Professional Documents

Culture Documents

DCS

Uploaded by

Ranjita SinghCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DCS

Uploaded by

Ranjita SinghCopyright:

Available Formats

EINDHOVEN UNIVERSITY OF TECHNOLOGY

DEPARTMENT: ELECTRICAL ENGINEERING

group: Measurement and Control

CLASSICAL AND ADVANCED CONTROL IN

DISTRIBUTED CONTROL SYSTEMS:

THE PRESENT AND THE FUTURE

by J. van den Dool

Report of the Internship

Performed for Honeywell Amsterdam,

Division Industrial Automation

from September upto October 1993

Honeywell Coordinator: J.C.J. van de Wiel

University Coordinator: prof. A.C. Backx

Date: May 3, 1994

The Department Electrical Engineering of the Eindhoven University

does not accept any responsibility for the contents of internship and

graduation reports

Summary

Historically, control research is being performed along two different lines: Servo

Control and Process Control. Nowadays Servo Control covers academic research,

Process Control covers the development and improvement of Distributed Control

Systems. Todays Process Industries are forced to improve their production methods. A

powerful method to their disposal is to improve the control algorithms in DCSs

covering primary, supervisory and optimization control. Here, Control Theory can

help. The past of both fields is described. The outlines of an ideal control system with

split architecture are sketched. Throughout the report this "model" is looked upon as

the ideal structure for mc 3000 (Honeywell's DCS). After a detailed description of

IDC 3000, it is proven that Model Based Control can be implemented. Bottlenecks in

developing IDe 3000 towards the ideal structure have a software character. Future

research will be directed on theory side to the solution of the Fundamental Control

Problem (a formulation for any control problem developed by Shell) and on DCS

side to the software of the higher levels and the automation of (parts of) the control

system design in which Artificial Intelligence is going to playa crucial role. Research

schools can contribute to "system engineering" education and high risk but potential

large pay-off research.

3

Contents

1 Introduction 7

2 History: Servo Control versus Process Control 8

2.0 Introduction

2.1 Developments in Control Theory

2.2 Developments in Process Control

3 General description of a Distributed Control System 13

3.1 What's in a name?

3.2 The up-to-date Hierarchical Process Control Concept

3.2.0 Introduction

3.2.1 The Hierarchical Process Control Structure

4 The TDC 3000 system of Honeywell 19

4.0 Introduction

4.1 Global description of IDC 3000

4.2 Currency of IDC 3000: Points

4.3 Controller functions within IDC 3000

4.3.1 SISO control within the Advanced Process Manager

4.3.2 Sequential Process Control within the Advanced Process Manager

4.3.3 Controller functions performed by the Application Module

4.3.3.1 Horizon Multivariable Predictive Control

4.3.3.2 Real Time Statistical Process Quality Control

4.3.3.3 Model Based Control versus Statistical Process Quality Control

4.4 What levels in the hierarchy are being filled in recent projects ?

5 Implementation of a Model Based Controller on TDC 3000 35

5.0 Introduction

5.1 The Internal Model based Control form

5.2 Internal Model based Control for a Distillation Column

5.3 Implementation on IDC 3000

5.3.1 Requirements

5.3.2 Results

5.3.3 Conclusions

6 Software and Hardware 45

6.1 Developments in Software and Hardware

6.1.1 Performance

6.1.2 Programming Languages

6.2 Hardware and Software requirements for the Hierarchical Control

System

7 Recent and future topics in Research 49

7.1 The Fundamental Control Problem

7.2 Areas of Research for the solution of the Fundamental Control Prob-

lem

7.3 The Fundamental Control Problem versus the Hierarchical Control

Structure

7.4 Areas of Research for the Hierarchical Control Structure

7.5 The role of Academia in Control Research

8

9

Process Automation Projects

Conclusions

References

6

55

57

58

1 Introduction

Historically, developments in "control" have taken place in two fields: Servo Control

and Process Control. Servo Control evolved from the control of ships' rudders to the

field of academic control theory nowadays. Process Control has evolved in the

chemical and physical process industries and has resulted in the development of

Distributed Control Systems of which IDC 3000 is an example.

Todays industries are confronted with a very dynamic and hardly predictable

marketplace which has to be serviced using the available plants and control systems:

redesign is too expensive. In most process control systems safety and operability

demands are met and now production must be improved using academic control

theories or the ''wisdom'' of the other field. This asks for a study of a recent Process

Control System (the IDC 3000 system of Honeywell) as to what extent classical and

advanced control concepts are, and could be implemented nowadays, and what the

requirements are, to be ready for future developments.

In chapter 2 the developments in both fields are described. Chapter 3 gives the

outlines of a model of an ideal control system, prepared for the future. Throughout

the report, this model will be treated as the ideal form of IDC 3000. In chapter 5 the

implementation on IDC 3000 of a compact Model Based Controller is treated and in

chapter 6 software and hardware requirements for the ideal Control System will be

described after a description of the availabilities. Chapter 7 contains a reflection on

the fundamentals of every control problem and its relation to the ideal control

system. It can be seen as the presentation of the themes around which the discussion

between the mentioned fields will continue. For both fields topics of recent and

future research will be described. In chapter 8 problems and solutions are described

for recent Process Automation Projects.

2 History: Servo Control versus Process Control

2.0 Introduction

Control systems have been developed along two different lines: servo mechanisms and

process control. Both fields started research at the same time and evolved separately

ever since. Now the two fields turn out to be: Academic Control and Process Control

or "theory" and "practice". The distance is felt as a gap because there is so little

communication between people that deal with the same processes nowadays.

Servo Control systems [3] are required when the force needed to move the

control mechanism is too large for the human operator (ships' rudders, aircraft

control surfaces). The function of the control system is to follow the position set by

the operator suppressing disturbances which in general are low. The response must be

fast (seconds at most). Servo systems traditionally operate in a large dynamic range.

In general they are built in large numbers for one particular application.

Process control systems [3] are applied in the chemical and physical process

industries. Applications of the systems are often unique. Their function is to maintain

the variable under control at a preset level in response to changes that occur in the

process or are attributable to external causes. Process control systems generally

operate in a limited dynamic range. The response of the plant will take at least

seconds, minutes commonly.

The persistence of the gap can be explained by the origin of the different

control engineers.

The inventors of servo mechanisms were -at that time- mechanical engineers

(later on a new species splitted off: electrical engineers). As said before the disturb-

ances to these mechanisms were minimal. Smarter control strategies were developed

but there were always the assumptions of minimal disturbances and the application on

linear processes (aero space: avionica).

The process control engineers originated from chemistry. Their main activity

was and is inventing new products and designing the necessary production processes.

Their top priorities being safety and continuous operation, they need(ed) reliable and

robust controllers and not the ones that were optimal in a small range.

Application of Model Based Control forces both parties to cooperate. In the

modem process control system both first principle models (rigourous, white) stem-

ming from process engineers and black box models from people that apply of

academic control are required.

Now the developments in both fiels will be described.

8

2.1 Developments in control theory [3]

Classical Control was developed before and during the Second World War. It

concerns PID controllers. The design for Single Input Single Output systems is based

on frequency domain descriptions. It is broadly applicated in industry (80%/90% of

all low level control loops). A general model suffices for tuning. Roughly tuned

controllers are robust to changes in the dynamics of the process.

Development of Modem or Multi Input Multi Outout control started the late 50s. In

industry MIMO control is called advanced control. Three of the most popular

techniques are [9]:

Pole Placement Control: As a control-system-design tool abandoned because

there is little insight in where to place poles.

