Professional Documents

Culture Documents

Water-to-water heat transfer in tube–tube heat exchangers

Uploaded by

Ahmad Arif SaktiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Water-to-water heat transfer in tube–tube heat exchangers

Uploaded by

Ahmad Arif SaktiCopyright:

Available Formats

Water-to-water heat transfer in tubetube heat exchanger:

Experimental and analytical study

Milind V. Rane

*

, Madhukar S. Tandale

Mechanical Engineering Department, Heat Pump Laboratory, Indian Institute of Technology Bombay, Powai,

Mumbai 400 076, India

Abstract

Tubetube heat exchanger (TTHE) is a low cost, vented double wall heat exchanger which increases reli-

ability by avoiding mixing of uids exchanging heat. It can be potentially used for heat recovery from

engine cooling circuit, oil cooling, desuperheating in refrigeration and air conditioning, dairy, and pharma-

ceutical industry, chemical industry, renery, etc. These tubetube heat exchangers are successfully demon-

strated for superheat recovery water heating applications, condenser and evaporator in heat pumps, lube oil

cooler for shipboard gas turbines, milk chilling and pasteurizing application. This paper presents an exper-

imental study on various layouts of TTHE for water-to-water heat transfer. The theoretical and experimen-

tal results on this type of heat exchanger conguration could not be located in literature. Overall heat

transfer coecient and pumping power were experimentally determined for a xed tube length and surface

area of serpentine layouts with dierent number of bends and results are compared with straight tube

TTHE. In the case investigated, serpentine layout TTHE with seven bends has shown optimum perfor-

mance, with overall heat transfer coecient 17% higher than straight tube TTHE. Two out of ve serpen-

tine layout TTHE have shown poor heat transfer performance than straight tube TTHE. The experimental

results also indicate that there is a denite optimum for a number of bends in serpentine layout TTHE. An

analytical model for prediction of thermo-hydraulic performance of straight layout has been developed and

validated experimentally.

Keywords: Double wall heat exchanger; Serpentine layout; Straight tube; Analytical model

1. Introduction

A tubetube heat exchanger (TTHE) is a double wall tubular heat exchanger wherein two or

more tubes are placed side-by-side and bonded thermally using thermal bonding material

(TBM) for eective transfer of heat. Use of bends and straight lengths in tubetube heat exchan-

ger results in signicant enhancement in heat transfer due to secondary ows induced in the

bends. The secondary ows induced in bend leads to heat transfer enhancement in bend as well

as in straight length downstream of bend without signicant increase in pressure drop [1,2].

Dean was rst to point out that the occurrence of a secondary ow at right angles to the main

ow is due to centrifugal force [4]. The distorted ow condition by the induced secondary ow

persists at a downstream distance of more than 50d

ti

for single-phase and 70d

ti

for two-phase

[5]. Chen et al. [6] proposed empirical correlation for U-type wavy tubes with small diameter

and short separation between consecutive bends (l/d

ti

= 1.937). Their correlation shows good

agreements with the experimental data. However, extrapolations of correlation with wider oper-

ating range needs further examination to check their applicability. Recently, Chen et al. [5] have

proposed a new correlation for friction factor applicable for wider separation between the consec-

utive bends (l/d

ti

= 030) but valid for limited range of Re (5010,000).

Ohadi et al. [7] have reported their study on eect of bend on pressure drop in a straight section

downstream of a 180 bend. They found about 9% higher pressure drop in downstream section

due to bend. Multi-stream Hampson heat exchanger with paired tubes reported by Kao [7] is heli-

cal coil type for three uids. The paired tubes are soldered with tinlead solder having thermal

conductivity about 10% of copper, which may not be eective in liquidliquid heat exchange

due to its low thermal conductivity.

In many heat transfer augmentation techniques, the augmentation is usually accompanied by

signicant increase in the pumping power required to overcome increase in pressure drop for

the same heat transfer rate. But, in case of TTHE with serpentine layout the secondary ows in-

duced due to bend continue their eect in the downstream portion of a bend [1,2]. Heat transfer

enhancement in downstream section is maximum at the leading edge and diminishes along its

length. Experimental and theoretical results on single-phase heat transfer on tubetube heat ex-

changer conguration could not be located in literature. This paper experimentally investigates

the thermo-hydraulic performance of serpentine layout TTHE with dierent number of bends

(3, 6, 7, 8 and 9) in water-to-water heat transfer. Also, an experimental comparison of thermo-

hydraulic performance of serpentine layout TTHE modules with straight tube TTHE is done.

An analytical model for prediction of thermo-hydraulic performance of straight tube TTHE is

developed and validated.

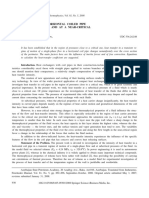

In this type of heat exchanger, there is a wide choice of congurations to select depending on

application like liquidliquid, gasliquid, two-phase etc. Fig. 1 shows dierent congurations of

TTHE. Conguration 11 is preferred for high thermal conductivity tube material, 21 for

gasliquid application and conguration nn for low thermal conductivity tube material. In

some of the applications dierent diameter tubes are paired together allowing greater exibility

2716

Nomenclature

A heat transfer surface area, m

2

BV ball valve

C Cold/heat capacity, J/K

d diameter of tube, m

dp pressure drop, N/m

2

d

bend

diameter of bend, m

FS full scale

f friction factor, dimensionless

H Hot

h heat transfer coecient, W/m

2

K

k thermal conductivity, W/m K

l length of tube, m

l

n

length of tube sector acting as a n, m

lpm liters per minute

l

st.section

length of straight section of serpentine tube, m

LMTD log mean temperature dierence, degree

m mass ow rate, kg/s

NTU number of transfer units

Nu Nusselt number, dimensionless

PICCV pressure independent characterized control valve

Pr Prandtl number, dimensionless

Q heat transfer rate, W

Re Reynolds number, dimensionless

R, R

th

thermal resistance, K/W

r fouling resistance, m

2

K/W

t temperature, C

TBM thermal bonding material

U overall heat transfer coecient, W/m

2

K

w thickness, m

w

g

gap between adjacent tubes, m

w

pp.tot

total pumping power, W

Subscripts

av average

bend tube bend

c cold

f fouling

h hot

i inside

o outside

2717

in optimising the heat exchanger with respect to heat transfer coecient and pressure drop. The

conguration 21 shown in Fig. 1(b) is used in TTHE for recovery of superheat from a 60 TR

chiller for one of the hotels in Mumbai [3].

