Professional Documents

Culture Documents

Steel Fibre Reinforced Concrete (SFRC) For Tunnel Linings - A Technical Approach

Uploaded by

Mehdi Bakhshi0 ratings0% found this document useful (0 votes)

229 views7 pagesSteel Fibre Reinforced Concrete (SFRC) for Tunnel Linings_A Technical Approach

Original Title

Steel Fibre Reinforced Concrete (SFRC) for Tunnel Linings_A Technical Approach

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentSteel Fibre Reinforced Concrete (SFRC) for Tunnel Linings_A Technical Approach

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

229 views7 pagesSteel Fibre Reinforced Concrete (SFRC) For Tunnel Linings - A Technical Approach

Uploaded by

Mehdi BakhshiSteel Fibre Reinforced Concrete (SFRC) for Tunnel Linings_A Technical Approach

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 7

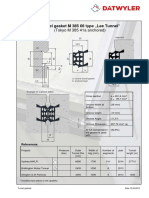

Tunnelling and Ground Conditions, Abdel Salam (ed.

) 1994 Balkema, Rotterdam, ISBN 90 5410 363 9

Steel fibre reinforced concrete (SFRC) for tunnel linings: A technical

approach

D.Moyson

N. V. Beknert, Belgium

ABSTRACT: Tunnel linings are loaded under the combined action of normal forces and bending moments. In this

paper it is shown that the bearing capacity of plain concrete can substantially be enhanced by the addition of steel

fibres. The steel fibres provide the concrete an improved bending behaviour resulting in a better bearing capacity,

especially for large eccentricities. This improved behaviour together with the practical advantages of the use of steel

fibre reinforced concrete (SFRC) makes this composite material particularly interesting for tunnel linings.

1 INTRODUCTION

SFRC is not a new material in the tunnelling world.

For several years, steel fibres are commonly used for

shotcrete, having several advantages (ref. 1):

I. Technical: the addition of steel fibres provides the

shotcrete an important degree of ductility. This

ductility results in an improved loading capacity of

steel fibre reinforced shotcreted (SFRS) shells

compared to plain shotcreted ones. The technical

performances of SFRS shells are comparable to

conventional reinforced shotcreted shells.

2. Practical: the steel fibres are easy to add to the

concrete aggregates. In ,comparison to conventional

mesh a lot oftime and labour can be saved.

3. Cost: the shorter execution time and savings in

labour costs makes SFRS a competitive alternative.

Since shortly, an increasing growth of SFRC has also

been established in the domain of prefabricated tunnel

segments and tunnel linings casted in situ. The same

practical and technical advantages as for shotcrete are

here obtained.

In what follows the bearing capacity of steel fibre

reinforced tunnel linings is discussed. In paragraph 2,

the toughness ratio of SFRC will be defined. This

toughness ratio is the essential property of SFRC and

represents the effect of the fibre reinforcement. Based

upon the toughness ratio and the stress-strain beha-

viour of plain concrete, the stress-strain behaviour of

SFRC is determined in paragraph 3. By integration of

the different stress distribution lines, corresponding to

the different considered deformation lines, the bearing

capacity in terms of bending moments and normal for-

ces are calculated for a specific cross section. This is

done in paragraph 4. In paragraph 5, the design of a

SFRC tunnel lining is established for a specific load

case according to the method of Bugieva.

2 THE TOUGHNESS OF SFRC

The basic properties of the composite material steel

fibre reinforced concrete (SFRC) are described in an

increasing number of normative publications. In

general they all characterise SFRC by two groups of

parameters : flexural strength and flexural toughness.

Flexural strength is expressed at first crack f., this

is when the pure elastic limit of the material is

reached. From this point on, the stress-strain

relationship is not linear. A second strength parameter

is the modulus of rupture or the ultimate flexural

strength f.. Ultimate flexural strength and flexural

strength at first crack are not different for plain

concrete nor for SFRC with fibre contents up to 40

kg/m3.

Flexural strength at first crack depends on concrete

characteristics and is not influenced by fibre content.

Ultimate flexural strength may increase compared to

plain concrete at fibre contents ;;:: 40 kg/m3,

depending mainly on the length/diameter ratio or

aspect ratio of the fibre. An increase of ca. 15 % is

achieved using 40 kg/m3 of r a m i x ~ ZC 50./50 fibre.

The r a m i x ~ ZC 50/.50 fibre is a steel wire drawn

fibre with a length of 50 mm and a diameter of .50

mm and is hooked at both ends, see figure I.

673

50 nun

figure 1: Dramix< ZC 50/.50

"C

Cll

.Q

d=0.5mm

deflection

figure 2: Typical load-deflection curve for SFRC

The characteristics of SFRC are measured by means

of third-point loading tests, where the beam

parameters are fixed in each standard or

recommendation. Figure 2 shows a typical load-

deflection curve for a SFRC beam reinforced with

steel wire drawn fibres with hooked ends.

