Professional Documents

Culture Documents

Sedecal Descargas 28

Uploaded by

ArsalanKhanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sedecal Descargas 28

Uploaded by

ArsalanKhanCopyright:

Available Formats

SOF T ST A R T E R S

Stop

Time

Start up Running

Slow

Dowm

C

u

r

r

e

n

t

Motor Thermal Protection

Programmations

Sedecal Group

Sedecal Control, S.A. was founded in March 1995.

The Company was intended for designing and

manufacturing of medium and high power soft

starters, frequency converters and power systems for

different applications in the field of heavy industry.

Sedecal Control is located in Algete (Madrid), and it

is part of Sedecal Group.

Soft Starter Concept

On the squirrel cage motors, the start up current can

be up to 5 - 10 I

N

.

The start up current is proportional to the applied

voltage.

50 % of applied voltage leads to 50% and 25% of

current and torque respectively.

The start up time is a function of the motor - machine

inertial characteristics. (Big fans need about 60

seconds, and pumps 20 seconds approximately).

Industries

Paper mill Pulpers, refinders, pumps and fans

Steel mill Big fans, compressors, pumps and fans

Petrol Big fans, compressors, pumps and fans

Chemistry Fermentation stations, compressors,

pumps and fans

Water Desalination stations, compressors, pumps

Advantages

SAP 600 and SAP 6000 soft starter controllers

ensure the soft starting and stopping of large

three-phase induction motors without excessive

peak currents, motor heating or mechanical

shocks.

This has a particular importance in large machi-

nes due to the power consumption in the

megawatt range. The energy adsorbed by the

motor winding and the shock torque have both

and important impact in the mechanical parts

and consequently, influences the equipment life-

time.

SAP 600 and SAP 6000 allow the reduction of

cable section and the energy peak power from

the electricity supplier.

SAP 600 and SAP 6000 compensate the voltage

drop on the power cables. The soft starter

controllers apply the pre-set current values.

SAP 600 and SAP 6000 use current control. The

pre-set current value is not affected by the line

voltage or the specific motor start-up currents.

The power and control circuits are communica-

ted through optical fibre.

SOFT STARTER

SAP

SAP - 6000

SAP - 600

Main Referent

Papelera Pennsular Paper mill

Siemens Disperser

Aceralia Steel mill

Europac Paper mill

Cadasa Waters treatments

Pridesa Waters treatments

Elctricas Centro Waters treatments

SOF T STAR T E R S

Supply voltage 200 - 3.300 V, 6.600 V - 13.000 V 220 to 690 V

Power range 220 kW to 20.000 kW 50 kW to 1.000 kW

Frequency 50 - 60 Hz 50 - 60 Hz

Overload 120 3,5 I

N

. 3,5 I

N

.

Overload 60 4 I

N

. 4 I

N

.

Overload 10 5 I

N

. 5 I

N

.

Overload 5 6 I

N

. 6 I

N

.

Continues overload 1,2 I

N

. 1,2 I

N

.

Control system Programmable current control Programmable current control

Overvoltage protection RC network (Snubber) and VDR RC network (Snubber)

Motor overload electronic protection Programmable CEI 655 - 8 Programmable CEI 655 - 8

Soft stop Optional Optional

Soft start Programmable from control panel Programmable from control panel

Underload Programmable from control panel Programmable from control panel

Underload time Programmable from control panel Programmable from control panel

Quick-start Programmable from control panel Programmable from control panel

Start Stop per hour (1 - 10) Programmable from control panel Programmable from control panel

Phase lose protection Programmable between (10900 mseg.) Programmable between (10900 mseg.)

Instantaneous overcurrent Included Included

Thyristor detector failure Included No

Phase rotation detector Included Included

RAM memory failure Included Included

Fuse detector failure Included Included

4 - 20 mA motor current Included Optional

Main phases fast fuses Included Optional

Motor digital current Included Included

Line digital voltage Included Included

Self diagnostic (50 error) Included Included

Bypass control Included Included

Perpetual calendars Included Included

Heatsinks temperature detector Included Included

Leakage current detector Optional Optional

Cooling system By forced air By forced air

Ambient temperature -10 + 40C -10 + 40C

Output - Interfase Input - Interfase Input - Interfase

Fault Acknowledgement contactor bypass Acknowledgement contactor bypass

Running Acknowledgement fans failure detector Acknowledgement fans failure detector

Order to close bypass contactor Heatsinks overtemperature Heatsinks overtemperature

Motor overload (1,2 I

N

.) Thyristors overtemperature failure detector Thyristors overtemperature failure detector

Order to open bypass contactor Fuse failure detector Fuse failure detector

Soft starter active Remote start-up (pulse) Remote start-up (pulse)

Start-up completed Stop (pulse) demanded by the user Stop (pulse) demanded by the user

Remote reset (pulse) Remote reset (pulse)

Thyristor failure signal External Conditions

Remote on - of Remote on - of

Signal for user purposes Signal for user purposes

E L E C T R I C A L S P E C I F I C A T I O N S

S A P 6 0 0 0 S A P 6 0 0

SEDECAL CONTROL, S.A.