TBM

(b)

H C H

TBM

(a)

TBM

(c)

H H C C C

H C

H

Fig. 1. Sectional view of three TTHE congurations. (a) 11 TTHE, (b) 21 TTHE and (c) nn TTHE.

min minimum

max maximum

N number of variables

pt per tube

t tube

tbm thermal bonding material

Greek symbols

e eectiveness, dimensionless

g

fs

n surface eciency, dimensionless

/ semi-ll angle subtended by thermal bonding material at tube centre, degree

2718

Some of the features of TTHE giving advantages over tube-in-tube and shell-and-tube heat

exchangers are:

(a) Possibility of using dierent material for tubes carrying uids in order to reduce the cost.

Reduction in material used by having two tubes used side-by-side, instead of one inside

the other as the case in tube-in-tube heat exchangers.

(b) For a particular design pressure, outer tube wall thickness is high which increases weight and

hence cost of heat exchanger. In TTHE, tubes are placed side-by-side. Hence, diameter of

tube replacing the outer tube is small. This reduces the thickness, weight and cost of the

tubes. This along with reduced cost of headers leads to cheaper and reliable design in spite

of small additional weight and cost due to TBM.

(c) An ability of TTHE to handle uids with brous materials, partial or complete extraction or

introduction of uids at intermediate temperature, increase or decrease the capacity of heat

exchanger by increasing or decreasing number of tube sets, good accessibility of all tubes for

ease of repair, in case of leakage.

2. Experimental setup

Schematic diagram of the experimental setup for conducting water-to-water heat transfer

experiments on TTHE modules is shown in Fig. 3. It includes a test section (TTHE module

covered with insulation), an electric water heater, valves, pump and instrumentation for measure-

ment. The experimental setup consists of two uid circuits. The rst circuit, as shown in Fig. 3,

is closed loop for hot water. Hot water is generated in an electric water heater, which has a capa-

city of about 9 kW. Flow rate of hot water from water heater is controlled by adjusting valve

and temperature of hot water at inlet to the test section is controlled by three-phase Variac.

Hot water temperature at inlet and outlet of the test section is measured by K type thermo-

couples.

The second circuit is cooling water circuit as shown in the upper half of the Fig. 3. This is open

loop with the digital turbine meter for measuring cooling water ow rate and pressure indepen-

dent characterized control valve (PICCV) for regulating the ow rate. The water ow rate is ad-

justed to dierent values and maintained constant by pressure independent characterized control

valve. Thermocouples are placed in cooling water stream to measure temperatures at inlet and

outlet of a test section.

2.1. Test section

The test section comprising tubetube heat exchanger module, is shown as a sectional view in

Fig. 2(a). Various modules of TTHE are fabricated for test. TTHE modules being tested consist of

two copper tubes of 9.525 mm OD, which are brazed all along their lengths with copper ller

material. The copper ller, which will be referred in this paper as thermal bonding material

(TBM), subtends semi-ll angle /

max

of 36.7 at the tube centre. The gap between the tubes, w

g

is measured at dierent sections along the length to calculate the average gap between the tubes

of TTHE module. The simulation results show that for TTHE with copper tubes, a gap of up to

2719

1 mm has insignicant eect on heat transfer. However, with lower thermal conductivity TBM,

the eect of gap will be considerable. The average gap between the tubes is less than 0.5 mm

for all modules tested. This small gap between the tubes allow thermal bonding material to ow

to other side of tubes during brazing.

Hot water ows through one tube and cooling water through other. All modules during the

tests are oriented such that the hot water tube is below the cooling water tube. This eliminates

(a)

(b)

Fig. 2. TTHE module. (a) Cross-sectional view of 11 TTHE module; (b) serpentine layout TTHE module with six

bends.

2720

the eects, though insignicant, of variants other than number of bends on performance of mod-

ules. All modules are insulated thermally from their surroundings during tests by the closed cell

foam insulation (thickness 25.4 mm and thermal conductivity 0.046 W/m K).

2.1.1. Straight layout

11 TTHE module (one tube for hot water and another tube for cooling water) fabricated using

two copper tubes with 9.525 mm OD. These straight tubes are brazed all along their lengths with

copper ller.

2.1.2. Serpentine layout

A pair of copper tubes with 9.525 mm OD is rst bent to a serpentine shape on tube bending

machine. The ratio of bend diameter to tube diameter (d

bend

/d

ti

) is 5.29. These tubes are brazed all

along their lengths. Five modules of serpentine layout with 3, 6, 7, 8 and 9 bends are fabricated

giving dierent ratio of length of the straight section to tube diameter (l

st.section

/d

ti

). Fig. 2(b)

shows serpentine layout TTHE with six bends.

2.2. Experimental method

The cooling water inlet temperature during the test is 29 0.5 C. The ow rate of water is ad-

justed by pressure independent characterized control valve and held constant irrespective of tap

water pressure. The cooling water ow rate is changed from 3 to 10 lpm in step of about

1 lpm. Flow rate on two sides is kept same in all sets of readings. The temperature of hot water

inlet to the test section is adjusted to 85 0.1 C by changing heater input through three-phase

Variac.

Fig. 3. Schematic of experimental setup for water-to-water heat transfer.

2721

2.2.1. Instrumentation

Instruments used for measuring various parameters during the experimentation are:

(a) Water ow rate is measured using digital turbine meter. Make: GPI turbine meter, Model

No. S050 N1/2

00

, Mid-ow, accuracy: 2% of reading in the range 3.837.9 lpm, range:

1.937.9 lpm.

