Professional Documents

Culture Documents

Scope:: About The Ballbal - Direct Spreadsheet ..

Uploaded by

snarf273Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Scope:: About The Ballbal - Direct Spreadsheet ..

Uploaded by

snarf273Copyright:

Available Formats

Moly-Cop Tools, Version 2.

0

About the BallBal_Direct Spreadsheet ...

Scope :

The BallBal_Direct spreadsheet was designed to compute the Size-by-Size Mass Balance around the Hydrocyclone

Classifiers of any given Conventional Ball Mill circuit, operating under the Direct configuration (see Flowsheet), on the

basis of actual plant measurements.

Theoretical Framework :

Whenever actual grinding data are collected in a plant environment, they will invariably be affected by natural

experimental and measurement errors, in such a way that the basic mass balance equation around the hydrocyclones, for

particles of size di :

fiCF CF = fiU U + fiO O

???

, for i = 1,n

will never be satisfied. In the above expression CF, U and O represent the mass flowrate of solids in the cyclones feed,

underflow and overflow streams, respectively. Similarly, fiCF, fiU and fiO represent the fraction of those total respective

streams corresponding to particles of size di.

The Ballbal_Direct routine allows for the calculation of a whole new set of corresponding adjusted or fitted values fiCF, fiU

and fiO, such that the objective functions :

fi = [ wCF (fiCF - fiCF)2 + wU (fiU - fiU)2 + wO(fiO - fiO)2 ]

,for every particle size di

are minimized and the adjusted values so generated strictly satisfy the mass balance restrictions :

fiCF CF = fiU U + fiO O

, for i = 1,n

where wCF, wU and wO are user-defined weighting factors included to represent the relative quality and reliability of the

samples from each of the 3 streams and the mass flowrates CF, U and O are calculated as :

CF = F (1 + CL)

U = F (CL)

O = F

where F is the dry Fresh Feedrate of solids to the grinding section and the Circulating Load (CL) is estimated by :

CL = { usd

[(fiO - fiCF) / (fiCF - fiU)] + ufs (1/fSO - 1/fSCF) / (1/fSCF -1/fSU) } / (usd + ufs)

all i

where fsCF, fsU and fsO are the weight fractions of total solids in the cyclones feed, underflow and overflow streams,

respectively, and also usd and ufs are user defined weighting factors included to represent the relative quality and reliability

of the size distribution measurements vs. the percent solids measurements in all 3 streams. In general, a high relative

value of a weighting factor is indicative of a more reliable measurement with respect to the other measurements

participating in the same equations. A statistically sound weighting factor may be calculated as 100/(% error) 2;

Moly-Cop Tools / 226496712.xls.ms_office

Page 1

5/5/2014 / 1:22 PM

Moly-Cop Tools, Version 2.0

About the Ballbal_Direct Spreadsheet ...

where (% error) corresponds to the combined sampling and measuring error percentage. Weighting factors must never be

set equal to zero.

The least-square minimization problem stated above may be linearized and solved through the Lagrange Multipliers

Method (see About ... in Cyclobal_Single).

Further refinement of the adjusted values so computed is achieved by imposing the condition that these values must

conform to the Plitt's Classification Efficiency curve : (see About ... in Cyclosim_Single)

Ei = Bpf + (1 - Bpf ) (1 - exp [ - 0.693 (di/d50c)m ])

with the aid of the Excel Subroutine Solver to minimize a least-square error objective function with respect to parameters

Bpf, d50c and m.

Finally, the size distributions for the remaining streams of the circuit (fresh feed, mill feed and mill discharge) are

calculated on the basis of the adjusted values so obtained.

Data Input and Program Execution :

Most of the data required by the model must be defined in each corresponding unprotected white background cell inside the red double-lined border - of the here attached Data_File worksheet. Gray background cells contain the results

of the corresponding formula there defined and are protected to avoid any accidental editing.

The remaining information required to run the program is entered in the Control_Panel worksheet, where the user is

requested to provide initial guesses of the Bpf, d50c and m parameters (see About ... in Cyclosim_Single). The Bpc

parameter is rarely used and was incorporated to take into account the possible short-circuit of coarse particles to the

overflow (as could be the case in highly pressurized cyclones). Finally, the user must specify the relative weighting factors

for the various feed, underflow and overflow streams plus the relative weighting factors for the size distribution and

percent solids measurements.

To run the program, select the objective function Cell E23 in Control_Panel and then, from the Tools Menu, select

Solver ..., then Min and then By Changing any combination of Cells C21:F21. Clicking on the Solve button will execute

the desired calculations.

Important Notice : Solver ... must be run every time any element of input data gets to be modified. Otherwise, the

current outputs are not valid.

Calculation results are summarized in the Reports worksheet.

New Moly-Cop Tools users are invited to explore the brief comments inserted in each relevant cell, rendering the whole

utilization of the worksheets self-explanatory. Eventually, the user may wish to remove the view of the comments by

selecting Tools / Options / View / Comments / None.

