1000

1 2000 1600 760-840

2 1000 1200

3 1000 500 980 10%

4 1000 1000 Max 10% less >900

5 50 230 >1000

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

Pump Designation:-9044Z013A

Type Designation:-0.9CC2

Manufacturer I.D.:- FORD LYNX

Engine:- 1.8TDCI

Testing Prerequisites

Inlet Feed Pressure - 0.2 BAR

Test Oil Specification- ISO4113

Test Oil Temperature- 40 deg C

Direction of Rotation - Clockwise

Remove injector pipes from test rail and blank off with T031-3005

Fit Transfer pressure adaptor T016-697 in place of Temperature sender and

re-connect temperature sender to T.P.adaptor. Connect test bench pressure gauge.

Fit Bosch type Pressure control valve to test rail (ie 0 281 200 872).

Connect Fuel Pump Cable T031-3001 to PCV in test rail.

Set S3000 Test Unit to PCV

1. LEAK TEST

2. RUNNING IN TEST

To be Carried out whenever rollers and shoes have been disturbed or replaced

Test

Bench Speed - RPM Rail Pressure - BAR Conditions Comments

1 350 250 15 Secs No Unusual noise

2 2000 1000 3 Mins No Leaks and

No abnormal

Temperature rise.

Test

Bench Speed - RPM Rail Pressure - BAR Time - Seconds Max Delta

T

1 400 400 60 5

2 800 400 60 5

3 1200 400 60 6

4 2000 800 60 8

5 2000 1200 60 9

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

MERLIN S3000 COMMON RAIL TEST SYSTEM

3. TRANSFER PRESSURE

3. PUMP PERFORMANCE

Fit Bosch type PCV to rail (ie 0281002872) and connect lead T031-3001.

Set S3000 Test Unit to PCV

4. SCV TEST

Connect pump lead T031-3001 to fuel pump SCV

Leave Bosch type PCV in rail (ie 0281002872)

Set S3000 test unit to SCV.

5. TEMP SENDER / SCV RESISTANCE CHECKS

Test

Bench Speed - RPM Rail Pressure - BAR Comments T.Pressure

BAR

1 400 230 4.5-5.5

2 1000 1600 5.8-6.2

3 2000 1600 6.5-7.0

Test

Bench Speed - RPM SCV DRV % Comments Delivery

CC/1000

1 1000

80

800-900

2 1000

60 0

3 1000

80

800-900

Test

Bench Speed - RPM Temp Sender

Resistance K

SCV Resistance

INLET FUEL

TEMP C

1

-

2.5-4.0 5.0-6.0 20

Test

Bench Speed - RPM Rail Pressure

BAR

Comments Delivery

CC/1000

1 2500 1600

2 2000 1600 620-700

3 1000 1200 680-760

4 1000 500 780 10%

5 1000 1000 Max 10% less 700

6 50 230 760+

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

MERLIN S3000 COMMON RAIL TEST SYSTEM

2

-

0.9-1.5 5.5-6.5 40

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

Pump Designation:-9044Z015A

Type Designation:-0.9CC2

Manufacturer I.D.:- FORD LYNX

Engine:- 1.8TDCI

Testing Prerequisites

Inlet Feed Pressure - 0.2 BAR

Test Oil Specification- ISO4113

Test Oil Temperature- 40 deg C

Direction of Rotation - Clockwise

Remove injector pipes from test rail and blank off with T031-3005

Fit Transfer pressure adaptor T016-697 in place of Temperature sender and

re-connect temperature sender to T.P.adaptor. Connect test bench pressure gauge.

Fit Bosch type Pressure control valve to test rail (ie 0 281 200 872).

Connect Fuel Pump Cable T031-3001 to PCV in test rail.

Set S3000 Test Unit to PCV

1. LEAK TEST

2. RUNNING IN TEST

To be Carried out whenever rollers and shoes have been disturbed or replaced

Test

Bench Speed - RPM Rail Pressure - BAR Conditions Comments

1 350 250 15 Secs No Unusual noise

2 2000 1000 3 Mins No Leaks and

No abnormal

Temperature rise.

Test

Bench Speed - RPM Rail Pressure - BAR Time - Seconds Max Delta

T

1 400 400 60 5

2 800 400 60 5

3 1200 400 60 6

4 2000 800 60 8

5 2000 1200 60 9

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

MERLIN S3000 COMMON RAIL TEST SYSTEM

3. TRANSFER PRESSURE

3. PUMP PERFORMANCE

Fit Bosch type PCV to rail (ie 0281002872) and connect lead T031-3001.

Set S3000 Test Unit to PCV

4. SCV TEST

Connect pump lead T031-3001 to fuel pump SCV

Leave Bosch type PCV in rail (ie 0281002872)

Set S3000 test unit to SCV.

5. TEMP SENDER / SCV RESISTANCE CHECKS

Test

Bench Speed - RPM Rail Pressure - BAR Comments T.Pressure

BAR

1 400 230 4.5-5.5

2 1000 1600 5.8-6.2

3 2000 1600 6.5-7.0

Test

Bench Speed - RPM SCV DRV % Comments Delivery

CC/1000

1 1000

80

800-900

2 1000

60 0

3 1000

80

800-900

Test

Bench Speed - RPM Temp Sender

Resistance K

SCV Resistance

INLET FUEL

TEMP C

1

-

2.5-4.0 5.0-6.0 20

Test

Bench Speed - RPM Rail Pressure

BAR

Comments Delivery

CC/1000

1 2500 1600

2 2000 1600 620-700

3 1000 1200 680-760

4 1000 500 780 10%

5 1000 1000 Max 10% less 700

6 50 230 760+

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

MERLIN S3000 COMMON RAIL TEST SYSTEM

2

-

0.9-1.5 5.5-6.5 40

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

Pump Designation:-9044Z016A/B

Type Designation:-0.9CC2

Manufacturer I.D.:- FORD LYNX

Engine:- 1.8TDCI FOCUS 115HP

CONNECT 90HP

Testing Prerequisites

Inlet Feed Pressure - 0.2 BAR

Test Oil Specification- ISO4113

Test Oil Temperature- 40 deg C

Direction of Rotation - Clockwise

Remove injector pipes from test rail and blank off with T031-3005

Fit Transfer pressure adaptor T016-697 in place of Temperature sender and

re-connect temperature sender to T.P.adaptor. Connect test bench pressure gauge.

Fit Bosch type Pressure control valve to test rail (ie 0 281 200 872).

Connect Fuel Pump Cable T031-3001 to PCV in test rail.