(b) Flow rate of cooling water below 3.8 lpm is measured by measuring weight of water using

weighing balance with an accuracy of 1% of reading. Make: PAG Oerlikon AG CH-Dieti-

kon Precisa Balances, Model No. 87113 type 2300-9535/H6200D. The range and resolution

of instrument is 06.2 kg and 0.1 g respectively. This was done since the accuracy of turbine

meter is lower than 2% for ow rate below 3.8 lpm.

(c) The pressure losses are measured by digital dierential pressure transducers. Make:

HBM, Digibar, range: 01.2 bar, resolution: 0.5% of the measurement, and accuracy:

2%. The instrument was calibrated using accurate dial gauge having accuracy of 0.1% of

FS.

(d) The uid temperatures are measured using K type thermocouples with an accuracy of

0.3 C. The range and resolution of instrument is 20 to 300 C and 0.1 C, respec-

tively. Thermocouples are calibrated using thermocouple calibrator in Instrumentation

Laboratory.

The bends in serpentine TTHE modules tested are not perfectly circular in cross-section due to

the manufacturing process used. As a result of this, the tube cross-section became elliptical due to

attening. The maximum attening of the bends of all modules tested is less than 8%. The atten-

ing is calculated by following equation [12]

flattening

d

tmax

d

tmin

0.5 d

tmax

d

t. min

1

Since 10% attening results in very small 0.3% reduction in cross-sectional area; 8% attening in

the present case is expected to have insignicant eect on pressure drop.

3. Results and discussion

Pressure drop and heat transfer results for the layouts tested in water-to-water heat transfer are

shown in Figs. 4 and 5.

3.1. Pressure drop

Fig. 4 represents variation in experimental pressure drop with mass ow rate on hot water side

for all six modules of TTHE. In serpentine layouts, the pressure drop increases with number of

bends. The straight layout TTHE has shown lowest pressure drop amongst all layouts tested,

which is as expected.

2722

2 4 6 8 10 12

Flow Rate of Water, m

h

(kg/min)

0

1

2

3

4

5

6

7

P

r

e

s

s

u

r

e

D

r

o

p

o

n

H

o

t

W

a

t

e

r

S

i

d

e

,

d

p

h

(

b

a

r

)

Straight

Serpentine (3 bends)

Serpentine (6 bends)

Serpentine (7 bends)

Serpentine (8 bends)

Serpentine (9 bends)

Fig. 4. Variations in pressure drop with mass ow rate of water.

0 8 12 16 20 24

Total Pumping Power, W

pp.tot

(W)

1.4

1.6

1.8

2.0

2.2

2.4

2.6

2.8

3.0

3.2

3.4

O

v

e

r

a

l

l

H

e

a

t

T

r

a

n

s

f

e

r

C

o

e

f

f

i

c

i

e

n

t

,

U

i

.

h

(

k

W

/

m

2

K

)

Straight

Serpentine (3 bends)

Serpentine (6 bends)

Serpentine (7 bends)

Serpentine (8 bends)

Serpentine (9 bends)

4

Fig. 5. Variations in experimental overall heat transfer coecient with total pumping power.

2723

3.2. Overall heat transfer coecient

Fig. 5 represents variation of experimentally determined overall heat transfer coecient with

total pumping power for six modules tested. For a xed pumping power, serpentine layout TTHE

with seven bends has shown highest overall heat transfer coecient. Its maximum value is higher

than straight tube TTHE by 17%.

When comparison is done amongst serpentine layouts, the overall heat transfer coecient is

highest in serpentine layout with seven bends and lowest with nine bends. For serpentine layout

with three bends, the overall heat transfer coecient is lower than serpentine layout with seven

bends in this range of ow rate. Thus, the experimental results indicate that in serpentine layout

TTHE, there is a denite optimum for a number of bends for a particular application.

In serpentine layout with three and six bends, with d

bend

/d

ti

of 55.3 and 28.1, respectively, part

of the straight sections does not oer enhancement in heat transfer. Eect of secondary ow

diminishes long before the uid enters the subsequent bend.

In serpentine layouts with eight and nine bends, with d

bend

/d

ti

of 20.9 and 15.8, respectively, the

secondary ow generated by the previous bend probably persists as the uid enters in the next

bend. Since the secondary ow is reversed in subsequent bends in a serpentine layout, pressure

drop increases without commensurate increase in heat transfer.

Benets of the bends are not realized, since number of bends per unit length is large as in the

case of eight and nine bends, the secondary ow is rst neutralized as it passes the bend and re-

versed as it comes out. The consecutive bend interactions are so severe that the performance of the

serpentine layout is worse than that of a straight tube TTHE.

The quantities measured directly include the volume ow rate of water, inlet and outlet temper-

ature of water. The uncertainty in measurement of volume ow rate of water is 2% of reading

(maximum uncertainty: 0.2 lpm). The uncertainty of temperature measurement is 0.3 C.

According to the uncertainty analysis based on Kline and McClintock method illustrated by Mof-

fat [11], the maximum uncertainties of overall heat transfer coecient, heat transfer rate, and log

mean temperature dierence is 3.3%, 3% and 0.76%, respectively.

4. Model development

An eectiveness-NTU method is used in the model developed for performance prediction of

tubetube heat exchanger. The present model developed for straight tubetube heat exchanger

incorporates following attributes:

(a) Layout: straight.

(b) Flow conguration: counter ow or parallel ow.

(c) Geometric parameters of tubes: number, diameter, thickness, material on two sides.

(d) Thermal bonding of tubes: material and its size (/), gap between the adjacent tubes.

Appropriate parameters like length of n, l

n

(part of the tube transferring heat by n eect),

number of tubes on two sides, semi-ll angle / are included in the model to analyse most of the

congurations (various congurations with dierent number of tubes) of tubetube heat exchan-

2724

ger. The performance parameters like overall heat transfer coecient, pressure drop, pumping

power, cost, and size of heat exchanger are calculated for straight layout. Input parameters to

the model are inlet temperatures and mass ow rates of water. Other input parameters necessary

for the analysis are ow arrangement, number of tubes, tube material, tube diameter, tube thick-

ness, thermal bonding material and its size.