Flexural toughness is expressed in very different-

ways. We find definitions of parameters that express

absolute toughness, as equivalent flexural strength f .

This absolute toughness is the average post-crack

strength measured on a test beam under bending up to

a defined deflection.

Relative toughness R. can be expressed by relating

the average post-crack strength to the flexural strength

at first crack, thus creating a toughness rating

expressing against what percentage of loading still can

be resisted after concrete failure.

In this article we will use the flexural strength and

the toughness rating according to the Japanese

standards (ref. 2). The average post crack strength or

equivalent flexural strength f. is calculated elastically

by dividing the total absorbed energy D during the

test (till a deflection of 1/150 of the span length) by

the deflection o, taking into account the dimensions of

the beam (1).

f. D.l (Nfmm

2

) (1)

= a.b.h

2

where

D = total absorbed energy during the test (Nmm)

I = span length (mm)

o = maximal deflection (mm)

b = width of the beam (mm)

h = height of the beam (mm)

The equivalent strength f. is the essential value

which characterises the effect of the steel fibre

reinforcement. Research has shown that the equi-

valent flexural strength, measured on beams according

to the Japanese standards, varies as a function of the

concrete flexural strength. On the other hand, it has

been shown that the relative toughness R.. for

concrete qualities up to 50 N/mm2, remains constant

and is only dependent on the fibre type and dosage.

The relative toughness R. can be expressed as a

percentage of the first crack flexural strength f. of the

plain concrete (2).

R = 100 f, (%) (2)

fo

R. is defined as the ratio between the ultimate

flexural strength of SFRC and the first crack strength

of the plain concrete (3).

R,. = f. (3)

fo

In the figure 3, the toughness ratio R. as well as the

modulus of rupture ratio R. are expressed as a

function of the dosage for the Dramix< ZC 50/.50.

The relation is based upon a large amount of tests _

performed by Bekaert and extern laboratories (ref. 3).

140

120

;- 100

Ru

80

0

or4 80

.,

------ Re

.--

..

40

20

0

0 10 20 30 40 50 80

dosaqe Dramix zc 50/.50 (kqfm3)

674

figure 3: R. and R. as a function of the dosage of

Dramix< ZC 50/.50

From the figure one can see that for a dosage of

50 kg/m3 of Dramix ZC 50/.50 fibres, the ultimate

strength of the concrete is increased by 20 %, while

the equivalent strength is 94 % of the first crack

strength of the concrete.

Based on these R. values, the equivalent flexural

strength values for all concretes up to 50 N/mm2, and

all fibres types and dosages can easily be calculated.

Example : Is the concrete giving a 5,0 MPa flexural

strength, than the design value of this concrete with

steel fibres giving a rating of 90 % will be 4,5 MPa.

These 90 % is achieved (according to the diagram)

using 45 kg/m3 of ZC 50/.50.

3 STRESS-STRAIN RELATIONSHIP FOR SFRC

The equivalent flexural strength f., which is the

average post crack flexural strength of the SFRC, is

deduced from the total absorbed energy (I) assuming

a linear variation of the stresses over the height of the

element as shown in figure 4a.

f.

figure 4a: elastic stress distribution

figure 4b: plastic stress distribution

However, in reality the SFRC does not behave in the

elastic uncracked state, but the concrete is cracked and

the stresses are no more linearly distributed across the

cross-section. The plastic stress distribution along the

cross-section, corresponding to the average post crack

resistance of the test specimen, can simplified be

drawn as in figure 4b.

The compression zone can clearly be distinguished

from the tensile zone. The width of the compression

zone is approximately 0.1 times the width of the

tensile zone. The compressive stresses vary linearly,

while the tensile stresses are constant. The tensile

stress should be considered as a post crack tensile

strength or equivalent tensile strength f .. provided by

the effect of the fibre reinforcement.

Using figures 4a and 4b as a basis, the value of the

post-crack tensile strength f .. can be determined under

the condition that the flexural moment capacity is the

same for the plastic as for the elastic stress

distribution (4).

b. h

2

/.,. b 0 h . 0,9 . 0,5 . h = ' -6-

!., = 0,37 . f. (4)

According to (2) the equivalent tensile strength can

also be written as a function of the ultimate flexural

strength of the plain concrete and the toughness ratio

R,. (5)

R.

!., = 0.37 . - . /

0

(5)

100

This equivalent tensile strength characterises the effect

of the fibre reinforcement. This value is essential,

since it represents the tensile strength that can be

taken up by the concrete thanks to the addition of steel

fibres. Research (ref. 4) has shown that this average

strength can effectively be provided by the steel fibres

for deformations up to 10 %o.

The addition of steel fibres does not only improve

the tensile behaviour of the concrete, the behaviour

under compression is also positively modified

compared to plain concrete. Although the steel fibres

does not enhance the compressive strength of the plain

concrete, they do improve the maximal strain under

compression. Thanks to the addition of steel fibres,

the behaviour of the concrete under compression is

modified from a brittle behaviour into a ductile

behaviour, providing a larger strain capacity. In (ref.