Set S3000 Test Unit to PCV

1. LEAK TEST

2. RUNNING IN TEST

To be Carried out whenever rollers and shoes have been disturbed or replaced

Test

Bench Speed - RPM Rail Pressure - BAR Conditions Comments

1 350 250 15 Secs No Unusual noise

2 2000 1000 3 Mins No Leaks and

No abnormal

Temperature rise.

Test

Bench Speed - RPM Rail Pressure - BAR Time - Seconds Max Delta

T

1 400 400 60 5

2 800 400 60 5

3 1200 400 60 6

4 2000 800 60 8

5 2000 1200 60 9

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

MERLIN S3000 COMMON RAIL TEST SYSTEM

3. TRANSFER PRESSURE

3. PUMP PERFORMANCE

Fit Bosch type PCV to rail (ie 0281002872) and connect lead T031-3001.

Set S3000 Test Unit to PCV

4. SCV TEST

Connect pump lead T031-3001 to fuel pump SCV

Leave Bosch type PCV in rail (ie 0281002872)

Set S3000 test unit to SCV.

5. TEMP SENDER / SCV RESISTANCE CHECKS

Test

Bench Speed - RPM Rail Pressure - BAR Comments T.Pressure

BAR

1 400 230 4.5-5.5

2 1000 1600 5.8-6.2

3 2000 1600 6.5-7.0

Test

Bench Speed - RPM SCV DRV % Comments Delivery

CC/1000

1 1000

80

800-900

2 1000

60 0

3 1000

80

800-900

Test

Bench Speed - RPM Temp Sender

Resistance K

SCV Resistance

INLET FUEL

TEMP C

1

-

2.5-4.0 5.0-6.0 20

Test

Bench Speed - RPM Rail Pressure

BAR

Comments Delivery

CC/1000

1 2500 1600

2 2000 1600 620-700

3 1000 1200 680-760

4 1000 500 780 10%

5 1000 1000 Max 10% less 700

6 50 230 760+

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

MERLIN S3000 COMMON RAIL TEST SYSTEM

2

-

0.9-1.5 5.5-6.5 40

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

Pump Designation:-9044Z020A

Type Designation:-0.9CC2

Manufacturer I.D.:- KIA/HYUNDAI

Engine:- 2.9L TCI 149HP

Testing Prerequisites

Inlet Feed Pressure - 0.2 BAR

Test Oil Specification- ISO4113

Test Oil Temperature- 40 deg C

Direction of Rotation - Clockwise

Remove injector pipes from test rail and blank off with T031-3005

Fit Transfer pressure adaptor T016-697 in place of Temperature sender and

re-connect temperature sender to T.P.adaptor. Connect test bench pressure gauge.

Fit Bosch type Pressure control valve to test rail (ie 0 281 200 872).

Connect Fuel Pump Cable T031-3001 to PCV in test rail.

Set S3000 Test Unit to PCV

1. LEAK TEST

2. RUNNING IN TEST

To be Carried out whenever rollers and shoes have been disturbed or replaced

Test

Bench Speed - RPM Rail Pressure - BAR Conditions Comments

1 350 250 15 Secs No Unusual noise

2 2000 1000 3 Mins No Leaks and

No abnormal

Temperature rise.

Test

Bench Speed - RPM Rail Pressure - BAR Time - Seconds Max Delta

T

1 400 400 60 5

2 800 400 60 5

3 1200 400 60 6

4 2000 800 60 8

5 2000 1200 60 9

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

MERLIN S3000 COMMON RAIL TEST SYSTEM

3. TRANSFER PRESSURE

3. PUMP PERFORMANCE

Fit Bosch type PCV to rail (ie 0281002872) and connect lead T031-3001.

Set S3000 Test Unit to PCV

4. SCV TEST

Connect pump lead T031-3001 to fuel pump SCV

Leave Bosch type PCV in rail (ie 0281002872)

Set S3000 test unit to SCV.

5. TEMP SENDER / SCV RESISTANCE CHECKS

Test

Bench Speed - RPM Rail Pressure - BAR Comments T.Pressure

BAR

1 400 230 4.5-5.5

2 1000 1600 5.8-6.2

3 2000 1600 6.5-7.0

Test

Bench Speed - RPM SCV DRV % Comments Delivery

CC/1000

1 1000

80

800-900

2 1000

60 0

3 1000

80

800-900

Test

Bench Speed - RPM Temp Sender

Resistance K

SCV Resistance

INLET FUEL

TEMP C

1

-

2.5-4.0 5.0-6.0 20

Test

Bench Speed - RPM Rail Pressure

BAR

Comments Delivery

CC/1000

1 2500 1600

2 2000 1600 620-700

3 1000 1200 680-760

4 1000 500 780 10%

5 1000 1000 Max 10% less 700

6 50 230 760+

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

MERLIN S3000 COMMON RAIL TEST SYSTEM

2

-

0.9-1.5 5.5-6.5 40

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

Pump Designation:-9044Z022A

Type Designation:-0.9CC2

Manufacturer I.D.:- KIA/HYUNDAI

Engine:- 2.9L TCI 149HP

Testing Prerequisites

Inlet Feed Pressure - 0.2 BAR

Test Oil Specification- ISO4113

Test Oil Temperature- 40 deg C

Direction of Rotation - Clockwise

Remove injector pipes from test rail and blank off with T031-3005

Fit Transfer pressure adaptor T016-697 in place of Temperature sender and

re-connect temperature sender to T.P.adaptor. Connect test bench pressure gauge.

Fit Bosch type Pressure control valve to test rail (ie 0 281 200 872).

Connect Fuel Pump Cable T031-3001 to PCV in test rail.

Set S3000 Test Unit to PCV

1. LEAK TEST

2. RUNNING IN TEST

To be Carried out whenever rollers and shoes have been disturbed or replaced

Test

Bench Speed - RPM Rail Pressure - BAR Conditions Comments

1 350 250 15 Secs No Unusual noise

2 2000 1000 3 Mins No Leaks and

No abnormal

Temperature rise.

Test

Bench Speed - RPM Rail Pressure - BAR Time - Seconds Max Delta

T

1 400 400 60 5

2 800 400 60 5

3 1200 400 60 6

4 2000 800 60 8

5 2000 1200 60 9

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

MERLIN S3000 COMMON RAIL TEST SYSTEM

3. TRANSFER PRESSURE

3. PUMP PERFORMANCE

Fit Bosch type PCV to rail (ie 0281002872) and connect lead T031-3001.

Set S3000 Test Unit to PCV

4. SCV TEST

Connect pump lead T031-3001 to fuel pump SCV

Leave Bosch type PCV in rail (ie 0281002872)

Set S3000 test unit to SCV.