Following assumptions were made in the model development.

(a) Steady state operation.

(b) No heat loss to the surroundings.

(c) No heat transfer in the direction of ow.

(d) Uniform uid distribution in all tubes in multiple tube tubetube heat exchanger.

(e) One dimensional ow of heat through part of the tube and thermal bonding material.

(f) No phase change.

4.1. Heat transfer equations

The net heat transfer depends on the waterside heat transfer coecients, fouling factors, ther-

mal resistance by tube walls, and thermal bonding material. The correlations for heat transfer

coecients and friction factors reported in the literature have been used in the model. Few impor-

tant equations used in the model are given below.

NTU is calculated by

NTU

UA

C

min

2

Theoretical relations for eectiveness as a function of NTU and heat capacity ratio are available

for dierent ow arrangements like counter ow or parallel ow. For counter ow, equation for

eectiveness is

e

1 expNTU 1 C

ratio

1 C

ratio

expNTU 1 C

ratio

3

where,

C

ratio

C

min

C

max

The maximum possible heat transfer rate is calculated by

Q

max

C

min

t

hi

t

ci

4

The actual heat transfer rate in heat exchanger is calculated by equation

Q e C

min

t

hi

t

ci

5

2725

4.2. Heat transfer coecient

The net heat transfer depends on heat transfer coecients, fouling factors, thermal resistance

by tube walls, and thermal bonding material.

Gnielinskis correlation [9] is used for heat transfer coecient calculation for transition region

as well as fully developed turbulent ow for a straight smooth circular tube

Nu

f

2

Re 1000 Pr

1 12.7

f

2

_

0.5

Pr

2=3

1

6

For 2300 6 Re 6 5 10

6

and 0.5 6 Pr 6 2000.

It is modied version of second Petukhov correlation, which agrees with most reliable experi-

mental data to an accuracy of 5%.

4.3. Friction factor

For friction factor in fully developed turbulent ow for a straight smooth circular tube, Prandtl,

Karman, Nikuradse (PKN) correlation is classical correlation valid for wide range of Re

(4 10

3

6 Re 6 10

7

). The correlation is also used for comparison of recent correlations.

1

f

p 1.7372 ln Re

f

_

_ _

0.3946 7

Predictions of this correlation agree with the extensive experimental measurements within 2 [4].

However, the PKN correlation is not explicit form; Techo, Tickner, James correlation [10] is

used for friction factor calculations.

1

f

p 1.7372 ln

Re

1.964 ln Re 3.8215

_ _

8

This explicit form of PKN correlation agrees within 0.1% of PKN correlation for 10

4

6

Re 6 2.5 10

8

.

5. Overall heat transfer coecient

The overall heat transfer coecient is obtained using following expression

1

UA

1

h

h

r

fh

_ _

1

A

h

g

fsh

R

thh

R

thtbm

R

thc

1

h

c

r

fc

_ _

1

A

c

g

fsc

9

R

thtbm

is thermal resistance of thermal bonding material. Thickness of thermal bonding material

(measured in the direction of heat transfer) varies from minimum at / = 0 to maximum at the

limiting value /

max

. R

thh

and R

thc

are thermal resistance of portion of tubes in contact with ther-

mal bonding material on hot water and cooling water side, respectively. Similarly, r

fh

and r

fc

are

fouling resistances on hot water and cooling water side, respectively. Thermal resistance of ther-

mal bonding material is calculated considering dierential element as shown in Fig. 2(a).

2726

Thermal resistance of dierential element is given by

R

d

to

1 cos / w

g

k

tbm

d

to

2

d/ cos / l

pt

_ _ 10

where, R is thermal resistance of the dierential element in terms of dierential angle d/. The ther-

mal resistances of all elements of TBM are in parallel. Therefore, the overall thermal resistance of

TBM is obtained by integrating 1/R term for the dierential element between the limits /

max

to

/

max

. The derived equation for overall thermal resistance of TBM is

R

thtbm

2

_

/

max

0

k

tbm

d

to

2

cos / l

pt

d

to

1 cos / w

g

d/

_ _1

11

Another approach to obtain thermal resistance of thermal bonding material is by calculating

equivalent/average thickness considering the area equivalence. Following equation gives equi-

valent/average thickness of thermal bonding material.

w

tbmav

w

g

sin /

max

1 cos /

max

1

2

/

max

p

180

sin /

max

cos /

max

_

sin /

max

d

to

12

The thermal resistance of thermal bonding material calculated using Eq. (11) and other calculated

by considering the approach of average thickness of thermal bonding material deviates within

10%.

0.0 0.1 0.2 0.3 0.4 0.5 0.6

Predicted Pressure Drop, dp

h

(bar)

0.0

0.1

0.2

0.3

0.4

0.5

0.6

E

x

p

e

r

i

m

e

n

t

a

l

P

r

e

s

s

u

r

e

D

r

o

p

,

d

p

h

(

b

a

r

)

45 deg line

Fig. 6. Experimental vs. simulated pressure drop.

2727

6. Experimental validation of model

The present model developed for straight tube TTHE is validated experimentally for water-

to-water heat transfer by testing a typical module of straight tube TTHE. The experimental setup

used for conducting experiments is explained in earlier section.

The experimental and simulated results on pressure drop and overall heat transfer coecient

for straight tube TTHE are represented in Figs. 6 and 7. The results show good agreement bet-

ween the results prediction by model and the experimental results. The average dierence between

the predicted and experimental results of pressure drop on hot water side is 2.3% and the maxi-

mum dierence is 4.2%. The average dierence between the predicted and experimental overall

heat transfer coecient is 2% and maximum dierence is 6.2%.

7. Conclusions

Five dierent serpentine layouts of TTHE have been experimentally evaluated for the eect of

varying straight lengths between bends on thermo-hydraulic performance. Tubes used in all ve

serpentine layout TTHE are 9.525 mm OD and 43 mm bend diameter. Maximum overall heat

transfer coecient is obtained for the serpentine layout TTHE with seven bends when the perfor-

mance is compared at same pumping power. Also, the overall heat transfer coecient in serpen-

tine layout TTHE with seven bends is higher than TTHE with straight layout by 17%.