4) a maximum strain of 5 %o in compression is

considered for SFRC, instead of 3.5 %o for plain

concrete.

Based upon the above mentioned characteristics for

SFRC, the stress-strain behaviour of plain concrete

can now be modified. In figure 5, the characteristic

stress-strain behaviour for the plain concrete is drawn.

675

The characteristic stress-strain behaviour is conform

to the actual standards.

10

strain (%o)

---- char. stress-strain

relation plain

concrete

8 6 4 2

figure 5: Characteristic stress-strain behaviour for

plain concrete

The characteristic stress-strain behaviour for SFRC

is drawn in figure 6.

---- Design stress-

strain relation

SFRC

::50 -------

l-40./

i ,'

I I

t ~

- - - - - char. stress-strain f /.

relation SFRC [

'-:-----::------:::--------::----' H10

10 8 6 z j

9

2

strain (%o)

i

" 10

figure 6: Characteristic and design stress-strain

behaviour for SFRC

The maximum tensile strength is equal to the

equivalent tensile strength f., as defined above and is

maintained till a deformation of 10 %o. The stress-

strain relation in the elastic range is the same as in

compression, apart of the sign. The stress-strain

behaviour in compression is equal to the one for plain

concrete, except for the maximum strain which is 5

%o instead of 3.5 %o.

In figure 6 the design stress-strain behaviour for

SFRC is also drawn. The design stress-strain

behaviour can be deduced from the characteristic

stress-strain curves by taking into account a safety

factor in tension and in compression. In compression

a safety factor 'Y. of 1.4 is taken. In tension a safety

factor 'Y is taken which is a function of the toughness

ratio. For a 100 % are more tough material a safety

factor of 1.15 is considered, this is the same value as

for steel. For a 0 % tough material a safety factor of

1.4 is considered as for plain concrete (6).

R

y, = min ( 1 ; 1,4 ~ ( 1,15 - 1,4 ) . 1 ~ ) (6)

4 THE BEARING CAPACITY OF SFRC

In figure 7 the different deformation conditions for

SFRC, which should be considered according to the

plastic theory, are drawn.

lc2 O"t.. _,cl

~ ~ .. :

figure 7: Deformation lines for SFRC

To each deformation line corresponds a specitic

stress distribution. For each deformation line, the

corresponding bearing moment M and normal force N

can easily be determined by integration of the stresses

over the cross-section.

In figure 8, the bearing normal forces and moments

of a section with a thickness of 300 mm is represented

for plain concrete and SFRC. Hereby e/d represents

the ratio between the eccentricity e and the thickness

d of the element. The eccentricity is the ratio between

M and N and is expressed in mm. The characteristics

for both concretes are exposed in table I.

table I: Characteristics of plain concrete and SFRC

plain concrete

char. compressive strength 50 Nlmm

2

safety factor 1.4

maximum strain -3.5 %o

SFRC

char. compressive strength 50 N/mm

2

safety factor 1.4

maximum strain -5 %o

char. flexural strength 5 N/111In'

50 kg/m3 Dramix ZC 50/.50

toughness ratio R. 94%

equiv. tensile strength 1.7 N/mm

2

safety factor 1.17

maximum strain 10 %o

676

12000

10000

E

.....

z

8000

.,

6000

...

ii

4000

E

0

z

2000

0

0

zone 1

50 kglrn3 zc

50/.50

-----no fibers

zone 2

zone 3

200 400 600

Moment (kNmfm)

figure 8: Bearing capacity of a plain and SFRC

section

From the figure one can distinguish three zones :

zone 1, 2 and 3 which corresponds respectively to

small, middle and large eccentricities.

For zone 1 the bearing capacity for SFRC is the

same as for plain concrete. The whole section is

loaded under compression and the maximum com-

pression stress is not influenced by the addition of

steel fibres.

In zone 2 an increasement in load bearing capacity can

be seen by the addition of steelfibres. The increa-

sement varies from a value of 0 % for the smallest

eccentricity till a value of oo for the largest

eccentricity, since for this eccentricity the plain

concrete shows no bearing capacity. In zone 3 the

bearing capacity of plain concrete remains 0, while

for SFRC important forces can be taken up.

The increasement of loadbearing capacity by the

additional steelfibres varies thus as a function of the

eccentricity. For large eccentricities the largest en-

hancements are obtained.

5 DESIGN OF TUNNEL LININGS

The method which will be discussed here to calculate

the forces acting on the segmental linings is the

method of Bugieva (ref. 5). This method takes into

consideration the interaction of the tunnel lining and

the surrounding rock. The method developed by

Bugieva is based on the analysis of the distribution of

bending moments and normal forces in the lining

which is supporting a uniform vertical load and is

transferring the load onto the surrounding rock in an

elastic manner. Figure 9 shows the assumed dis-

tribution of elastic reactions around the rock.

figure 9: Elastic reaction around the rock according to

Bugieva

The calculation of the elastic reaction forces in the

rock, which are due to the deformation of the lining,

makes use of the coefficient of ground reaction. The

bending moments and normal forces in a circular

lining are the functions of the coefficient of ground

reaction and the rigidity of the tunnel lining. An

increase in the coefficient of ground reaction or in the

flexibility of the tunnel lining will result in a decrease

in the acting forces in the cross section of the tunnel.