Pelaya, 9 - Polgono Industrial Ro de Janeiro

28110 Algete (Madrid) ESPAA

Tels.: (34) 91 628 05 44 / 91 628 15 92

Fax: (34) 91 628 05 74

Email: FLopez@sedecal.com

You might also like

- Appendix B - Distance Tables - Metric Units PDFDocument15 pagesAppendix B - Distance Tables - Metric Units PDFitisINo ratings yet

- QSK60 Series 50hzDocument4 pagesQSK60 Series 50hzbacuoc.nguyen3560% (1)

- S 1514Document4 pagesS 1514bacuoc.nguyen356No ratings yet

- IGEL MV Soft Starter Catalogue To ArgenDocument4 pagesIGEL MV Soft Starter Catalogue To ArgenanksyeteNo ratings yet

- AtelectasisDocument37 pagesAtelectasisSandara ParkNo ratings yet

- Sinpac Cap Start Run Switches CVR - SeriesDocument5 pagesSinpac Cap Start Run Switches CVR - SeriesstoragebinNo ratings yet

- Combined Overcurrent & Earth-Fault Relay: Type SPAJ 140 CDocument8 pagesCombined Overcurrent & Earth-Fault Relay: Type SPAJ 140 CturboedNo ratings yet

- Danfoss MCD3000 BrosuraDocument2 pagesDanfoss MCD3000 BrosurazvekoslavNo ratings yet

- DFHD - Model Specification SheetDocument4 pagesDFHD - Model Specification SheetAlejandro Lagares100% (1)

- 2CV Series For 230 Vac Capacitor Start Motors and 2VR Series For 230 Vac Capacitor Start/Capacitor Run MotorsDocument2 pages2CV Series For 230 Vac Capacitor Start Motors and 2VR Series For 230 Vac Capacitor Start/Capacitor Run MotorsmachevallieNo ratings yet

- Installation and Maintenance Manual Type SSM Medium Voltage 200 - 7,500 HPDocument120 pagesInstallation and Maintenance Manual Type SSM Medium Voltage 200 - 7,500 HPHans MortenNo ratings yet

- SS8 CPGKDocument4 pagesSS8 CPGKRoozbeh BahmanyarNo ratings yet

- 6.51-56 SSMDocument6 pages6.51-56 SSMWanessa SuárezNo ratings yet

- Diesel Generator Set X3.3 Series Engine: Specification SheetDocument4 pagesDiesel Generator Set X3.3 Series Engine: Specification Sheetjavier.oyarzo.pNo ratings yet

- Diesel Generator Set QSK60 Series Engine: Description FeaturesDocument4 pagesDiesel Generator Set QSK60 Series Engine: Description Featuresbacuoc.nguyen356No ratings yet

- Manual Stamford Avr MX342 PDFDocument4 pagesManual Stamford Avr MX342 PDFSeVictor Rudas CajaNo ratings yet

- Diesel Generator Set KTA19 Series Engine: 576kVA - 650kVA 50Hz 501kW 60HzDocument4 pagesDiesel Generator Set KTA19 Series Engine: 576kVA - 650kVA 50Hz 501kW 60HzSandro MunizNo ratings yet

- Avr Newage mx321 PDFDocument4 pagesAvr Newage mx321 PDFLiya MahagamaNo ratings yet

- Diesel Generator Set 4B3.9 Series Engine: Description FeaturesDocument4 pagesDiesel Generator Set 4B3.9 Series Engine: Description FeaturesM Han AfiNo ratings yet

- Primary Current InjectorDocument2 pagesPrimary Current Injector021804No ratings yet

- Voltage Influence On Typical Protection and Controls ForDocument22 pagesVoltage Influence On Typical Protection and Controls ForM Kumar MarimuthuNo ratings yet

- HEC 7S - RuDocument6 pagesHEC 7S - Rut_syamprasadNo ratings yet

- MX 321Document4 pagesMX 321derickteo5971100% (1)

- Zenith ZTG SeriesDocument8 pagesZenith ZTG SeriesFlo MircaNo ratings yet

- Under & Over Current RelayDocument2 pagesUnder & Over Current RelayRenghat RumahorboNo ratings yet

