Professional Documents

Culture Documents

Chapter 1

Uploaded by

Firdaus LasnangOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chapter 1

Uploaded by

Firdaus LasnangCopyright:

Available Formats

Chapter 1

Warehouse management is part of the logistics system. Logistics is the process of planning, implementing and controlling the efficient, effective flow and storage of goods, services, and related information from point of origin to point of consumption for the purpose of conforming to customers requirements. Activities include but are not limited to warehousing, transportation, private fleets, inventory control, purchasing, production scheduling, customer service and long range planning. The objective of the warehouse is to minimize cost & maximize customer service. To do this efficient warehouse operations perform the following: Provide timely customer service Keep track of item so they can be found readily and correctly.

Minimize the total physical efforts & thus the cost of moving the goods into & out of storage. Provide communication links with customers.

1. Receiving To receive the goods from inbound carrier into the warehouse Providing assurance that the quantity & quality of goods are as ordered. Disbursing goods to storage or others.

2. Prepackaging

Perform in the warehouse when product are received in bulk.

3. Putaway 4. Storage The physical containment of goods while it is awaiting a demand. The act of placing merchandise in storage.

5. Order Picking The process of removing items from storage to meet a specific demand.

6. Packaging and/or Pricing An optional step after picking process.

7. Sortation and/or accumulation. 8. Unitizing and shipping

Row material and component warehouse Hold raw materials at or near the point of induction into a manufacturing or assembly process.

Work in process warehouses Hold partially completed assemblies and products at various points along an assembly or production line. Finished goods warehouses Hold inventory used to balance and buffer the variation between production schedules and demand. Fulfillment warehouses and fuifillment centers Receive, pick and ship small orders for individual consumers.

Distribution warehouses and distribution centers Accumulate and consolidate products from various points of manufacturing within a single firm, or from several firms for combined shipment to common customers.

Local warehouses Distribute in the field in order to shorten transportation distances to permit rapid response to customer demand. Value-added services warehouses Serve as the facility where key product customization activities executed, including packaging, labeling, marking, pricing and return processing.

1.profile Create and maintain profiles.

2. benchmark Benchmark warehouse performance, practices and operating infrastructure against world class standards. 3. innovate Innovate: reconfigure warehouse processes by eliminating and streamlining as much work content as possible. 4. automate Automate the warehouse means to computerize and mechanize.

5. humanize Humanize warehouse operations by involving operators in redesigning in all processes and daily activities.

Chapter 3

Putaway accuracy: the percent of items putaway correctly.

Inventory accuracy: the percent of warehouse locations without inventory discrepancies. Picking accuracy: the percent of order lines picked without errors. Shipping accuracy: the percent of order lines shipped without errors.

Chapter 4

Chapter 10

1. Excellent utilization of dock resources (dock doors, dock equipments, dock space, dock operators & dock supervisors) because the receiving & shipping processes can share dock doors. 2. Facilitating cross-docking because the receiving & shipping docks are adjacent to one another & may be co-mingled. 3. Excellent lift truck utilization because putaway & retrieval trips are easily combined & because the storage locations closest to the receiving & shipping docks are natural locations to house fast moving items. 4. Enables expansion opportunities in three directions (left, right & rear) 5. Yields excellent security because there is a single side of the building used for entry & exit. 6.

Chpter 11

You might also like

- Logistics And Supply Chain Management System A Complete Guide - 2020 EditionFrom EverandLogistics And Supply Chain Management System A Complete Guide - 2020 EditionNo ratings yet

- Ch1 Week 1Document101 pagesCh1 Week 1harshmaroo100% (2)

- Warehouse ManagementDocument10 pagesWarehouse ManagementAkshat JainNo ratings yet

- Exam Midterm - Emad Mohamed Attia Supply ChainDocument6 pagesExam Midterm - Emad Mohamed Attia Supply ChainEmad Attia100% (1)

- Introduction to Logistics and Supply Chain ManagementDocument3 pagesIntroduction to Logistics and Supply Chain ManagementOswin Dsouza100% (1)