677

The bending moments M and normal forces N acting

on the cross section of a tunnel lining can be

calculated by the following formulas of Bugieva (1 a

& b).

M = p . R

2

.(A + B + 2 . C . n) (N.mm) (la)

N = p . R .( D + F + 2 . G . n ) (N) (7b)

where

p

=

R

=

I

=

E

=

k

=

uniform vertical load (N/mrn2)

radius (mrn)

moment of inertia (mm4)

elasticity modulus (N/mm2)

coefficient of ground reaction of surrounding

rock (N/mm3)

and (8 a & b)

1

n = -----

m

m + 0,06416

E. I

R

4

.k

(Sa)

(8b)

The values for A,B,C,D and Fare exposed in table 2.

table 2: Values for A,B,C,D and F

A B c D F G

a=O 0.01628 o.o8n -0.0070 0.2122 -0.2122 0.02100

W4 -0.0250 0.0250 -0.00084 0.1500 0.3500 0.1485

W2 -0.1250 -0.1250 0.00825 0.0000 1.0000 0.0057

3n/4 0.0250 -0.0250 0.00022 -0.1500 0.9000 0.01380

n o.osn 0.1628 -0.00837 -0.2122 0.7122 0.02240

Figure lO shows a typical distribution of the

moments along the circumference.

figure 10: Distribution of the moments along the

circumference

Example

The maximal uniform vertical load p acting on the

crown of the tunnel section for a very blocky and

seamy rock is given by Terzaghi (ref. 6) (9) :

p = 2 - 1,1 _ R _ y, (N/m2) (9)

where

R = radius of the tunnel (m)

"f, = unit weight of the rock (N/m3)

For R = 3 m, and for "f, = 25 000 N/m3:

p = 165 000 N/m2.

The coefficient of ground reaction of the

surrounding rock can be written as (10) :

E,

k = ---'---

R(1+v,)

(10)

where

v, = Poisson's ratio for rock

E, = Modulus of elasticity (N/mm2)

For v,=0.25, E,= lOE3 N/mm2 and R=3000 mm:

k = 0.27 N/mm3

The bending moments and normal forces can be

calculated according to (7 a & b) where:

R=3m

I = 2.25 10E9 mrn4 (thickness d=300 mrn)

E = 20 000 N/mm2

k = 0.27 N/mrn3

m = 0.002058

n = 15.11

The values for M, N and e/d are represented in table

3.

table 3: Acting moments and normal forces according

to Bugieva

Cl M N e/d

(kNrnlm) (kN)

a=O 57.2 314 0.61

II/4 37.7 470 0.27

II/4 1.2 581 0.01

31I/4 9.8 578 0.06

II 4.1 582 0.02

The different values of M and N are also represented

in figure 11.

In figure 11, the bearing moments and normal forces

for SFRC as well as for plain concrete are also

represented.

From the figure one can see that the loads, acting on

a section at the crown, exceeds the bearing capacity of

the plain elements. The plain elements are thus not

appropriate. The steel fibre reinforced elements on the

other hand have a bearing capacity which is several

times higher than the acting loads. In table 4 the ratio

between the bearing capacity and the acting forces are

exposed for the plain as well as for the SFRC

678

,....

3000 1

---50 kg/m3 ZC

50/.50

5 -----no fibers

2500 t

8 2000 t

r:::I_ nun .,;, ..

z o: r

0 so 100 1SO

Moment (kNmlm)

figure 11: Acting anO bearing moments and normal

forces

200

elements. From the table one can see that the bearing

capacity of the SFRC elements amounts to 3.6 times

the acting loads, for plain concrete that value is only

0.7. In other words by addition of 50 kg/m3 of

ZC 50/.50 steel fibres, the bearing capacity

in the most critical section is improved by a factor of

5 (=3.6/0.7).

table 4: The ratio between the bearing capacity and

the acting forces

a plain concrete SFRC

0 0.7 3.6

"'4

10.5 11.0

"'2

18.3 18.3

3"/4

17.4 17.4

"

14.1 14.1

6 CONCLUSIONS

The bearing capacity of plain concrete can impor-

tantly be enhanced by the addition of steel fibres. The

steel fibres provide the concrete an improved bending

behaviour resulting in a better bearing capacity

especially for large eccentricities.

For a specific case it has been shown that the

bearing capacity by addition of 50 kg/m3 of Dramix!JI

ZC 50/.50 steel fibres, in the most critical section of

the tunnel lining, is enhanced by a factor of 5.

This improved behaviour together with the practical

advantages of the use of steel fibre reinforced concrete

makes this composite material particularly interesting

for tunnel linings.

