Professional Documents

Culture Documents

Effect of Mechanical Milling On Corrosion Resistance

Uploaded by

Suta VijayaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Effect of Mechanical Milling On Corrosion Resistance

Uploaded by

Suta VijayaCopyright:

Available Formats

Effect of Mechanical Milling on Corrosion Resistance and Biocompatibility of Titanium-Hydroxyapatite Composites

Anawati1, Hiroaki Tanigawa1, Hidetaka Asoh1, Takuya Ohno2, Masahiro Kubota2, and Sachiko Ono1 Department Applied Chemistry, Kogakuin University, 2665-1 Nakano, Hachioji, Tokyo 192-0015, Japan 2 Department of Mechanical Engineering, Nihon University, 1-2-1 Izumi-cho, Narashino-shi, Chiba 2758575, Japan bq40967@ns.kogakuin.ac.jp High strength Ti has drawn considerable attention for biomedical implants application especially for orthopedic implants which exposed to high mechanical stress. It has been known that Ti exhibits excellent corrosion properties and biocompatibility, attributed to the naturally formed oxide film covering the metal surface, in a living organism. Despite this biocompatible characteristic, Ti does not promote the formation of bone mineral hydroxyapatite (HAp) layer. To improve the biocompatibility of the material, in this study, high strength Ti was alloyed with HAp prepared by mechanical milling (MM) technique followed by spark plasma sintering (SPS) [1]. Concentration of HAp in the alloys was varied from 10%, 20% up to 30%. Effect of mechanical milling time was investigated on 4 h and 8 h milled samples for each HAp concentration. The effect of HAp in the alloys which may alter the corrosion properties of pure Ti in chloride environment was investigated by electrochemical technique. The study was based on potentiodynamic and potentiostatic polarization measurements in neutral solution of 9 g/l NaCl at 36.5C. Potentiodynamic polarization data showed that mechanically milled (MMed) pure Ti demonstrated passive behaviour. Addition of 10% HAp in the alloys did not affect the polarization curve of Ti, independent of mechanical milling time. Increasing HAp concentration to 20 % and 30 % in the alloy reduced the corrosion resistance of Ti as shown by decrease in corrosion potential and significant increase in current density output relative to pure Ti. In addition, the 8 h MMed alloys showed active-passive transitions peaks at -0.6 VAg/AgCl and +0.2 VAg/AgCl which probably indicated dissolution of Ti oxide/hydroxide layer followed each time by repassivation. Potentiostatic test at +0.5 VAg/AgCl for all of the alloys showed similar trend of steady state current density after 2 minutes exposure in 9 g/l NaCl solution. The stable current density indicated surface passivation which confirmed the potentiodynamic data. [1] T. Ohno and M. Kubota, Journal of Japan Institute of Light Metals 60 (2010) 647.

1

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Balanced Score Card and StrategyDocument20 pagesBalanced Score Card and Strategyprasad_cooldude100% (1)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- New Techniques for Using Old Geophysical Logs in Reservoir CharacterizationDocument25 pagesNew Techniques for Using Old Geophysical Logs in Reservoir CharacterizationSuta VijayaNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- KPI - by Duncan WilliamsonDocument6 pagesKPI - by Duncan WilliamsonSuta VijayaNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Environmental, Social and Governance KPIDocument14 pagesEnvironmental, Social and Governance KPISuta Vijaya100% (1)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- New Approach To Calculate The Mud Invasion in Reservoirs Using Well Logs - Mariléa RibeiroDocument5 pagesNew Approach To Calculate The Mud Invasion in Reservoirs Using Well Logs - Mariléa RibeiroSuta VijayaNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Creating A Process Based ManageDocument7 pagesCreating A Process Based ManageSutthisak InthawadeeNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- KPI Report For The Minister For ConstructionDocument34 pagesKPI Report For The Minister For ConstructionEssam Abdelmonem Mohamed PmpNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- How To Choose Key Performance IndicatorsDocument4 pagesHow To Choose Key Performance IndicatorsSuta VijayaNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Performance Management Plan TemplateDocument6 pagesPerformance Management Plan TemplateSuta VijayaNo ratings yet

- Fundamentals of Quantitative Log InterpretationDocument26 pagesFundamentals of Quantitative Log InterpretationSuta VijayaNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Discovering The Right Key Performance IndicatorsDocument18 pagesDiscovering The Right Key Performance IndicatorsSuta VijayaNo ratings yet