- SCR/SCRF Series: Industry's First Choice For Time-Tested Proven ReliabilityDocument8 pagesSCR/SCRF Series: Industry's First Choice For Time-Tested Proven ReliabilityAdrian M FahriNo ratings yet

- Diesel Generator Set: Continuous Model:YM9-1P Standby Model:YM10S-1PDocument4 pagesDiesel Generator Set: Continuous Model:YM9-1P Standby Model:YM10S-1PYashveer TakooryNo ratings yet

- CNC ControllerDocument12 pagesCNC ControllerMihai ViteazuNo ratings yet

- Integrated Off Grid Inverter ICA 3000, 5000, 8000 - HXDocument2 pagesIntegrated Off Grid Inverter ICA 3000, 5000, 8000 - HXCNP WEB0% (1)

- Schneider RelaysDocument12 pagesSchneider Relaysrajpre1213No ratings yet

- Switch On To The Best: Cam Operated Rotary SwitchesDocument32 pagesSwitch On To The Best: Cam Operated Rotary Switchesbagastc100% (1)

- Technical CS: Parameters CG Power NTPL Yeoman Electrical & ElectronicsDocument2 pagesTechnical CS: Parameters CG Power NTPL Yeoman Electrical & ElectronicsStephen BridgesNo ratings yet

- Automatic RegulatorDocument2 pagesAutomatic RegulatorJason AguilarNo ratings yet

- Star Delta Wiring Diagram Motor Start yDocument16 pagesStar Delta Wiring Diagram Motor Start ydataroma100% (1)

- 90kVA PDFDocument4 pages90kVA PDFXander DelinyaNo ratings yet

- Sag SwellDocument149 pagesSag Swellfurqan mahmudNo ratings yet

- A6251m PDFDocument7 pagesA6251m PDFYudi ElektroNo ratings yet

- Fuse Contactor Selection - 6.6kVDocument10 pagesFuse Contactor Selection - 6.6kVapmanungadeNo ratings yet

- STRW6754Document9 pagesSTRW6754electronicaliderNo ratings yet

- Genset 1000 KvaDocument4 pagesGenset 1000 Kvasahat100% (1)

- Overcurrent Abb Make Spaj 140 Manual PDFDocument12 pagesOvercurrent Abb Make Spaj 140 Manual PDFNesarkiran BagadeNo ratings yet

- Three-Phase Overcurrent Relay Spaj 131 C: Product GuideDocument12 pagesThree-Phase Overcurrent Relay Spaj 131 C: Product GuideSharaf Ali ZyoudNo ratings yet

- Contactors Regul - Modif.Document2 pagesContactors Regul - Modif.Momir Cokorilo100% (1)

- Sorensen DLM 3kW-4kW DatasheetDocument6 pagesSorensen DLM 3kW-4kW DatasheetDumi BogdanNo ratings yet

- Mx341 Avr Newage StamfordDocument4 pagesMx341 Avr Newage Stamfordabuzer1981No ratings yet

- Generator TroubleshootingDocument22 pagesGenerator TroubleshootingMichael Cabrera Rabino100% (1)

- AVR AS440 Data SheetDocument4 pagesAVR AS440 Data SheetMazhar Hussain100% (2)

- Data SheetDocument7 pagesData SheetOvi PanteaNo ratings yet

- 1 Performance DataDocument9 pages1 Performance DataYusep KurniaNo ratings yet

- Perkins Diesel Generator P400pub 360kwDocument4 pagesPerkins Diesel Generator P400pub 360kwTariq KoyrattyNo ratings yet

- Catálogo Técnico Transferencias OTMDocument116 pagesCatálogo Técnico Transferencias OTMCarolina Alicia Bravo VillegasNo ratings yet

- MARELLI Catalogo e Scheda TecnicaDocument20 pagesMARELLI Catalogo e Scheda TecnicaFabio Emanuele Branda0% (1)

- 10 KvaDocument4 pages10 KvaLeonardusHSijabatNo ratings yet

- Switch YardDocument60 pagesSwitch Yardjigdung100% (3)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsFrom EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsRating: 3.5 out of 5 stars3.5/5 (6)

- 110 Waveform Generator Projects for the Home ConstructorFrom Everand110 Waveform Generator Projects for the Home ConstructorRating: 4 out of 5 stars4/5 (1)

- Boat Maintenance Companions: Electrics & Diesel Companions at SeaFrom EverandBoat Maintenance Companions: Electrics & Diesel Companions at SeaNo ratings yet