- EssayDocument3 pagesEssayAditya PrasenanNo ratings yet

- LogisticsDocument17 pagesLogisticsTuấn PhanNo ratings yet

- Introduction To SCMDocument38 pagesIntroduction To SCMArif Shan50% (2)

- Supply Chain Analytics: Flexibility, Risks & OptimizationDocument4 pagesSupply Chain Analytics: Flexibility, Risks & OptimizationUmamaheswar PutrevuNo ratings yet

- OSCM MCQDocument3 pagesOSCM MCQNikhil BhaleraoNo ratings yet

- Multiple choice questions on logistics and supply chain conceptsDocument13 pagesMultiple choice questions on logistics and supply chain conceptsRinky VekariaNo ratings yet

- POM Quiz QuestionsDocument12 pagesPOM Quiz QuestionsPrashant PanditNo ratings yet

- Questions and AnswersDocument127 pagesQuestions and AnswersDavid LugunduNo ratings yet

- SCM For 2016 - 2017Document7 pagesSCM For 2016 - 2017Neha JhaNo ratings yet

- Aircel's Retail Visibility in DhanbadDocument72 pagesAircel's Retail Visibility in DhanbadDipanjan DasNo ratings yet

- SCA Week5 2020 ASSIGN-SOLDocument4 pagesSCA Week5 2020 ASSIGN-SOLUmamaheswar PutrevuNo ratings yet

- Layout Strategies Powerpoint PresentationDocument29 pagesLayout Strategies Powerpoint PresentationstanisNo ratings yet

- Om0001-Model Question PaperDocument8 pagesOm0001-Model Question PaperAshwani K SharmaNo ratings yet

- Lecture - Materials ManagementDocument48 pagesLecture - Materials ManagementJoju Johny100% (1)

- SUPPLY CHAIN AND PRODUCT DESIGN TOPICSDocument11 pagesSUPPLY CHAIN AND PRODUCT DESIGN TOPICSCzar Ysmael Rabaya100% (1)

- Chapter 1 Section1 StudentsDocument4 pagesChapter 1 Section1 Studentsjohn brownNo ratings yet

- Logistics Supply Chain Multiple Choice QuestionsDocument183 pagesLogistics Supply Chain Multiple Choice QuestionsSanjay sadafule100% (1)

- Question 1: The Logistics Functions and Various Objectives of The LogisticsDocument10 pagesQuestion 1: The Logistics Functions and Various Objectives of The LogisticsVandita KhudiaNo ratings yet

- Principles of Management MCQ (Chapter 1-6)Document7 pagesPrinciples of Management MCQ (Chapter 1-6)shravan naikNo ratings yet

- Michael Phelps Strategy & Success as Olympic SwimmerDocument16 pagesMichael Phelps Strategy & Success as Olympic SwimmerTushar Dey100% (1)

- PDF Ba 5025 Logistics Management Notes - Compress PDFDocument96 pagesPDF Ba 5025 Logistics Management Notes - Compress PDFUdayanidhi RNo ratings yet

- SC119 Umoja Property Management Overview CBT v8Document68 pagesSC119 Umoja Property Management Overview CBT v8ckumar971100% (1)

- MCQ OSCM Unit 1 1 PDFDocument21 pagesMCQ OSCM Unit 1 1 PDFbhupesh joshi100% (1)

- Supply Chain ManagementDocument26 pagesSupply Chain Managementzahid_497No ratings yet

- SCM questions and supplier evaluationDocument3 pagesSCM questions and supplier evaluationKool BhardwajNo ratings yet

- Master Production ScheduleDocument2 pagesMaster Production ScheduleklintNo ratings yet

- The Basic Principles of Lean Production and 5S MethodologyDocument11 pagesThe Basic Principles of Lean Production and 5S MethodologyOliyad ebbaNo ratings yet

- Chapter Five: Freight Forwarding OverviewDocument19 pagesChapter Five: Freight Forwarding OverviewAhmed HonestNo ratings yet

- Inventory Management FAQDocument5 pagesInventory Management FAQsurenNo ratings yet