1.0 1.5 2.0 2.5 3.0

Predicted Overall Heat Transfer Coefficient, U

i.h

(kW/m

2

K)

1.0

1.5

2.0

2.5

3.0

E

x

p

e

r

i

m

e

n

t

a

l

O

v

e

r

a

l

l

H

e

a

t

T

r

a

n

s

f

e

r

C

o

e

f

f

i

c

i

e

n

t

,

U

i

.

h

(

k

W

/

m

2

K

)

45 deg line

Fig. 7. Experimental vs. predicted overall heat transfer coecient.

2728

In waterwater heat transfer, not all serpentine TTHE layouts are better than straight layout.

The serpentine layout TTHE with three and nine bends have shown lower heat transfer perfor-

mance than straight layout TTHE. However, at very low pumping power (below 3 W), serpentine

layout with three bends has shown slightly better heat transfer performance than straight tube

TTHE. The maximum dierence in performance of optimum serpentine layout TTHE (seven

bends) and nine bend serpentine TTHE, which is a non-optimum, is 30%. Thus, due care should

be taken while designing TTHE with serpentine layout to maximize the benets of this design.

In case of serpentine layout TTHE, the experimental results indicate that there is a denite opti-

mum for a number of bends for a particular application. In the present case, the optimum number

of bends in serpentine layout is 7.

An analytical model for simulation of straight tube TTHE in waterwater heat transfer is val-

idated experimentally. Eectiveness-NTU approach is used in the model for performance predic-

tions. The average and maximum deviation between predicted and experimental values of overall

heat transfer coecient is 2% and 6.2%, respectively. Similarly, average and maximum deviation

is pressure drop 2.3% and 4.2%, respectively.

References

[1] M.V. Rane, M.S. Tandale, Tubetube heat exchangers, Filed PCT/IN03/00377, 2003.

[2] M.V. Rane, M.S. Tandale, An experimental study on various layouts of tubetube heat exchanger in steam

condensation, Experimental Thermal and Fluid Science, submitted for publication.

[3] M.V. Rane, M.S. Tandale, Benets of superheat recovery on chillers- case study for a hotel installation, Paper

presented at 21st IIR International Congress of Refrigeration, Washington, DC, August 2003, pp. 1722.

[4] R.K. Shah, S.D. Joshi, Convective heat transfer in curved ducts, in: S. Kakak, R.K. Shah (Eds.), Handbook of

Single-phase Convective Heat Transfer, rst ed., John Wiley and Sons, 1987.

[5] I.Y. Chen, J.C. Huang, C.C. Wang, Singe-phase and two-phase frictional characteristics of small U-tube wavy

tubes, International Communication Heat Mass Transfer 31 (3) (2004) 303314.

[6] I.Y. Chen, S.K. Lai, C.C. Wang, Frictional performance of small diameter U-type wavy tubes, ASME Journal of

Fluids Engineering 47 (2003) 22412249.

[7] M.M. Ohadi, E.M. Sparrow, A. Walawalkar, A.I. Ansari, Pressure drop characteristics for a turbulent ow in a

straight circular tube situated downstream of a bend, International Journal of Heat Mass Transfer 33 (4) (1990)

583591.

[9] V. Gnielinski, New equations for heat and mass transfer in turbulent pipe and channel ow, International

Chemical Engineering 16 (2) (1976) 359368.

[10] R. Techo, R.R. Tickner, R.E. James, An accurate equation for the computation of the friction factor from smooth

pipes from the Reynolds number, ASME Transaction Journal of Applied mechanics 32 (1965) 443.

[11] R.J. Moat, Describing the uncertainties in experimental results, Experimental Thermal and Fluid Science 1 (1988)

317.

[12] D.F. Geary, Return bend pressure drop in refrigeration systems, ASHRAE Transactions 2342 (1980) 250265.

2729

You might also like

- Hazardous Locations: Guide To Equipment Certification Requirements ForDocument1 pageHazardous Locations: Guide To Equipment Certification Requirements ForVishnu LalNo ratings yet

- Ferro Magnetism and Anti Ferro MagnetismDocument31 pagesFerro Magnetism and Anti Ferro MagnetismPrachiNo ratings yet

- Conduit Technical Standard PDFDocument13 pagesConduit Technical Standard PDFAykut BacakNo ratings yet

- Conduit Technical Standard PDFDocument13 pagesConduit Technical Standard PDFAykut BacakNo ratings yet

- Performance Analysis of A Plate Heat Exchanger and Its Comparison With Double Pipe Exchanger PDFDocument5 pagesPerformance Analysis of A Plate Heat Exchanger and Its Comparison With Double Pipe Exchanger PDFesatjournalsNo ratings yet

- Optimization of Shell and Tube Heat ExchangerDocument29 pagesOptimization of Shell and Tube Heat ExchangerAna QuintanaNo ratings yet

- Boiling and CondensationDocument11 pagesBoiling and CondensationahaaNo ratings yet

- Performance Analysis of Shell and Tube Heat ExchangersDocument5 pagesPerformance Analysis of Shell and Tube Heat ExchangersMichał KisielewskiNo ratings yet

- ANSI Flanges Dimensions Specs Grades ClassesDocument23 pagesANSI Flanges Dimensions Specs Grades ClassesVenkatesh GangadharNo ratings yet

- Production of Hydrogen Gas by Steam Reforming ProcessDocument38 pagesProduction of Hydrogen Gas by Steam Reforming ProcessAinggararuban GaneshanNo ratings yet

- Flash Point Lab ReportDocument14 pagesFlash Point Lab ReportNesha Arasu67% (3)

- Boyle's Law Questions PDFDocument3 pagesBoyle's Law Questions PDFamvijayagopal100% (1)

- Heat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersFrom EverandHeat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersRating: 4 out of 5 stars4/5 (13)

- Viscosity Index Improvers for LubricantsDocument20 pagesViscosity Index Improvers for LubricantskhilpatiNo ratings yet