- Characteristic Logging Tool Responses For Various LithologiesDocument1 pageCharacteristic Logging Tool Responses For Various LithologiesSuta VijayaNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- KPI Deployment GuideDocument36 pagesKPI Deployment Guideser222No ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- KPI PresentationDocument43 pagesKPI PresentationYarra Rendy FahrizalNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Well Logging 2Document4 pagesWell Logging 2Suta VijayaNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Well Log Analysis For The Interpretation of Hydrocarbon EvidenceDocument5 pagesWell Log Analysis For The Interpretation of Hydrocarbon EvidenceSuta VijayaNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Decision Analysis ForPetroleum Exploration - Thomas W. EnglerDocument18 pagesDecision Analysis ForPetroleum Exploration - Thomas W. EnglerSuta Vijaya100% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Lithology Analysis Using Neutron-Gamma LoggingDocument6 pagesLithology Analysis Using Neutron-Gamma LoggingSuta VijayaNo ratings yet

- Calculation Procedures - Reserve EstimationDocument8 pagesCalculation Procedures - Reserve EstimationSuta VijayaNo ratings yet

- Valuing Exploration Andproduction ProjectsDocument3 pagesValuing Exploration Andproduction ProjectsSuta VijayaNo ratings yet

- Decision Analysis ForPetroleum Exploration - Thomas W. EnglerDocument18 pagesDecision Analysis ForPetroleum Exploration - Thomas W. EnglerSuta Vijaya100% (1)

- Quick-Look LithologyDocument1 pageQuick-Look LithologySuta VijayaNo ratings yet

- Valuing Exploration Andproduction ProjectsDocument3 pagesValuing Exploration Andproduction ProjectsSuta VijayaNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Unesco - Eolss Sample Chapters: Methods of Exploration and Production of Petroleum ResourcesDocument0 pagesUnesco - Eolss Sample Chapters: Methods of Exploration and Production of Petroleum ResourcesALIALIRAZARAZAMALIKNo ratings yet

- Upstream Petroleum Economic Analysis - SPEDocument3 pagesUpstream Petroleum Economic Analysis - SPESuta VijayaNo ratings yet

- Prospect Assessment and Risk Analysis - Example From Niger DeltaDocument6 pagesProspect Assessment and Risk Analysis - Example From Niger DeltaSuta VijayaNo ratings yet

- Uncertainty Quantification and Risk Analysis For Petroleum ExplorationDocument9 pagesUncertainty Quantification and Risk Analysis For Petroleum ExplorationSuta VijayaNo ratings yet

- Investment Risk Assessment of Potential HydrocarbonDocument24 pagesInvestment Risk Assessment of Potential HydrocarbonSuta VijayaNo ratings yet

- Calculation Procedures - Reserve EstimationDocument8 pagesCalculation Procedures - Reserve EstimationSuta VijayaNo ratings yet

- Investment and Decision Analysis For Petroleum ExplorationDocument24 pagesInvestment and Decision Analysis For Petroleum Explorationsandro0112No ratings yet

- Hamworthy Flue Gas Generator PLC ControlledDocument3 pagesHamworthy Flue Gas Generator PLC ControlledHARISHNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- New DataDocument872 pagesNew DataRoomman ArifNo ratings yet

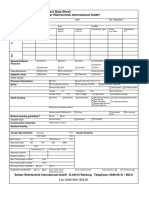

- Agitator Data Sheet Stelzer Rührtechnik International GMBH: CompanyDocument1 pageAgitator Data Sheet Stelzer Rührtechnik International GMBH: CompanyDeepikaNo ratings yet

- Fosroc Renderoc Putty Levels Walls and CeilingsDocument2 pagesFosroc Renderoc Putty Levels Walls and CeilingsVincent JavateNo ratings yet

- Model Question Steel Design 1st InternalDocument4 pagesModel Question Steel Design 1st Internalসন্দীপ চন্দ্রNo ratings yet

- Dutile IronDocument9 pagesDutile IronSaravanan ManiNo ratings yet

- Permanent Mold Casting (Gravity Die Casting)Document19 pagesPermanent Mold Casting (Gravity Die Casting)Hasyim AdhariNo ratings yet

- Opal's Spectacular Colors and Properties RevealedDocument1 pageOpal's Spectacular Colors and Properties RevealedJohn Angelo Fernandez OquianaNo ratings yet