Moly-Cop Tools / 226496712.xls.ms_office

Page 2

5/5/2014 / 1:22 PM

Moly-Cop Tools

TM

(Version 2.0)

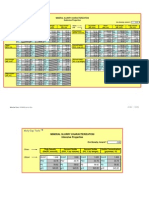

Ballbal_Direct : MASS BALANCE CLOSURE AROUND A BALL MILL GRINDING CIRCUIT

Sample N

Weighting Factors :

Streams :

Fresh Feed

Mill Discharge

Cyclone Feed

Cyclone U'flow

Cyclone O'flow

0

1

1

1

1

Size Distributions

% Solids

1

1

Initial Guesses :

Bpf

Bpc

0.372

0.000

d50c

179.8

% Passing

100

10

m

1.619

Mill Discharge

Cyclone U'flow

Obj. Function :

Classifier Constants :

a1

a2

a3

a4

l

0.005

Cyclone O'flow

Fresh Feed

9.68

1.401

54.95

0.524

0.950

Moly-Cop Tools / 226496712.xls.ms_office

1

10

100

1000

10000

Particle Size, microns

Note : Current calculations are not valid, if SOLVER has not been run after the last data modification.

5/5/2014 / 1:22 PM

Moly-Cop Tools

TM

(Version 2.0)

BALLBAL : Mass Balance Closure around a Ball Mill Grinding Circuit

Circuit Type

DIRECT

Remarks

Sample N

Base Case Example

Mill Dimensions and Operating Conditions

Eff. Diam. Eff. Length

Speed

Charge

ft

ft

% Critical

Filling,%

18.5

22.0

72.0

38.00

rpm

12.82

Balls

Filling,%

38.00

Cyclone Dimensions (inches) and Operating Pressure (psi)

Number

Diameter

Height

Inlet

Vortex

10

20.0

75.0

3.50

7.50

Default Values:

60.0

5.0

7.0

Interstitial

Slurry Filling,%

100.00

Apex

3.67

3.5

Lift

Angle, ()

35.0

3348

0

536

3885

10.0

4316

Balls

Overfilling

Slurry

Net Power

% Losses

Gross kW

Charge

Volume,

m3

63.76

psi

7.98

Mill Charge Weight, tons

Ball

Slurry

Charge

Interstitial

Excess

296.48

47.48

0.00

Feedrate, ton/hr (dry)