Decoupling: Earliest method for MIMO control. First suggested in 1949 ([9D],

page 309). Decoupling converts the multivariable problem into independent

SISO problems. The general philosophy now is to remove all 'interactions'

whenever the performance is not deteriorated.

Linear Quadratic Optimal Control: Suggested in late 50s by Kalman. Based on

the State Space Description of the processes to be controlled. Through the

assumption that signals are stationary, controllers can be designed that mini-

mize quadratic criteria. Signals that depend linearly on the states of the system

are fed back within the controller. When the states cannot be observed

physically, optimal (Kalman) filters can be used to derive the states from

inputs and outputs to the process.

During the early 70s nothing was left of the enthusiasm of the 60s about

the optimal control theory. In the LQ Optimal Control scheme disturbances

are assumed to have infinite bandwidth (white noise) and to afflict the output

only. LQC tries to control the process over infinite bandwidth. This requires an

exact model of the process dynamics! To cope with model uncertainty (by

phase and amplitude variations) feedback is used explicitly in classical control.

But the problem of model uncertainty is not dealt with by state space methods

which made them inadequate for practice.

During the 80s research was looking for a mathematical tractable relation between a

model uncertainty description and a measure of performance. This led to:

Robust Control (H_inf and H

2

) minimizes the weighted sensitivity operator (transfer

of output disturbance to the process outputs). The expected uncertainty is modeled in

the frequency domain and the control system is designed to minimize the worst

performance. Performance is specified by a bound on the sensitivity operator. H

2

minimizes the 2-norm or average value of the weighted sensitivity operator and

H_inf minimizes the inf-norm or maximum value. The biggest problem is how to use

Robust Control in practice. The weights determine how degrees of freedom will be

used to match desired process response criteria. There is no systematic procedure to

obtain the uncertainty description and the selection of weights is not obvious. For H

2

the weights can be obtained from well defined experiments. Case studies and experi-

ments help here to gain insight.

9

Adaptive controllers essentially are linear controllers that periodically tune the

parameters to improve robustness. This requires a second feedback loop in which

information is gathered about the changing dynamic behaviour of the process.

Examples are Self Tuning Control and Model Reference Adaptive Control. Major

drawbacks are: minimum phase behaviour of process required, large sensitivity to

noise, the parameters must be updated significantly slower than the slowest relevant

process dynamics and expressing the stability of the system requires complex mathe-

matics.

Continued research on optimal control led to the Model Based Control concept in the

60s. To improve the control of a process, the controller needs to 'know' the process

e.g. contain detailed knowledge about its dynamics including the process equipment.

This requires an off-line identification procedure that delivers a model. MBC enables

manipulation of system dynamics up to physical constraints, compensation for non-

desired system properties, decoupling, smooth setpoint tracking and disturbance

rejection. The dynamics of some processes are so complex that MBC is the only way

to control them.

When the model of a process has been obtained, still nothing has been said

about the controller structure. The design of a specific controller uses the extensive

degrees of freedom for manipulation of process dynamics in a particular way. The

control design depends on the desired process response. The translation of criteria for

process response (rise time, overshoot, response time, ..) into useful control design

criteria is the biggest problem in this field. When using Robust Control for the design

of the controller, this problem is incorporated by the selection of proper weighting

functions.

Identifying a process within prescribed bounds is very expensive. Certainly not

all processes apply for this treatment. Within the MBC class we distinguish Linear

Unconstrained Control (for example Internal Model based Control in which a

parametric State Space model resides) and Linear Model Predictive Control

(Dynamic Matrix Control and Model Algorithmic Control which use non-parametric

process description). In the second concept constraints are dealt with explicitly. The

methods use different process model representations.

Intelligent controllers cope with process non-linearities and complex information. Three

subclasses exist:

Fuzzy control: Uses "fuzzy sets" and "fuzzy" rational equations. Fuzzy set theory

allows to partially belong to a set. The membership of a set is expressed by a

number between 0 and 1. This facilitates the implementation of constructions

like "for many ..." or "the rudder doesn't function correctly."

Expert systems: Expert systems are used to connect long rows of "if...then..

else..." rules (forward chaining). Through internal feedback the system can

learn and achieve a higher speed by testing off-line what if-conditions were

executed (backward chaining). Expert systems are dedicated controllers that

are based primarily on human knowledge and experience.

Neural Networks: Based on the principles of switching in our own neurons,

many small processors are connected in parallel and in feedback. The outputs

are functions of weighed sums of inputs. The weights can be adapted by learn

processes.

10

2.2 Developments in process control

Before reading the history of process control one should realize that the ranking of

priorities of process industry significantly differ from advanced-control theory

developers:

1. Safety

2. Keeping the plant in operation: shut downs are very precious because produc-

tion stops and the plant must be cleaned before restart

3. Optimizing quality and efficiency

During [3] the first thirty years of this century the operator used simple measurement

devices (pressure and temperature gauges) to determine the adjustment of the

positions of the valves and meet the desired values. The plants were small and

operation always in steady state. Control mechanisms were mechanical.

The development of pneumatic transmission of measurement signals made it

possible to collect all indicators, recorders and other equipment into one central

location in the late 30s and 40s. The regulator mechanisms had been developed into

pneumatic servo mechanisms that were located in the control room as well.

During and after the Second World War process plants grew larger and

because only S1S0 controllers under direct supervision of the operators were used,

control consoles grew proportionally. Now the disadvantages of centralization became

clear: (i) the quantity of information offered in the control room became too great for

human comprehension and (ii) the increasing distance between controller and points

of measurement and regulation introduced a significant delay into the control loops.

From the 60s the second problem could be solved by the development of

electronic analog signal transmission. This development had long been delayed in

many industries by the danger of electrical energy in explosable atmospheres. So far

the development of control system design had been based on the universal S1S0

controller rather than on the customer's wishes and although the theory behind

feedforward, interactive, cascade or ratio control existed, the implementation was

delayed because this required hardwired or piped interconnections between the

individual controllers and the design of the control panel could only be altered when

the plant was shut down. Replacement of pneumatic by electronic control of pro-

cesses is still ongoing.

The appearance of digital computers (Direct Digital Control) in the 60s didn't

solve any of the problems. The computers were large, expensive and not reliable.

Application of a central computer was only justified if it replaced 100 S1S0 control-

lers and at the same time this centralization in a medium which was not reliable

created a dangerous situation. This forced the computers to play a supervisory role at

first (setpoint optimization).

The development of the microprocessor and the integrated circuits made it

possible to distribute intelligence over a control system. During the first half of the

70s Distributed Control Systems were developed. Through the User Station the

operator can have access to all control loops to facilitate coordination and steering.

During the second half of the 70s it became possible and economic to use micropro-

cessors in control systems. This led to increased computational power and higher

11

robustness.

The advantages of using computers within a distributed architecture:

The distributed architecture overcomes the "all or nothing" problem of control

system availability

A reconfiguration of the interconnections between SISO controllers is possible

while the plant is operating

Through the data processing capability of computers it is possible to display

large amounts of data in a way that the operator can make use of it

It reduces the amount of cabling required since digital signals can be multi-

plexed and the analogidigital interface can be located near the points of

regulation and measurement.

With each new version of DCS software information about the process is added. Its

representation to the operator asked for more graphic capabilities in the 80s. As an

example, SPQC is treated here.

During the second half of the 80s Statistical Process Quality Control [10] was

introduced. SPQC uses statistical methods to improve process productitivity and

product quality.