REFERENCES

1. "Tunnelling the world",

M. Vandewalle, 1990.

2. JSLE-SF 1 to 7 : "Method of tests

for steel fibre reinforced concrete", Concrete

Library of the Japanese Society of Civil

Engineers, June 1984.

3. "Steel fibre concrete under flexural load",

D. Nemegeer, 1993.

4. "Zur Qualitatspriifung von Stahlfaserbeton fiir

Tunnelschalen mit Biegezugbeanspruchung",

J. Dietrich, Bochum, 1992.

5. "Traite de construction des tunnels", K. Szechy,

1970

6. "Handbuch des Tunnel und Stallenbaus", B.

Maid!, 1988

679

You might also like

- ACI TCMDocument72 pagesACI TCMMehdi BakhshiNo ratings yet

- Barton-TBM Tunnelling in Sheared and Fractured Rock Masses. Cartagena, ColombiaDocument36 pagesBarton-TBM Tunnelling in Sheared and Fractured Rock Masses. Cartagena, Colombiacastille1956No ratings yet

- 2 Track Stucture 3 (Track Engineering)Document37 pages2 Track Stucture 3 (Track Engineering)ReginaldoPinhoNo ratings yet

- Hydrocyclones For Particle Size SeparationDocument7 pagesHydrocyclones For Particle Size SeparationJean DejardinNo ratings yet

- Guideline For Design of SFRCDocument65 pagesGuideline For Design of SFRCscribdnikoNo ratings yet

- FIPREP 0058 1986 E Tensioning of Tendons Force Elongation RelationshipDocument25 pagesFIPREP 0058 1986 E Tensioning of Tendons Force Elongation Relationshipdinhhuy214No ratings yet

- Design of Piles Under Cyclic Loading: SOLCYP RecommendationsFrom EverandDesign of Piles Under Cyclic Loading: SOLCYP RecommendationsAlain PuechNo ratings yet

- Elasto-Plastic Solution of A Circular TunnelpdfDocument16 pagesElasto-Plastic Solution of A Circular TunnelpdfssheafiNo ratings yet

- Interaction of Shotcrete With Rock and RockboltsDocument16 pagesInteraction of Shotcrete With Rock and RockboltsJaime Salazar L100% (1)

- Che 3G04 Winter 2004 Mcmaster UniversityDocument33 pagesChe 3G04 Winter 2004 Mcmaster UniversityAris Koreya100% (2)

- Stress Ribbon and Cable-Supported Pedestrian Bridges CAP 9 PDFDocument15 pagesStress Ribbon and Cable-Supported Pedestrian Bridges CAP 9 PDFAnonymous VkzquW39No ratings yet

- (Paper) Design of Tunnel Under Seismic ConditionDocument23 pages(Paper) Design of Tunnel Under Seismic ConditionRAJENDRA PRASADNo ratings yet

- Bullflex Tunnel Support PackerDocument131 pagesBullflex Tunnel Support Packerdafo407No ratings yet

- RILEM TC 162-TDF - Test and Design Methods For Steel Fibre Reinforced Concrete - 3Document9 pagesRILEM TC 162-TDF - Test and Design Methods For Steel Fibre Reinforced Concrete - 3CuriosoNo ratings yet

- Design and Construction of A Segmental LiningDocument9 pagesDesign and Construction of A Segmental LiningLiew Yen Ching100% (1)

- E Ect of Building Sti Ness On Tunnelling-Induced Ground Movement-MAIRDocument13 pagesE Ect of Building Sti Ness On Tunnelling-Induced Ground Movement-MAIRSérgio BernardesNo ratings yet

- Half Joint Assessment Management Plan Report - Issue 2 June 2017Document30 pagesHalf Joint Assessment Management Plan Report - Issue 2 June 2017Beacher QNo ratings yet

- Anisotropic Behaviour of Stratified Rock Masses in TunnellingDocument10 pagesAnisotropic Behaviour of Stratified Rock Masses in TunnellingYérika LópezNo ratings yet

- Underground Cavern DesignDocument6 pagesUnderground Cavern DesignIsaacQuispeAriasNo ratings yet

- WTC 2020 - Full Paper 1 (ACI 533) - 402 - FinalDocument6 pagesWTC 2020 - Full Paper 1 (ACI 533) - 402 - FinalMehdi BakhshiNo ratings yet

- John Endicott PDFDocument46 pagesJohn Endicott PDFRobert Blake Designs100% (1)

- Tunnel Segmental Lining Durability (Fastening)Document10 pagesTunnel Segmental Lining Durability (Fastening)Cristián GonzálezNo ratings yet

- Ghali Et All - Headed Studs in Concrete State of The ArtDocument11 pagesGhali Et All - Headed Studs in Concrete State of The ArtbllldNo ratings yet

- Shield Tunneling Technologies in JapanDocument6 pagesShield Tunneling Technologies in JapanChin Thau WuiNo ratings yet