400.0

Ore Density, ton/m3

Balls Density, ton/m3

2.80

7.75

Apparent

Density

ton/m3

5.395

EXPERIMENTAL SIZE DISTRIBUTIONS

i

Mesh

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

1.05

0.742

0.525

0.371

3

4

6

8

10

14

20

28

35

48

65

100

150

200

270

400

-400

Opening

25400

19050

12700

9500

6700

4750

3350

2360

1700

1180

850

600

425

300

212

150

106

75

53

38

0

Totals

% Solids

Slurry Density, ton/m3

Weighting Factor

Moly-Cop Tools / 226496712.xls.ms_office

Mid-Size

21997

15554

10984

7978

5641

3989

2812

2003

1416

1001

714

505

357

252

178

126

89

63

45

19

ton/hr

0.00

20.00

66.40

56.28

41.32

33.36

27.36

21.64

20.40

15.60

14.16

12.04

10.36

8.84

7.52

6.48

5.52

4.72

3.40

24.60

400.00

Fresh Feed

% Retained % Passing

0.00

5.00

16.60

14.07

10.33

8.34

6.84

5.41

5.10

3.90

3.54

3.01

2.59

2.21

1.88

1.62

1.38

1.18

0.85

6.15

100.00

100.00

100.00

95.00

78.40

64.33

54.00

45.66

38.82

33.41

28.31

24.41

20.87

17.86

15.27

13.06

11.18

9.56

8.18

7.00

6.15

0.00

95.00

2.569

0.000

ton/hr

Mill Discharge

% Retained % Passing

0.00

13.69

31.26

30.71

27.88

29.03

33.26

38.59

50.47

59.40

75.81

92.58

107.08

108.22

94.65

74.57

55.19

40.68

29.37

230.40

1222.84

0.00

1.12

2.56

2.51

2.28

2.37

2.72

3.16

4.13

4.86

6.20

7.57

8.76

8.85

7.74

6.10

4.51

3.33

2.40

18.84

100.00

100.00

100.00

98.88

96.32

93.81

91.53

89.16

86.44

83.28

79.16

74.30

68.10

60.53

51.77

42.92

35.18

29.08

24.57

21.24

18.84

0.00

72.00

1.862

1.000

ton/hr

0.00

18.17

41.49

40.76

37.01

38.53

44.14

51.21

66.98

78.83

100.61

122.86

142.11

143.62

125.60

98.97

73.25

53.99

38.98

305.76

1622.84

Cyclone Feed

% Retained % Passing

0.00

1.12

2.56

2.51

2.28

2.37

2.72

3.16

4.13

4.86

6.20

7.57

8.76

8.85

7.74

6.10

4.51

3.33

2.40

18.84

100.00

100.00

100.00

98.88

96.32

93.81

91.53

89.16

86.44

83.28

79.16

74.30

68.10

60.53

51.77

42.92

35.18

29.08

24.57

21.24

18.84

0.00

62.20

1.666

1.000

ton/hr

Cyclone U'flow

% Retained % Passing

0.00

18.17

41.49

40.76

37.01

38.53

44.14

51.21

66.98

78.83

100.51

120.92

131.20

116.40

85.79

56.90

36.44

24.14

16.23

117.22

1222.84

0.00

1.49

3.39

3.33

3.03

3.15

3.61

4.19

5.48

6.45

8.22

9.89

10.73

9.52

7.02

4.65

2.98

1.97

1.33

9.59

100.00

100.00

100.00

98.51

95.12

91.79

88.76

85.61

82.00

77.81

72.34

65.89

57.67

47.78

37.05

27.54

20.52

15.87

12.89

10.91

9.59

0.00

76.00

1.955

1.000

ton/hr

Cyclone O'flow

% Retained % Passing

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.10

1.94

10.90

27.23

39.81

42.06

36.81

29.86

22.75

188.54

400.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.02

0.49

2.73

6.81

9.95

10.52

9.20

7.46

5.69

47.13

100.00

100.00

100.00

100.00

100.00

100.00

100.00

100.00

100.00

100.00

100.00

100.00

99.97

99.49

96.76

89.96

80.00

69.49

60.29

52.82

47.13

0.00

40.00

1.346

1.000

5/5/2014 / 1:22 PM

Moly-Cop Tools

TM

(Version 2.0)

Sample N

Remarks

Base Case Example

psi

7.98

# of Cyclones

Vortex

Apex

10

7.50

3.67

% Solids

76.00

ton/hr

F80

400.0

9795

kWh/ton

Wio

40.00 % Solids

60.29 % - Size 18

150.0 P80

Circ. Load

m3/hr

0.372 Bpf

0.392 Bpw

Water,

m3/hr

10.79

15.08

Moly-Cop Tools / 226496712.xls.ms_office / Flowsheet

305.73

1566

Water,

m3/hr

355.1

% Solids

62.20

223.9

Gross kW

% Balls

% Critical

% Solids

4316.1

38.00

72.00

72.00

5/5/2014 / 1:22 PM

Moly-Cop ToolsTM, Version 2.0

Sample:

BALLBAL

Grinding Circuit Mass Balance Estimator

Remarks:

Base Case Example

CIRCUIT MASS BALANCE

Configuration : DIRECT

Ore, ton/hr

Water, m3/hr

Slurry, ton/hr

Slurry, m3/hr

Slurry Dens., ton/m3

% Solids (by volume)

% Solids (by weight)

Fresh

Feed

400.0

21.1

421.1

163.9

2.569

87.2

95.0

Mill

Mill

Feed

Discharge

1622.9

1622.9

407.3

631.1

2030.2

2254.1

986.9

1210.8

2.057

1.862

58.7

47.9

79.9

72.0

Sump

Water

0.0

355.1

355.1

355.1

1.000

0.0

0.0

Cyclone

Feed

1622.9

986.2

2609.2

1565.8

1.666

37.0

62.2

Cyclone

U'flow

1222.9

386.2

1609.2

823.0

1.955

53.1

76.0

Cyclone

O'flow

400.0

600.0

1000.0

742.9

1.346

19.2

40.0

Particle Size Distributions (Cummulative % Passing)

i

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Mesh

Opening

1.05

0.742

0.525

0.371

3

4

6

8

10

14

20

28

35

48

65

100

150

200

270

400

25400

19050

12700

9500

6700

4750

3350

2360

1700

1180

850

600

425

300

212

150

106

75

53

38

D80, microns

100.00

100.00

95.00

78.40

64.33

54.00

45.66

38.82

33.41

28.31

24.41

20.87

17.86

15.27

13.06

11.18

9.56

8.18

7.00

6.15

100.00

100.00

97.65

91.00

85.02

80.20

75.77

71.36

66.87

61.49

55.67

48.60

40.41

31.69

23.97

18.22

14.31

11.73

9.95

8.74

100.00

100.00

98.88

96.32

93.81

91.53

89.16

86.44

83.28

79.16

74.30

68.10

60.53

51.77

42.92

35.18

29.08

24.57

21.24

18.84

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

100.00

100.00

98.88

96.32

93.81

91.53

89.16

86.44

83.28

79.16

74.30

68.10

60.53

51.77

42.92

35.18

29.08

24.57

21.24

18.84

100.00

100.00

98.51

95.12

91.79

88.76

85.61

82.00

77.82

72.34

65.89

57.68

47.79

37.06

27.54

20.52

15.87

12.89

10.91

9.59

100.00

100.00

100.00

100.00

100.00

100.00

100.00

100.00

99.99

99.99

99.99

99.96

99.48

96.76

89.96

80.01

69.49

60.29

52.82

47.13

9795

4679

1273

1273

2021

150.0

Specific Energy Consumption :

Operational Work Index :

Moly-Cop Tools / 226496712.xls.ms_office

10.79 KWH/ton (Gross)

15.08 KWH/ton

Page 6

5/5/2014 / 1:22 PM

Moly-Cop ToolsTM, Version 2.0

Sample:

BALLBAL

Grinding Circuit Mass Balance Estimator

Remarks:

Base Case Example

CLASSIFIERS PERFORMANCE

Number of Cyclones :

Cyclone Dimensions, in :

Diameter

Height

Inlet

Vortex

Apex

Ore Density, ton/m3

10

Operating Conditions :