In rebuilding their (parts-)manufacturing industries after WW II, the Japanese

put an extreme priority on quality which led to the Japanese miracle. Because of its

direct relation with "Quality Management", SPQC receives a lot of attention from the

management of process industries. However it is not that natural to apply SPQC in

process industries. Inspired by its parts-manufacturing background, SPQC starts with

the assumption that the process will remain on target unless an unexpected event

occurs. A situation is "in statistical control" whenever the measurements are indepen-

dently and normally distributed about the target with constant variance.

Engineering process control assumes that the process under study is always

being disturbed by disturbances whose sources may be known but cannot be elimin-

ated and that the best one can expect for being "in a state of statistical control" is that

the quality measurement behaves as a stationary process centered about the target

with as small a variance as possible.

The great value of SPQC lies in the fact that operators can work with it in a

very easy and pleasant way. It provides a means of listening to the process and the

control system to eliminate causes of problems. The introduction of gateways

in the 80s linked ncss with PLCs, analyzers and other computers. This development

meant further integration of the control system.

In the 90s the control system is being further integrated; the system gets deeper and

wider which facilitates management to pop up whatever information they want (more

or less detailed, recent or old, far away and close) and direct their orders world-wide.

"Open Use" and "Object Oriented" are key words of the 90s.

12

3 General description of a Distributed Control System

3.1 What's in a name?

The word "distributed" [3] in Distributed Control Systems reflects on systems which

depend on distributed signal processing of plant measurement and control signals. In

this type of signal processing, measurement data are converted to their digital form,

stored in a memory and multiplexed for serial telemetry over the data link. Nowadays

a lot of people use the word "distributed" to denote that intelligence is distributed

over different levels within one control system: primary, supervisory and optimization

control.

For the data link there are three configurations: star, ring and multidrop (see

figure 3.1). The configuration depends on the nature of the data transfers required by

the system architecture. The advantage of the ring configuration is that it tolerates

one break.

To overcome the problem of distortion of digital signals and failure of I/O

equipment (AD interface and multiplexing) duplication or even triplication (nuclear

plants) of these elements is required. Received and decoded signals are compared to

identify distortion.

From now on Distributed Control Systems will denote control systems that

monitor and control a process in real time. It provides a user interface to the process

and supplies real time control actions to the actuators.

3.2 The up-to-date hierarchical process control concept

3.2.0 Introduction

Originally DCSs were developed to keep processes in operation (second priority of

process industry, chapter 2.2), safety being guaranteed by "robust" mechanical process

design and an independent, hardwired safeguarding system. Nowadays one is inte-

rested in matching the third priority: optimization.

Todays industries are confronted with a full customer [4] market. This means

that they have to deal with a very dynamic and hardly predictable marketplace, in

other words produce relatively small quantities with low margins and in spite of this

remain competitive and profitable. Count to this the high social attention for

environmental problems we arrive at the situation that industries need reliable

methods, techniques and tools to operate processes at maximum efficiency, with total

quality control and maximum flexibility.

Most industries cannot afford to redesign their plants. The mentioned goals

must be achieved using existing plants and control system hardware.

Translated into control terminology industries need fully integrated optimal

control of all interacting unit processes such that decisions taken at management level

13

(entered in management terminology) are executed by the control system in the most

economic way.

Because process operation has to be close to the process constraints the

control system has a hierarchical structure. Now, the up-to-date concept will be

described [4].

3.2.1 The hierarchical process control structure

In the hierarchical concept, control in the broadest contents is executed at different

levels, with different priorities, at different sample frequencies. 9 Levels can be

discerned [1], [4]:

14

Minicomput4'lr

Local op,nator

intcrrfacQ and

store

Star links

Plant

microcomputer

Plant

microcomputQr

Plant

microcomputer

tal

Minicomputer

Local operator

interface and

store

Plant

microcomputcpr

Plant

microcomputer

Plant

(b)

Plant

(data

oIcqUJsltion)

microcomputer

Plant

(data

.acqIJisition)

mlcrocomputClr

Plant

( data

acquIsition)

microcomputer

Figure 3.1 Data link configuration [3J

(a) star (b) ring (c) multidrop

15

level 0 :

level 1 :

level 2 :

level 3 :

level 4 :

level 5 :

level 6 :

level 7 :

level 8 :

field instrumentation and AID interfaces

manual emergency system

Safe Guarding System

interlocking

primary process control

T < = 1 second

unit process control

: second < = T < = 1 minute

constraint handling and unit process optimization

1 minute < =T < = 1 hour

dynamic plant performance optimization

1 hour < = T < = 1 day

production optimization

T > = 1 day

From level 4 upto and including level 8 sample times are derived by multiplying the

sample time of the lower level typically 10 times. Average sample times are given.

For some processes, unit process control has a sample time of 1 hour.

In figure 3.2 the 5 last levels are given together with their interconnections.

Oyru.m: PIlM

pwiorn'llroc:4

opciMnOOf'l

Primary

c:ontrol

Figwe 3.2

ProdJcaon Khedulinc and rnodoII bued dyn,,,,,c PI"t pwionnaflca

opOnwuaon

Hierarchical process control [4]

The field instrumentation and AID inteifaces level covers the sensors and actuators

(valves) that are connected to the field and the AID and DIA converters that

interface the process and the control system.

The manual emergency system is a system that can be started by pushing "the red

button" and brings the process to a safe shut-down state. It is hard wired and fully

separated from the control system.

The safe guarding system is a system that accomodates the so called safe guarding

logic and automatically leads the process to a safe state when certain conditions are

not met. Safe guarding systems are fail-safe micro computer based.

16

Interlocking is the lowest level of the control system. To prevent the process of getting

into an abnormal situation, it checks and, if necessary, corrects all I/O signals.

The primary process control level covers the control of primary process inputs (e.g.

pressure, flow, speed, ..). In this level manual, feedforward and feedback control takes

place which is mainly executed by SISO PID control systems. Dependent on the appli-

cation the tuning can be fIxed or automatic. The primary control in general results in

smoothly responding linear or weakly non lineal process inputs (figure 3.3). At this

level the operator is able to dictate setpoints to the PID controllers ("automatic"

control) or to enter the controller outputs directly ("manual" control).

5P --Jl,.,)PIDL...-

1

......

_ 4 ~ ~ I

PV

Figure 3.3 Example of primary process control

When in normal operation, the setpoint inputs of the SISO PIDs are the manipulated

variables for the next level: unit process control. This mode is called supervision.

First a general definition: the process outputs are the variables to be controlled

(Controlled Variables) and the inputs for the controller. Another name is Process

Variables. The manipulated variables (MV) are the inputs to the process being the

outputs of the controller.

The unit process control level covers the control of MIMO processes, in industry called

"advanced" control. A unit process is a part of the plant consisting of several inputs

(setpoints to the primary process control) that can be manipulated within a defined

range, a set of disturbances that cannot be manipulated and a set of process outputs

that have to be controlled according to given specifications. The manipulated and

controlled variables have strong dynamic interactions which makes model based

control the best way to control the MIMO process units.

As by the first level the transfers between manipulated and controlled

variables were made smoothly nonlinear and operation often takes place in specifIc

points or ranges, the dynamic behaviour of the process unit can be approximated by a

set of linear models.

The inputs of the unit process can be manipulated within bounds. To prevent

the signals of overshooting the bounds, a constraint handler is introduced. Constraints

are variables or functions of variables to be kept within bounds. We distinguish two

types: hard constraints do not allow violations, soft constraints temporarily do for the

satisfaction of other criteria. The constraint handler uses a process model to simulate

process responses over some horizon and to detect whether constraints at inputs,

outputs or states are violated. The constraint handler will adjust signals if necessary. It

17

interfaces the unit process control level and the unit process optimization level.