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetFrom EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetRating: 2 out of 5 stars2/5 (1)

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetFrom EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetNo ratings yet

- 1st Term 9th 2019Document2 pages1st Term 9th 2019ArsalanKhanNo ratings yet

- Chap 04 Solutions Ex 4 1 CalculusDocument1 pageChap 04 Solutions Ex 4 1 CalculusSikandar KhanNo ratings yet

- DepositSlip GAT183 1918632066818Document1 pageDepositSlip GAT183 1918632066818Usman ShahzadNo ratings yet

- Muhammad Naveed - Team#45 - Germany SourcingDocument28 pagesMuhammad Naveed - Team#45 - Germany Sourcingarshad khanNo ratings yet

- Solved Idioms From 1971 To 2015 - Updated PDFDocument58 pagesSolved Idioms From 1971 To 2015 - Updated PDFImranRazaBozdarNo ratings yet

- Enquiry Receipt (For Candidate) : Humanities (Part-I)Document4 pagesEnquiry Receipt (For Candidate) : Humanities (Part-I)ArsalanKhanNo ratings yet

- ReadMe 7thundersDocument2 pagesReadMe 7thundersd0o0No ratings yet

- Gat Sample Test 02Document24 pagesGat Sample Test 02Amjad bbsulk71% (7)

- ReportDocument4 pagesReportArsalanKhanNo ratings yet

- Untitled DocumentDocument4 pagesUntitled DocumentArsalanKhanNo ratings yet

- Umer CVDocument1 pageUmer CVArsalanKhanNo ratings yet

- Press Note No. 30 Dated 27-12-2018 Regarding Online Admission of HSSC Annual Exam 2019Document4 pagesPress Note No. 30 Dated 27-12-2018 Regarding Online Admission of HSSC Annual Exam 2019ArsalanKhanNo ratings yet

- Exercise 3.1 (Solutions) : Question # 1 (I) Question # 2 (Ii) Question # 2 (Iii)Document2 pagesExercise 3.1 (Solutions) : Question # 1 (I) Question # 2 (Ii) Question # 2 (Iii)sohail2798No ratings yet

- Class Month S.No Student Name R.No Date Month Security Admission Tution Mess G.Fund TotalDocument1 pageClass Month S.No Student Name R.No Date Month Security Admission Tution Mess G.Fund TotalArsalanKhanNo ratings yet

- Ssca2018ds PDFDocument2 pagesSsca2018ds PDFArsalanKhanNo ratings yet

- Water Supply BillDocument1 pageWater Supply Billarshad khanNo ratings yet

- SWJ HHM 2006 CHM 34 Vaginal AcupressureDocument14 pagesSWJ HHM 2006 CHM 34 Vaginal AcupressureAruna BandaraNo ratings yet

- Answers: Cambridge International AS and A Level Mathematics Mechanics Practice BookDocument24 pagesAnswers: Cambridge International AS and A Level Mathematics Mechanics Practice BookArsalanKhanNo ratings yet

- Acupressure BookDocument14 pagesAcupressure BookDilek E100% (4)

- Payment / Received VoucherDocument1 pagePayment / Received VoucherArsalanKhanNo ratings yet

- Ssca2018ds PDFDocument2 pagesSsca2018ds PDFArsalanKhanNo ratings yet

- Chapter Matrices Ex 3 1Document31 pagesChapter Matrices Ex 3 1ArsalanKhanNo ratings yet

- Abandon:: N. Syn. RelinquishDocument25 pagesAbandon:: N. Syn. Relinquisharshad khanNo ratings yet

- Troubleshooting and Repair of Consumer Electronics EquipmentDocument53 pagesTroubleshooting and Repair of Consumer Electronics Equipmentartust0% (1)

- FTA 500Fs4 Manual PDFDocument26 pagesFTA 500Fs4 Manual PDFArsalanKhanNo ratings yet

- Siqarah Science College Paper Science: Total Marks 30 Pass Marks 15 Fill in The Blanks.. 10Document1 pageSiqarah Science College Paper Science: Total Marks 30 Pass Marks 15 Fill in The Blanks.. 10ArsalanKhanNo ratings yet

- AqeeqahKayAhkam o MasailByShaykhMuhammadYusufKhanDocument31 pagesAqeeqahKayAhkam o MasailByShaykhMuhammadYusufKhanArsalanKhanNo ratings yet

- Apnal Aamaal Ki Hifazat KejiyeDocument35 pagesApnal Aamaal Ki Hifazat KejiyeSyed Saqib Jalal MadaniNo ratings yet