- Components of 4plDocument2 pagesComponents of 4plCh RajkamalNo ratings yet

- Principles of Supply Chain Management: A Balanced Approach: Prepared by Daniel A. Glaser-Segura, PHDDocument20 pagesPrinciples of Supply Chain Management: A Balanced Approach: Prepared by Daniel A. Glaser-Segura, PHDmanikamathurNo ratings yet

- Tata Steel Logistics QuizDocument2 pagesTata Steel Logistics QuizpathakshirishNo ratings yet

- SCM Quiz 1Document17 pagesSCM Quiz 1Hoàng LêNo ratings yet

- What Is Supply Chain ManagementDocument6 pagesWhat Is Supply Chain ManagementHusain ShiyajiNo ratings yet

- UNIT-3: Procurement, Purchasing & Manufacturing StrategiesDocument20 pagesUNIT-3: Procurement, Purchasing & Manufacturing StrategiesFadekemi AdelabuNo ratings yet

- Full MCQ SCMDocument87 pagesFull MCQ SCMFidas RoyNo ratings yet

- Unit 2 L2 Network DesignDocument23 pagesUnit 2 L2 Network DesignJUILI dharmadhikariNo ratings yet

- Application Letter-Save The ChildrenDocument1 pageApplication Letter-Save The ChildrenKaren Roldan Rosalejos100% (2)

- HSM 2419 Advanced Transport ManagementDocument2 pagesHSM 2419 Advanced Transport ManagementDon GordonNo ratings yet

- Notes Logistics Supply Chain Management IgnouDocument353 pagesNotes Logistics Supply Chain Management IgnouAashika Shome100% (1)

- Summary Logistics Chapter 1 5 7-8-10 en 14.docx FDocument21 pagesSummary Logistics Chapter 1 5 7-8-10 en 14.docx FasdfasfasdfasdfasdfsdafNo ratings yet

- Information Systems in Logistics - FinDocument26 pagesInformation Systems in Logistics - FinAkshayraje ChandaneNo ratings yet

- Contemporary Logistics: Twelfth Edition, Global EditionDocument47 pagesContemporary Logistics: Twelfth Edition, Global EditionEge GoksuzogluNo ratings yet

- Supply Chain Management US-CMADocument7 pagesSupply Chain Management US-CMAAysha RiyaNo ratings yet

- Assignment For BASIC ELEMENTS OF LOGISTICS MANAGEMENTDocument9 pagesAssignment For BASIC ELEMENTS OF LOGISTICS MANAGEMENTjeganrajrajNo ratings yet

- MCQ and Short Answers For Week 12Document25 pagesMCQ and Short Answers For Week 12paradron MhwNo ratings yet

- Abhi - Introduction Scope and Historical Background of SCMDocument22 pagesAbhi - Introduction Scope and Historical Background of SCMKristin Pena100% (1)

- Improve Productivity with Operations ManagementDocument20 pagesImprove Productivity with Operations ManagementsultanatkhanNo ratings yet

- Chapter 2.achieving Strategic Fit & ScopeDocument42 pagesChapter 2.achieving Strategic Fit & ScopeSyed Mohammed ArfatNo ratings yet

- Assignment LogisticsDocument9 pagesAssignment LogisticsArham Orb100% (1)

- Unit 4 WarehousingDocument7 pagesUnit 4 WarehousingLaimi MutikishaNo ratings yet

- Ome 664: Project Procurement and Contracting: Lecture Three: Warehouse ManagementDocument35 pagesOme 664: Project Procurement and Contracting: Lecture Three: Warehouse ManagementYonas Alemayehu100% (1)

- WarehousingDocument33 pagesWarehousingMervyn Joe Sebastian100% (2)

- Customer-Oriented Logistics Management/TITLEDocument46 pagesCustomer-Oriented Logistics Management/TITLEdeveshNo ratings yet

- AccountingDocument1 pageAccountingFirdaus LasnangNo ratings yet

- Integrated Management System Auditor Training (ISO 9001, ISO 14001, OHSAS 18001)Document3 pagesIntegrated Management System Auditor Training (ISO 9001, ISO 14001, OHSAS 18001)Firdaus LasnangNo ratings yet