The unit process optimization level guarantees optimal operation of the supervised

unit processes. This can also be denoted by "coordinated" control that can decide to

shift the process from one point of operation to the other. In this level the overall

dynamic performance optimization for the whole plant is combined with the operation

of the unit processes up to hard constraints. Unit processes usually have more

manipulated variables than controlled variables. The corresponding degrees of

freedom can be used for further unit process optimization. Options for using these

degrees of freedom:

introduction of additional (soft) constraints

minimization of additional criteria (mostly related to operation economics)

operation of input variables at preferred variables (ideal resting values)

The soft constraint values and ideal resting values depend upon instantaneous

operating conditions and have to be determined from plant wide optimization.

The dynamic plant performance optimization level covers the optimization of the

overall plant. This includes the determination of production schedules with the

corresponding unit process operation conditions. These conditions include the setpoint

values for the unit process control level, the soft constraints that are sent to the

constraint handler and the ideal resting values in the unit process optimization level

and additional criteria for the unit process control systems.

The production schedules determine when, what product, in what unit process

will be made. Production schedules are based upon characteristics of the production

facilities and production planning information.

To determine the corresponding operating conditions of the process units,

linear programming techniques based on steady state plant simulation are used

nowadays. As stated before industries are confronted with a dynamic marketplace that

orders relatively small quantities of specific (narrow banded) quality. Production must

be possible for different input-product-qualities (crudes for crude distiller). Different

qualities of input product mean different steady states which are not always reached

due to changes in inputs and small amounts of ordered quantities. This is why the

operating conditions based on steady state plant simulation will not be optimal. A

better optimization technique will be to use rigorous (white box) dynamic model

based simulators for the unit processes that significantly contribute to the overall

plant performance.

The production optimization level covers overall optimization of production. Optimal

production planning is determined considering the products requested, required

maintenance etc. A target planning is obtained which is used to determine the

production schedules. This activity is nowadays also denoted by Computer Integrated

Manufacturing.

18

4 The TDC 3000 system of Honeywell

4.0 Introduction

The IDC 3000 system [6] is a Distributed Control System with a multidrop data link

configuration [3]. TDC replaces Total Distributed Control which stresses the split

architecture of the controller functions. In figure 4.1 the IDC 3000 architecture is

given.

A global description of TDC 3000 follows, TDC 3000 will be projected on the

general hierarchical control structure given in figure 3.2 and control functionality will

be treated.

4.1 Global description of mc 3000

Within the TDC 3000 system (figure 4.1) four levels can be discerned: the process

control networks level covers the primary process control and unit process control level

(figure 3.2), the process supervisory level covers the unit process optimization level, the

production level covers the dynamic plant performance optimization level and the plant

management level covers the production optimization level.

There are two types of process control networks: The Data Hiway which is an

"old" system and will not be described here and the Universal Control Network which

was introduced in 1988.

The Universal Control Network is a 5 Mbit/sec token ring network compatible

with IEEE and ISO standards. This description of TDC 3000 focusses on the UCN

and not on the Data Hiway because it is the most advanced control subsystem within

IDC 3000 and is applicated in most of todays process automation projects. The UCN

has three types of nodes: the Process Manager, the Advanced Process Manager and

the Logic Manager. Both types of PM's do data acquisition and have modulating of

sequential control as well as interlocking capabilities. The advanced type has larger

memory capacity (table 5.1). The primary function of the LM is to provide rapid

execution of logic-type operations. It is composed of PLC's and an interface to the

UCN.

The Local Control Network 5 Mbit/sec serial coax token ring. Its maximum

length is 300 m and 32 redundant devices can be connected. When a device possesses

the circulating token it is allowed to broadcast its information to all nodes on the

UCN network.

The nodes at the upper side of the LCN perform the operator interface, save

the history and process supervision task. Via the Universal Station one can supervise

any part of the system that is lower in hierarchy including the nodes on the LCN. The

History Module is a hard disk that contains the software of the system, the graphic

objects and the collected history. The Application Module can be used in combination

with UCN nodes A)PM, LM) to extend the control capabilities.

To make the transition between transmission techniques and communication

19

protocols, interfaces are required to connect the different networks. The Hiway

Gateway connects the Data Hiway to the LCN, the Network Interface Module

connects the UCN to the LeN and the Programmable Logic Controller Gateway

connects the Safe Guarding System to the LCN. Several LCN's can be connected by a

Network Gateway.

The Local Area Network stretches out plant-wide. Its interfaces to the LCN are

the PLant Network Modules. Its nodes execute the management information task.

VAX. computers perform the dynamic plant performance optimization and by means

of other host computers (including a simple Personal Computer) the production

manager can optimize the overall plant production (Computer Integrated Manufactur-

ing).

4.2 Currency of TDC 3000: Points

The IDC 3000 operator console contains several User Stations (up to 10) with shared

peripherals. From the console three

20

Honeywell

'"

\

.,11

1

1

1

tl

MAGNEW

3000

,ii '

i

ST 3000

,

l:]). ,'.I,jil

)j.j .

11 ..

" --:....

sn 3000

rl

N

__-:_,_, . __... "._. ". _ .......,.- ... _._ _ . _.-. ._.,_ "- .. _. _ . _ .--0- --.----..- ..... --- " .. _.- ._ ... _. __ ... __. ......,.

AM ,', = ApplicationModule , EOS '" Enhanced Operator Station lCNE' , '" Local'Coriit' PG ,'"

AMC,':: '" Advanced Multifunction Controller' '" General Purpose Computer Interface, ll.MUX': '" Low,Lev ' ' PLC,'; = Proghu'r:i'

BC",:"'" Basic Controller HeM,;'", H1wax. qquplipg Module,,' I.M30i(:';",

BOS,; ',;= Basic Operator Station ,,"'HG : ",Hiy..ay Gateway 'MC', '<"'" Multif ST3000,,:';";Sma '

'" Compressoi"Control Corporation "HM , "'Hi$tory Module NNG

1M

' ':_- NN, ;'{,

CG Computer Gateway HIM" == Hlway Interface Module \., , STDCM:>;"'sm!itt.t

ClM, ':' '" Communication Link Module.; HTG. ",' Hydrostatic Tank Gauging PC ' ;" Personfil' ,,-:'- ;'.

CM50N' "', 50 N LAN '" Local Are,a Network PCIM '" Personal Computer Interface Module' STT3000';'

DH 'is'''' Dam Hlway '" lCS620 '" Honeywell PLC PCNM '" Personal C\:>mputer Network Module UCN '"

nua n""tO"'l Ulu.....'" D,," I t"a.1 _ I ..."".... 1 1"'".........1 .. 1,.,...........(, _ 0-...... 1 ,,_.. ..I_I 1-"--'---

sections of a process, subdivided in unit processes, can be controlled: area, unit and

point.

An area is a portion of a process controlled by one operator. Example:

polymer area. A unit is a portion of an area represented by a number of points, a set

of alarms and messages. The control responsibility of the operator for the given unit

is limited to this set. Example: reactor unit. A point represents all of the information

about a specific process related item and can be considered as a data record repre-

senting a number of related I/O and parameters. It is the basic element to which

control functions are applied. The main elements of a point are:

Point ID

Parameters

Functions

Point ID is the name of the point (tagname) throughwhich it can be called. In

"Parameters" is declared what inputs and outputs are used and the values of tuning

constants. Example: PID constants. "Functions" defines the operation of the point.

Example: PID. As an example possible points of the (A)PM are listed below.