Feed Flowrate, m3/hr

Pressure, psi

D50 (corr.), microns

Water By-Pass, %

Solids By-Pass, %

Plitt's Parameter

Circulating Load, %

20.00

75.00

3.50

7.50

3.67

2.80

1565.8

8.0

179.8

39.2

37.2

1.62

306

Mass Balance around the Classifiers

i

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Mesh

1.05

0.742

0.525

0.371

3

4

6

8

10

14

20

28

35

48

65

100

150

200

270

400

Opening

25400

19050

12700

9500

6700

4750

3350

2360

1700

1180

850

600

425

300

212

150

106

75

53

38

Ore, ton/hr

Water, m3/hr

Slurry, ton/hr

Slurry, m3/hr

Slurry Dens., ton/m3

% Solids (by volume)

% Solids (by weight)

Moly-Cop Tools / 226496712.xls.ms_office

Mid-Size

21997

15554

10984

7978

5641

3989

2812

2003

1416

1001

714

505

357

252

178

126

89

63

45

19

Size Distributions, % Passing

Feed

U'flow

O'flow

100.00

100.00

98.88

96.32

93.81

91.53

89.16

86.44

83.28

79.16

74.30

68.10

60.53

51.77

42.92

35.18

29.08

24.57

21.24

18.84

100.00

100.00

98.51

95.12

91.79

88.76

85.61

82.00

77.82

72.34

65.89

57.68

47.79

37.06

27.54

20.52

15.87

12.89

10.91

9.59

100.00

100.00

100.00

100.00

100.00

100.00

100.00

100.00

99.99

99.99

99.99

99.96

99.48

96.76

89.96

80.01

69.49

60.29

52.82

47.13

1622.9

986.2

2609.2

1565.8

1.666

37.0

62.2

1222.9

386.2

1609.2

823.0

1.955

53.1

76.0

400.0

600.0

1000.0

742.9

1.346

19.2

40.0

Page 7

Classifier Efficiency

Actual

Corrected

1.000

1.000

1.000

1.000

1.000

1.000

1.000

1.000

1.000

1.000

0.999

0.984

0.923

0.811

0.683

0.575

0.497

0.447

0.416

0.383

1.000

1.000

1.000

1.000

1.000

1.000

1.000

1.000

1.000

1.000

0.998

0.975

0.878

0.698

0.495

0.323

0.200

0.119

0.071

0.018

Classifier Constants

a1

9.680

a2

1.401

a3

54.950

a4

0.524

l

0.950

Bpc

0.000

5/5/2014 / 1:22 PM

Moly-Cop ToolsTM, Version 2.0

Sample:

BALLBAL

Grinding Circuit Mass Balance Estimator

Remarks:

Base Case Example

BALL MILL PERFORMANCE

Eff. Diameter, ft

Eff. Length, ft

Speed, % Critical

App. Density, ton/m3

Charge Level, %

Balls Filling, %

Lift Angle, ()

i

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Mesh

1.05

0.742

0.525

0.371

3

4

6

8

10

14

20

28

35

48

65

100

150

200

270

400

Opening

25400

19050

12700

9500

6700

4750

3350

2360

1700

1180

850

600

425

300

212

150

106

75

53

38

Mill Power, kW (Gross)

Mill Power, kW (Net)

Throughput, ton/hr

% Solids (by weight)

Sp. Energy, KWH/ton

Reduction Ratio

Arbiter's Flow Number

18.5

22.0

72.0

5.39

38.0

38.0

35.0

Size Distributions

Mill

Mill

Feed

Discharge

Mid-Size

21997

15554

10984

7978

5641

3989

2812

2003

1416

1001

714

505

357

252

178

126

89

63

45

19

D80, microns

Moly-Cop Tools / 226496712.xls.ms_office

4316

3885

1622.9

79.9

2.66

3.67

2.47

Page 8

100.00

100.00

97.65

91.00

85.02

80.20

75.77

71.36

66.87

61.49

55.67

48.60

40.41

31.69

23.97

18.22

14.31

11.73

9.95

8.74

100.00

100.00

98.88

96.32

93.81

91.53

89.16

86.44

83.28

79.16

74.30

68.10

60.53

51.77

42.92

35.18

29.08

24.57

21.24

18.84

4679

1273

5/5/2014 / 1:22 PM

Number of Cyclones

10

Classifier Dimensions, inches.

DC

h

DI

DO

DU

20

75

3.5

7.5 3.66950756

Classifier Constants

a1

a2

a3

a4

l

9.6796047 1.40108488 54.9499769 0.52420218 0.95014792

Circulating Load, CL

3.05734845

Slurry Split, S

1.10786196

Cyclone Pressure, ft

11.0562088

Cyclone Pressure, lb/in2

7.98

Corrected Cut Size, d50c, microns

179.777474

Water By-Pass

0.39161592

Fines By-Pass

0.37209305

Coarse By-Pass

8.9094E-05

Plitt's Parameter

1.61945494

Opening

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

25400

19050

12700

9500

6700

4750

3350

2360

1700

1180

850

600

425

300

212

150

106

Mid-Size

21997.0453

15554.2599

10984.0794

7978.09501

5641.36508

3989.04751

2811.76101

2002.99775

1416.33329

1001.49888

714.142843

504.975247

357.071421

252.190404

178.325545

126.095202

Solids, tons

Water, m3/hr

Slurry, tons

Slurry, m3/hr

Solids Density, ton/m3

Slurry Density, ton/m3

% Solids (by volume)

