Professional Documents

Culture Documents

Astm Standard Specification For Chemical Pasivation Treatments For Stainless Steel A967

Uploaded by

ramquimicaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Astm Standard Specification For Chemical Pasivation Treatments For Stainless Steel A967

Uploaded by

ramquimicaCopyright:

Available Formats

&Designation: A 967 - 01

E1

~L~

INTERNATIONAL

Standard Specification for

Chemical Passivation Treatments for Stainless Steel Parts

1

This standard. is issued under the fixed designation A 967; the number immediately following the designation indicates the year of

original adoption or. Inthe case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscnpt epsilon (E) indicates an editorial change since the last revision or reapproval.

(' NOTE-Paragraph 3. I. 1.5 was deleted editorially in Apl;1 2002. Paragraph 10.2 was corrected editOlially in April 2002.

1. Scope

1.1 This specification covers several different types of

chemical passivation treatments for stainless steel parts. It

includes recommendations and precautions for descalinz

'"

cleaning, and passivation of stainless steel parts. It includes

several alternative tests, with acceptance criteria, for confirma-

tion of effectiveness of such treatments for stainless steel parts.

1.2 Practices for the mechanical and chemical treatments of

stainless steel surfaces are discussed more thoroughly in

Practice A 380. "

1.3 Several alternative chemical treatments are defined for

passivation of stainless steel parts. Appendix Xl gives some

nonmandatory information and provides some general guide-

lines regarding the selection of passivation treatment appropri-

ate to particular grades of stainless steel but makes no

recommendations regarding the suitability of any grade, treat-

\...J ment, and acceptance criteria for any particular application or

class of applications.

1.4 The tests inthis specification are intended toconfirmthe

effectiveness of passivation, particularly with regard to the

removal of free iron and other exogenous matter. These tests

include the following practices:

1.4.1 Practice A-Water Immersion Test,

1.4.2 Practice B-High Humidity Test,

1.4.3 Practice C-Salt Spray Test,

1.4.4 Practice D-Copper Sulfate Test,

1.4.5 Practice E-Potassium Ferricyanide-Nitric Acid Test,

and

1.4.6 Practice F-Free Iron Test.

1.5 The values stated in inch-pound units areto beregarded

as the standard. The SI units given in parentheses are for

information only.

1.6 The following precautionary caveat pertains only to the

test method portions, Sections 14through 18of this specifica-

tion: This standard does not purport to address all of the safety

concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and

I This specification is under the jurisdiction of ASTM Committee AOI on Steel,

Stainless Steel, and Related Alloys and is the direct responsibility of Subcommittee

AO1.14 on Methods of Corrosion Testing.

Current edition approved Oct. 10, :!OOI. Published December 2001. Originally

published as A 967 - 96. Last previoius edilion A 967 - 99.

health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

A 380 Practice for Cleaning, Descaling, and Depassivation

of Stainless Steel Parts, Equipment, and Systems?

B 117 Practice for Operating Salt Spray (Fog) Apparatus"

B 254 Practice for Preparation of and Electroplating on

S t a i n l e s s S t e e l

4

2.2 Federal Specification:

QQ-P-35C Passivation Treatments for Corrosion-Resistant

Steels"

3. Terminology

3.1 Definition of Term Specific to This Standard-s-is is

necessary to define which of the several commonly used

definitions of the term passivation will be used in this

specification. (See Discussion.)

3.1.1 Discussioll-StainJess steels areautopassivating inthe

sense that the protective passive filmis formed spontaneously

on exposure to air or moisture. The presence of exogenous

surface contamination, including dirt, grease, free iron from

contact with steel tooling, and so forth, may interfere with the

formation of the passive film. The cleaning of these contami-

nants from the stainless steel surface will facilitate the spon-

taneous passivation by allowing the oxygen uniform access to

the surface. The passive film may be augmented by chemical

treatments that provide an oxidizing environment for the

stainless steel surface.

3.1.1.1 In this specification, passivation, unless otherwise

specified, is defined as the chemical treatment of a stainless

steel with amild oxidant, such as a nitric acid solution, for the

purpose of theremoval of free iron or other foreign matter, but

which is generally not effective inremoval of heat tint or oxide

scale on stainless steel. In the case of stainless steels with

additions of sulfur for the purpose of improved machinability,

2 Annual Book of ASTM Standards, Vol 01.03.

-'Annual Book of ASTM Standards, Vol 03.02.

, Annual Book of ASTM Standards, Vol 02.05.

5 Available from Superintendent of Documents, U.S. Government Printing

Office, Washington. DC 20402.

Copyrighl ASTM tnternational, 100 Barr Harbor Drive. PO BoxClOO. West Conshohocken. PA 194282959, United States.

AA967-01E1

ulf

passivation may also include the removal of sulfides from the

surface of the metal for the purpose of maximizing corrosion

resistance.

3.1.l.2 The formation of the protective passive film on a

stainless steel, also called passivation in a more general

context, will occur spontaneously in air or other oxygen-

containing environment when the stainless steel surface is free

of oxide scale and exogenous matter.

3.1.1.3 Chemical treatments, such as sodium dichromate

solutions, may facilitate the more rapid formation of the

passive filmon astainless steel surface already free of scale or

foreign matter. Such treatments, also sometimes called passi-

vation in common usage, are designated as post-cleaning

treatments in this specification in order to distinguish them

from chemical treatments capable of removing free iron from

stainless steels.