Analog Input Points:

Digital Input Points:

Analog Output Point:

Digital Output Points:

Digital Composite

Points:

Totalizer Points:

PID Control Points:

Logic Slot Points:

Process Module Data

Points:

Numerics, flags, timers

bring in continuous process data

bring in digital information

typically used to drive control valve

control individual relais

combine related DI and DO into one point (e.g.

on/off values)

accumulates continuous flows over time

closed loop control of process value, contain AI

andAO

interlocking: part of the interface between process

and control system, check whether outputs of the

control system or Process Variables are within

predefined safety bounds.

user written algorithms by means of Control Lan-

guages

Each point is associated with a slot of the memory in the control device A)PM,LM,-

AM).

A SISO control point has two inputs: Process Variable (PV) which is the

actual process output, SetPoint which is the desired value for the PV. It has one

OutPut to the final control element (control valve). A control point has three modes

of operation: manual, automatic and cascade. When just has been switched to

"manual", OP is held at current position and the operator is in direct control of OP.

When in "automatic" the operator controls SP and the controller automatically adjusts

OP to keep PV on SP. In "cascade" OP of one controller (master/primary) is SP input

to the following controller (slave/secondary). When switching from "manual" to

22

"automatic", the process is not allowed to be disturbed by step changes in OP. This

requires bumpless transfer mechanisms (e.g. PV tracking).

Some points are more important to the operator than others. Within APM

three point forms are distinguished. The full point form is to be fully specified. The

component point form only delivers information to the system. The untagged point

form has no name and is referenced by module (= node) number, slot number, and

whether its type is input or output point.

4.3 Controller functions within TDC 3000

In figure 4.2 the distribution of the IDC 3000 nodes over the levels from section 3.2.1

is depicted.

We will focuss on control now rather than on handling abnormal situations and

interlocking. In the following the control possibilities will be treated for the Advanced

Process Manager and Application Module. The LM will not be examined. It's one of

the APM's peers on the DCN. It uses ladder logic to execute programs fast.

23

Control Hierarchy

e.g. PC Production Optimization

Dynamic Plant Performance

Optimization

Unit Process Optinlization and

Constraint Handling

Primary Process Control

(A)PM Unit Process Control

AM

e.g. VAX

TDC 3000

LM Interlocking

PLCG Safe Guarding System

Figure 4.2 Relation between TDC 3000 and the general hierarchical process control

structure

24

4.3.1 SISO control within the Advanced Process Manager

When a point requires standard SISO control within the APM, it is referred to as a

"regulatory control point". An algorithm can be allocated through a special menu. The

possible algorithms are treated below.

The Derivative (PID) controller is a SISO feedback

controller that reduces the error between Process Variable and SetPoint to zero. It

receives PV and SP and outputs the Control Variable in percentages of the maximum

values.

A PID point in the APM can be the master of another datapoint in the same

APM or in another APM on the same DCN.

A PID point in the APM can be the slave of another datapoint on the same DCN or

in the Application Module (constraint handling) or in another computer through the

Computer Gateway.

There are two possible forms: interactive and non-interactive form. In the

interactive form the P and I action are added and multiplicated with a special version

of the D action. In the noninteractive form all actions are added (also "digital

computer version"). The latter is used to emulate the old pneumatic PID form. The

values of the constants can be easily copied in the interactive form.

Both forms have 4 different equations, introduced by the different values the

P,I and D act on.

D Ion PV-SP

A

B

C

P, I, D act on PV-SP

P,I on PV-SP, D on PVt-PV

t

_

T

I on PV-SP, P,D on PVt-PV

t

_

T

to reduce error to zero as quickly as possible

eliminates spikes in CV when quick changes

in SP

smoothest and slowest response to changes

in SP

In the A,B,C equations the P and I actions are added.

For the Interactive form:

Equation A - P, I, and 0 act on the error

CV

s

= k x (1 + Tl * s * 1 + T2 * s

T1 * s 1 + a * T2 s (PV? s - S? ? s) )

Equation B - P and I act on error, 0 acts on PV

1 + Tl * s

cV

s

= K x (-----'--...;:.

T1 * s

1 + T2 * s

1 + a x T2

pVP

s

-

s

1 + Tl x s

T: s

... sPPsJ

Equation C - I acts on error, P and 0 act on PV

1

CV

s

= K x (

+ Tl x s

Tl * s

i + T2

1 T a

s

1

?V?s - x SPPsJ

Tl x 5

Equation 0 - Integral control, only

* PVPs - SPP

s

)

s

25

For the Noninteractive fonn:

Equation A- P, I, and D act on the error

1 + T1 * 5

CV5 = K '" [( T1 * 5 + 72 * 5) * (?

VP

5 - SPP5) ]

Equation B- P and I act on error, D acts on PV

1 + T1 * 5

CV

5

= K '" [( + 'x2 * 5)

71 '" 5

Equation C- I acts on error, P and 0 act on PV

1 + 71 '" s

71 " s

* SPP

s

) ]

1 + 71 '" s

CVs = K '" [( 71 * 5

Equation 0 - Integral contrOl, only

1

CV

S

= 71 * 5 * (PVP

s

-

+ 72 '" S)

SPP

s

)

1

- '" SPPs]

T1 " 5

cv

=

Output of the PID algorithm, full value in percent

a

=

A constant equal to O.l. l/a is the high-frequency gain or rate

amplitude.

K

=

Gain. See 8.13.1.3.7.

PVP

=

The process variable in percent

s

=

The Laplace operator

spp

=

The setpoint in percent

Tl

=

The time constant in minutes per repeat for interactive

form.

T2

= The derivative time constant in minutes.

26

There are four options for changing the gain (K). In linear gain the (constant) value is

specified by the user. Through gap gain modification K is decreased when the error

reaches a specific (small) value. In nonlinear gain modification K is proportional to

the square of the error. In external gain modification K can depend on an input value

from the process or a user written program.

The PID controller is completed by anti-windup handling (if windup then I

action is stopped) and bumpless transfer mechanisms between "manual, automatical

and cascade".

The PID with FeedForward (PIDFF) controller is identical to the normal PID

controller but now the influence of an extra variable can be put in the output of the

controller. The feedforward signal is added to or multiplicated with the output of a

normal PID controller and accumulated. Before the FF signal is fed-in it must have

been subjected to deadtime compensation or lead-lag compensation.

PID with external reset feedback (PIDERFB) accepts a reset feedback signal

from another datapoint, typically a PV of slave-datapoint that receives SP of PID-

ERFB. This technique prevents a wind-up.

PID Position Proportional Controller (PIDPOSPR) is a normal PID in cascade

with a PosProp controller. The OP of PID is the PV of PosProp which generates raise

and lower pulses.

Ratio Control (RATIOCTL) calculates the SP for a PID that must realize the

desired ratio of controlled and not controlled variable.

Ramp and Soak (RAMPSOAK) is used as a setpoint programmer for a

following PID.

Auto Manual (AUTOMAN) is the slave of a cascade that may add to the OP of

the master-controller a bias value that is provided by the operator.

Incremental Summer (INCRSUM) is the incremental sum of the weighed

changes in at most 4 variables.

Switch (SWITCH) chooses between the outputs of at most 4 controllers.

The Override Selector (ORSEL) passes the input (1 out of at most 4) through

with the highest or lowest value. Through this it is possible to measure and control a

specific process variable and have another variable selected to constrain the con-

trolled variable under a specific condition.

4.3.2 Sequential Process Control within the Advanced Process Manager

The point within the APM that executes a Sequential Process Control program is the

Process Module Data Point. These points allow to implement MIMO or unit process

control within the APM (see chapter 5). The language by which the Sequential

Process Control is implemented is Control Language/APM. Control Language

employs a variety of general and process oriented statements with improves both

security and throughput. The maximum number of statements is roughly 3*(1500Q-n)

with n = number of memory units used by datapoints. The programs can be loaded

easily from the Universal Station. Through a PMDP sequential programs can be

started, status can be observed and alarms can be sent to the system.