- Umbrella Arch Method Performance, Structural Behavior and DesignDocument15 pagesUmbrella Arch Method Performance, Structural Behavior and Designzimbazimba75No ratings yet

- Bridge Manual PDF Complete v3.4Document374 pagesBridge Manual PDF Complete v3.4Anonymous YakppP3vAnNo ratings yet

- 3D Simulation of Mechanized Tunnel Excavation PDFDocument14 pages3D Simulation of Mechanized Tunnel Excavation PDFChin Thau WuiNo ratings yet

- Design Segmental Precast Linning Tunnel LiningDocument29 pagesDesign Segmental Precast Linning Tunnel LiningMirna KristiyantoNo ratings yet

- Stress Ribbon and Cable-Supported Pedestrian Bridges INDEXDocument9 pagesStress Ribbon and Cable-Supported Pedestrian Bridges INDEXAnonymous VkzquW39No ratings yet

- GT9R6A1 - 1998 - Watertightness of Precast Concrete Lining Segments PDFDocument8 pagesGT9R6A1 - 1998 - Watertightness of Precast Concrete Lining Segments PDFOmar ElioNo ratings yet

- QuimicaDocument422 pagesQuimicaVernon SandovalNo ratings yet

- ITA WG2 Guidelines For The Design of Segmental Tunnel LiningsDocument60 pagesITA WG2 Guidelines For The Design of Segmental Tunnel LiningsMehdi Bakhshi100% (1)

- GT6R4A1Document39 pagesGT6R4A1Mehdi BakhshiNo ratings yet

- 122103-TBM5-RT-SL-0001 - (FDS) DSGN RPT Segment - 1637 - ExtractsDocument40 pages122103-TBM5-RT-SL-0001 - (FDS) DSGN RPT Segment - 1637 - ExtractsTina ChenNo ratings yet

- Temporary Excavation Support System For A New Railway Bridge and Highway Underpass in Pittsburgh, Pennsylvania by Andrew G. Cushing and Christopher J. LewisDocument8 pagesTemporary Excavation Support System For A New Railway Bridge and Highway Underpass in Pittsburgh, Pennsylvania by Andrew G. Cushing and Christopher J. LewisAndrew CushingNo ratings yet

- Conmsiderations On The Usual Methods of Tunnel Lining DesignDocument28 pagesConmsiderations On The Usual Methods of Tunnel Lining DesignTony ChanNo ratings yet

- Watertight Permanent Shotcrete Linings for TunnelsDocument5 pagesWatertight Permanent Shotcrete Linings for TunnelsmalikNo ratings yet

- Strut&tieDocument135 pagesStrut&tieRutik PatelNo ratings yet

- Micropile Presentation - SAS PDFDocument73 pagesMicropile Presentation - SAS PDFicabullangueroNo ratings yet

- Brochure - Tunnelling Applications - Permanent Spray Concrete LiningDocument28 pagesBrochure - Tunnelling Applications - Permanent Spray Concrete LiningMehdi Bakhshi100% (1)

- Concrete Tunnel Lining Fire Resistance and ProtectionDocument8 pagesConcrete Tunnel Lining Fire Resistance and ProtectionMehdi BakhshiNo ratings yet

- Hif 20035Document153 pagesHif 20035PTchongNo ratings yet

- UNIT 4 Raman Spectroscopy 12309Document24 pagesUNIT 4 Raman Spectroscopy 12309NathanianNo ratings yet

- Large Diameter Diaphragm Wall ShaftsDocument7 pagesLarge Diameter Diaphragm Wall ShaftsmeñoxNo ratings yet

- Overcoming Squeezing in The Yacambu Quibor Tunnel PDFDocument33 pagesOvercoming Squeezing in The Yacambu Quibor Tunnel PDFajgarcesv7301No ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- Performance-Based Standard Specifications For Maintenance and Repair of Concrete Structures in JapanDocument18 pagesPerformance-Based Standard Specifications For Maintenance and Repair of Concrete Structures in JapanMatheus AlmeidaNo ratings yet

- Pressure Gradients at The Tunnel Face of An EPB ShieldDocument6 pagesPressure Gradients at The Tunnel Face of An EPB ShieldBob MoncrieffNo ratings yet

- Advances in Grouting TechnologyDocument18 pagesAdvances in Grouting TechnologyletuananhbNo ratings yet

- Stonecutters BridgeDocument20 pagesStonecutters BridgeMarcos MorrisonNo ratings yet

- Ba3993 Assesment of Reinforced Concrete Half-JointedDocument22 pagesBa3993 Assesment of Reinforced Concrete Half-JointedvaleNo ratings yet

- Design of Continuity Slabs and The Metro Viaduct Designs PDFDocument6 pagesDesign of Continuity Slabs and The Metro Viaduct Designs PDFraviNo ratings yet

- Dynamic Behavior of Suspension Bridges under Moving LoadsDocument13 pagesDynamic Behavior of Suspension Bridges under Moving LoadssergiostolovasNo ratings yet