- CFD Analysis of Heat Transfer in A Double Pipe Heat Exchanger Using FluentDocument48 pagesCFD Analysis of Heat Transfer in A Double Pipe Heat Exchanger Using FluentManishSharma90% (10)

- Lecture Notes Enzyme 2 Enzyme Kinetics WebDocument29 pagesLecture Notes Enzyme 2 Enzyme Kinetics WebAldren RebaLdeNo ratings yet

- eArt-Performance Analysis of Spiral Tube Heat ExchangerDocument4 pageseArt-Performance Analysis of Spiral Tube Heat ExchangerMoly69xNo ratings yet

- Heat Transfer Coefficients of Shell and Coiled Tube Heat ExchangersDocument5 pagesHeat Transfer Coefficients of Shell and Coiled Tube Heat ExchangersShalehAhmad100% (1)

- PressurenDrop in Double Pipe Heat ExchangersDocument5 pagesPressurenDrop in Double Pipe Heat ExchangersdikimNo ratings yet

- Heat Transfer and Pressure Drop Characteristics of Finned Tube Banks in Forced Convection (Comparison of The Heat Transfer Characteristics Between Spiral Fin and Serrated Fin)Document14 pagesHeat Transfer and Pressure Drop Characteristics of Finned Tube Banks in Forced Convection (Comparison of The Heat Transfer Characteristics Between Spiral Fin and Serrated Fin)nadir adel100% (1)

- A Design Adn Rating Method For Shell and Tube Heat ExchangerDocument8 pagesA Design Adn Rating Method For Shell and Tube Heat Exchangerhuynhthanhtamga1981100% (1)

- Heat Exhanger Individual ReportDocument16 pagesHeat Exhanger Individual ReportMusa OtoNo ratings yet

- InstruCalc Flow Element SizingDocument1 pageInstruCalc Flow Element SizingerjainrachitNo ratings yet

- Heat ExchangerDocument25 pagesHeat ExchangerFarisRazzak67% (3)

- Tubo y CorazaDocument9 pagesTubo y CorazaJaime Diaz RuizNo ratings yet

- Heat Transfer and Turbulent Flow Friction in A Circular Tube Fitted With Conical-Nozzle TurbulatorsDocument11 pagesHeat Transfer and Turbulent Flow Friction in A Circular Tube Fitted With Conical-Nozzle TurbulatorsAnonymous 7BQxlt8cNo ratings yet

- Heat Transfer Behaviors in A Tube With Combined Conical-Ring and Twisted-Tape InsertDocument11 pagesHeat Transfer Behaviors in A Tube With Combined Conical-Ring and Twisted-Tape InsertAnonymous 7BQxlt8cNo ratings yet

- Performance of Shell-And-Dimpled-Tube Heat Exchangers For Waste Heat Recovery V. HDocument10 pagesPerformance of Shell-And-Dimpled-Tube Heat Exchangers For Waste Heat Recovery V. HPhilip ShihNo ratings yet

- 6 PDFDocument5 pages6 PDFmukesh poundekarNo ratings yet

- Effect of Variable Adiabatic Length On A Heat Pipe PerformanceDocument8 pagesEffect of Variable Adiabatic Length On A Heat Pipe PerformanceTJPRC PublicationsNo ratings yet

- SSRN Id4147313Document29 pagesSSRN Id4147313Rajeev PandeyNo ratings yet

- Part TwoDocument10 pagesPart TwoAhmed KhalidNo ratings yet

- Experimental Study of Shell-Side Heat Transfer Coefficient and Pressure Drop For An Integrally Helical Baffled Heat Exchanger Combined With Different Enhanced Tubes PDFDocument6 pagesExperimental Study of Shell-Side Heat Transfer Coefficient and Pressure Drop For An Integrally Helical Baffled Heat Exchanger Combined With Different Enhanced Tubes PDFRengga Ahmad PrasetiaNo ratings yet

- Researchpaper Review On Twisted Tapes Heat Transfer EnhancementDocument9 pagesResearchpaper Review On Twisted Tapes Heat Transfer EnhancementShreyas RathoreNo ratings yet

- Heat Transfer Augmentation Using Twisted Wire Mesh InsertsDocument5 pagesHeat Transfer Augmentation Using Twisted Wire Mesh InsertsVeeresh FuskeleNo ratings yet

- Heat Transfer Processes in Detergent IndustryDocument17 pagesHeat Transfer Processes in Detergent Industryعبدالمحسن علي ENo ratings yet

- Applied Energy: Junye WangDocument8 pagesApplied Energy: Junye WangResearcherzNo ratings yet

- Heat Transfer in Staggered Tube BanksDocument9 pagesHeat Transfer in Staggered Tube BanksMohammed Bate'eNo ratings yet

- Heat Transfer in a Horizontal Coiled Pipe at Near-Critical PressureDocument5 pagesHeat Transfer in a Horizontal Coiled Pipe at Near-Critical PressureM. SukarmanNo ratings yet

- Flat-Plate Heat ExchangerDocument12 pagesFlat-Plate Heat ExchangerhuangjlNo ratings yet

- An Experimental Study of Thermal Performance of Shell-And-coil Heat ExchangersDocument7 pagesAn Experimental Study of Thermal Performance of Shell-And-coil Heat ExchangersAbul Lais NalbandNo ratings yet

- Effects of Baffle Inclination Angle On Flow and Heat Transfer of A Heat Exchanger With Helical BafflesDocument10 pagesEffects of Baffle Inclination Angle On Flow and Heat Transfer of A Heat Exchanger With Helical BafflesAhmad Restian Adi NugrohoNo ratings yet

- Review B InggrisDocument10 pagesReview B InggrisWillyam PrizkiabiNo ratings yet

- Research Article: Characteristics of Heat Transfer For Heat Pipe and Its CorrelationDocument8 pagesResearch Article: Characteristics of Heat Transfer For Heat Pipe and Its Correlationأمير معروفNo ratings yet

- Forced ConvectionDocument9 pagesForced ConvectionAmeer ShNo ratings yet

- Paper Conical Ring InsertsDocument8 pagesPaper Conical Ring InsertssergioteroNo ratings yet