5. TEMP SENDER / SCV RESISTANCE CHECKS

Test

Bench Speed - RPM Rail Pressure - BAR Comments T.Pressure

BAR

1 400 230 4.5-5.5

2 1000 1600 5.8-6.2

3 2000 1600 6.5-7.0

Test

Bench Speed - RPM SCV DRV % Comments Delivery

CC/1000

1 1000

80

800-900

2 1000

60 0

3 1000

80

800-900

Test

Bench Speed - RPM Temp Sender

Resistance K

SCV Resistance

INLET FUEL

TEMP C

1

-

2.5-4.0 5.0-6.0 20

Test

Bench Speed - RPM Rail Pressure

BAR

Comments Delivery

CC/1000

1 2500 1600

2 2000 1600 620-700

3 1000 1200 680-760

4 1000 500 780 10%

5 1000 1000 Max 10% less 700

6 50 230 760+

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

MERLIN S3000 COMMON RAIL TEST SYSTEM

2

-

0.9-1.5 5.5-6.5 40

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

Pump Designation:-9044Z032A

Type Designation:-0.9CC2

Manufacturer I.D.:- FORD

Engine:- LYNX 2.0TDCi 16V

Testing Prerequisites

Inlet Feed Pressure - 0.2 BAR

Test Oil Specification- ISO4113

Test Oil Temperature- 40 deg C

Direction of Rotation - Clockwise

Remove injector pipes from test rail and blank off with T031-3005

Fit Transfer pressure adaptor T016-697 in place of Temperature sender and

re-connect temperature sender to T.P.adaptor. Connect test bench pressure gauge.

Fit Bosch type Pressure control valve to test rail (ie 0 281 200 872).

Connect Fuel Pump Cable T031-3001 to PCV in test rail.

Set S3000 Test Unit to PCV

1. LEAK TEST

2. RUNNING IN TEST

To be Carried out whenever rollers and shoes have been disturbed or replaced

Test

Bench Speed - RPM Rail Pressure - BAR Conditions Comments

1 350 250 15 Secs No Unusual noise

2 2000 1000 3 Mins No Leaks and

No abnormal

Temperature rise.

Test

Bench Speed - RPM Rail Pressure - BAR Time - Seconds Max Delta

T

1 400 400 60 5

2 800 400 60 5

3 1200 400 60 6

4 2000 800 60 8

5 2000 1200 60 9

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

MERLIN S3000 COMMON RAIL TEST SYSTEM

3. TRANSFER PRESSURE

3. PUMP PERFORMANCE

Fit Bosch type PCV to rail (ie 0281002872) and connect lead T031-3001.

Set S3000 Test Unit to PCV

4. SCV TEST

Connect pump lead T031-3001 to fuel pump SCV

Leave Bosch type PCV in rail (ie 0281002872)

Set S3000 test unit to SCV.

5. TEMP SENDER / SCV RESISTANCE CHECKS

Test

Bench Speed - RPM Rail Pressure - BAR Comments T.Pressure

BAR

1 400 230 4.5-5.5

2 1000 1600 5.8-6.2

3 2000 1600 6.5-7.0

Test

Bench Speed - RPM SCV DRV % Comments Delivery

CC/1000

1 1000

80

800-900

2 1000

60 0

3 1000

80

800-900

Test

Bench Speed - RPM Temp Sender

Resistance K

SCV Resistance

INLET FUEL

TEMP C

1

-

2.5-4.0 5.0-6.0 20

Test

Bench Speed - RPM Rail Pressure

BAR

Comments Delivery

CC/1000

1 2500 1600

2 2000 1600 620-700

3 1000 1200 680-760

4 1000 500 780 10%

5 1000 1000 Max 10% less 700

6 50 230 760+

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

MERLIN S3000 COMMON RAIL TEST SYSTEM

2

-

0.9-1.5 5.5-6.5 40

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

Pump Designation:-9044Z033A

Type Designation:-0.9CC2

Manufacturer I.D.:- FORD

Engine:- LYNX 2.0TDCi 16V

Testing Prerequisites

Inlet Feed Pressure - 0.2 BAR

Test Oil Specification- ISO4113

Test Oil Temperature- 40 deg C

Direction of Rotation - Clockwise

Remove injector pipes from test rail and blank off with T031-3005

Fit Transfer pressure adaptor T016-697 in place of Temperature sender and

re-connect temperature sender to T.P.adaptor. Connect test bench pressure gauge.

Fit Bosch type Pressure control valve to test rail (ie 0 281 200 872).

Connect Fuel Pump Cable T031-3001 to PCV in test rail.

Set S3000 Test Unit to PCV

1. LEAK TEST

2. RUNNING IN TEST

To be Carried out whenever rollers and shoes have been disturbed or replaced

Test

Bench Speed - RPM Rail Pressure - BAR Conditions Comments

1 350 250 15 Secs No Unusual noise

2 2000 1000 3 Mins No Leaks and

No abnormal

Temperature rise.

Test

Bench Speed - RPM Rail Pressure - BAR Time - Seconds Max Delta

T

1 400 400 60 5

2 800 400 60 5

3 1200 400 60 6

4 2000 800 60 8

5 2000 1200 60 9

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

MERLIN S3000 COMMON RAIL TEST SYSTEM

3. TRANSFER PRESSURE

3. PUMP PERFORMANCE

Fit Bosch type PCV to rail (ie 0281002872) and connect lead T031-3001.

Set S3000 Test Unit to PCV

4. SCV TEST

Connect pump lead T031-3001 to fuel pump SCV

Leave Bosch type PCV in rail (ie 0281002872)

Set S3000 test unit to SCV.

5. TEMP SENDER / SCV RESISTANCE CHECKS

Test

Bench Speed - RPM Rail Pressure - BAR Comments T.Pressure

BAR

1 400 230 4.5-5.5

2 1000 1600 5.8-6.2

3 2000 1600 6.5-7.0

Test

Bench Speed - RPM SCV DRV % Comments Delivery

CC/1000

1 1000

80

800-900

2 1000

60 0

3 1000

80

800-900

Test

Bench Speed - RPM Temp Sender

Resistance K

SCV Resistance

INLET FUEL

TEMP C

1

-

2.5-4.0 5.0-6.0 20

Test

Bench Speed - RPM Rail Pressure

BAR

Comments Delivery

CC/1000

1 2500 1600

2 2000 1600 620-700

3 1000 1200 680-760

4 1000 500 780 10%

5 1000 1000 Max 10% less 700

6 50 230 760+

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

MERLIN S3000 COMMON RAIL TEST SYSTEM

2

-

0.9-1.5 5.5-6.5 40

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

Pump Designation:-9044Z034A

Type Designation:-0.9CC2

Manufacturer I.D.:- FORD

Engine:- PUMA 2.0TDCi 16V

Testing Prerequisites

Inlet Feed Pressure - 0.2 BAR

Test Oil Specification- ISO4113

Test Oil Temperature- 40 deg C

Direction of Rotation - Clockwise

Remove injector pipes from test rail and blank off with T031-3005

Fit Transfer pressure adaptor T016-697 in place of Temperature sender and

re-connect temperature sender to T.P.adaptor. Connect test bench pressure gauge.