3.1.1.4 The chemical treatments capable of removing heat

tint or oxide scalefromstainless steel andcapable of dissolving

the stainless steel itself, typically called pickling, are substan-

tially more aggressive than treatments used for passivation, as

defined in 3.l.l.l. The surface of stainless steel that has been

pickled is free of scale, free iron, and exogenous foreign

matter, and does not require a separate treatment for passiva-

tion as defined in 3.1.1.1. The passivation process defined in

3.1.1.2 will occur without further chemical treatment but may

be augmented and improved by the post-cleaning treatments

defined in 3.1.1.3.

3.1.1.5 Electrochemical treatments, including electropick-

lingandelectropolishing capable of removing heat tint or oxide

~ scalefromstainless steel and capable of dissolving thestainless

steel itself, are substantially more aggressive than treatments

used for passivation, as defined in 3.1.1.1. The surface of

stainless steel resulting from these treatments is free of scale,

free iron, and exogenous foreign matter, and does not require a

separate treatment for passivation as defined in 3.1.1.1. The

passivation process defined in 3.1.1.2 will occur without

further chemical treatment, but may be augmented and im-

proved by the post-cleaning treatments defined in 3.l.1.3.

Statements regarding chemical treatments, unless otherwise

specified, are taken to include electrochemical treatments.

4. Ordering Information

4.1 It is the responsibility of the purchaser to specify a test

practice appropriate to any particular material and application.

This specification was written for the purpose of providing an

alternative to United States Federal Specification QQ-P-35C.

Determination of the suitability of this specification for that

purpose is the responsibility of the purchaser.

4.2 Unless specified by the purchaser, the chemical treat-

ment applied to thestainless steel parts shall beselected by the

seller from among the listed passivation treatments.

5. Materials and Preparation for Passivation Treatments

5.1 The passivation treatments shall beof oneor moreof the

following types. The effectiveness of aparticular treatment for

aparticular grade of stainless steel inaparticular application is

demonstrated by meeting the specified testing requirements:

'---../ 5.1.1 Treatments in nitric acid,

5.1.2 Treatments in citric acid,

5.l.3 Other chemical treatments, including electrochemical

treatments,

5.1.4 Neutralization, and

5.1.5 Post-cleaning treatments.

5.2 Materials:

5.2.1 The chemicals used for passivation treatments shall

produce passivated surfaces that meet the requirements of one

or more of the tests of this specification. Attention shall be

given to maintaining adequate volume, concentration, purity,

and temperature control appropriate to the size and amount of

stainless steel to be treated.

5.2.2 The processor shall maintain a record with regard to

concentration and temperature of the passivation solution

sufficient to demonstrate that the specified passivation condi-

tions were maintained for each lot of stainless steel parts

processed. Such records shall beavailable for inspection when

specified inthepurchase order. The processor is not required to

reveal the precise composition of proprietary chemical mix-

tures but shall maintain a unique identification of the mixture

that will ensure its accurate representation for subsequent use.

5.2.3 The processor shall be responsible for the safe dis-

posal of all material generated by this process.

5.3 Preparation for Passivation Treatments:

5.3.1 The pretreatment methods and procedures used prior

to the passivation treatment, including mechanical and chemi-

cal methods, singly or in combination, for descaling and

pickling, shall be in accordance with Practice A 380. When

electrochemical cleaning is required, it shall be performed in

accordance with Practice B 254.

5.3.2 The resulting pretreated surface shall be substantially

free of oil, grease, rust, scale, and other foreign matter.

5.3.3 When thefinal pretreatment of apart includes pickling

of the entire surface of the part, no further passivation

treatment is required prior to testing of the surface unless

specified by the purchaser.

6. Treatments in Nitric Acid Solutions

6.1 Passivation Treatment:

6.l.1 Stainless steel parts shall be treated in one of the

following aqueous solutions and maintained within the speci-

fied temperature range for the specified time.

6.1.1.1 Nitric J-The solution shall contain 20to25 volume

percent of nitric acid and 2.5 +0.5 weight percent of sodium

dichromate. The parts shall be immersed for a minimum of 20

min at a temperature in the range from 120 to 130F (49 to

54C).

6.l.1.2 Nitric 2-The solution shall contain 20to45volume

percent of nitric acid. The parts shall be immersed for a

minimum of 30 min at a temperature in the range from 70 to

90F (21 to 32C).

6.1.1.3 Nitric 3-The solution shall contain 20to25volume

percent nitric acid. The parts shall be immersed for aminimum

of20 min at atemperature intherange from 120to 140F (49

to 60C).

6.1.1.4 Nitric 4-The solution shall contain 45 to55 volume

percent of nitric acid. The parts shall be immersed for a

minimum of 30min at a temperature in the range from 120to

130

0

P (49 to 54C).

2

AA 967-01e1

'1.111

r'">. 6.1.1.5 Nitric 5-0ther combinations of temperature, time,

and concentration of nitric acid, with or without other chemi-

cals, including accelerants, inhibitors, or proprietary solutions,

capable of producing parts that pass the specified test require-

ents.

6.2 Water Rinse-Immediately after removal from the pas-

sivating solution the parts shall be thoroughly rinsed, using

stagnant, countercurrent, or spray washes singly or in cornbi-

ation, with or without a separate chemical treatment for

neutralization (see 9.1) of the passivation media, with a final

rinsebeing carried out using water with amaximum total solids

content of 200 ppm.

iT. Treatments in Citric Acid

7.1 Passivation Treatment:

7.1.1 Stainless steel parts shall be treated in one of the

0110wing aqueous solutions and maintained within the speci-

fied temperature range for the specified time.