% Solids (by weight)

Classifier

Efficiency

Cyclone

Cyclone

Cyclone

Feed

U'flow

O'flow

162.28

122.29 39.9976596

98.62

38.62

60.00

260.900583 160.906434 99.9941491

156.57487 82.2935019 74.2813679

2.8

2.8

2.8

1.66629922 1.95527508 1.34615385

37.0166231 53.0708379 19.2307692

62.20

76.00

40.00

Cyclone

Feed

0.99991091

0.99991091

0.99991091

0.99991091

0.99991091

0.99991091

0.99991091

0.99991091

0.9999109

0.99990221

0.99893774

0.98424486

0.92345509

0.8106073

0.68310439

0.57492387

0.00

18.17

41.49

40.76

37.01

38.53

44.14

51.21

66.98

78.83

100.61

122.86

142.11

143.62

125.60

98.97

Page 9

ton/hr (model)

Cyclone

Cyclone

U'flow

O'flow

0

18.1704205

41.4863539

40.7527943

37.0027718

38.52856

44.1313704

51.2035787

66.9702371

78.8207828

100.498739

120.925168

131.228132

116.420874

85.800946

56.8973834

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.01

0.01

0.11

1.94

10.88

27.20

39.80

42.07

18

19

20

21

75

53

38

0

89.1627725

63.0476011

44.8776113

19

0.49738363

0.44696565

0.41642412

0.38341866

Total

Page 10

73.25

53.99

38.98

305.76

36.4322838

24.1322881

16.2315388

117.233604

36.82

29.86

22.75

188.53

1622.84

1222.87

399.98

% Retained (model)

Cyclone

Cyclone

Cyclone

Feed

U'flow

O'flow

0.00

1.12

2.56

2.51

2.28

2.37

2.72

3.16

4.13

4.86

6.20

7.57

8.76

8.85

7.74

6.10

0.00

1.49

3.39

3.33

3.03

3.15

3.61

4.19

5.48

6.45

8.22

9.89

10.73

9.52

7.02

4.65

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.03

0.48

2.72

6.80

9.95

10.52

% Passing (model)

Cyclone

Cyclone

Cyclone

Feed

U'flow

O'flow

100.00

100.00

98.88

96.32

93.81

91.53

89.16

86.44

83.28

79.16

74.30

68.10

60.53

51.77

42.92

35.18

29.08

100.00

100.00

98.51

95.12

91.79

88.76

85.61

82.00

77.82

72.34

65.89

57.68

47.79

37.06

27.54

20.52

15.87

Cyclone

Feed

100.00

100.00

100.00

100.00

100.00

100.00

100.00

100.00

99.99

99.99

99.99

99.96

99.48

96.76

89.96

80.01

69.49

Page 11

% Passing (exp)

Cyclone

Cyclone

U'flow

O'flow

100.00

100.00

98.88

96.32

93.81

91.53

89.16

86.44

83.28

79.16

74.30

68.10

60.53

51.77

42.92

35.18

29.08

100.00

100.00

98.51

95.12

91.79

88.76

85.61

82.00

77.81

72.34

65.89

57.67

47.78

37.05

27.54

20.52

15.87

100.00

100.00

100.00

100.00

100.00

100.00

100.00

100.00

100.00

100.00

100.00

99.97

99.49

96.76

89.96

80.00

69.49

Cyclone

Feed

(Weighted Error)^2

Cyclone

U'flow

1

1

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

4.51

3.33

2.40

18.84

2.98

1.97

1.33

9.59

9.20

7.47

5.69

47.13

100.00

100.00

100.00

24.57

21.24

18.84

12.89

10.91

9.59

60.29

52.82

47.13

24.57

21.24

18.84

12.89

10.91

9.59

60.29

52.82

47.13

0.000

0.000

0.000

0.000

0.000

0.000

0.000

Page 12

Error)^2

Cyclone

O'flow

1

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

Page 13

0.000

0.000

0.000

0.000

Overall

0.000

Page 14

You might also like

- Scope:: About The Ballbal - Direct Spreadsheet ..Document18 pagesScope:: About The Ballbal - Direct Spreadsheet ..Erik Huarcaya SalcedoNo ratings yet

- Introduction to the simulation of power plants for EBSILON®Professional Version 15From EverandIntroduction to the simulation of power plants for EBSILON®Professional Version 15No ratings yet

- Scope:: About The Ballbal - Direct Spreadsheet ..Document14 pagesScope:: About The Ballbal - Direct Spreadsheet ..alonsogonzalesNo ratings yet

- Copia de Copy of Ballbal - Direc - Mol I (03!06!15)Document30 pagesCopia de Copy of Ballbal - Direc - Mol I (03!06!15)Travis BradyNo ratings yet

- Investigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsFrom EverandInvestigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsNo ratings yet

- Scope:: About The Ballbal - Reverse Spreadsheet ..Document15 pagesScope:: About The Ballbal - Reverse Spreadsheet ..julio carpio FrancoNo ratings yet