Fit Bosch type Pressure control valve to test rail (ie 0 281 200 872).

Connect Fuel Pump Cable T031-3001 to PCV in test rail.

Set S3000 Test Unit to PCV

1. LEAK TEST

2. RUNNING IN TEST

To be Carried out whenever rollers and shoes have been disturbed or replaced

Test

Bench Speed - RPM Rail Pressure - BAR Conditions Comments

1 350 250 15 Secs No Unusual noise

2 2000 1000 3 Mins No Leaks and

No abnormal

Temperature rise.

Test

Bench Speed - RPM Rail Pressure - BAR Time - Seconds Max Delta

T

1 400 400 60 5

2 800 400 60 5

3 1200 400 60 6

4 2000 800 60 8

5 2000 1200 60 9

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

MERLIN S3000 COMMON RAIL TEST SYSTEM

3. TRANSFER PRESSURE

3. PUMP PERFORMANCE

Fit Bosch type PCV to rail (ie 0281002872) and connect lead T031-3001.

Set S3000 Test Unit to PCV

4. SCV TEST

Connect pump lead T031-3001 to fuel pump SCV

Leave Bosch type PCV in rail (ie 0281002872)

Set S3000 test unit to SCV.

5. TEMP SENDER / SCV RESISTANCE CHECKS

Test

Bench Speed - RPM Rail Pressure - BAR Comments T.Pressure

BAR

1 400 230 4.5-5.5

2 1000 1600 5.8-6.2

3 2000 1600 6.5-7.0

Test

Bench Speed - RPM SCV DRV % Comments Delivery

CC/1000

1 1000

80

800-900

2 1000

60 0

3 1000

80

800-900

Test

Bench Speed - RPM Temp Sender

Resistance K

SCV Resistance

INLET FUEL

TEMP C

1

-

2.5-4.0 5.0-6.0 20

Test

Bench Speed - RPM Rail Pressure

BAR

Comments Delivery

CC/1000

1 2500 1600

2 2000 1600 620-700

3 1000 1200 680-760

4 1000 500 780 10%

5 1000 1000 Max 10% less 700

6 50 230 760+

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

MERLIN S3000 COMMON RAIL TEST SYSTEM

2

-

0.9-1.5 5.5-6.5 40

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

Pump Designation:-9044Z035A

Type Designation:-0.9CC2

Manufacturer I.D.:- FORD/JAGUAR

Engine:- LYNX 2.0TDCi 16V

Testing Prerequisites

Inlet Feed Pressure - 0.2 BAR

Test Oil Specification- ISO4113

Test Oil Temperature- 40 deg C

Direction of Rotation - Clockwise

Remove injector pipes from test rail and blank off with T031-3005

Fit Transfer pressure adaptor T016-697 in place of Temperature sender and

re-connect temperature sender to T.P.adaptor. Connect test bench pressure gauge.

Fit Bosch type Pressure control valve to test rail (ie 0 281 200 872).

Connect Fuel Pump Cable T031-3001 to PCV in test rail.

Set S3000 Test Unit to PCV

1. LEAK TEST

2. RUNNING IN TEST

To be Carried out whenever rollers and shoes have been disturbed or replaced

Test

Bench Speed - RPM Rail Pressure - BAR Conditions Comments

1 350 250 15 Secs No Unusual noise

2 2000 1000 3 Mins No Leaks and

No abnormal

Temperature rise.

Test

Bench Speed - RPM Rail Pressure - BAR Time - Seconds Max Delta

T

1 400 400 60 5

2 800 400 60 5

3 1200 400 60 6

4 2000 800 60 8

5 2000 1200 60 9

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

MERLIN S3000 COMMON RAIL TEST SYSTEM

3. TRANSFER PRESSURE

3. PUMP PERFORMANCE

Fit Bosch type PCV to rail (ie 0281002872) and connect lead T031-3001.

Set S3000 Test Unit to PCV

4. SCV TEST

Connect pump lead T031-3001 to fuel pump SCV

Leave Bosch type PCV in rail (ie 0281002872)

Set S3000 test unit to SCV.

5. TEMP SENDER / SCV RESISTANCE CHECKS

Test

Bench Speed - RPM Rail Pressure - BAR Comments T.Pressure

BAR

1 400 230 4.5-5.5

2 1000 1600 5.8-6.2

3 2000 1600 6.5-7.0

Test

Bench Speed - RPM SCV DRV % Comments Delivery

CC/1000

1 1000

80

800-900

2 1000

60 0

3 1000

80

800-900

Test

Bench Speed - RPM Temp Sender

Resistance K

SCV Resistance

INLET FUEL

TEMP C

1

-

2.5-4.0 5.0-6.0 20

Test

Bench Speed - RPM Rail Pressure

BAR

Comments Delivery

CC/1000

1 2500 1600

2 2000 1600 620-700

3 1000 1200 680-760

4 1000 500 780 10%

5 1000 1000 Max 10% less 700

6 50 230 760+

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

MERLIN S3000 COMMON RAIL TEST SYSTEM

2

-

0.9-1.5 5.5-6.5 40

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

Pump Designation:-9044Z080A

Type Designation:-0.9CC2

Manufacturer I.D.:- FORD

Engine:- PUMA 2.4TDCI

Testing Prerequisites

Inlet Feed Pressure - 0.2 BAR

Test Oil Specification- ISO4113

Test Oil Temperature- 40 deg C

Direction of Rotation - Clockwise

Remove injector pipes from test rail and blank off with T031-3005

Fit Transfer pressure adaptor T016-697 in place of Temperature sender and

re-connect temperature sender to T.P.adaptor. Connect test bench pressure gauge.

Fit Bosch type Pressure control valve to test rail (ie 0 281 200 872).

Connect Fuel Pump Cable T031-3001 to PCV in test rail.

Set S3000 Test Unit to PCV

1. LEAK TEST

2. RUNNING IN TEST

To be Carried out whenever rollers and shoes have been disturbed or replaced

Test

Bench Speed - RPM Rail Pressure - BAR Conditions Comments

1 350 250 15 Secs No Unusual noise

2 2000 1000 3 Mins No Leaks and

No abnormal

Temperature rise.