- Creep Calculation of Extradosed BridgeDocument9 pagesCreep Calculation of Extradosed Bridgesiva_ascinfratechNo ratings yet

- Immersed Tunnels: in The Permanent Stage Is Kept at ADocument1 pageImmersed Tunnels: in The Permanent Stage Is Kept at AmaherelabdNo ratings yet

- Kuchma Et Al-1998-Progress in Structural Engineering and MaterialsDocument10 pagesKuchma Et Al-1998-Progress in Structural Engineering and MaterialsxforceNo ratings yet

- CIE3150 2017 Case Study Beam V 03-2Document19 pagesCIE3150 2017 Case Study Beam V 03-2FerdiVKNo ratings yet

- 2011 Bridge SarkadyDocument17 pages2011 Bridge SarkadyTan Duy LeNo ratings yet

- SEO-OPTIMIZED TITLE FOR LARGE DIAMETER SCL TUNNEL PAPERDocument6 pagesSEO-OPTIMIZED TITLE FOR LARGE DIAMETER SCL TUNNEL PAPERNathan VincentNo ratings yet

- Fiber Reinforced Conrete in Fib Model Code 2010Document20 pagesFiber Reinforced Conrete in Fib Model Code 2010Daniel De Andrade SouzaNo ratings yet

- Bridge Standards: Are They Appropriate For Tunnel Design?Document11 pagesBridge Standards: Are They Appropriate For Tunnel Design?dafo407100% (1)

- 2005 Swartz Trapezoidal Tapered RingsDocument13 pages2005 Swartz Trapezoidal Tapered RingsJames HillNo ratings yet

- Segmental Ring Design: New Challenges With High Tunnel DiametersDocument16 pagesSegmental Ring Design: New Challenges With High Tunnel Diametersjerrin jose sajanNo ratings yet

- Duddeck ErdmannDocument1 pageDuddeck ErdmannLuis ZhanNo ratings yet

- C. PT. BAUER - Thomas Domanski .... Specific Quality Aspects at Jeddah Tower Project - JakartaDocument75 pagesC. PT. BAUER - Thomas Domanski .... Specific Quality Aspects at Jeddah Tower Project - JakartaRajinda BintangNo ratings yet

- Study of Geotechnical Failures Through Physical ModelingDocument10 pagesStudy of Geotechnical Failures Through Physical ModelingbetongleeNo ratings yet

- Below Grade Waterproofing Sheet Membrane PDFDocument2 pagesBelow Grade Waterproofing Sheet Membrane PDFfreezefreezeNo ratings yet

- Jsce SF4Document4 pagesJsce SF4Mehdi BakhshiNo ratings yet

- Jsce NL 05Document8 pagesJsce NL 05Mehdi BakhshiNo ratings yet

- Tunnel Segment Gasket Design - Solutions and Innovations: Bakhshi, Mehdi and Nasri, VeryaDocument10 pagesTunnel Segment Gasket Design - Solutions and Innovations: Bakhshi, Mehdi and Nasri, VeryaMehdi BakhshiNo ratings yet

- Diagram M 385 66Document8 pagesDiagram M 385 66Mehdi BakhshiNo ratings yet

- WTC 2020 - Full Paper 4 (REM Lining) - 414 - FinalDocument8 pagesWTC 2020 - Full Paper 4 (REM Lining) - 414 - FinalMehdi BakhshiNo ratings yet

- Full Paper WTC2020 - 404 PDFDocument5 pagesFull Paper WTC2020 - 404 PDFMehdi BakhshiNo ratings yet

- Dot 25309 DS1Document251 pagesDot 25309 DS1dongheep811No ratings yet

- Befib 2020-Id 144Document18 pagesBefib 2020-Id 144Mehdi BakhshiNo ratings yet

- Epoxy-Coated Reinforcement in Highway StructuresDocument70 pagesEpoxy-Coated Reinforcement in Highway StructuresMehdi BakhshiNo ratings yet

- Construction of tunnels with varied cross sectionsDocument1 pageConstruction of tunnels with varied cross sectionsMehdi BakhshiNo ratings yet

- Tac 2014 Paper 165Document9 pagesTac 2014 Paper 165Mehdi BakhshiNo ratings yet

- Deterioration of Concrete by The Oxidation of Sulphide Minerals in The AggregateDocument10 pagesDeterioration of Concrete by The Oxidation of Sulphide Minerals in The AggregateMehdi BakhshiNo ratings yet

- UFGS 35 20 23 - Dredging For Waterway and Marine ConstructionDocument13 pagesUFGS 35 20 23 - Dredging For Waterway and Marine ConstructionJose Leo MissionNo ratings yet

- Self-Healing Capability of Fibre Reinforced CementDocument13 pagesSelf-Healing Capability of Fibre Reinforced CementMehdi BakhshiNo ratings yet