A CLIAPM sequential program is able to read and write values from any node

on the same VCN, to be subjected as a slave to a datapoint in the Application

27

Module, to use local variables, to start another sequential program and to communi-

cate with the operator.

The PMDP's can be partitioned on a process unit base (figure 4.3).

Advanced Process Manager Module

(APMM)

t

::::

I

"

Process ModUle Data POints

~ 6

,

2 3 4 5 ($eQuence Slots)

-

C

)

<

~

Ie

)

<:

- -

<

D

"

~ r

~ 'rI

,

f I /

Unit' Unit2 Unit3 U n t ~ U..,,:5

Process &:iuipment

Figwe 4.3 Sequence Program Partitioning / Unit partitioning

Generally, a sequential program consists of two main sections: a data declaration

section and an execution section. The execution section can be divided as follows:

normal sequence:

phase:

step:

statement:

subroutines:

Main program, conditions normal, subdivided into

different process phases are marked by key points of

synchronization in the control program (charging, heat-up,

etc.)

executes minor process function (opening valve including

checks)

one eLIAPM instruction, elementary action (opening

valve)

Repetitive functions that can be called by main program,

other subroutines and abnormal condition handlers. At

most two levels of nesting. No use possible of subroutine

libraries.

28

abnonnal condition handlers:

Hold:

Shutdown:

Emergency

Shutdown:

Perform corrective action when abnormal

conditions are encountered. Three types:

partial shutdown (lowest priority)

systematic shutdown

complete and sudden shutdown (highest priority)

The normal sequence can be started by an operator at the US, a statement "Initiate"

in another sequence, CL block in AM, user written program in VAX computer

(Computing Module), abnormal condition handlers and by a predefined process

condition detected by the sequence program.

4.3.3 Control performed by the Application Module

The Application Module is one of the modules on the LCN. The AM can communi-

cate with all modules attached to the LCN including other LeNs and the process

control networks (Hiway and UCN). It can provide directly control outputs to

actuators in the field or to datapoints in the surrounding modules (including itself). In

figure 4.4 all functions are given.

: BUILT-IN !

! ALG(JArrHLAS

..

PROCESS DATABASE

I

g

Figure 4.4 Application Module Functions

The AM contains built-in algorithms that perform point processing and control. The

process database contains datapoints. The Internetwork Point Processor provides for

closed loop control across the Network Gateway (connection to other LCN). As in

the APM, points can be defined in the AM that execute CLIAM programs. Programs

can be coded at the US or in "Workbook"-environment (runs at DOS machine) and

afterwards compiled at the US to eLIAM object code. A user-written CL block can

be bound to one datapoint or written as a generic CL-block.

CLIAM programs have two modes: foreground and background. Background

programs have lowest priority (executed when CPU time is available). Within the

AM, CL can be extended with the possibility to retrieve history from the History

Module (at most 262 values collected in one call) and by adding a Math Library

which covers a set of math subroutines (manipulating matrices, CPU usage calcula-

tions, ..) for those AMs with high performance processor and math coprocessor.

Apart from user-written and standard algorithms that adapt signals from

29

datapoints in various ways the AM contains the same built-in control algorithms as in

the APM.

Several standard software application packages are available that run in the

AM:

Looptune II: optimally tunes PID control loops

Horizon Multivariable

Predictive Control: MIMO Model Based C0ntrol

Real Time SPQC-II uses statistical control for early detection of quality prob-

lems

Only HMPC and SPQC-II will be described here.

4.3.3.1 Horizon Multivariable Predictive Control

Horizon Multivariable Predictive Controller (HMPC) is a model based control

algorithm that executes in the Application Module. HMPC is used in stead of simple

PID control if the process has difficult dynamics (dead time, instabilities, high order)

or as supervisory control/unit process control.

The model allows the controller to predict how the process will react c.q. what

the PV will do in the future for a certain controller output now. The algorithm

calculates the OP now that will make the output of the model (=PV) equal to the

setpoint in future time. So HMPC has only one tuning constant: future time =

Correction Horizon. For the tradeoff between response, effort and robustness see

figure 4.5.

Small H

Fast correction

Large ouptut change!>

Sensitive to model errors

H --..

La!'.&e H

Slow correction

Small ouptut changes

Tolerant of model errors

Figure 4.5 Tradeoff between response, effort and robustness

HMPC works well if the process can be approximated by a linear, time invariant (step

response is same when test is repeated at different times) model. Most processes are

linear over the normal operating range but slowly or infrequently changing dynamics

can be dealt with as well by reidentifying the model.

The output of the controller can be sent directly to the process or cascaded to

the SP of a slave controller. The process "seen" by the upstream controller includes

everything between the OP and PV, induding all downstream controllers.

If some of the process disturbances can be measured or calculated it is

beneficial to feed them forward. Feedforward makes the controller aware of the

30

effects of disturbances before they cause a deviation of the PV fed back to the con-

troller and SP (see figure 4.6).

Figure 4.6

r

- - - - - -

-

- - - - -

,

I

Process 2

I

I

HPC

I

Feedforward I

Actual

Process

+

HPC

Process 1

Controller

L

- - - - - - - - - - - -

J

Control loop with one feedfolWard

Feedforward can also be used to implement non-interacting control by compensating

for the interactions between two or more loops (see figure 4.7).

SP2

PV2

r-------------------l

PV1

I OPl

I

I I

I

S ~

HPC I

ProcesI511

J.

I

ControUer 1

I

I

I I

+

'<,Y I

I +

I

I HPC

I PV12 I

I I

l

Feedforwa.rd 12

I

I

I

Process 12

I

I

I Actual Proce&s

I PV21

I

I I

HPC

I

Process 21

Feedfarward 21

I

I

I I

I

+

I

I

I OP2 I

I

I

+

x',..

HPC

Procma 22

I ControUer2

I

I

I I

'U'

I

I

L ___________________ J

Figure 4.7 Noninteracting control

31

HMPC consists of four software products: Data Collector, Identifier, HMPC controller

and Simulator.

The Data collector collects data for building the mode1(s). Once the variables

that will be used are identified, the responses of the outputs are collected to changes

in the inputs of the unit and stored in the AM data base. In the real world production

may not be stopped so the collection must take place within the disturbance margins.

Because the following step takes place in a PC, the data must be transferred from the

AM.

The Model Identifier creates mathematical models for each Control Variable

expressed in Manipulated Variables. HMPC uses the Finite Impulse Response form

but parametric models like the Auto Regressive Moving Average form are also

supported. Before the real identification takes place the data have to be prepared.

During a data conditioning session, invalid data must be replaced by linear interpo-

lations, the sample frequency must be adapted to the dynamics of the signal, the data

must be filtered. The Data Analysis determines whether there is enough information

to create a good model (through Signal to Noise ratio, Correlation-, Spectrum- and

transfer function analysis). In a MatLab environment the model is built off line. If

available the user can also enter the transfer function matrix, a routine will transform

it to parameters of the model.

Figwe 4.8

History Module

LeN Resident

PC Resident

I Identifier

HMPC Data Flow

32

Editor

The HMPC controller definition and fine tuning takes place in the Pc. It is an

interactive process that requires a simulator that is -of course- the model. In figure

4.8 the HMPC data flow is depicted.

If the user is satisfied, the models and HMPC controller structure are trans-

ferred to the AM to actually control the unit.

