Professional Documents

Culture Documents

Ashcroft Autoclave

Uploaded by

puccio78Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ashcroft Autoclave

Uploaded by

puccio78Copyright:

Available Formats

Ashcroft Inc.

9/2012

PRODUCT INFORMATION

High Pressure Connection Page: ASH/PI-61A

INTRODUCTION

Pressure fittings are available in a wide variety of sizes and configurations. The most commonly

used connection in North America is the National Pipe Thread (NPT), which creates a seal by

the intermeshing of the threads along a tapered thread line. Since this method can still allow a

leak path between the thread crests and roots, the application of a thread sealer is required, in the

form of Teflon

tape or a hardening liquid chemical compound referred to as pipe dope.

However, process interface requirements, dynamic forces and differing international standards

often preclude the use of NPT fittings in favor of more sophisticated pressure connections.

Among the various alternatives are fittings that form the pressure seal through the use of an O-

ring, gasket or metal-to-metal compression assembly. But despite the many application-specific

connection requirements, the most compelling divergence from NPT is the need to contain

higher pressures.

THE HIGH PRESSURE SEAL

High pressure is a relative term. Depending on the users perspective, high pressure may be

defined as low as 200 and as high as 60,000 psi. For the purposes of this discussion, we will refer to

high pressure as any pressure outside the maximum sealing capacity of an NPT fitting, which is

approximately 20,000 psi.

With NPT unable to contain higher pressures, a stronger, better sealing fitting designed specifically

for high pressure will be required. Depending on the pressure level, there are several different

types to choose from. In instrumentation, the most common is the

9

16-18 UNF-2B female port for

O.D. high pressure tubing (often designated by the brand reference Autoclave F-250-C). The

inlet itself is a very simple female straight-thread port, distinguishable by its interior flat bottom

with a counter-sunk pressure passage hole in the center. To installers who are unfamiliar with this

connection, the first step will be to ask the question: when installing the instrument, what type of

(male) fitting does it mate to?

In fact, the mating connection is not a single fitting, but a three part assembly. Since high pressures

cannot be contained with conventional piping or hoses, special high pressure, thick walled O.D.

tubing often serves as the necessary conduit. Thus, to form a seal capable of containing high

pressures, a metal-to-metal seal must be established whereby the tip of the tubing is forced into a

counter-sink (seat) at the opening of the pressure passage hole inside (at the bottom of) the female

port. To achieve this, a compression fit must be created through the use of three components: 1)

the systems high pressure tubing, prepared with a 59 chamfered tip and left hand thread, 2) the

collar (sleeve) and 3) the gland nut. Assembled properly, tightening the gland into the female port

will exert pressure on the collar, thus forcing the tip of the tubing into the seat at the bottom of the

female port and thereby creating the high pressure seal (see Figures 2 and 3).

In rare cases where an instrument may be equipped with the

9

16-18 high pressure female port but

is to be used in a lower pressure application, solid adaptors designed to simulate the

tubing/collar/gland assembly are available to yield a

1

4 NPT male or female inlet. (See Figure 1 for

suppliers and part numbers).

Ashcroft Inc. 9/2012

TUBE PREPARATION AND ASSEMBLY

To create the mating tube/collar/gland assembly, the tubing tip must first be formed and the

fitting components must be assembled per the following steps:

1. To prepare the tubing, two operations are required:

A) Coning the tube tip: The tip of the high pressure tubing must first be coned or

beveled to a 59 angle to produce the tubes sealing surface. (See Figure 2). This can be

accomplished by the use of a lathe or special coning tools offered by the component

suppliers (see figure 1).

B) Threading the tubing: A -28 UNF-2A left hand thread (See Figure 2) must be turned onto

the end of the tubing. Special tools and dies are also available specifically for this

operation.

2. Slide the gland nut over the tubing so that the male threads face the open end of the tube.

3. Thread the female collar onto the left hand threads on the tubing.

4. Slide the gland nut down over the collar.

5. Insert the entire assembly into the female port of the gauge so that the coned end of the

tubing seats into the countersink (seat) inside the female port.

6. Engage the

9

16 male threads of the gland nut into the female threads of the instruments port.

As the gland nut is tightened, it will exert pressure upon the collar, forcing the coned tip of

the tubing into the seat.

7. If the tubing appears to be loose inside the assembly, back out the gland nut and remove the

assembly from the instrument port. Turn the collar counter-clockwise so that it is positioned

farther up the tubing (away from the tip) so that the coned end of the tubing protrudes farther

out (away from) the gland nut. Conversely, if the tube is protruding out so far that the gland nut

cannot engage at least 4 complete threads, turn the collar clockwise to shorten the distance that

the tubing tip protrudes away from the gland nut. When properly adjusted, return to step 6.

SUPPLIERS

Tubing, gland nuts, collars, adaptors and tools

are offered by the following suppliers. (Some

may refer you to a local distributor.)

Parker Autoclave Engineers

Erie, PA

814-860-5700 Fax: 814-838-5855

www.autoclave.com

Newport Scientific, Inc.