- FTA 500Fs4 Manual PDFDocument26 pagesFTA 500Fs4 Manual PDFArsalanKhanNo ratings yet

- Triton Model 8100 ManualDocument150 pagesTriton Model 8100 ManualMichael JessieNo ratings yet

- 2020 ROTH IRA 229664667 Form 5498Document2 pages2020 ROTH IRA 229664667 Form 5498hk100% (1)

- Installing Touareg R5 CamshaftDocument1 pageInstalling Touareg R5 CamshaftSarunas JurciukonisNo ratings yet

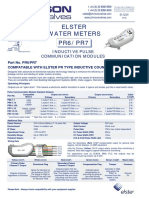

- Data Sheet No. 01.12.01 - PR6 - 7 Inductive Pulse ModuleDocument1 pageData Sheet No. 01.12.01 - PR6 - 7 Inductive Pulse ModuleThaynar BarbosaNo ratings yet

- Guides To The Freshwater Invertebrates of Southern Africa Volume 2 - Crustacea IDocument136 pagesGuides To The Freshwater Invertebrates of Southern Africa Volume 2 - Crustacea IdaggaboomNo ratings yet

- Syllabus For Bachelor of Physiotherapy (BPT) Academic ProgrammeDocument36 pagesSyllabus For Bachelor of Physiotherapy (BPT) Academic ProgrammevikasmaeNo ratings yet

- The Case - Lijjat PapadDocument16 pagesThe Case - Lijjat Papadganesh572No ratings yet

- Chapter 2 and 3 ImmunologyDocument16 pagesChapter 2 and 3 ImmunologyRevathyNo ratings yet

- Bisleri Water Industry: Project ReportDocument53 pagesBisleri Water Industry: Project ReportJohn CarterNo ratings yet

- Study Notes On Isomers and Alkyl HalidesDocument3 pagesStudy Notes On Isomers and Alkyl HalidesChristian Josef AvelinoNo ratings yet

- Join Our Telegram Channel: @AJITLULLA: To Get Daily Question Papers & SolutionsDocument24 pagesJoin Our Telegram Channel: @AJITLULLA: To Get Daily Question Papers & SolutionsNaveen KumarNo ratings yet

- G1 Series User Manual Ver. 1.2Document101 pagesG1 Series User Manual Ver. 1.2unedo parhusip100% (1)

- Unit 8 Packet KeyDocument21 pagesUnit 8 Packet KeyHiddenNo ratings yet

- READING 4 UNIT 8 Crime-Nurse Jorge MonarDocument3 pagesREADING 4 UNIT 8 Crime-Nurse Jorge MonarJORGE ALEXANDER MONAR BARRAGANNo ratings yet

- Service Bulletins For Engine Model I0360kb.3Document6 pagesService Bulletins For Engine Model I0360kb.3Randy Johel Cova FlórezNo ratings yet

- SPA - MichaelDocument1 pageSPA - Michaelgilberthufana446877No ratings yet

- Laboratory Cold ChainDocument22 pagesLaboratory Cold ChainEmiNo ratings yet

- Mushrooms and Religion: Amanita MuscariaDocument8 pagesMushrooms and Religion: Amanita MuscariaGummyCola50% (2)

- SGT PDFDocument383 pagesSGT PDFDushyanthkumar DasariNo ratings yet

- Solar Refrigeration: Prepared by M.DevakumarDocument21 pagesSolar Refrigeration: Prepared by M.DevakumarEasy StudyNo ratings yet

- RRC Group D Notification 70812Document11 pagesRRC Group D Notification 70812admin2772No ratings yet

- Soil SSCDocument11 pagesSoil SSCvkjha623477No ratings yet

- ResumeDocument3 pagesResumejohn DaqueNo ratings yet

- "Next Friend" and "Guardian Ad Litem" - Difference BetweenDocument1 page"Next Friend" and "Guardian Ad Litem" - Difference BetweenTeh Hong Xhe100% (2)

- ReliabilityDocument5 pagesReliabilityArmajaya Fajar SuhardimanNo ratings yet

- Xi 3 1Document1 pageXi 3 1Krishnan KozhumamNo ratings yet

- BV Lesson Plan 4Document3 pagesBV Lesson Plan 4api-252119803No ratings yet

- G103 Remov Waste Dust Extraction UnitDocument2 pagesG103 Remov Waste Dust Extraction UnitJoseCRomeroNo ratings yet

- Inducement of Rapid Analysis For Determination of Reactive Silica and Available Alumina in BauxiteDocument11 pagesInducement of Rapid Analysis For Determination of Reactive Silica and Available Alumina in BauxiteJAFAR MUHAMMADNo ratings yet