- Rockwool 2Document8 pagesRockwool 2leroniusNo ratings yet

- 7.1 - Cooling Water SystemDocument8 pages7.1 - Cooling Water SystemSayem kaifNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Global Energy Balance in The Exchanger and Losses StudyDocument4 pagesGlobal Energy Balance in The Exchanger and Losses StudyJames Clerk MaxwellNo ratings yet

- (PChemI - Atkins) Chapter 4Document36 pages(PChemI - Atkins) Chapter 4Raja Akmal100% (1)

- Vechi RWX62Document18 pagesVechi RWX62Mihai ConstantinescuNo ratings yet

- Manual H 001Document87 pagesManual H 001Joel Armando NoriegaNo ratings yet

- Better corrosion resistance with Thalachrome SE 120Document1 pageBetter corrosion resistance with Thalachrome SE 120thyskieNo ratings yet

- Aggregate Crushing Value TestDocument4 pagesAggregate Crushing Value TestAjay KumarNo ratings yet

- PMI Procedure PDFDocument10 pagesPMI Procedure PDFMohammed Abdul Majid IrfanNo ratings yet

- VIBRATORY ROLLER OPERATOR'S MANUALDocument43 pagesVIBRATORY ROLLER OPERATOR'S MANUALkadaimamak100% (1)

- Brazing Methods GuideDocument9 pagesBrazing Methods GuideVitorHugoNo ratings yet

- ME-6401 Kinematics of Machines: Basic ConceptsDocument81 pagesME-6401 Kinematics of Machines: Basic ConceptsMugilNo ratings yet

- Part 1Document82 pagesPart 1Jaydeep ZankatNo ratings yet

- 4261 CombustorsDocument29 pages4261 CombustorsLakshman Reddy LuckyNo ratings yet

- Flexible joints, hoses, expansion joints & vibration isolators catalogDocument18 pagesFlexible joints, hoses, expansion joints & vibration isolators catalogReza TambaNo ratings yet

- Atrita Pulverizer Products and ServicesDocument36 pagesAtrita Pulverizer Products and ServicesYousuf AliNo ratings yet

- Neptune Orthopaedics Standard Operating Procedure-ProductionDocument3 pagesNeptune Orthopaedics Standard Operating Procedure-Productiondhir.ankurNo ratings yet

- Avn800xc Avn2000ac PJ DB GB 14-06-30 HK2052 01Document2 pagesAvn800xc Avn2000ac PJ DB GB 14-06-30 HK2052 01MinaSaeedNo ratings yet

- Computer Integrated ManufacturingDocument28 pagesComputer Integrated ManufacturingsoorajthevallyNo ratings yet

- Unit 3 Production and Cost AnalysisDocument6 pagesUnit 3 Production and Cost Analysismanjunatha TK100% (1)

- LG EcoV DX PDFDocument62 pagesLG EcoV DX PDFAnonymous THUA6AsJ100% (1)

- Case Study On Plant Location and Plant Layout of Pharmaceutical IndustryDocument10 pagesCase Study On Plant Location and Plant Layout of Pharmaceutical IndustryJfjf86% (7)

- Guidelines for Implementing Process Safety ManagementFrom EverandGuidelines for Implementing Process Safety ManagementNo ratings yet

- Safety Critical Systems Handbook: A Straight forward Guide to Functional Safety, IEC 61508 (2010 EDITION) and Related Standards, Including Process IEC 61511 and Machinery IEC 62061 and ISO 13849From EverandSafety Critical Systems Handbook: A Straight forward Guide to Functional Safety, IEC 61508 (2010 EDITION) and Related Standards, Including Process IEC 61511 and Machinery IEC 62061 and ISO 13849Rating: 4 out of 5 stars4/5 (5)

- Introduction to Petroleum Process SafetyFrom EverandIntroduction to Petroleum Process SafetyRating: 3 out of 5 stars3/5 (2)

- A Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesFrom EverandA Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesRating: 5 out of 5 stars5/5 (1)

- Practical Industrial Safety, Risk Assessment and Shutdown SystemsFrom EverandPractical Industrial Safety, Risk Assessment and Shutdown SystemsRating: 4 out of 5 stars4/5 (11)

- Chemical Process Safety: Learning from Case HistoriesFrom EverandChemical Process Safety: Learning from Case HistoriesRating: 4 out of 5 stars4/5 (14)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Incidents That Define Process SafetyFrom EverandIncidents That Define Process SafetyNo ratings yet