- Tutorial 5 - Linear Regression S and ADocument8 pagesTutorial 5 - Linear Regression S and AFirdaus LasnangNo ratings yet

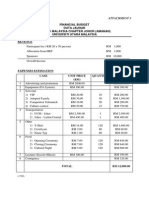

- Financial budget for Kelab 1 Malaysia Chapter Johor eventDocument1 pageFinancial budget for Kelab 1 Malaysia Chapter Johor eventFirdaus LasnangNo ratings yet

- Tutorial 6 AnsDocument4 pagesTutorial 6 AnsFirdaus LasnangNo ratings yet

- A1 Pengakuan Diri Student Declaration1 2Document1 pageA1 Pengakuan Diri Student Declaration1 2Firdaus LasnangNo ratings yet

- Gfma2023 A141 Assignment QuestionDocument1 pageGfma2023 A141 Assignment QuestionFirdaus LasnangNo ratings yet

- Driver Vehicle Checklist Fault ReportDocument2 pagesDriver Vehicle Checklist Fault ReportFirdaus LasnangNo ratings yet

- SIPTIK VII Full Paper Submission FormatDocument2 pagesSIPTIK VII Full Paper Submission FormatFirdaus LasnangNo ratings yet

- Factors of Shipping Accident at Nigeria Column-ZUE EDITDocument9 pagesFactors of Shipping Accident at Nigeria Column-ZUE EDITFirdaus LasnangNo ratings yet

- URT Group Member Evaluation FormDocument1 pageURT Group Member Evaluation FormFirdaus LasnangNo ratings yet

- A1 Pengakuan Diri Student Declaration1 2Document1 pageA1 Pengakuan Diri Student Declaration1 2Firdaus LasnangNo ratings yet

- Service Quality and Customer Satisfaction: Rapid Kuantan in Kuantan Route, MalaysiaDocument7 pagesService Quality and Customer Satisfaction: Rapid Kuantan in Kuantan Route, MalaysiaFirdaus LasnangNo ratings yet

- chp1 Introa132Document17 pageschp1 Introa132Cheah Han MingNo ratings yet

- Legal SystemDocument1 pageLegal SystemFirdaus LasnangNo ratings yet

- Legal SystemDocument1 pageLegal SystemFirdaus LasnangNo ratings yet

- Bab 12 Money & BankingDocument34 pagesBab 12 Money & BankingFirdaus LasnangNo ratings yet

- Economic Environment IbDocument4 pagesEconomic Environment IbFirdaus LasnangNo ratings yet

- Strategic Management UumDocument36 pagesStrategic Management UumFirdaus Lasnang67% (3)

- Porters Five Forces DiagramDocument1 pagePorters Five Forces DiagramabollatiNo ratings yet

- Evolution of Italian Marine Protected AreasDocument13 pagesEvolution of Italian Marine Protected AreasFirdaus LasnangNo ratings yet

- MITSMR Deloitte Social Business Report Summer 2013Document31 pagesMITSMR Deloitte Social Business Report Summer 2013oscarmelovegaNo ratings yet

- BEEI1013 Exr. MonopolyDocument8 pagesBEEI1013 Exr. MonopolyFirdaus LasnangNo ratings yet

- chp1 Introa132Document17 pageschp1 Introa132Cheah Han MingNo ratings yet

- Quality in Shipping: IMO's Role and Problems of ImplementationDocument9 pagesQuality in Shipping: IMO's Role and Problems of ImplementationFirdaus LasnangNo ratings yet

- Chp1 IntroductionDocument17 pagesChp1 IntroductionFirdaus LasnangNo ratings yet

- CHP 7 Waiting Line ModelDocument15 pagesCHP 7 Waiting Line ModelFirdaus LasnangNo ratings yet

- Dennis M. Brown and Oliver L. Flake: Rural Transportation: An Annotated BibliographyDocument66 pagesDennis M. Brown and Oliver L. Flake: Rural Transportation: An Annotated BibliographyFirdaus LasnangNo ratings yet