Test

Bench Speed - RPM Rail Pressure - BAR Time - Seconds Max Delta

T

1 400 400 60 5

2 800 400 60 5

3 1200 400 60 6

4 2000 800 60 8

5 2000 1200 60 9

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

MERLIN S3000 COMMON RAIL TEST SYSTEM

3. TRANSFER PRESSURE

3. PUMP PERFORMANCE

Fit Bosch type PCV to rail (ie 0281002872) and connect lead T031-3001.

Set S3000 Test Unit to PCV

4. SCV TEST

Connect pump lead T031-3001 to fuel pump SCV

Leave Bosch type PCV in rail (ie 0281002872)

Set S3000 test unit to SCV.

5. TEMP SENDER / SCV RESISTANCE CHECKS

Test

Bench Speed - RPM Rail Pressure - BAR Comments T.Pressure

BAR

1 400 230 4.5-5.5

2 1000 1600 5.8-6.2

3 2000 1600 6.5-7.0

Test

Bench Speed - RPM SCV DRV % Comments Delivery

CC/1000

1 1000

80

800-900

2 1000

60 0

3 1000

80

800-900

Test

Bench Speed - RPM Temp Sender

Resistance K

SCV Resistance

INLET FUEL

TEMP C

1

-

2.5-4.0 5.0-6.0 20

Test

Bench Speed - RPM Rail Pressure

BAR

Comments Delivery

CC/1000

1 2500 1600

2 2000 1600 620-700

3 1000 1200 680-760

4 1000 500 780 10%

5 1000 1000 Max 10% less 700

6 50 230 760+

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

MERLIN S3000 COMMON RAIL TEST SYSTEM

2

-

0.9-1.5 5.5-6.5 40

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

Pump Designation:-9044Z090A

Type Designation:-0.9CC2

Manufacturer I.D.:- FORD

Engine:- PUMA 2.0TDCi 16V EURO3

2.2TDCi 150HP EURO4

Testing Prerequisites

Inlet Feed Pressure - 0.2 BAR

Test Oil Specification- ISO4113

Test Oil Temperature- 40 deg C

Direction of Rotation - Clockwise

Remove injector pipes from test rail and blank off with T031-3005

Fit Transfer pressure adaptor T016-697 in place of Temperature sender and

re-connect temperature sender to T.P.adaptor. Connect test bench pressure gauge.

Fit Bosch type Pressure control valve to test rail (ie 0 281 200 872).

Connect Fuel Pump Cable T031-3001 to PCV in test rail.

Set S3000 Test Unit to PCV

1. LEAK TEST

2. RUNNING IN TEST

To be Carried out whenever rollers and shoes have been disturbed or replaced

Test

Bench Speed - RPM Rail Pressure - BAR Conditions Comments

1 350 250 15 Secs No Unusual noise

2 2000 1000 3 Mins No Leaks and

No abnormal

Temperature rise.

Test

Bench Speed - RPM Rail Pressure - BAR Time - Seconds Max Delta

T

1 400 400 60 5

2 800 400 60 5

3 1200 400 60 6

4 2000 800 60 8

5 2000 1200 60 9

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

MERLIN S3000 COMMON RAIL TEST SYSTEM

3. TRANSFER PRESSURE

3. PUMP PERFORMANCE

Fit Bosch type PCV to rail (ie 0281002872) and connect lead T031-3001.

Set S3000 Test Unit to PCV

4. SCV TEST

Connect pump lead T031-3001 to fuel pump SCV

Leave Bosch type PCV in rail (ie 0281002872)

Set S3000 test unit to SCV.

5. TEMP SENDER / SCV RESISTANCE CHECKS

Test

Bench Speed - RPM Rail Pressure - BAR Comments T.Pressure

BAR

1 400 230 4.5-5.5

2 1000 1600 5.8-6.2

3 2000 1600 6.5-7.0

Test

Bench Speed - RPM SCV DRV % Comments Delivery

CC/1000

1 1000

80

800-900

2 1000

60 0

3 1000

80

800-900

Test

Bench Speed - RPM Temp Sender

Resistance K

SCV Resistance

INLET FUEL

TEMP C

1

-

2.5-4.0 5.0-6.0 20

Test

Bench Speed - RPM Rail Pressure

BAR

Comments Delivery

CC/1000

1 2500 1600

2 2000 1600 620-700

3 1000 1200 680-760

4 1000 500 780 10%

5 1000 1000 Max 10% less 700

6 50 230 760+

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

MERLIN S3000 COMMON RAIL TEST SYSTEM

2

-

0.9-1.5 5.5-6.5 40

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

Pump Designation:-9044Z100A

Type Designation:-0.9CC2

Manufacturer I.D.:- Ford

Engine:- Mondeo 2.0 TDCi 150HP Euro4

Testing Prerequisites

Inlet Feed Pressure - 0.2 BAR

Test Oil Specification- ISO4113

Test Oil Temperature- 40 deg C

Direction of Rotation - Clockwise

Remove injector pipes from test rail and blank off with T031-3005

Fit Transfer pressure adaptor T016-697 in place of Temperature sender and

re-connect temperature sender to T.P.adaptor. Connect test bench pressure gauge.

Fit Bosch type Pressure control valve to test rail (ie 0 281 200 872).

Connect Fuel Pump Cable T031-3001 to PCV in test rail.

Set S3000 Test Unit to PCV

1. LEAK TEST

2. RUNNING IN TEST

To be Carried out whenever rollers and shoes have been disturbed or replaced

Test

Bench Speed - RPM Rail Pressure - BAR Conditions Comments

1 350 250 15 Secs No Unusual noise

2 2000 1000 3 Mins No Leaks and

No abnormal

Temperature rise.

Test

Bench Speed - RPM Rail Pressure - BAR Time - Seconds Max Delta

T

1 400 400 60 5

2 800 400 60 5

3 1200 400 60 6

4 2000 800 60 8

5 2000 1200 60 9

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

MERLIN S3000 COMMON RAIL TEST SYSTEM

3. TRANSFER PRESSURE

3. PUMP PERFORMANCE

Fit Bosch type PCV to rail (ie 0281002872) and connect lead T031-3001.

Set S3000 Test Unit to PCV

4. SCV TEST

Connect pump lead T031-3001 to fuel pump SCV

Leave Bosch type PCV in rail (ie 0281002872)

Set S3000 test unit to SCV.