(Formerly AMINCO),

"Superpressure" Line

Jessup, MD

301-498-6700 Fax: 301-490-2313

www.newport-scientific.com

BuTech Pressure Systems

Erie, PA

814-833-4904 Fax: 814-833-2612

www.butech-valve.com

High Pressure Equipment Company (HIP)

Erie, PA

800-289-7447 Fax: 814-838-6075

www.highpressure.com

The Swagelok Company (Sno-Trik

)

Solon OH

see website for local distributor

www.swagelok.com

Ashcroft Inc. 9/2012

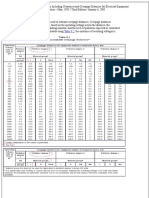

FIGURE 1

PART NUMBER CROSS REFERENCE GUIDE FOR

1

4 HIGH PRESSURE

TUBING FITTING COMPONENTS AND ACCESSORIES

Item Autoclave Newport BuTech HIP Sno-Trik

Gland Nut or AGL 40 45-11313 or 60G4 60-2HM4 -

45-11314

Collar (Sleeve) ACL 40 45-11316 or 60C4 60-2H4 -

45-11317

Coning Tool MC TH4 48-15013 60CT4 2-HF4 MS-469-CT

Threading Tool 402A 48-15025 THT4-H 2-MHF4 -

HP Male to 1/4 NPT-M Adapter 15MA H4P4 45-16370 MA4H4P 30-21HM4NMB SS-44M-1-4

HP Male to 1/4 NPT-F Adapter 15M94B8 45-16071 10A4H4P 30-21NFBHM4 SS-44M-7-4

with 45-11064

Also sells HP Tubing Yes Yes Yes Yes Yes

Notes:

1) Abbreviation HP = High Pressure

2) All gland nuts, collars and adapters identified above are 316 SS except: Newport - Top P/N

designates 416 SS (bottom P/N designates 316 SS) HIP - Standard material for gland nuts and

collars is 17-4PH Nickel. 316 SS is optionally available under the same P/N.

3) Newport (AMINCO) also offers the gland nut and collar set under a single P/N; 44-11310.

4) All coning and threading tools are complete sets which include all necessary dies and cutting

bits.

5) Autoclave also sells tube bending equipment.

6) Autoclave and Butech also sell motorized threading machines.

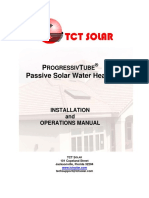

(REF.)

.375 DIA.

(REF.)

(REF.)

LEFT HAND THREAD

1/4-28 UNF-2B

(GAUGE INLET PORT)

HIGH PRESSURE PORT

9/16-18 UNF-2B

GLAND NUT COLLAR

1/4 HIGH PRESSURE TUBING

1/4'' HIGH

COLLAR

HIGH PRESSURE PORT

9/16-18 UNF-2B

9/16-18 UNF-2A

LEFT HAND THREAD

1/4-28 UNF-2A

CONE DIA.

.125

.562

1/2

59

GLAND NUT

PRESSURE SEALING

SURFACE

(GAUGE INLET PORT)

PRESSURE

TUBING

TUBE ASSEMBLY REV. 3

(ASSEMBLED)

(EXPLODED)

FIGURE 3

FIGURE 2

1/4'' HIGH PRESSURE TUBING ASSEMBLY

1/4 HIGH PRESSURE TUBING ASSEMBLY

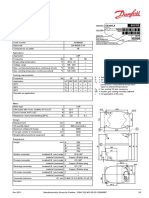

Figure 4

High Pressure Tubing Specification

(Typical) 316 Stainless Steel

Maximum Work-

ing Pressure

@ 72F O.D. I.D.

20,000 psi 1/4 .109

60,000 psi 1/4 .083, .094

100,000 psi 1/4 .0625

Notes:

1) Some vendors offer alternate tubing materials. I.D.

dimension may vary with material.

2) Some manufacturers classify 20,000 psi as medium

pressure tubing.

Ashcroft Inc. 09/2012 Rev. 2

Teflon is a registered trademark of the E. I. du Pont de Nemours and Company

Sno-Trik is a registered trademark of the Swagelok Company.

You might also like

- Wescol SS-N-10-2GDocument12 pagesWescol SS-N-10-2Gpuccio78No ratings yet

- HiP Autoclave ToolsDocument4 pagesHiP Autoclave Toolspuccio78No ratings yet

- High Pressure Regulator Handles Up To 200 BarDocument1 pageHigh Pressure Regulator Handles Up To 200 Barpuccio78No ratings yet

- Fix It!: Bladder Accumulator Problems?Document1 pageFix It!: Bladder Accumulator Problems?puccio78No ratings yet

- New Shaft Alignment TechniqueDocument9 pagesNew Shaft Alignment TechniquelangtuNo ratings yet