7.1.1.1 Citric i-The solution shall contain 4 to 10weight

percent of citric acid. The parts shall be immersed for a

minimum of 4 min at a temperature in the range from 140to

160F (60 to 71C).

7.1.1.2 Citric 2-The solution shall contain 4 to 10weight

oercent of citric acid. The parts shall be immersed for a

minimumof 10min at a temperature in the range from 120to

L40F (49 to 60C).

7.1.1.3 Citric 3- The solution shall contain 4 to 10weight

ercent of citric acid. The parts shall be immersed for a

inimum of 20 min at a temperature in the range from 70 to

l20F (21 to 49C).

7.1.1.4 Citric 4-0ther combinations of temperature, time,

ind concentration of citric acid, with or without other cherni-

:als to enhance cleaning, including accelerants, inhibitors, or

>roprietary solutions capable of producing parts that pass the

pecified test requirements.

7.1.1.5 Citric 5-0ther combinations of temperature, time,

nd concentrations of citric acid, with or without other cherni-

als to enhance cleaning, including accelerants, inhibitors, or

roprietary solutions capable of producing parts that pass the

pecified test requirements. Immersion bath to becontrolled at

. pH of 1.8-2.2.

7.2 Water Rinse-Immediately after removal from the pas-

ivating solution, the parts shall be thoroughly rinsed, using

agnant, countercurrent, or spray washes, singly or in combi-

ation, with or without a separate chemical treatment for

Ieutralization of the passivation media (see 9.2), with a final

Iinsebeingcarried out using water with amaximum total solids

ontent of 200 ppm.

!. Treatments in Other Chemical Solutions, Including

Electrochemical Treatments

8.1 It is recognized that the purpose of removal of all

6 xogenous matter from a stainless steel surface, including the

emoval of free iron, can be accomplished by different media,

ith potential for benefits to be gained from use of proprietary

s ills and art, including proprietary passivation media. Such

n'eatments may include externally applying an electrical po-

ntial on the stainLesssteel parts, as in the case of electropol-

i ;hing. The suitability of such passivation treatments for use in

meeting the requirements of this specification shall be deter-

mined by the capability of the processed parts meeting the

specified test requirements.

8.2 Stainless steel parts shall be treated in a specified

aqueous solution, with or without externally applied electrical

potential, and maintained within aspecified temperature range

for a time sufficient for the processed parts to meet the

specified test requirement.

8.3 Water Rinse-Immediately after removal from the pas-

sivating solution, the parts shall be thoroughly rinsed, using

stagnant, countercurrent, or spray washes, singly or in combi-

nation, with or without a separate cbemical treatment for

neutralization of tbe passivation media (see 9.2), with a final

rinse being carried out using water with amaximum total solids

content of 200 ppm.

9. Neutralization

9.1 Tbe chemical reactions of the passivating media on tbe

surface of tbe stainless steel shall be stopped by rinsing of tbe

stainless steel part, with or without a separate neutralization

treatment.

9.2 Tbe suitability of a neutralization procedure is deter-

mined by the capability of the processed PaJ 1Smeeting tbe

specified test requirements. (See Note 1.)

NOTE I-The selection of medium and procedures for a neutralization

depends of the chemistry of the passi vation and on economic consider-

ations. An example of aneutralizing treatment would be immersion of the

part for a minimum of 30 rnin in a solution of 5 % NaOH at 160 to 180F

(71 to 82C), followed by a water rinse.

10. Post-Cleaning Treatments

10.1 Although tbe passive film cbaracteristic of stainless

steel will form spontaneously in air or any otber oxygen-

containing environment, the processor shall, when specified,

apply achemical treatment tbat will accelerate tbeformation of

the passive filmon a chemically clean stainless steel surface.

An example of a medium that serves to accelerate tbe forma-

tion of tbe passive filmbut does not contribute to the removal

of free iron from tbe stainless steel surface would be an

aqueous solution of sodium dicbromate.

10.2 When specified, within one hour after the final water

rinse as required in 6.2, 7.2, or 8.3, all ferritic and martensitic

steel parts shall beimmersed inan aqueous solution containing

4to 6weight percent of sodium dichromate at atemperature in

therange from 140to 160F (60to 71C) for aminimum of 30

min, followed by a rinse in accordance with 6.2, 7.2, or 8.3.

The parts shall then be tboroughly dried.

10.3 The purcbaser may specify other post-cleaning treat-

ments.

11. Finish

11.1 Tbe passivated parts shall exhibit a chemically clean

surface and shall, on visual inspection, show no etching,

pitting, or frosting resulting from the passivation procedures.

12. Testing Agency

12.1 When required, tbe purchaser shall be permitted to

perform sucb inspections as necessary to determine that tbe

testing agency is capable of performing the specified test.

3

(6A 967 - 01

Et

'~I'

~1.. Lot, Frequency of Testing, and Selection of Test 16.2 The sample representing the lot of passivated parts

13.1 Definition of Lot-A lot shall consist of one of the shall be tested by the salt spray test conducted in accordance

with Practice B 117 for a minimum of 2 h using a S % salt

following, at the option of the processor:

13.1.1 The passivated parts of similar alloy and manufac- solution.

tu.ing methods that are pretreated and passivated in a single 16.3 The tested sample shall not exhibit rust or staining

d or within atime frame that will ensure consistent passiva- attributable to the presence of free iron particles imbedded in

ti n results; the surface.