5. TEMP SENDER / SCV RESISTANCE CHECKS

Test

Bench Speed - RPM Rail Pressure - BAR Comments T.Pressure

BAR

1 400 230 4.5-5.5

2 1000 1600 5.8-6.2

3 2000 1600 6.5-7.0

Test

Bench Speed - RPM SCV DRV % Comments Delivery

CC/1000

1 1000

80

800-900

2 1000

60 0

3 1000

80

800-900

Test

Bench Speed - RPM Temp Sender

Resistance K

SCV Resistance

INLET FUEL

TEMP C

1

-

2.5-4.0 5.0-6.0 20

Test

Bench Speed - RPM Rail Pressure

BAR

Comments Delivery

CC/1000

1 2500 1600

2 2000 1600 620-700

3 1000 1200 680-760

4 1000 500 780 10%

5 1000 1000 Max 10% less 700

6 50 230 760+

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

MERLIN S3000 COMMON RAIL TEST SYSTEM

2

-

0.9-1.5 5.5-6.5 40

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

Pump Designation:-9044Z130A

Type Designation:-0.9CC2

Manufacturer I.D.:- FORD/JAGUAR

Engine:- PUMA 2.0TDCI EURO 4

130/155HP

Testing Prerequisites

Inlet Feed Pressure - 0.2 BAR

Test Oil Specification- ISO4113

Test Oil Temperature- 40 deg C

Direction of Rotation - Clockwise

Remove injector pipes from test rail and blank off with T031-3005

Fit Transfer pressure adaptor T016-697 in place of Temperature sender and

re-connect temperature sender to T.P.adaptor. Connect test bench pressure gauge.

Fit Bosch type Pressure control valve to test rail (ie 0 281 200 872).

Connect Fuel Pump Cable T031-3001 to PCV in test rail.

Set S3000 Test Unit to PCV

1. LEAK TEST

2. RUNNING IN TEST

To be Carried out whenever rollers and shoes have been disturbed or replaced

Test

Bench Speed - RPM Rail Pressure - BAR Conditions Comments

1 350 250 15 Secs No Unusual noise

2 2000 1000 3 Mins No Leaks and

No abnormal

Temperature rise.

Test

Bench Speed - RPM Rail Pressure - BAR Time - Seconds Max Delta

T

1 400 400 60 5

2 800 400 60 5

3 1200 400 60 6

4 2000 800 60 8

5 2000 1200 60 9

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

MERLIN S3000 COMMON RAIL TEST SYSTEM

3. TRANSFER PRESSURE

3. PUMP PERFORMANCE

Fit Bosch type PCV to rail (ie 0281002872) and connect lead T031-3001.

Set S3000 Test Unit to PCV

4. SCV TEST

Connect pump lead T031-3001 to fuel pump SCV

Leave Bosch type PCV in rail (ie 0281002872)

Set S3000 test unit to SCV.

5. TEMP SENDER / SCV RESISTANCE CHECKS

Test

Bench Speed - RPM Rail Pressure - BAR Comments T.Pressure

BAR

1 400 230 4.5-5.5

2 1000 1600 5.8-6.2

3 2000 1600 6.5-7.0

Test

Bench Speed - RPM SCV DRV % Comments Delivery

CC/1000

1 1000

80

800-900

2 1000

60 0

3 1000

80

800-900

Test

Bench Speed - RPM Temp Sender

Resistance K

SCV Resistance

INLET FUEL

TEMP C

1

-

2.5-4.0 5.0-6.0 20

Test

Bench Speed - RPM Rail Pressure

BAR

Comments Delivery

CC/1000

1 2500 1600

2 2000 1600 620-700

3 1000 1200 680-760

4 1000 500 780 10%

5 1000 1000 Max 10% less 700

6 50 230 760+

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

MERLIN S3000 COMMON RAIL TEST SYSTEM

2

-

0.9-1.5 5.5-6.5 40

M

E

R

L

I

N

D

I

E

S

E

L

S

Y

S

T

E

M

S

L

T

D

You might also like

- EPA10 Maxxforce 11, 13 Engine Service ManualDocument591 pagesEPA10 Maxxforce 11, 13 Engine Service ManualRod Ramos92% (39)

- Hyundai Common Rail DelphiDocument68 pagesHyundai Common Rail DelphiJATC50% (2)

- Valve Body and Mechatronic Service PDFDocument44 pagesValve Body and Mechatronic Service PDFSamuel Zuniga100% (1)

- Pratt & Whitney Wasp Manual PDFDocument353 pagesPratt & Whitney Wasp Manual PDFsjd40100% (22)

- Adjust 2-spring Nozzles and Nozzle HoldersDocument41 pagesAdjust 2-spring Nozzles and Nozzle HoldersCostas Ponehundred75% (4)

- Al Injector Common RailDocument2 pagesAl Injector Common Railنعمان بن سلطان100% (4)

- Boschinjectortestplans 29 WEBDocument156 pagesBoschinjectortestplans 29 WEBedward06No ratings yet

- Audels Engineers and Mechanics Guide Volume 2 From WWW Jgokey ComDocument520 pagesAudels Engineers and Mechanics Guide Volume 2 From WWW Jgokey Comjdsa123100% (1)

- CRI Diesel Injector PartsDocument37 pagesCRI Diesel Injector PartsFaraz Haider80% (5)

- Chrysler 42RE transmission testing guideDocument2 pagesChrysler 42RE transmission testing guideUrszula Walczewska100% (1)

- Common Rail SparesDocument20 pagesCommon Rail SparesMilan Blagojevic100% (4)

- Spare Parts Denso Common Rail InjectorsDocument10 pagesSpare Parts Denso Common Rail Injectorserdemsecen100% (5)

- Ricambi DensoDocument10 pagesRicambi DensoSprinter Transit Van100% (1)

- S3000 Common Rail Test System DataDocument28 pagesS3000 Common Rail Test System Dataصلاح طه السيد0% (1)

- InyectorDocument20 pagesInyectorDaen50% (2)

- Piezo ElectricmeteringDocument7 pagesPiezo Electricmeteringeko sulistyo utomo100% (1)

- EPS 205 Frequently Asked Questions 2 8.28 PDFDocument32 pagesEPS 205 Frequently Asked Questions 2 8.28 PDFDarshan Diesel100% (2)

- DSG Pinout - Passat PDFDocument5 pagesDSG Pinout - Passat PDFAspro Brazil Se Iglesias100% (2)

- Denso Type CR Injector ShimsDocument11 pagesDenso Type CR Injector ShimsCostinDodenech100% (2)

- Bosch Pump Test Plans 4 Web 3232Document146 pagesBosch Pump Test Plans 4 Web 3232Eduardo Alvarez HuizaNo ratings yet

- 222 enDocument48 pages222 enAspro Brazil Se Iglesias75% (8)