- LP Modeling for Profit MaximizationDocument44 pagesLP Modeling for Profit MaximizationFirdaus Lasnang0% (1)

- Material Handling EquipmentDocument5 pagesMaterial Handling EquipmentMelissa D'silvaNo ratings yet

- Indian Aviation Industry: Presented By: Steveford Marwein (547) Anupam NathDocument14 pagesIndian Aviation Industry: Presented By: Steveford Marwein (547) Anupam Nathanupam_2010No ratings yet

- 132kV ND BOM (1.3 MTR BASE)Document24 pages132kV ND BOM (1.3 MTR BASE)ramudureddyNo ratings yet

- Lightning Protection Codes & Earthing StructuresDocument6 pagesLightning Protection Codes & Earthing Structuresan_iboreg8720No ratings yet

- Kati List 2020Document114 pagesKati List 2020Zeeshan Ahmed80% (5)

- Adva Flow 411Document2 pagesAdva Flow 411Doug WeirNo ratings yet

- Vancouver Airport HistoryDocument46 pagesVancouver Airport HistoryCAP History Library100% (1)

- FEpoxy BoxDocument2 pagesFEpoxy BoxJamie ClarkNo ratings yet

- HVAC Pipe and Equipment Hanger GuideDocument10 pagesHVAC Pipe and Equipment Hanger GuideAmeen Mohamed Ali SanadNo ratings yet

- Professional Pilot December 2016Document104 pagesProfessional Pilot December 2016tugayyoung100% (1)

- Fire in A CNG Bus (Netherland)Document63 pagesFire in A CNG Bus (Netherland)Aisar Labibi RomasNo ratings yet

- Boarding PassDocument12 pagesBoarding PassDika NovianaNo ratings yet

- Provident Kenworth Rajendra Nagar HyderabadDocument3 pagesProvident Kenworth Rajendra Nagar HyderabadProvident KenworthNo ratings yet

- Standard Steel Doors and FramesDocument11 pagesStandard Steel Doors and Frameshrol31060100% (1)

- WW Grainger Mcmaster Carr CaseDocument15 pagesWW Grainger Mcmaster Carr CaseAkhil Ayyakutty100% (2)

- Logistics Collaboration Survey of Bangladesh CompaniesDocument187 pagesLogistics Collaboration Survey of Bangladesh CompaniesGolam Samdanee TaneemNo ratings yet

- Company ListDocument13 pagesCompany Listroyalviren0% (1)

- Content Owner: Chetan Kothari Compiled By: Abhishek MurarkaDocument25 pagesContent Owner: Chetan Kothari Compiled By: Abhishek MurarkaJ.BNo ratings yet

- Tupolev ANT 41Document3 pagesTupolev ANT 41PauloHenriqueRibeiroNo ratings yet

- Vinod Thesis PDFDocument116 pagesVinod Thesis PDFVinodNo ratings yet

- US and Canada Health Care System - Emanuel BaisireDocument8 pagesUS and Canada Health Care System - Emanuel Baisirebaimac75No ratings yet

- Professional PracticeDocument11 pagesProfessional PracticeKirk Heraldo100% (1)

- SMED Case Study PDFDocument3 pagesSMED Case Study PDFBagus DhakaNo ratings yet

- Input Rates Material 1st Bi Annual 2015, Government of PunjabDocument114 pagesInput Rates Material 1st Bi Annual 2015, Government of PunjabHamid NaveedNo ratings yet

- CasesDocument25 pagesCasesLindsey CookNo ratings yet

- Closed MillsDocument104 pagesClosed MillsDa DelivererNo ratings yet

- STOCK DATADocument49 pagesSTOCK DATABellwetherSataraNo ratings yet

- Rough Carpentry and Architectural Woodwork SectionsDocument5 pagesRough Carpentry and Architectural Woodwork SectionsAngel Mendez RoaringNo ratings yet

- Import & Export of Major Textile ItemsDocument4 pagesImport & Export of Major Textile Itemsgizex2013No ratings yet

- Shaft Clearance FitsDocument5 pagesShaft Clearance FitssjnicholsonNo ratings yet