13.1.2 The passivated parts of the same product of one size

fr mone heat in one shipment; or

13.1.3 When few parts are involved, the passivated parts

fr man entire production run.

13.2 Unless agreater frequency of testing is specified on the

pi chase order, one test per lot shall be sufficient.

13.3 One or more of the following tests, when specified on

thpurchase order, shall be performed on each lot of stainless

st el parts. Not all of the following tests are suitable for all

gt Ides of stainless steel. (See Note 2.)

13.3.1 Practice A-Water Immersion Test,

13.3.2 Practice B-High Humidity Test,

13.3.3 Practice C-Salt Spray Test,

13.3.4 Practice D-Copper Sulfate Test, and

13.3.S Practice E-Potassium Ferricyanide-Nitric Acid

T st.

OTE 2-Some of the tests may produce positive indications not

as' ociated with the presence of free iron on tbe stainless steel surface. An

ex unple would be application of Practice C on some lesser-alloyed

mrrtensiric or ferritic stainless steels.

Practice A-Water Immersion Test

4.1 This test is used for the detection of free iron or any

ot er anodic surface contaminants on stainless steel.

14.2 The sample representing the lot of passivated parts

s IIIbe alternately immersed in a non-rusting tank of distilled

w: ter for I h and allowed to dry inair for 1h. This cycle shall

be repeated a minimum of twelve times.

l4.3 The tested sample shall not exhibit rust or staining

at( ibutable to the presence of free iron particles embedded in

th surface.

IS Practice B-High Humidity Test

5.1 This test is used for the detection of free iron or any

ot! er anodic surface contaminants on stainless steel.

15.2 The test shall be performed using a humidity cabinet

ca iable of maintaining the specified test conditions.

S.3 The sample representing the lot of passivated parts

sh IIbecleaned by immersion in acetone or methyl alcohol or

by swabbing with a clean gauze saturated with acetone or

me thyl alcohol, and dried in an inert atmosphere or desiccated

co tainer, The cleaned and dried part shall be subjected to 97

+ % humidity at 100 :!: SOF (38 :!: 3C) for a minimum of

24 h.

5.4 The tested sample shall not exhibit rust or staining

atnibutable to the presence of free iron particles imbedded in

thd surface.

16 Practice C-Salt Spray Test

6.1 This test is used for the detection of free iron or any

ot~er anodic surface contaminants on stainless steel.

17. Practice D-Copper Sulfate Test

17.1 This test is recommended for thedetection of free iron

on the snrface of austenitic stainless steels in the 200 and 300

series, precipitation hardened stainless steels, and ferritic 400

series stainless steels having a minimum of 16% chromium.

This test is not recommended for martensitic 400 series

stainless steels or for ferritic 400 series stainless steels with less

than 16% chromium because these steels will give a positive

indication irrespective of the presence or absence of anodic

surface contaminants. This test shall not be applied to parts to

be used in food processing.

17.2 The test solution is prepared by dissolving 4 g of

copper sulfate pentahydrate (CuS0

4

'SH

2

0) in 2S0 mL of

distilled water to which 1mL of sulfuric acid (H

2

S0

4

, sp gr

1.84) has been added. Aqueous copper sulfate solutions more

than two weeks old shall not be used for this test.

17.3 The test solution is swabbed on the surface of the

sample representing the lot of passivated parts, applying

additional solution as needed to keep the surface wet for a

period of at least 6 min. At the end of this period, the surface

shall becarefully rinsed anddried with care taken not todisturb

copper deposits if present.

17.4 The tested sample shall not exhibit copper deposits.

18. Practice E-Potassium Ferricyanide-Nitric Acid Test

18.1 This test isrecommended when detection of very small

amounts of free iron is required. It is recommended for

detection of free iron on austenitic 200 and 300 series stainless

steels. This test is not recommended for detection of free iron

on ferritic or martensitic 400 series stainless steels, because

these steels will give a positive indication irrespective of the

presence or absence of anodic surface contaminants. This test

shall not be applied to parts to be used in food processing.

18.2 The test solution is prepared by adding 10 g of

chemically pure potassium ferricyanide to 500 mL of distilled

water, adding 30 mL of 70% nitric acid, agitating until all of

the ferricyanide is dissolved, and diluting to 1000 mL with

distilled water. The test solution shall bemixed fresh ontheday

of the test.

18.3 The test solution is swabbed on the surface of the

sample representing the lot of passivated parts. The formation

of a dark blue color within 30 s denotes the presence of

metallic iron.

18.4 The tested sample shall not exhibit thedark blue color

indicative of free iron on the surface.

18.5 When the test is negative, the surface shall be thor-

oughly washed with warm water to removal all traces of the

test solution. When thetest ispositive, thedark blue stain shall

be removed with asolution of 10% acetic acid and 8% oxalic

acid, followed by a thorough hot water rinse.

4

~ A 967-01E1

".11,

r"> 9. Practice F-Free Iron Test

19.1 This test is used for the detection of free iron on the

surface of stainless steel. It is especially useful for large parts

that have been uniformly cleaned but that are inconvenient for

reasons of size of equipment or ease of handling of the part to

place in the environments defined in Practice A (Section 14) or

Practice B (Section IS). Unless otherwise specified by the

purchaser, the number of tests and the locations of the tests

shall be at the option of the processor to assure a representative

testing of the part.