- 1 s2.0 0960148194904111 MainDocument10 pages1 s2.0 0960148194904111 MainSadegh AhmadiNo ratings yet

- Flow Dynamics Numerical InvestigationDocument15 pagesFlow Dynamics Numerical InvestigationKar AbhishekNo ratings yet

- Numerical Investigation Flow DynamicsDocument15 pagesNumerical Investigation Flow DynamicsKar AbhishekNo ratings yet

- IETEPune2094ijarseDocument13 pagesIETEPune2094ijarseVictor BettNo ratings yet

- HEDocument10 pagesHEMohamed BelallNo ratings yet

- International Journal of Heat and Mass Transfer: Jun Yu, Lin Su, Kang Li, Mingkang Liu, Hua ZhangDocument13 pagesInternational Journal of Heat and Mass Transfer: Jun Yu, Lin Su, Kang Li, Mingkang Liu, Hua ZhangJhon AguirreNo ratings yet

- Journal Pre-Proof: Case Studies in Thermal EngineeringDocument26 pagesJournal Pre-Proof: Case Studies in Thermal EngineeringJennyPaolaGonzalezRobertoNo ratings yet

- Concentric Tube Heat Exchanger ReportDocument19 pagesConcentric Tube Heat Exchanger Reportillyzl100% (1)

- Analysis of A Helical Coil Once-Through Molten Salt Steam Generator: Experimental Results and Heat Transfer EvaluationDocument10 pagesAnalysis of A Helical Coil Once-Through Molten Salt Steam Generator: Experimental Results and Heat Transfer EvaluationCristina VladutaNo ratings yet

- 10 1016@j Ijheatmasstransfer 2012 03 074Document6 pages10 1016@j Ijheatmasstransfer 2012 03 074mohamed mostafaNo ratings yet

- Numerical and Experimental Study of The Heat Transfer Process in A DTDocument21 pagesNumerical and Experimental Study of The Heat Transfer Process in A DTIynulF.OmarNo ratings yet

- 1 s2.0 S1359431108004845 MainDocument6 pages1 s2.0 S1359431108004845 Main1AdityaPathania1No ratings yet

- Twisted Tape and Wire Coil InsertsDocument6 pagesTwisted Tape and Wire Coil InsertsAntoni MacierewiczNo ratings yet

- Modeling Heat Pipe Heat Exchangers for Heat RecoveryDocument7 pagesModeling Heat Pipe Heat Exchangers for Heat Recoverynicky nolivosNo ratings yet

- Performance of Heat Pipe For Different Working Fluids and Fill RatiosDocument7 pagesPerformance of Heat Pipe For Different Working Fluids and Fill RatiosElmy Zola GintingNo ratings yet

- Review Paper On Investigation of Perfomance For Shell and Tube Heat Exchanger - 45688Document5 pagesReview Paper On Investigation of Perfomance For Shell and Tube Heat Exchanger - 45688lvmengke1994No ratings yet

- Experimental Study of Transition From Laminar To Turbulent Flow in Vertical Narrow ChannelDocument6 pagesExperimental Study of Transition From Laminar To Turbulent Flow in Vertical Narrow ChannelMariovane DoniniNo ratings yet

- Unit III Heat Exchange EquipmentDocument17 pagesUnit III Heat Exchange EquipmentaberraneNo ratings yet

- Thermal Analysis Formulas STHXDocument23 pagesThermal Analysis Formulas STHXFaheem Fiaz ChohanNo ratings yet

- Case Studies Thermal Engineering 1Document13 pagesCase Studies Thermal Engineering 1stefano guercilenaNo ratings yet

- J Enconman 2006 03 034Document16 pagesJ Enconman 2006 03 034sergioteroNo ratings yet

- Zhu Et Al. - 2022 - Heat Transfer Enhancement For Microchannel Heat SiDocument14 pagesZhu Et Al. - 2022 - Heat Transfer Enhancement For Microchannel Heat Simosab.backkupNo ratings yet

- Advances in Heat Pipe Technology: Proceedings of the IVth International Heat Pipe Conference, 7-10 September 1981, London, UKFrom EverandAdvances in Heat Pipe Technology: Proceedings of the IVth International Heat Pipe Conference, 7-10 September 1981, London, UKNo ratings yet

- Batch Controller Manual: Load, Monitor and TroubleshootDocument35 pagesBatch Controller Manual: Load, Monitor and TroubleshootAhmad Arif SaktiNo ratings yet

- Librecad Users Extensive Manual: 1.1 Documents Purpose and CreditsDocument77 pagesLibrecad Users Extensive Manual: 1.1 Documents Purpose and CreditsAhmad Arif SaktiNo ratings yet

- Winahyo Setyowibowo: Fields of Competence Key AssignmentsDocument2 pagesWinahyo Setyowibowo: Fields of Competence Key AssignmentsAhmad Arif SaktiNo ratings yet

- PVC Insulated Copper and Aluminum Wire Armored Power CablesDocument5 pagesPVC Insulated Copper and Aluminum Wire Armored Power CablesAhmad Arif SaktiNo ratings yet

- BC PRseries - hardware.UserManualDocument145 pagesBC PRseries - hardware.UserManualAhmad Arif SaktiNo ratings yet

- Sti Conduit Installation 2015Document31 pagesSti Conduit Installation 2015Ragab AbulmagdNo ratings yet

- Effects of Beta Ratio and Reynold's Number On Coefficient of Discharge of Orifice MeterDocument6 pagesEffects of Beta Ratio and Reynold's Number On Coefficient of Discharge of Orifice MeterWanda DarmawanNo ratings yet

- 12PM 12 Wed Feb 2020 3PM 6PM 9PM 13 Thu 3AM 6AM 9AMDocument1 page12PM 12 Wed Feb 2020 3PM 6PM 9PM 13 Thu 3AM 6AM 9AMAhmad Arif SaktiNo ratings yet