- 13 15Document108 pages13 15Mehdi BakhshiNo ratings yet

- Cechar Abrasivity Index CAIDocument86 pagesCechar Abrasivity Index CAIRachmat S AraNo ratings yet

- West End Dam-Section 35 20 23 DREDGINGDocument6 pagesWest End Dam-Section 35 20 23 DREDGINGMehdi BakhshiNo ratings yet

- Simulation of Train Load On Deformation of Big - Diameter Shield TunnelDocument4 pagesSimulation of Train Load On Deformation of Big - Diameter Shield TunnelMehdi BakhshiNo ratings yet

- 8 M Diameter 7 KM Long Beles Tailrace Tunnel (Ethiopia) Bored and Lined in Basaltic Formations in Less Than 12 MonthsDocument13 pages8 M Diameter 7 KM Long Beles Tailrace Tunnel (Ethiopia) Bored and Lined in Basaltic Formations in Less Than 12 MonthsMehdi BakhshiNo ratings yet

- E EignungsprufungDocument8 pagesE EignungsprufungMehdi BakhshiNo ratings yet

- Backcalculation of Residual Tensile StrengthDocument11 pagesBackcalculation of Residual Tensile StrengthMehdi BakhshiNo ratings yet

- sp280 6Document18 pagessp280 6Mehdi BakhshiNo ratings yet

- Class 9 Icse - Physics-Heat and Energy-Part A - Lesson A.2Document3 pagesClass 9 Icse - Physics-Heat and Energy-Part A - Lesson A.2reenaagarwal795No ratings yet

- Mechanical Design II Clutches, Brakes, Couplings & FlywheelsDocument19 pagesMechanical Design II Clutches, Brakes, Couplings & FlywheelsterratempestNo ratings yet

- TitraDocument8 pagesTitraAbdoul RahimNo ratings yet

- CFB Boiler Design, Operation and Maintenance: by Pichai ChaibamrungDocument179 pagesCFB Boiler Design, Operation and Maintenance: by Pichai ChaibamrungkoszioNo ratings yet

- Relativistic Velocity and Acceleration Transformations From Thought ExperimentsDocument8 pagesRelativistic Velocity and Acceleration Transformations From Thought ExperimentssanniaNo ratings yet

- CH3 MergerDocument45 pagesCH3 MergerRuthNo ratings yet

- Final Exam "Intro To Optics": Problems & SolutionsDocument7 pagesFinal Exam "Intro To Optics": Problems & SolutionsDavid SalahNo ratings yet

- DNV SOFTWARE PIPELINE TOOLDocument2 pagesDNV SOFTWARE PIPELINE TOOLandrey25No ratings yet

- 1 s2.0 S0925838815310471 MainDocument6 pages1 s2.0 S0925838815310471 MainHuckkey HuNo ratings yet

- Factors Affecting Steam Turbine Performance-MergedDocument26 pagesFactors Affecting Steam Turbine Performance-MergedrahulNo ratings yet

- Misc - Projectile MotionDocument18 pagesMisc - Projectile Motionapi-3723453No ratings yet

- Astm E1050Document7 pagesAstm E1050Budi HermantoNo ratings yet

- Ficha Técnica. Bomba Neumática Dosificadora PDFDocument2 pagesFicha Técnica. Bomba Neumática Dosificadora PDFAlejandra SantacruzNo ratings yet

- CH5 8wGODocument1 pageCH5 8wGOkpmaityNo ratings yet

- THERMODYNAMICSDocument21 pagesTHERMODYNAMICSUttam SinghNo ratings yet

- Magneto Abrasive Flow MachiningDocument11 pagesMagneto Abrasive Flow MachiningBhuvnesh SinghNo ratings yet

- The NDT TechnicianDocument12 pagesThe NDT TechnicianAnca ElenaNo ratings yet

- CEB 706 Group Project - QuestionDocument6 pagesCEB 706 Group Project - QuestionKrishan ChaudharyNo ratings yet

- WELDINGDocument94 pagesWELDINGharshaNo ratings yet

- High-performance industrial gear oilsDocument5 pagesHigh-performance industrial gear oilsKeshab ShresthaNo ratings yet

- Tablas SI - Moran & Shapiro - Fundamentals of Engineering Thermodynamics 5th Edition (Con R12)Document53 pagesTablas SI - Moran & Shapiro - Fundamentals of Engineering Thermodynamics 5th Edition (Con R12)Yasir MumtazNo ratings yet

- Traversable Wormholes: Some Simple Examples: Matt VisserDocument7 pagesTraversable Wormholes: Some Simple Examples: Matt VisserllapeyreNo ratings yet

- Barrel Design of BorawasDocument23 pagesBarrel Design of BorawasSunita ChaurasiaNo ratings yet

- RPC Ultra High Strength ConcreteDocument19 pagesRPC Ultra High Strength ConcreteSivaramakrishnaNalluriNo ratings yet

- TORING LC Exer4 7LDocument19 pagesTORING LC Exer4 7LLanoline ToringNo ratings yet