19.2 The test is performed by placing a clean cloth pad that

has been thoroughly soaked with distilled or derninaralized

water on the surface of the part at a part temperature of SOF

(lOC) or greater for a period of not less than 60 minutes. The

cloth shall be in contact with the steel for an area of at least 20

square inches (130 crrr'). The pad shall be maintained wet

hrough the test period, either by a method of retarding external

evaporation, by the further addition of potable water, or by

backing the pad with a sponge or similar water source. The

cloth pad used shall be used for only one such test, being

hanged for each test so as to avoid risk of contamination.

fter removal of the cloth pad, the surface of the part shall be

llowed to dry in air before inspection.

19.3 The tested part shall not exhibit rust or staining

attributable to the presence of free iron particles embedded in

the surface.

20. Rejection and Retest

20.1 Any lot failing to meet the specified test requirements

of the purchase order shall be rejected. A rejected lot may, at

the option of the processor, be re-passivated, with or without

re-pretreatment, and then be retested. The number of samples

tested from a lot subject to retest shall be twice the original

specified test frequency, to the limit of the number of pieces in

the lot. All samples must pass the specified acceptance criterion

for the specified test for the retested lot to be accepted.

21. Precision and Bias

21.1 No statement is made concerning either the precision

or bias of Practices A, B, C, D, and E because the results state

merely whether there is conformance to the criteria for success

specified in the procedure.

22. Certification

22.1 When specified in the purchase order, a report of the

practice and tests used, including the record of process condi-

tions when specified in accordance with 3.1.1.2, shall be

supplied to the purchaser.

APPENDIX

(Nonmandatory Information)

Xl. INFORMATION REGARDING PASSIVATION TREATMENTS

NOTE XI. I-The following information is based on asection of Federal

,pecification QQ-P-35C (Oct. 28. 1988) identified as information of a

~eneral or explanatory nature that may be helpful, but is not mandatory.

inor changes have been made in the text to facilitate references to the

nain document and to correct technical inaccuracies.

XLI Intended Use-The passivation treatments provided

y this specification are intended to improve the corrosion

esistance of parts made from stainless steels of all types.

X 1.1.1 During processing operations such as forming, ma-

'hining, tumbling, and lapping, iron particles or other foreign

I,articles may become smeared over or imbedded into the

. urface of stainless steel parts. These particles must be re-

noved or they will appear as rust or stain spots. This condition

nay be prevented by chemically treating the parts to remove

he iron particles or other foreign particles, and then allowing

he passive fi 1mto form on the cleaned surface, with or without

hemical enhancement of the formation of this oxide film.

X1.1.2 This specification is not intended for the black oxide

oating of parts typically used for photographic or optical

istruments.

X1.2 Ordering Data-Purchasers should select the pre-

erred options permitted by this specification and include the

llowing information in the purchase order:

X1.2.1 Title, number, and date of this specification;

X 1.2.2 Identification of material by type and applicable

product specification;

X1.2.3 Test practices to be imposed (see 104);

X1.204 Definition of lot size, if other than described in this

specification; and

X1.2.S Required documentation, if other than the minimum

required by this specification.

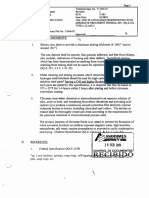

Xl.3 Grades of Stainless Steel-Different types of stainless

steel are selected on a basis of properties required, for example,

corrosion resistance and design criteria, and fabrication re-

quirements. Table XLI is a compilation that serves as a guide

for the selection of passivation treatment for different grades,

but is far from complete either in grades or in passivation

treatments.

X104 Clean Water-Clean water is defined as water con-

taining a maximum total solid content of 200 ppm. Rinsing can

be accomplished by a combination of stagnant, countercurrent

or spray rinses, or both, prior to final rinse.

Xl.S Chemically Clean SUlface-A chemically clean sur-

face is defined as a surface upon which water, when applied

momentarily to the surface, will remain on that surface in an

even, continuous film, and in addition is free of any foreign

material or residual film deposit which would be detrimental to

the quality of the part.

5

(6A 967 - 01"1

'1111

Passivation Treatment ~ .------L- Passivation Treatment

_,---=G""ra:::d:.::e -"-N"'it"'ri:.::c_' _~ic ~_ Nitric 3 Nlt"~- --. Gr~d~n N1trJ."_1 .. Nii~Nitric3 Nitric 4

J!!lll j ~. -t; .--.. ,'1~11F l.:j . .~- 'J

----'1:::1:::;'-.j:.::!c:; _ _ -+_-__-_ -_ ~..:f... -.---~ ._ .:.i ~iP-j- :=. ~.- -~

530500 _ _ ~43020 _ _ --i--- ._

_ . 530800 _ _ ,_ _ 543023 _

~~~~~~-==-..J= ~::~~~. -:: .__J --

530940 :~arte~c ' I '--+

~~~~~~ .--- .- i:~~~~- ----i---~--------!-.-~=1. -.-.-':--=

831600---r--- .1_ ._ _ .. _ _ . 841400 f-------~1-=-----;--

531603 .. 54160Q_ _ ._ . _ _ ~' _

531609 _ _ !. --_---.-::~-.----- i 541623

532100 .._ _ . _ ._ . 842000

_ .;;32109 _ ._ i .. _ _ 1-- _ . _ . 5-,4",3.:'-;.=..00=---+_

~3j!()2. ' _ _ . _ _ 1--.. : ..._ , 844002

_ 534709 _ _ .. L ..., ._. I' 544003

D~plex ! . 844004

_ _ 532900 .... f..- _ Precipitation

~ritic_____ . .....Hardening L.