- Maximator AutoclaveDocument6 pagesMaximator Autoclavepuccio78No ratings yet

- Accumulator Maintenance PDFDocument15 pagesAccumulator Maintenance PDFsyukur1No ratings yet

- Drilling String InspectionDocument7 pagesDrilling String Inspectionrais ridha100% (2)

- Rupk 78Document39 pagesRupk 78puccio78No ratings yet

- 2005 CB1300SDocument15 pages2005 CB1300Spuccio78No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Chem Academy: ThermodynamicsDocument5 pagesChem Academy: ThermodynamicsHamit RanaNo ratings yet

- PermaGard - Paint ProtectionDocument2 pagesPermaGard - Paint ProtectionFaith_No_MoreNo ratings yet

- Pyrocrete 241 + Application Instructions NZAUDocument4 pagesPyrocrete 241 + Application Instructions NZAULong An ĐỗNo ratings yet

- Assignment 1Document3 pagesAssignment 1Ansuman SahooNo ratings yet

- Request For Modification Permit-New - GuidelineDocument9 pagesRequest For Modification Permit-New - GuidelineGregorio PossagnoNo ratings yet

- Id-Technik Catalogue EnglishDocument37 pagesId-Technik Catalogue EnglishtonyminarasNo ratings yet

- Introduction To CeramicsDocument3 pagesIntroduction To CeramicsHarini MunasingheNo ratings yet

- Method Statement For AFS.15.04.19 R0 PDFDocument12 pagesMethod Statement For AFS.15.04.19 R0 PDFkrishna100% (1)

- Hygrobar B WaterstopDocument2 pagesHygrobar B WaterstopMahesh SavandappaNo ratings yet

- Behavior of Reinforced Concrete Wide Concealed-Beam PDFDocument12 pagesBehavior of Reinforced Concrete Wide Concealed-Beam PDFMarimuthu KaliyamoorthyNo ratings yet

- Deliverable List & Price Terminal BBM DexDocument1 pageDeliverable List & Price Terminal BBM DexEvi Puspita SariNo ratings yet

- Electrical Layout Design and Load Calculation GuideDocument75 pagesElectrical Layout Design and Load Calculation Guide2GI20AT021 Devki HanamshetNo ratings yet

- 10cv82 PDFDocument59 pages10cv82 PDFAatifNo ratings yet

- Bosch Washing Machine WAS32461GB 90004608573Document6 pagesBosch Washing Machine WAS32461GB 90004608573David GoldNo ratings yet

- PWHT ReqDocument13 pagesPWHT ReqAbhay KarandeNo ratings yet

- UL 840 Third Edition January 2005 Section 9 Creepage DistancesDocument4 pagesUL 840 Third Edition January 2005 Section 9 Creepage DistancesRobert LegaultNo ratings yet

- MODEL 206-F-TYPE 4 Modulating Float Valve: Key FeaturesDocument4 pagesMODEL 206-F-TYPE 4 Modulating Float Valve: Key Featuresชวลิตศ์ จิตรเที่ยงNo ratings yet

- 14.Stress-Strain Relationship in Axial Compression For EPS ConcreteDocument7 pages14.Stress-Strain Relationship in Axial Compression For EPS ConcreteManuel GutarraNo ratings yet

- Smm7 Estimate ExampleDocument42 pagesSmm7 Estimate ExampleDiasz100% (2)

- Detailed Lesson Plan in Science 5 (Series Circuit)Document12 pagesDetailed Lesson Plan in Science 5 (Series Circuit)Shiella Mae Olermo Cardona100% (2)

- ProgressivTube Installation Operations Manual 03 02 09 PDFDocument58 pagesProgressivTube Installation Operations Manual 03 02 09 PDFMohamd LabeabNo ratings yet

- Bolt Tightening Handbook Linear Motion ADocument44 pagesBolt Tightening Handbook Linear Motion AMarcos MorachickNo ratings yet

- DBR PDFDocument7 pagesDBR PDFrajeev shahNo ratings yet

- SS Ni LiteDocument114 pagesSS Ni Litepaeg6512No ratings yet

- ASTM D2850 Triaxial Test Cohesive SoilsDocument15 pagesASTM D2850 Triaxial Test Cohesive SoilsMin MiynNo ratings yet

- Gs26Clx LBP Compressor R404A/R507 220-240V 50Hz: GeneralDocument2 pagesGs26Clx LBP Compressor R404A/R507 220-240V 50Hz: GeneralmustafaNo ratings yet

- HW1Document1 pageHW1Mohammed Essam ShatnawiNo ratings yet

- Previous question papers portalDocument2 pagesPrevious question papers portalGuru VishalNo ratings yet

- CER 127.2 Act. 10 Loss On Ignition Drying and Firing Shrinkage Tests PARTIALDocument8 pagesCER 127.2 Act. 10 Loss On Ignition Drying and Firing Shrinkage Tests PARTIALGrandeur Paglinawan IINo ratings yet

- Passed Report - Glass - 17.5mmDocument29 pagesPassed Report - Glass - 17.5mmsaravqwerty100% (1)