4.3.3.2 Real Time Statistical Process Quality Control II

Real Time SPQC is a software package that runs in the AM that helps to minimize

the process variation and maximize the product quality. SPQC could be seen as an

intelligent observer of the process and is a means of extending the operator's view.

When certain ranges are crossed the operator is notified and can take corrective

action. SPQC has three main functions:

automatic data acquisition from any point in TDC 3000 or manually entered

control charting makes distributions easy to comprehend

statistical alarms: point alarms, range limit alarms

Using these tools in a proper way helps the user to detect quality problems before

they occur, to detect changes in raw materials and to determine which production

areas affect most the end product quality.

4.3.3.3 Model Based Control versus Statisical Process Quality Control

Well designed Model Based Control systems know and use the dynamics of the

process to perform optimally control. During the identification procedure the most

important disturbances were involved in the control system design. The quality of the

product in a steady state is being guaranteed when the circumstances are the same as

during the identification.

MBC can be combined succesfully with SPQC to processes that show fast and

slow dynamics, the latter caused by slow disturbances. The MBC uses the fast

dynamics and the SPQC filters out the slow disturbances.

For processes that are hard to identify and can be controlled only by roughly

tuned PID controllers, SPQC can help. The assumption that the process behaviour is

statistical might be the best under certain conditions.

4.4 What levels in the hierarchy are being filled in recent projects ?

In this section the 9 levels of section 3.2.1 and figure 4.2 are important.

Section 3.2 was based upon the up-to-date hierarchical process control concept.

Up-to-date means optimal here. However, in recent process automation projects less

advanced structures are used due to the different priorities of process industry stated

in section 2.2.

The levels 0 up to 4 (field instrumentation up to primary process control) are

filled in for almost every project. Experience gained in former projects is represented

33

by standard solutions for standard problems being gathered in libraries.

As the primary process control level, the unit process control level (5) is

responsible to the unit process in operation in a specific point. In most applications it

directly receives supervision from the operator at the User Station instead of the

higher hierarchical level. For those applications the operator has a larger responsibil-

ity, interfacing the higher optimization levels (of which some can be automated) and

the lower control and emergency levels.

The presence of an AM on the UCN (figure 4.2) does not necessarily mean

that the unit process optimization level (6) is automated. In a lot of applications it is

only an extension of the APM that executes special user written algorithms at the

same level of control as the APM. In practice level 6 is denoted by "co-ordinated

control". It can provide two different types of coordination: (i) sequential process

control to move to another point of operation (in the unit process optimization

terminology this motion would be optimal) and (ii) all kinds of calculation programs.

Examples: calculation of controller constants at certain time intervals (Adaptive

Control), "Bang-bang Control" [1].

As stated in section 3.2.1 still a lot of research has to be done to develop the

dynamic plant performance optimization level (7): requires white box modelling and

simulation of the total plant in order to derive production schedules with operating

conditions.

The production optimization level (8) or Computer Integrated Manufacturing

is connected directly to the management information systems (supplies, data).

Applications are known. Its success as a means of directing orders is of course

determined by the quality of the lower levels.

34

5 Implementation of a Model Based Controller on

TDC 3000

5.0 Introduction

In 1992 Honeywell implemented a Model Based Controller in the IDC 3000 system

[11]. It was a pilot project: one wanted to know what possible problems could occur

during the project (planning, effort, responsibility), to what extend IDC 3000 is

prepared for the implementation of a Model Based Controller (level of standard

software and hardware, operator interface: turning the controller on and of) and how

much system capacity the controller would take (memory units, processor time).

5.1 The Internal Model based Control form

The Model Based Controller developed by IPCOS (SETPOINT IPCOS now) has the

Internal Model based Control form [4] of which the most general scheme is depicted

in figure 5.1.

Incernal model

hued control

syn.em

Process

outpuu

Figure 5.1

Intemal Model based Control scheme [4]

The philosophy behind the scheme is that as much information as possible is fed

forward and only unmeasurable disturbancesare fed back. In practice only for

minimizing the error (difference between process and controller output) feedback is

necessary.

The scheme contains several model based controllers. The feedback controller

can be designed with H inf, the feedforward setpoint compensator is designed to

prevent that operating co-nstraints are violated by changes in the operating point of

the process. In "Model" the process transfers are modelled, in the feedforward

disturbance compensator disturbance transfers of measured disturbances to the

process outputs are modelled. The latter compensates measured disturbances by

subtracting the modelled output disturbances from the error signal and adding them

35

HIHo

Top product

Reflux level

controller

....

. .

Bottom product

Reflux tank

Condensor

r- - - - -

I

I

I

I

I r --

I I

I I

I

I

I

J

Reflux setpoint

--------,

I

I

MIMO

controller

Reflux

Feedflow

Preheater

Reboiler steamflow

setpoint

r-----------,

I

t I

I I

I

----------------------------------

Stearn

Feed

Cooling water

..

t\.)

c,

t:;'

....

-.

;::::

l::l

....

c

:::l

('l

c

E'"

-

....

...

:::l

l::l..

0'\

("')

C

:::l

....

::::::

<'l:>

"'I

to the model output. The constraint handler uses a process model to simulate process

responses over some horizon and to detect whether constraints at inputs, outputs or

states are violated. If so it will adjust signals.

5.2 Internal Model based Control for a Distillation Column

In figure 5.2 the distillation process and the controller are depicted. Of the primary

process control level only the PID controllers that receive setpoint values of the

MIMO controller are shown.

Inputs of the controller are:

top purity

bottom purity

feedflow

Outputs of the controller:

setpoint for the reboiler steamflow

setpoint for the reflux flow

The controller architecture is not listed here because it is confidential informa-

tion. The general structure of the controller is given in figure 5.1. The controller

contains only two models. Apart from the process (including the primary control

level) transfer model, the feedflow is the input of the feedforward disturbance model.

The feedforward setpoint compensator is not used and the feedback controller is a

Proportional action only. A limiter limits the control signals to the process and the

controller uses de-filtering. Defiltering is applicated when both the filtered and the

un-filtered version of a signal should influence the steer signal. The models are State

Space versions.

5.3 Implementation on TDC 3000

5.3.1 Requirements

The MIMO controller acts as a unit process controller. As depicted in figure 4.2 the

unit process control level is covered by the (A)PM. The IMC controller was compact

(State Space) enough to implement it in the PM (Process Module Data Point). The

implementaton of an explicit constraint handler was not part of the project. If it had

been or will become, it ought to be implemented on the AM (unit optimization level)

where there is enough space even to deal with a number of complex soft constraints.

The goal of the project was not to prove that the controller performed well

(control the process) but that it could be implemented easily on IDC 3000 (A)PM.

This is the reason why the models used in the controller could do as the process

simulator during the final tests. This raises one withdrawal: The MIMO controller is

based on models of the primary process control level + the distillation process. If the

models used in the MIMO controller function as simulators, the controller should be

attached directly to the simulator. In this case the operator can only enter the desired

top and bottom qualities and simulate the feedflow through a setpoint value. To

increase the operator's power, the same PIDs as in the primary process level and

37

w

co

TDC-3000

Implementation .

blockscheme

IPCOS IMC

Operator

settings

field inputs

digital)

>... ".3'-' eywell Amsterdam

..... 11-92

digital

CL(JLOCK Col_Mirna

:;0,

;-<euoilel

rlf) 0"'1

Umk(l)

1.:Sp(2) 1------1..

C,JS Aulc

Usp(1) 1------1..

7

",

(cJS Aulo

Ilr,I-,(l: 1--------------------------'

PIO ",'!