- Modeling and Simulation of Thermal Power Plants with ThermoSysPro: A Theoretical Introduction and a Practical GuideFrom EverandModeling and Simulation of Thermal Power Plants with ThermoSysPro: A Theoretical Introduction and a Practical GuideNo ratings yet

- Scope:: About The Ballbal - Reverse Spreadsheet ..Document12 pagesScope:: About The Ballbal - Reverse Spreadsheet ..snarf273No ratings yet

- CycloBal SingleDocument13 pagesCycloBal SinglevirginialeaoNo ratings yet

- Scope:: About The Ballbal - Direct Spreadsheet ..Document19 pagesScope:: About The Ballbal - Direct Spreadsheet ..M. Ali ParvezNo ratings yet

- Scope:: About The Cyclobal - Single Spreadsheet ..Document18 pagesScope:: About The Cyclobal - Single Spreadsheet ..Gaby Nancy Catura MaynaNo ratings yet

- Scope:: About The Ballbal - Reverse Spreadsheet ..Document14 pagesScope:: About The Ballbal - Reverse Spreadsheet ..lewis poma rojasNo ratings yet

- Balance de HidrociclonDocument13 pagesBalance de HidrociclonFlavioCesarChirmeSisaNo ratings yet

- Ballbal ReversedfdfdfdDocument14 pagesBallbal ReversedfdfdfdnoseNo ratings yet

- Ballbal DirectDocument14 pagesBallbal DirectGonzalo LopezNo ratings yet

- BallParam - Reverse Ejemplo N°5Document70 pagesBallParam - Reverse Ejemplo N°5RDario Dario RosemaryNo ratings yet

- Scope:: Cyclosim - Single) and The Estimation of The Characteristic Ore Grinding ParametersDocument55 pagesScope:: Cyclosim - Single) and The Estimation of The Characteristic Ore Grinding ParametersAldo PabloNo ratings yet

- BallParam DirectDocument52 pagesBallParam DirectThaigroup CementNo ratings yet

- CycloSim SingleDocument124 pagesCycloSim SingleGaby Nancy Catura MaynaNo ratings yet

- Cyclosim SingleDocument10 pagesCyclosim SingleRolando QuispeNo ratings yet

- BgalDocument13 pagesBgalFiqa SuccessNo ratings yet

- CHAPT 12a PDFDocument2 pagesCHAPT 12a PDFindocode100% (1)

- CycloSim SingleDocument12 pagesCycloSim Singlejvchique100% (1)

- Cyclosim SingleDocument12 pagesCyclosim SingleAch_The_KingNo ratings yet

- Section 1: Introduction To ReliabilityDocument30 pagesSection 1: Introduction To ReliabilitysukhmeetNo ratings yet

- 05 Degree of Freedom AnalysisDocument6 pages05 Degree of Freedom AnalysisLucas Wang100% (1)

- BallParam Batch MultiTestDocument327 pagesBallParam Batch MultiTestlewis poma rojasNo ratings yet

- Scope:: About The Ballparam - Direct Spreadsheet ..Document47 pagesScope:: About The Ballparam - Direct Spreadsheet ..Anderson D. CTNo ratings yet

- Back Allocation Overview 4442573 01Document12 pagesBack Allocation Overview 4442573 01Ledavid Leonel Flores Rivera100% (1)

- Models - Mixer.centrifugal PumpDocument22 pagesModels - Mixer.centrifugal Pumpcarlos tNo ratings yet

- Chapter 2Document40 pagesChapter 2Halkawt G MuhammadNo ratings yet

- Handout 2Document22 pagesHandout 2aaa206No ratings yet

- Mediacharge Dynamics BallMillsDocument30 pagesMediacharge Dynamics BallMillstanainaNo ratings yet

- Equalization ExampleDocument7 pagesEqualization ExampleDanang M AbroriNo ratings yet

- Cyclosim SingleDocument9 pagesCyclosim SinglehadryanaNo ratings yet

- User Manual For Rate Time SpreadsheetDocument15 pagesUser Manual For Rate Time SpreadsheetJorge Leopoldo VeraNo ratings yet

- Chap 10DDocument4 pagesChap 10DToat SumohandoyoNo ratings yet

- Pipenet Vision Spraysprinkler ModuleDocument48 pagesPipenet Vision Spraysprinkler ModuleElton Situmeang50% (2)

- SAGParam OpenDocument129 pagesSAGParam OpenCristian Riquelme ContrerasNo ratings yet

- Managerial Accounting Somnath Das: StandardDocument6 pagesManagerial Accounting Somnath Das: StandardShah GeeNo ratings yet

- Ballsim ReverseDocument58 pagesBallsim Reversesnarf273No ratings yet

- BG3801 L8 Simulations of Physiological Control System Using SimulinksDocument14 pagesBG3801 L8 Simulations of Physiological Control System Using SimulinksNur Farahin NasrunNo ratings yet

- Computational Fluid Dynamics: Práticas de Engenharia Química IvDocument37 pagesComputational Fluid Dynamics: Práticas de Engenharia Química IvPedro SilvaNo ratings yet

- Chapter1 Design of Multicomponent Distillation Column................................................. 2Document12 pagesChapter1 Design of Multicomponent Distillation Column................................................. 2waleed ur rehmanNo ratings yet