840500 - 1 ' K66286 i-----IL-

..-~+~~~--.i-~~----.---~~~j-I---~~~~--- ---'t: ; ~~-,-- -~~~~~~_'+-T ' __-+ -_+:,!------l

543000 !-_ 8157~' .;--_ _ _ -+ 1

_ _ 84_ 3_ 4_ 00_ _ _ . ~oo I ._ 1-----

"--11~~~~ I ----1-:- ~-1 S-~~1--- - : ... -.- _ _ .. .._! _ .. -_. _ ;=

~S44600 _ _ i- ----.----.- ._ _ -i--.- ._ _ , 836200

844627 .

---:-----~-.-. ---

._ -

--- ---~-:::-+.:.--=

.... -! ----- .. _ -

F IG. X1.1 Recommended Nitric Acid Passivation Treatments for Different Grades of Stainless Steel

1.6 Test Specimens-When using test specimens instead

of Parts, the specimens can effectively represent the parts only

if ~ey have been exposed to the same processing steps, such as

ma~fhining, grinding, heat treating, welding, and so forth, as the

pal ts they are to represent.

(1.7 Carburized Suifaces-Stainless steel parts with car-

bur ized surfaces cannot be passivated because the carbon

co nbines with the chromium forming chromium carbides on

the surface.

d.S Nitrided Suifaces-Stainless steel parts with nitrided

su 'aces should not be passivated because the treatment will

se erely corrode the nitrided case.

X1.9 This specification provides for the same passivation

treatments as Fed. Spec. QQ-P-35C, but also includes a

number of altemative passivation treatments. The effectiveness

of any passivation treatment is demonstrated by the parts

meeting the specified testing requirements after treatment.

Xl.lO Martensitic Grade 440C-High-strength grades

such as 440C are subject to hydrogen embrittlement or

intergranular attack when exposed to acids. Cleaning by

mechanical methods or other chemical methods is recom-

mended.

Xl.ll The salt spray test is typically used to evaluate

austenitic stainless steels and may not be applicable to all

martensitic or fenitic stainless steels.

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility

This standard issubject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at ameeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards. at the address shown below.

6

aA 967-01E1

, . 11

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org).

7

You might also like

- Zinc and Zinc Alloy Plating: Bach. of Eng. E-46800 Xativa (Spain)Document30 pagesZinc and Zinc Alloy Plating: Bach. of Eng. E-46800 Xativa (Spain)Hari SuthanNo ratings yet

- Coating and Drying Defects: Troubleshooting Operating ProblemsFrom EverandCoating and Drying Defects: Troubleshooting Operating ProblemsRating: 5 out of 5 stars5/5 (1)

- Black Oxide MIL DTL 13924DDocument11 pagesBlack Oxide MIL DTL 13924DadamhomeNo ratings yet

- Du-Zinc 019Document7 pagesDu-Zinc 019KaRenthLuNaNo ratings yet

- Metal Finishing Processes Best PracticesDocument44 pagesMetal Finishing Processes Best PracticesHoang TanNo ratings yet

- Electropolishing WorkbookDocument16 pagesElectropolishing WorkbookAhmet BozgeyikNo ratings yet

- Out of The Trap Selected Lectures of Alan W. Watts PDFDocument164 pagesOut of The Trap Selected Lectures of Alan W. Watts PDFAKU95100100% (2)

- Space Product Assurance: Manual Soldering of High-Reliability Electrical ConnectionsDocument106 pagesSpace Product Assurance: Manual Soldering of High-Reliability Electrical ConnectionsEloy Bauer EspitiaNo ratings yet

- Pigment Content & Mixing Notes PDFDocument4 pagesPigment Content & Mixing Notes PDFDulce Gabriel100% (1)

- Acid ZincDocument27 pagesAcid ZincHacı OsmanNo ratings yet

- MicrostructuresDocument10 pagesMicrostructuresErin BarryNo ratings yet

- The New Rational Manager KTDocument224 pagesThe New Rational Manager KTWilson Millan100% (3)

- Mouliding Defects and RemediesDocument8 pagesMouliding Defects and RemediesMatta SatishNo ratings yet

- Electroplating of PlasticsDocument4 pagesElectroplating of PlasticsislammughalNo ratings yet

- Astm A 967 - 01 - Chemical Passivation Stainless Steel PDFDocument7 pagesAstm A 967 - 01 - Chemical Passivation Stainless Steel PDFElwe SingoloNo ratings yet

- Ultraseed Ce Inoculant: ISO 9001 ISO 14001 ISO/TS 16949Document4 pagesUltraseed Ce Inoculant: ISO 9001 ISO 14001 ISO/TS 16949Vikrant KhavateNo ratings yet

- ASTM A 967 PassivationDocument7 pagesASTM A 967 PassivationFelipe Martínez Cervantes100% (6)

- Electroplating Anodizing Metal PDFDocument53 pagesElectroplating Anodizing Metal PDFCrystian Kobee EmpeynadoNo ratings yet

- Acid Zinc 2Document6 pagesAcid Zinc 2Muhammad SaqibNo ratings yet

- Filtration of Iron and Steel Castings PDFDocument24 pagesFiltration of Iron and Steel Castings PDFbvphimanshu100% (1)

- Anodizing Standards and and Quality Control Tests Quality Control Tests of America's AutomakersDocument25 pagesAnodizing Standards and and Quality Control Tests Quality Control Tests of America's AutomakersshrikantbagalNo ratings yet