Ulilkl7J JI

Q V 302

FOe"

F"e:J Fl ',w

OIA30:-

ToC' Qualil y

011,30'

eu.]:;',

'Jrli.

L:_:__PI_[l__

---11-1 YIl)

I" DAS PV ., CALC (,1 (SPI Ysk(1)

L"C NTV, p. ", YI<(2)

" {iA:; PV (A' r (", (:,P) Ysi2)

C, 301

t"'"

c

.g

s:::i

'E'

.,

-

;::..

(J

w

s

-

;::..

t...l

c::.

c::.

Ilrll..d2:

'-----------------------------4-1

AI'I'IIOVAL

1 , ..

Irn,s

1;11-

...... :j,'.'.( "CI'

:)IA[;I1AM : ClOP

:J' _,"'1" " 10.\-1,

iNTERlljAL M:JDEL : Of\: T LER

:,

I '1.0.

,--

'-1111:) FOP DCTIL LAT10:-1 LOLUI'N

f',:, ... '

: -'l:' 79 Ion JI'I

.

All

I I I I I I I

r'""f 'Jr, 372201 .... ,

Honeyweil

lNOLJSTR1Al AliTOMr"::N

PM300 \' -,I,

Program structure

Sequence Col_Mimo(PM; Point Col_Mimo)

External definitions and references

Local Variable definitions

Local Constant definitions

Phase Init

Define variables with a constant value (singles and arrays)

Phase Control

Step Read Val

Read Quality PV's

Read Quality SP's

Read Feedflow PV

Read Reflux and Reboiler PV's

Calculate Fs filter

Step Proc mod

Multiply Am_Xmk = PJn * Xmk

Multiply Bm_Xmk = 8m * Xmk

Add XJm< = Am_Xmk + Bm_Xmk

Multiply Cm_Xmk = em * Xmk

Multiply Om Umk = Om * Umk

Add Ymk = Cm Xmk + Om Umk

- -

Step Dist_mod

Multiply Ad_Xdk = Ad * Xdk

Multiply Bd Udk = Bd * Udk

Add Xdk = Ad Xdk + Bd Udk

- -

Multiply Cd_Xdk = Cd * Xdk

Multiply od Udk = Dd * Udk

Add Ydk = Cd_Xdk + od_Udk

Calculate Fr filter

Calculate Reflux and Reboiler SP's

Goto Phase Control

End Mimo Col

Figure 5.5 Sequential Program Structure for MIMO Process Module Data Point

40

cI) linqLd :3 t er'

..._-- - ---II

-1

., _.. , , ' ,

h. l' 1'.J ,.,

, -__.._..--.--:-,,---..1

:30.110 I

'.. :.1 I

. -- I .111'''''''''''''''''''')

I .Refluxtank

I

l....lIlol4--fo!-r-r-rt ======== I;';' r-(O} Cp b ,i

I

L.U.__ __ _Jp. _ S..

I T - ,- I" "., .. j I I 0. f

l

I.U 1..1 ..'; 1.1 I ..J I. '.,

I I'

L

I

r

-lo........ -+_. .J .-..

--- ---- --.-.--..-.- ------( iJ ", 1 f F"1 ';1

b_l_

1

1_'.... 1_e_r'__...... jIalll- __.-l._ .

Condensate Bottom product

i

r-----

i .'-.

i

'F'

i, "0"

"ToO-

I PCO': :'I I 1,1 Ci

IMC DISfILLHTION CJLUMN

three delays were interconnected between the controller and simulator. In this

configuration, disturbances can be introduced by changing the tuning constants of the

PID controllers. The limiting of the setpoints requires some logic as well.

It was only practical to implement the simulator in the same PM. Eventually

the required system configuration was:

1 x User Station

1 x Local Control Network

1 x Network Interface Module

1 x Universal Control Network

1 x Process Manager, release 300

1 x alarm printer

The resulting architecture does not contain a unit optimization level to provide the

MIMO controller with setpoints for top and bottom quality. Instead they are entered

directly by the operator from the US using the setpoints of the interconnected PIDs.

This also holds for the simulated reflux- and reboiler valves. When the PID control-

lers are in automatic mode, the operator can enter setpoint values for the PID

controllers during the "start-up" of the process. After this, the controllers are switched

to cascade mode (normal operation). In figure 5.3 the IDC 3000 implementation

blockscheme for the IPCOS IMC is shown. In figure 5.4 the resulting loop diagram

for the PM 300 is depicted.

The Sequential Process Control structure of the controller in a PMDP is given in

figure 5.5. In "Step Proc_mod" the state and output vectors of the process model are

updated, in "Step Dist_mod" the state and output vectors of the disturbance model

are updated. This updating requires matrix multiplication for which no standard built-

in algorithm is available right now in the PM (in the AM it is). In this case all matrix-

multiplications are written out in full CL which makes this implementation very

specific. In figure 5.6 the operator's view on the controlled process is shown.

5.3.2 Results

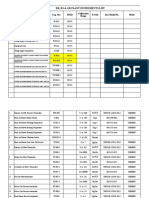

In table 5.1 the available and required performance for the implementation of the

MIMO controller in the (A)PM 300 is given.

42

Table 5.1 Available and required performance of the (A)PM 300 for implementation

of the MIMO controller

# Memory Units # Processing units # Variables

System capacity (available)

APM300 10000 1600 2048+80*n

PM 300 3200 1600 2048+8O*n

Control Scheme (required)

-Basic Control 70 70 at 1 s scan

-MIMO Control 100 Max. 150 at 10 s scan 300

Aver. 15 at 10 s scan

-SP limits processing

(estimation) 35 Max. 20 at 10 s scan 25

Aver. 2 at 10 s scan

Total amount

required 205 for APM 2.1 % Max. 240 15% 325 < 16 %

205 for PM 6.5 % Aver. 90 5.6 %

The required amount of CPU is expressed in so called processing units. The scanning

frequency of the MIMO controller can be specified and is typically 10 times slower

than the scanning of the connected primary controllers. The memory size is denoted

by the number of Memory Units. The number of Variables depends on the number of

Process Module Data Points (n). Each configured PMDP has 80 local variables.

5.3.3 Conclusions

In table 5.1 the most important constraints are the number of variables and the

maximum number of processing units required. These values determine the number

of control loops that can be implemented in the (A)PM. As to this number there is

no difference between APM and PM. In this implementation 6 MIMO loops including

additional requirements could be implemented but in practice one per (A)PM would

do.

The number of variables can be decreased and robustness can be improved by

declaring the parameters that do not change (contents of State Space matrices, scaling

factors) to be constants. This would mean a variable reduction of at least 70 %.

Drawbacks of this operation would be that constants could not be changed and

visualized during runtime, the use of generic subroutines is impossible (manipulations

index impossible) and declaration in both controller and simulator is necessary. The

operation would make it possible to implement 8 MIMO controllers in one (A)PM.

Because only one process-unit MIMO controller is required in the APM, its complex-

ity can be increased and a constraint handler could be added.

If the PID controller is out of cascade mode, the MIMO controller sequence

"holds" while the process simulator continues. Of course, this causes a large error

between MIMO controller output and process simulator output and consequently,

when switching back in cascade mode, it takes a long time to get back the process

simulator PVs according the SP values.

Mter all we may conclude that the (A)PM allows MIMO controller implemen-

tation without any problems as far as (A)PM performance is concerned (takes only a

43

few percents of total). The MIMO controller perfectly copes with the primary

controllers in the (A)PM. In particular as far as bumpless transfer is concerned after

switching back to cascade (MIMO) control. The operator need not worry and can