- Bk2q-9k546-Ag 20190701 112041 PDFDocument2 pagesBk2q-9k546-Ag 20190701 112041 PDFคุณชายธวัชชัย เจริญสุขNo ratings yet

- JT15D Ata 73Document22 pagesJT15D Ata 73Egor85100% (1)

- 2.0L FsiDocument46 pages2.0L Fsismellybum67% (3)

- DENSO X2 InstructionDocument13 pagesDENSO X2 InstructionAnonymous 5tkF5bFwO100% (3)

- 8V92 Engine Exploded ViewDocument975 pages8V92 Engine Exploded ViewAndi AsruddinNo ratings yet

- Denso CR Injector & Pump Repair Kits 2016Document24 pagesDenso CR Injector & Pump Repair Kits 2016Euro Diesel100% (7)

- Kawasaki KZ 250 - 305 '79 A '82 - Service ManualDocument313 pagesKawasaki KZ 250 - 305 '79 A '82 - Service Manualmartin_trumpeto295% (21)

- S5000-1-Test-Data Ui Up Bosch, DelphiDocument29 pagesS5000-1-Test-Data Ui Up Bosch, DelphiEdinson Ariel Chavarro Quintero100% (1)

- Common Railmod3Document261 pagesCommon Railmod3Edinson Ariel Chavarro Quintero100% (1)

- Merlin Diesel Systems Ltd injector calibration and testing documentationDocument126 pagesMerlin Diesel Systems Ltd injector calibration and testing documentationLucas Man100% (2)

- S3000 Common Rail Test System DataDocument28 pagesS3000 Common Rail Test System DataFernando SanchezNo ratings yet

- Siemens Injector Test Data New6 PDFDocument20 pagesSiemens Injector Test Data New6 PDFJose HasinNo ratings yet

- Bosch CR Pumps Test Data PDFDocument146 pagesBosch CR Pumps Test Data PDFInyectronix Vyh100% (2)

- ASNU Catalog 10 09Document77 pagesASNU Catalog 10 09Aspro Brazil Se IglesiasNo ratings yet

- Manuale Injectors Delphi 15-23-2 Ediz IngDocument7 pagesManuale Injectors Delphi 15-23-2 Ediz IngKary Shito100% (2)

- Modifikacii HP 3Document5 pagesModifikacii HP 3pankituna5487No ratings yet

- Siemens Injector Test Data New6Document20 pagesSiemens Injector Test Data New6cartronix2010100% (2)

- Common RailDocument1 pageCommon RailcolyalbaitzNo ratings yet

- 2002 Nissan Altima 2.5 Timing Chain MarksDocument16 pages2002 Nissan Altima 2.5 Timing Chain MarksInternal88100% (1)

- Delphiinjectortestplans 12WEBDocument30 pagesDelphiinjectortestplans 12WEBkampee100% (1)

- 722 6 VacTestLocationsDocument4 pages722 6 VacTestLocationsUrszula WalczewskaNo ratings yet

- Delphi Injector Test PlansDocument21 pagesDelphi Injector Test PlansZauron Kent Touchit67% (6)

- EDocument34 pagesEEdinson Ariel Chavarro Quintero100% (1)

- 001-05a Merlin Equipment and Accessories Catalogue 0810 - WEB 0311Document173 pages001-05a Merlin Equipment and Accessories Catalogue 0810 - WEB 0311Aspro Brazil Se IglesiasNo ratings yet

- Marks On Bosch Common Rail InjectorsDocument25 pagesMarks On Bosch Common Rail InjectorsBarkat HussainNo ratings yet

- Denso Bosch Common RailDocument29 pagesDenso Bosch Common RailCiprian Albert100% (27)

- Bearing NotesDocument132 pagesBearing NotesSarvagnaMNNo ratings yet

- Siemens Injector Test Data New6 PDFDocument20 pagesSiemens Injector Test Data New6 PDFJuan David Cepeda GonzalesNo ratings yet

- Denso FIRAD Catalogue PDFDocument20 pagesDenso FIRAD Catalogue PDFdchosgo2639No ratings yet

- CR Injectors Clamping Deviсe Service ManualDocument12 pagesCR Injectors Clamping Deviсe Service Manualachaccha100% (3)

- DELPHI Nozzles CatalogDocument16 pagesDELPHI Nozzles Cataloganshel100% (1)

- VDO Diesel IAM Roadmap Q3 2018 ENDocument13 pagesVDO Diesel IAM Roadmap Q3 2018 ENLuis Miranda100% (2)

- Common Rail Spare Parts ListDocument52 pagesCommon Rail Spare Parts Listcartronix2010100% (3)

- Denso Control Valve & Rod 2016Document4 pagesDenso Control Valve & Rod 2016Екатерина КалашниковаNo ratings yet

- Spec Instrument Dlja Rjadnyh TNVDDocument69 pagesSpec Instrument Dlja Rjadnyh TNVDSubhojit SamontaNo ratings yet

- History and Working of Unit Injector SystemDocument26 pagesHistory and Working of Unit Injector SystemKumar ByesNo ratings yet

- Inyectores Delphi Tabla ValoresDocument30 pagesInyectores Delphi Tabla Valoresbruttus139No ratings yet

- CR Injector Repair Kits 2016Document32 pagesCR Injector Repair Kits 2016Euro Diesel100% (2)

- S3000 Common Rail Test DataDocument20 pagesS3000 Common Rail Test Dataaddelyn_robescu8794100% (7)

- A5 Common RailDocument24 pagesA5 Common RailanshelNo ratings yet

- 2017 Common Rail Parts Catalog-ERIKC DieselDocument60 pages2017 Common Rail Parts Catalog-ERIKC DieselЕкатерина КалашниковаNo ratings yet

- Illidio SerraDocument24 pagesIllidio SerraVictor GarciaNo ratings yet

- Siemens Pump Test Plans 4Document10 pagesSiemens Pump Test Plans 4DJAMel LNo ratings yet

- S3000 Common Rail Test System DataDocument28 pagesS3000 Common Rail Test System DataInkanata Sac94% (16)

- Common Rail Nozzle TypeDocument4 pagesCommon Rail Nozzle TypeJean LucasNo ratings yet

- Injector Numbers and Spec-1Document1 pageInjector Numbers and Spec-1Michael RauschNo ratings yet

- Engine Formulas: Cylinder Swept Volume (VDocument7 pagesEngine Formulas: Cylinder Swept Volume (VDhanraj PatilNo ratings yet

- 9520A192G - PlanDocument3 pages9520A192G - PlanMihai-Eugen Popa100% (1)