- Managerial Economics (M.com IVth Sem.) - M COM IV 26-4Document9 pagesManagerial Economics (M.com IVth Sem.) - M COM IV 26-4za714521No ratings yet

- Scope:: About The Cyclosim - Single Spreadsheet ..Document14 pagesScope:: About The Cyclosim - Single Spreadsheet ..Flia Diaz ZunigaNo ratings yet

- Coriolis Flow Meter FSI Workshop 15.0Document22 pagesCoriolis Flow Meter FSI Workshop 15.0Reza NazariNo ratings yet

- Chapter 3 Process SimulationDocument19 pagesChapter 3 Process SimulationYang Yew Ren100% (1)

- Optimization of Separation Process: Distillation ColumnDocument28 pagesOptimization of Separation Process: Distillation ColumnAnonymous rIu5j3yNo ratings yet

- Models - Cfd.water Purification ReactorDocument11 pagesModels - Cfd.water Purification ReactorzaidNo ratings yet

- Cyclosim SingleDocument8 pagesCyclosim SingleEmiliano GilNo ratings yet

- AERODYNAMIC NOISE Worksheet InstructionsDocument6 pagesAERODYNAMIC NOISE Worksheet InstructionsMuhammad Adil KhanNo ratings yet

- Workshop 2 P-Only Control of Tank LevelDocument5 pagesWorkshop 2 P-Only Control of Tank LevelJoselyn ChewNo ratings yet

- Matlab GUI For A Fluid Mixer: Sponsor ID NAG13-03006Document12 pagesMatlab GUI For A Fluid Mixer: Sponsor ID NAG13-03006bavar88No ratings yet

- Balsim DualDocument53 pagesBalsim Dualsnarf273No ratings yet

- Propylene-Propane - Howat Swift - McCabe ThieleDocument19 pagesPropylene-Propane - Howat Swift - McCabe ThieleFred FaberNo ratings yet

- Design and AnalysisDocument5 pagesDesign and AnalysiscliveNo ratings yet

- EpibrwDocument4 pagesEpibrwsnarf273No ratings yet

- Less Is MoreDocument3 pagesLess Is Moresnarf273No ratings yet

- On-Line Slurry Particle Size AnalyzerDocument8 pagesOn-Line Slurry Particle Size Analyzersnarf273No ratings yet

- EpibrwDocument12 pagesEpibrwsnarf273No ratings yet

- EpibrwDocument12 pagesEpibrwsnarf273No ratings yet

- Outotec Grinding 2012 Low ResDocument7 pagesOutotec Grinding 2012 Low Ressnarf273No ratings yet

- EpibrwDocument8 pagesEpibrwsnarf273No ratings yet

- Case Study: Minerals Processing SolutionsDocument4 pagesCase Study: Minerals Processing Solutionssnarf273No ratings yet

- Slurry Sampling: Slurry Sampling For On-Line Analysis and AccountingDocument8 pagesSlurry Sampling: Slurry Sampling For On-Line Analysis and Accountingsnarf273No ratings yet

- Contact Cell Info - Gen PDFDocument10 pagesContact Cell Info - Gen PDFsnarf273No ratings yet

- Advanced Control ToolsDocument10 pagesAdvanced Control Toolssnarf273No ratings yet

- SPI Vs JK-EN PDFDocument1 pageSPI Vs JK-EN PDFsnarf273No ratings yet

- Courier HX: High-Performance On-Stream Solution Analyzer SystemDocument8 pagesCourier HX: High-Performance On-Stream Solution Analyzer Systemsnarf273No ratings yet

- SAGSim RecycleDocument197 pagesSAGSim Recyclesnarf273No ratings yet

- Media Charge TrajectoriesDocument9 pagesMedia Charge Trajectoriessnarf273No ratings yet

- SPI Vs JK-EN PDFDocument1 pageSPI Vs JK-EN PDFsnarf273No ratings yet

- Utilities Size DistributionDocument3 pagesUtilities Size DistributionAndrés Mancilla BustamanteNo ratings yet

- Fuersteneau Power Model (See Mill Power - Ball Mills Spreadsheet For Further Details On Such Model)Document3 pagesFuersteneau Power Model (See Mill Power - Ball Mills Spreadsheet For Further Details On Such Model)Rolando QuispeNo ratings yet

- Scope:: About The Media Charge - Level Spreadsheet ..Document4 pagesScope:: About The Media Charge - Level Spreadsheet ..snarf273No ratings yet

- Utilities Conv FactorsDocument4 pagesUtilities Conv FactorsingequimicaNo ratings yet

- Utilities SlurriesDocument2 pagesUtilities Slurriessnarf273No ratings yet

- Media Charge MBWTDocument6 pagesMedia Charge MBWTsnarf273No ratings yet

- Fuersteneau Power Model (See Mill Power - Ball Mills Spreadsheet For Further Details On Such Model)Document3 pagesFuersteneau Power Model (See Mill Power - Ball Mills Spreadsheet For Further Details On Such Model)Rolando QuispeNo ratings yet