- How To Passivate Stainless Steel PartsDocument11 pagesHow To Passivate Stainless Steel Partsnqh2009No ratings yet

- ANKURDocument20 pagesANKURDevashish JoshiNo ratings yet

- Cast IronDocument15 pagesCast IronJohnNo ratings yet

- Exposicion de BrechasDocument65 pagesExposicion de Brechasjuandelfor100% (2)

- Electroplating Cost Calculation - RefDocument12 pagesElectroplating Cost Calculation - RefJitendra PatilNo ratings yet

- Failure and Metallurgical Analyses - STPADocument3 pagesFailure and Metallurgical Analyses - STPAdaveNo ratings yet

- Chemical Processing Scope Determination MatrixDocument20 pagesChemical Processing Scope Determination MatrixnorlieNo ratings yet

- Solder Paste LiteratureDocument1 pageSolder Paste LiteraturescmeswarNo ratings yet

- TALAT Lecture 5203: Anodizing of AluminiumDocument27 pagesTALAT Lecture 5203: Anodizing of AluminiumCORE Materials100% (2)

- Corrosion of SS in Nitric Acid ServiceDocument23 pagesCorrosion of SS in Nitric Acid ServiceAdriaan de Witt100% (1)

- DVD Transcript Wonders of CreationDocument7 pagesDVD Transcript Wonders of Creationkennyshaw10% (1)

- AnodizingDocument9 pagesAnodizingalphadingNo ratings yet

- Anodizing Ver 1Document14 pagesAnodizing Ver 1aditya_welekarNo ratings yet

- Anodizing Presentation CDocument21 pagesAnodizing Presentation Croohollah13No ratings yet

- Electropolish PDFDocument85 pagesElectropolish PDFElangovan NatarajanNo ratings yet

- Sedimentary Environment JPKDocument61 pagesSedimentary Environment JPKRaihanNo ratings yet

- Chromate Conversion Coatings and Their Current AppDocument5 pagesChromate Conversion Coatings and Their Current AppDeni HermawanNo ratings yet

- Best Practices in Adhesive Bonding - Max DavisDocument43 pagesBest Practices in Adhesive Bonding - Max DavisAndrea SantoriNo ratings yet

- Black PassivationDocument12 pagesBlack PassivationZineb100% (1)

- ATOTECH - EcoTri - Bright Zinc Plating - Hexavalent Chrome FreeDocument4 pagesATOTECH - EcoTri - Bright Zinc Plating - Hexavalent Chrome FreeWK Sinn100% (1)

- Dissonant Heritage. The Management of The Past As A Resource in Conflict. J.E. Tunbridge and G.J. AshworthDocument305 pagesDissonant Heritage. The Management of The Past As A Resource in Conflict. J.E. Tunbridge and G.J. AshworthFRANCISCO ALBERTO DE LA ROSA MANJARREZ100% (1)

- Principles of Metal Surface Treatment and Protection: Pergamon International Library of Science, Technology, Engineering and Social Studies: International Series on Materials Science and TechnologyFrom EverandPrinciples of Metal Surface Treatment and Protection: Pergamon International Library of Science, Technology, Engineering and Social Studies: International Series on Materials Science and TechnologyNo ratings yet

- Effect of Heat Treatment On The Microstructure and Mechanical Properties of A Welded AISI 410 Martensitic Stainless SteelDocument8 pagesEffect of Heat Treatment On The Microstructure and Mechanical Properties of A Welded AISI 410 Martensitic Stainless SteelAlexis Guzmán MéndezNo ratings yet

- HC 80 (Hard Chromium Process)Document5 pagesHC 80 (Hard Chromium Process)Sinar Cemaramas AbadiNo ratings yet

- ASTM - Tratamientos de PasivacionDocument7 pagesASTM - Tratamientos de PasivacionFrank Herrera RodríguezNo ratings yet

- DacrometDocument6 pagesDacrometdavideNo ratings yet

- Brazing Allloy Cusil ABADocument12 pagesBrazing Allloy Cusil ABADheeraj SharmaNo ratings yet

- Injection-Molding-Flaws-and-Defects LopottDocument28 pagesInjection-Molding-Flaws-and-Defects Lopotttalán gybrNo ratings yet

- E313 Standard Practice For Calculating Yellowness and Whiteness Indices From Instrumentally Measured Color CoordinatesDocument6 pagesE313 Standard Practice For Calculating Yellowness and Whiteness Indices From Instrumentally Measured Color CoordinatesCalidad EquisplastNo ratings yet

- GMW14668Document20 pagesGMW14668Carlos LanzillottoNo ratings yet

- Treatment of Electroplating WasteDocument8 pagesTreatment of Electroplating WasteHajar HadisNo ratings yet

- Thread GallingDocument4 pagesThread GallingAbdullah AnsariNo ratings yet

- Titration Methods For Sulfuric Acid Anodizing Baths - Products FinishingDocument2 pagesTitration Methods For Sulfuric Acid Anodizing Baths - Products Finishingabhishek_giteNo ratings yet

- Study Data of Passivation - of - Zinc PDFDocument11 pagesStudy Data of Passivation - of - Zinc PDFvkmsNo ratings yet

- Chromic Acid Lanxess-MSDS PDFDocument10 pagesChromic Acid Lanxess-MSDS PDFyuk ming wongNo ratings yet

- Rapid Stress Relief and TemperingDocument8 pagesRapid Stress Relief and Temperingtbmari100% (1)