- 981 Aperflux 851 Ct-S 503-E Settembre 13 Low ResDocument12 pages981 Aperflux 851 Ct-S 503-E Settembre 13 Low ResAhmad Arif SaktiNo ratings yet

- Effects of Beta Ratio and Reynold's Number On Coefficient of Discharge of Orifice MeterDocument6 pagesEffects of Beta Ratio and Reynold's Number On Coefficient of Discharge of Orifice MeterWanda DarmawanNo ratings yet

- Unmanaged Versus Managed Switches: Podcast TranscriptDocument3 pagesUnmanaged Versus Managed Switches: Podcast TranscriptDumi DumDumNo ratings yet

- 2008 Commercial Boiler EfficiencydeterminetestDocument11 pages2008 Commercial Boiler EfficiencydeterminetestMakhdum Muhardiana PutraNo ratings yet

- WP Best Practices TuningDocument13 pagesWP Best Practices Tuningnixsol75No ratings yet

- Haute Couture (Card Fusion) Price TrackerDocument36 pagesHaute Couture (Card Fusion) Price TrackerAhmad Arif SaktiNo ratings yet

- SOP For Bosch 7000 Series CameraDocument20 pagesSOP For Bosch 7000 Series CameraAhmad Arif SaktiNo ratings yet

- Liermann2013 PIDtuningruleDocument10 pagesLiermann2013 PIDtuningruleAhmad Arif SaktiNo ratings yet

- Smallvolumeprover BrochureDocument12 pagesSmallvolumeprover BrochureanafadoNo ratings yet

- Quantum Computer Website - SimulasiDocument1 pageQuantum Computer Website - SimulasiAhmad Arif SaktiNo ratings yet

- ThesisDocument46 pagesThesisAhmad Arif SaktiNo ratings yet

- White Paper Continuous Historian Faq Deltav en 57808Document14 pagesWhite Paper Continuous Historian Faq Deltav en 57808Ahmad Arif SaktiNo ratings yet

- GE Druck PV211 BrochureDocument2 pagesGE Druck PV211 BrochureAhmad Arif SaktiNo ratings yet

- IR5500 ManualDocument72 pagesIR5500 ManualPedro julio Osorio MarmolNo ratings yet

- Automatic Flight Control System (Afcs)Document28 pagesAutomatic Flight Control System (Afcs)Ahmad Arif SaktiNo ratings yet

- Data Percobaan P1 REKBANDocument9 pagesData Percobaan P1 REKBANAhmad Arif SaktiNo ratings yet

- Sizing a Flare Stack and Calculating Flame Distortion from Wind VelocityDocument49 pagesSizing a Flare Stack and Calculating Flame Distortion from Wind VelocityBayu AjipNo ratings yet

- An Overview of Methods To Mitigate Condensate Banking in Retrograde Gas ReservoirsDocument6 pagesAn Overview of Methods To Mitigate Condensate Banking in Retrograde Gas ReservoirsAdanenche Daniel EdohNo ratings yet

- Steam BoilerDocument17 pagesSteam BoilerMohamed Abd El-Naiem - EGYPTROLNo ratings yet

- Buffer Systems Maintain pHDocument10 pagesBuffer Systems Maintain pHEzat JrNo ratings yet

- Atomic StructureDocument9 pagesAtomic StructureAlyaa MohamedNo ratings yet

- Chemistry Oct2011Document87 pagesChemistry Oct2011Jerc ZajNo ratings yet

- Formal Report 5 Heat EngineDocument8 pagesFormal Report 5 Heat EngineRichmond L. CrisostomoNo ratings yet

- Ourse: CHE442 - SEPARATION PROCESS 1 (3 Credits /compulsory)Document8 pagesOurse: CHE442 - SEPARATION PROCESS 1 (3 Credits /compulsory)Anonymous TUXPKUSRDUNo ratings yet

- Created By: Heri Reksa S.Pd. Chemistry Teacher SMAN 1 BogorDocument45 pagesCreated By: Heri Reksa S.Pd. Chemistry Teacher SMAN 1 BogorHeri ReksaNo ratings yet

- PET Recycling Literature ReviewDocument69 pagesPET Recycling Literature ReviewPrachi ShahNo ratings yet

- Inorganica Chimica Acta: Research PaperDocument7 pagesInorganica Chimica Acta: Research Paperhenry martinez quiñonezNo ratings yet

- ConductivitySensor BrochureDocument4 pagesConductivitySensor BrochureJames TakeNo ratings yet

- BibliographyDocument2 pagesBibliographyAdhi HutariNo ratings yet

- Cloruro de ViniloDocument25 pagesCloruro de ViniloJulissa MármolNo ratings yet

- AlcoholDocument45 pagesAlcoholMichaelWongNo ratings yet

- D and F Block Elements IIT JEE Notes PDFDocument15 pagesD and F Block Elements IIT JEE Notes PDFDILPREET SINGHNo ratings yet

- CHM 420 Experiment 6: Acid and BasesDocument7 pagesCHM 420 Experiment 6: Acid and BasesSyahirah FazialNo ratings yet

- Shock TubeDocument16 pagesShock TubeAhmed El MorsyNo ratings yet

- 1.concentration Part 1Document6 pages1.concentration Part 1Dharmvir tantyNo ratings yet

- 3.SALT ANALYSIS Cobalt NitrateDocument4 pages3.SALT ANALYSIS Cobalt Nitratemohnish100% (1)

- Lecture 3Document32 pagesLecture 3Quang TrườngNo ratings yet

- MEG 203 Engineering ThermodynamicsDocument77 pagesMEG 203 Engineering ThermodynamicsOyekale IniNo ratings yet

- Me 598 - Lecture 1 - Overview of Materials Characterization Techniques.20110215.4d5ad7e0f3d0e6.28002081Document57 pagesMe 598 - Lecture 1 - Overview of Materials Characterization Techniques.20110215.4d5ad7e0f3d0e6.28002081Saad SalmanNo ratings yet

- Chemistry-Theory (Cyi 101) Organic ChemistryDocument15 pagesChemistry-Theory (Cyi 101) Organic ChemistryPrasann KatiyarNo ratings yet