- Ballbal DirectDocument13 pagesBallbal DirectDavid RojasNo ratings yet

- Cyclobal SingleDocument11 pagesCyclobal SingleRolando QuispeNo ratings yet

- Balsim DualDocument53 pagesBalsim Dualsnarf273No ratings yet

- Cyclosim SingleDocument10 pagesCyclosim SingleRolando QuispeNo ratings yet

- Cyclobal SingleDocument11 pagesCyclobal SingleRolando QuispeNo ratings yet

- Mean Value of A Series Against A Fix Reference Value: Moly-Cop Tools (Version 2.0)Document3 pagesMean Value of A Series Against A Fix Reference Value: Moly-Cop Tools (Version 2.0)snarf273No ratings yet

- Ballsim ReverseDocument58 pagesBallsim Reversesnarf273No ratings yet

- Sustainable Production of Acrolein: Investigation of Solid Acid-Base Catalysts For Gas-Phase Dehydration of GlycerolDocument7 pagesSustainable Production of Acrolein: Investigation of Solid Acid-Base Catalysts For Gas-Phase Dehydration of GlycerolnayarapradoNo ratings yet

- Fruit Recognition Deep LearningDocument53 pagesFruit Recognition Deep Learningsaran20099No ratings yet

- Brochure Tialoc Chemical Resistant Piping Systems: Page 1 of 20Document20 pagesBrochure Tialoc Chemical Resistant Piping Systems: Page 1 of 20Fernando Cesar PérezNo ratings yet

- GLR EstimateDocument2 pagesGLR EstimateanbujeNo ratings yet

- LBS SchneiderDocument20 pagesLBS SchneiderTien Dang ThanhNo ratings yet

- AMIA Definition of Biomedical InformaticsDocument15 pagesAMIA Definition of Biomedical InformaticsAndre FrancoNo ratings yet

- Network AssignmentDocument4 pagesNetwork AssignmentOsamah ElaiwahNo ratings yet

- Science 6 Special - Properties of MatterDocument9 pagesScience 6 Special - Properties of MatterAxcyl Volleybolista PremaylonNo ratings yet

- ZipGrade User Guide JPDocument6 pagesZipGrade User Guide JPJinsen Paul MartinNo ratings yet

- Leeson Speedmaster ManualDocument80 pagesLeeson Speedmaster ManualOrbán Árpád100% (1)

- 7) Progress PaymentDocument5 pages7) Progress Paymentkerwin jayNo ratings yet

- Multiple-Unit Material Balances I: Cheme 101 - 6.4 Worksheet 1 Semester Ay 2020-2021 Department of Chemical EngineeringDocument6 pagesMultiple-Unit Material Balances I: Cheme 101 - 6.4 Worksheet 1 Semester Ay 2020-2021 Department of Chemical EngineeringAcademicBMNo ratings yet

- Manual For Powermatic BD31A Combination Belt and Disc SanderDocument28 pagesManual For Powermatic BD31A Combination Belt and Disc SanderJack BowenNo ratings yet

- Liebherr Hydraulic Components For Heavy Duty On Highway Engines Application Flyer Es WebDocument4 pagesLiebherr Hydraulic Components For Heavy Duty On Highway Engines Application Flyer Es WebDaniel Castillo PeñaNo ratings yet

- Credazone 6 GiudeDocument3 pagesCredazone 6 Giudeguddu84No ratings yet

- LIDO Introduction PDFDocument127 pagesLIDO Introduction PDFStiliyana Bakalova100% (2)

- BSC (Hons) in Civil EngineeringDocument33 pagesBSC (Hons) in Civil EngineeringFaisal NazeerNo ratings yet

- Solvent Extraction: Please Submit Question 4 For MarkingDocument3 pagesSolvent Extraction: Please Submit Question 4 For MarkingThembi Matebula100% (1)

- FonaDocument36 pagesFonaiyadNo ratings yet

- Nokia 5310 Service Manual Level 1 and 2Document16 pagesNokia 5310 Service Manual Level 1 and 2adybosss100% (1)

- Create Your Own Operating System - Lucus DarnellDocument138 pagesCreate Your Own Operating System - Lucus DarnellRahul Rana100% (6)

- Load TablesDocument3 pagesLoad Tablesidinjan.ashtariNo ratings yet

- Instruction ManualDocument462 pagesInstruction ManualCaraluaNo ratings yet

- Guide For High Performance CoatingsDocument34 pagesGuide For High Performance Coatingsro snNo ratings yet

- S. No. Unit: (Ch. 23 Item 7)Document4 pagesS. No. Unit: (Ch. 23 Item 7)Muhammad Abdul Wajid RaiNo ratings yet

- TR200 Surface Tester ManualDocument3 pagesTR200 Surface Tester Manualprasadjoshi781429No ratings yet

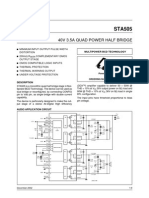

- STA505Document10 pagesSTA505kizonzNo ratings yet

- Refrigeration Orrifice Selection Chart PDFDocument2 pagesRefrigeration Orrifice Selection Chart PDFMacSpares100% (1)

- Via Fill PlugDocument7 pagesVia Fill PluganeeshdNo ratings yet

- OMN-FAC-411 - Piping General RequirementsDocument38 pagesOMN-FAC-411 - Piping General RequirementsvinodNo ratings yet