- Causes and Remedies of Blow Holes in SanDocument33 pagesCauses and Remedies of Blow Holes in SanNikhil KumarNo ratings yet

- Zylite Stabilizer Ds v05Document5 pagesZylite Stabilizer Ds v05Santiago TuestaNo ratings yet

- T-1046.02 (Qqz-325 Type II Class II)Document2 pagesT-1046.02 (Qqz-325 Type II Class II)jazz reyNo ratings yet

- Chrom I TingDocument11 pagesChrom I TingAshish RawatNo ratings yet

- Peel StrengthDocument13 pagesPeel StrengthJulia Turpo SuarezNo ratings yet

- Longtermoxidationbehaviour PDFDocument10 pagesLongtermoxidationbehaviour PDFAnonymous lmCR3SkPrKNo ratings yet

- APU Aluminum 0411Document8 pagesAPU Aluminum 0411roohollah13No ratings yet

- Che Ical Passiv T On Treatmen S or Stain Ess Steel Parts: M A I T F LDocument7 pagesChe Ical Passiv T On Treatmen S or Stain Ess Steel Parts: M A I T F LÖzgür ÇalışkanNo ratings yet

- Increasing Profits Through Utility Reduction, Saving Our Clients MoneyDocument2 pagesIncreasing Profits Through Utility Reduction, Saving Our Clients MoneyramquimicaNo ratings yet

- Folleto PDFDocument2 pagesFolleto PDFramquimicaNo ratings yet

- Tema Designations of Heat ExchangersDocument6 pagesTema Designations of Heat ExchangersNikunj KNo ratings yet

- Issued Sales Specification Chevron Phillips Chemical CompanyDocument1 pageIssued Sales Specification Chevron Phillips Chemical CompanyramquimicaNo ratings yet

- 120 19092019 PDFDocument309 pages120 19092019 PDFramquimicaNo ratings yet

- 1 Random PackingDocument12 pages1 Random PackingramquimicaNo ratings yet

- Titan Summary of ApplicationsDocument2 pagesTitan Summary of ApplicationsramquimicaNo ratings yet

- Nevastane Sdo - enDocument1 pageNevastane Sdo - enramquimicaNo ratings yet

- Free On-Line Human Design Report: First KeyDocument7 pagesFree On-Line Human Design Report: First KeyInessa PosticaNo ratings yet

- Deep Water by William DouglasDocument10 pagesDeep Water by William DouglasAyu HarshalNo ratings yet

- Intro To Town Planning, 1st LectureDocument18 pagesIntro To Town Planning, 1st LectureA KhanNo ratings yet

- FRQ Fa AnswerDocument46 pagesFRQ Fa AnswerAllan YUNo ratings yet

- Foundation Repair and StrengtheningDocument24 pagesFoundation Repair and Strengtheningnimmi kpNo ratings yet

- Curriculum Implementation MatrixDocument11 pagesCurriculum Implementation MatrixReymart VillapeñaNo ratings yet

- Prestressed ConcreteDocument35 pagesPrestressed ConcreteRp Singh100% (1)

- Submitted by : Manisha Thakur Mehnaz Dhar Faisal BazazDocument30 pagesSubmitted by : Manisha Thakur Mehnaz Dhar Faisal BazazManisha ThakurNo ratings yet

- Research Paper - Phototaxis in Zophobas MorioDocument9 pagesResearch Paper - Phototaxis in Zophobas Morioapi-393048315No ratings yet

- Natural Vegetation and Wildlife Notes PDFDocument8 pagesNatural Vegetation and Wildlife Notes PDFupsbabhani2020No ratings yet

- REVISION FOR THE SECOND TERM TEST 10 BTDocument4 pagesREVISION FOR THE SECOND TERM TEST 10 BThaiianhNo ratings yet

- XcdsfasazDocument4 pagesXcdsfasazZaid HadiNo ratings yet

- A Mineral System ApproachDocument4 pagesA Mineral System ApproachKaharuddin HawingNo ratings yet

- Corrosion1 0Document47 pagesCorrosion1 0Akshat GroverNo ratings yet

- IJTRD10881Document3 pagesIJTRD10881ImranNo ratings yet

- China Fact SheetDocument3 pagesChina Fact SheetMuhammad Al ZayatNo ratings yet

- Coral Reef Restoration A Guide To EffectDocument56 pagesCoral Reef Restoration A Guide To EffectDavid Higuita RamirezNo ratings yet

- Threatened Plants Philippines Paper Updated 07feb2008 ALS Format 2 PDFDocument47 pagesThreatened Plants Philippines Paper Updated 07feb2008 ALS Format 2 PDFWilly Ortega100% (1)

- Sumatra - Geology, Resources and TectonicsDocument35 pagesSumatra - Geology, Resources and Tectonicsadinda novianaNo ratings yet

- Schiffman CB10 PPT 04Document42 pagesSchiffman CB10 PPT 04Sonali TazrinNo ratings yet

- Liveable Neighbour Hoods Community Design Code Ed 1 - GWA Australia - 1997Document4 pagesLiveable Neighbour Hoods Community Design Code Ed 1 - GWA Australia - 1997PublicHealthbyDesignNo ratings yet

- 4.Take Only Memories, Leave Only Footprints YBM (신정현) 4-1Document10 pages4.Take Only Memories, Leave Only Footprints YBM (신정현) 4-1강영민No ratings yet

- Reflective Writing - SBU3043 A202Document2 pagesReflective Writing - SBU3043 A202Atikalla AtieNo ratings yet