- ERIKC Update CRDi Catalog-Diesel Injector Spare PartsDocument63 pagesERIKC Update CRDi Catalog-Diesel Injector Spare PartsЕкатерина КалашниковаNo ratings yet

- Workshop 2011 - 03121936Document551 pagesWorkshop 2011 - 03121936FR100% (2)

- 2009-03 CR Injector SparesDocument10 pages2009-03 CR Injector SparesAspro Brazil Se IglesiasNo ratings yet

- Tescom RegulatorDocument4 pagesTescom RegulatormiaberyNo ratings yet

- Grundfos Selectric BrochureDocument2 pagesGrundfos Selectric Brochuremihaitoader69No ratings yet

- NIMCO CV300newDocument24 pagesNIMCO CV300newBruno SamaeianNo ratings yet

- TLV - Electro-Pneumatic Control Valve For Steam PDFDocument2 pagesTLV - Electro-Pneumatic Control Valve For Steam PDFsirballesterosNo ratings yet

- Optimex Prei RangeDocument12 pagesOptimex Prei RangeThomas DamonNo ratings yet

- HDI Direct Injection System ComponentsDocument21 pagesHDI Direct Injection System ComponentsJuhasz EndreNo ratings yet

- Rotary Table Tooling Plate P/N 3725 for Sherline 4Document1 pageRotary Table Tooling Plate P/N 3725 for Sherline 4Aspro Brazil Se IglesiasNo ratings yet

- Nozzles Catalogue 2014-04 + UpdatesDocument102 pagesNozzles Catalogue 2014-04 + UpdatesAspro Brazil Se IglesiasNo ratings yet

- 80 1044 PDFDocument26 pages80 1044 PDFAspro Brazil Se Iglesias100% (1)

- Common Rail ToolsDocument7 pagesCommon Rail ToolsAspro Brazil Se IglesiasNo ratings yet

- Common Rail ToolsDocument7 pagesCommon Rail ToolsAspro Brazil Se IglesiasNo ratings yet

- Nozzles Catalogue 2014-04 + UpdatesDocument102 pagesNozzles Catalogue 2014-04 + UpdatesAspro Brazil Se IglesiasNo ratings yet

- Common Rail ToolsDocument7 pagesCommon Rail ToolsAspro Brazil Se IglesiasNo ratings yet

- Nozzles Catalogue 2014-04 + UpdatesDocument102 pagesNozzles Catalogue 2014-04 + UpdatesAspro Brazil Se IglesiasNo ratings yet

- Common Rail ToolsDocument7 pagesCommon Rail ToolsAspro Brazil Se IglesiasNo ratings yet

- Untitled - Ford Injector Programming Tdci AdDocument7 pagesUntitled - Ford Injector Programming Tdci AdAspro Brazil Se IglesiasNo ratings yet

- Neo Crin All InfoDocument11 pagesNeo Crin All InfoAspro Brazil Se Iglesias100% (1)

- Untitled - Ford Injector Programming Tdci AdDocument7 pagesUntitled - Ford Injector Programming Tdci AdAspro Brazil Se IglesiasNo ratings yet

- Common Rail ToolsDocument7 pagesCommon Rail ToolsAspro Brazil Se IglesiasNo ratings yet

- Bel Ray GEO Ashless PDSDocument1 pageBel Ray GEO Ashless PDSDaniel ColinsNo ratings yet

- S15 SR20DET: Pin # Color Pin # Color Description DescriptionDocument2 pagesS15 SR20DET: Pin # Color Pin # Color Description DescriptionazisNo ratings yet

- Timing Chain: Service and Repair InstallationDocument3 pagesTiming Chain: Service and Repair InstallationDiego496No ratings yet

- Thermal Engineering Lab Manual FinalDocument72 pagesThermal Engineering Lab Manual Finalrajeshkumar061087_58No ratings yet

- Cat Acert Technology Engines: Rod Topel Industrial Engine MarketingDocument117 pagesCat Acert Technology Engines: Rod Topel Industrial Engine Marketingcarlos sernaNo ratings yet

- 310K 310SK 410K 310SKTMC 410KTMC T304355Document2 pages310K 310SK 410K 310SKTMC 410KTMC T304355Denis HernandezNo ratings yet

- Hybrid Electric Vehicles: Author: E-Mail: Course: Class/Year: Main Functional Requirement: Design ParameterDocument7 pagesHybrid Electric Vehicles: Author: E-Mail: Course: Class/Year: Main Functional Requirement: Design ParameterDhanraj PatilNo ratings yet

- Pembangkit Listrik Tenaga Panas Laut (Otec) Diusulkan OlehDocument9 pagesPembangkit Listrik Tenaga Panas Laut (Otec) Diusulkan OlehFebrianto WibowoNo ratings yet

- CRANKSHAFTDocument24 pagesCRANKSHAFTShubham GoelNo ratings yet

- Acetylene Powered Engine Report GTUDocument31 pagesAcetylene Powered Engine Report GTUAshish VadhavaniNo ratings yet

- 4.10T Parts Catalog (Ok)Document79 pages4.10T Parts Catalog (Ok)Noor Sa'adahNo ratings yet

- Injector Dynamics Horsepower CalculatorDocument9 pagesInjector Dynamics Horsepower CalculatorwillyhuaNo ratings yet

- Camshaft and Valve Clearance Revisions for 1995 MY Jaguar XJ12Document2 pagesCamshaft and Valve Clearance Revisions for 1995 MY Jaguar XJ12Mariano Cal GarciaNo ratings yet

- ME 2213 (Inertia Forces in Reciprocating Parts) (1) (2 Files Merged)Document53 pagesME 2213 (Inertia Forces in Reciprocating Parts) (1) (2 Files Merged)tanvir2013004No ratings yet

- Solved Papers: Agricultural Engineering (Ag)Document58 pagesSolved Papers: Agricultural Engineering (Ag)Vamsi KrishnaNo ratings yet

- Dokumen - Tips Perkins 1300 Series WH Diesel Engine Service Repair Manual 1624273452Document17 pagesDokumen - Tips Perkins 1300 Series WH Diesel Engine Service Repair Manual 1624273452amskroud brahimNo ratings yet

- 8M33-2D DrawingDocument6 pages8M33-2D DrawingDany_WallyNo ratings yet

- Exam - Motor KnowledgeDocument147 pagesExam - Motor KnowledgeAbraham Straughter100% (2)

- Desalination Through Diesel Engine Exhaust Waste HeatDocument5 pagesDesalination Through Diesel Engine Exhaust Waste HeatIJORATNo ratings yet

- PTE 2014 Product CatalogDocument44 pagesPTE 2014 Product CatalogPatricio ValenzuelaNo ratings yet