Professional Documents

Culture Documents

Merlin Gerin Power Logic

Uploaded by

Luis GutierrezOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Merlin Gerin Power Logic

Uploaded by

Luis GutierrezCopyright:

Available Formats

Merlin Gerin

PowerLogic system

Circuit Monitor Power Meter

Technical overview and

selection guide

One or more

PCs (local

and/or

remote)

I nformation and control

The PowerLogic system gives you

complete information and control

over your electrical power network ...

The PowerLogic system integrates all the intelligent

components of the electrical network, using standard

communications and powerful software.

This gives you the tools you need to manage the cost

and quality of power.

Other

compatible

devices

LV circuit

breakers Power monitoring devices

Modbus

Communications

Power

management

software

MV protection

and control

Ethernet

Modem or

Ethernet

Gateway

(when

required)

1

Circuit Monitor

CM-4000

CM-2350

CM-2250

Power Meter

PM-650

PM-620

PM-600

Interactice power monitoring

I Revenue-class accuracy - better than 0.1%

current/voltage

I Time/date stamping

I Digital and analogue I/O.

Advanced analysis and recording

I Harmonics analysis

I Voltage disturbance records

I On-board memory to store data and events

I Web enabled support

I GPS support.

Essential power monitoring

I Revenue-class accuracy 0.2% current/voltage

I On-board memory for energy consumption

analysis

I On-board clock/calendar for time/date stamping.

Application flexibility

I Separate meter and display modules

I Direct-connect up to 600V; higher voltages with

VTs.

PM-100

High-performance metering

I Combining a number of devices (voltmeter,

ammeter, wattmeter, watthour meter, etc.)

I Providing true rms measurements up to the 31st

harmonic.

Reduced dimensions and wiring

I More space available in low voltage switchboards

I Standard size DIN 144 x 144mm.

Circuit Monitoring

CM-4000

2

The PowerLogic Circuit Monitor is a multi-function, digital

instrumentation, data acquisition and control device capable of

replacing a variety of meters, relays, transducers, and other

components.

I True RMS metering up to the 225th

harmonic

I ANSI C12.20 Revenue Accuracy

I Industrial temperature range (-25

0

C to

70

0

C)

I No metering VTs required up to 600V

I Field interchangeable current/voltage

module CVM

I VT/CT wiring diagnostics

I Standard kWh pulse output

I Standard 8MB onboard memory

(field upgradeable to 16MB, 32MB and

higher)

I Standard RS-485 and RS-232 Modbus

RTU communications ports (38k4 Baud)

I Simultaneous operation of 5

communications ports

I Two option card slots for field installable

option cards

I Waveform capture up to 512 samples/cycle

I Sag/Swell disturbance monitoring

I Extended waveform capture (up to 30

seconds)

I Oscillatory voltage transient capture

I Field installable 10/100MB Ethernet

Communications option card with standard

and configurable web pages

I Field installable digital I/O option card

I Field installable analog/digital I/O extender

module

I Sequence of events recording to 1 msec

resolution

I GPS time-based synchronisation support

I Programmable logic

I Revenue metering security switch and tab

for wire seal

I UL listed, CSA approved, CE marking,

NOM approved, FCC compliant

CM-4000T

CM-4000 Optional displays

I Includes CM4000

features plus high

speed voltage

transient detection

and capture

I High performance

DSP based

technology

I Field

interchangeability of

the CVM and the

CVMT allows the

user to deploy high

speed voltage

transient detection

and capture where it

is needed

I High visibility

remote VF

(vacuum

fluorescent)

display with I/R

communications

port

I Remote LC (liquid

crystal) display

with back lighting

I Displays metering

data, min/max

values, alarms,

inputs

I Standard and

user configurable

display screens

CM-2000

3

I True rms metering

I Accepts standard CT and VT inputs

I High accuracy: 0.2% current and voltage

I Over 50 displayed meter values

I Min/max displays for metered data

I Power quality readings: THD, k-factor, crest

factor

I Real time harmonic magnitudes and angles

I Current and voltage sag/swell detection

and recording

I On-board clock/calendar

I Easy front panel setup (password

protected)

I RS-485 communications standard

I Front panel, RS-232 optical

communications port standard

I Modular, field installable analog and digital

I/O

I 1 ms time stamping of status inputs for

sequence-of-events recording

I I/O modules support configurable energy

pulse output

I Setpoint controlled alarm/relay functions

I On-board event and data logging

I Waveform and event captures, user

selectable for 4, 12, 36, 48, or 60 cycles

I High speed, triggered event capture

I Programming language for application

specific solutions

I Field upgradeable firmware

I Optional voltage/power module for direct

connection to 380V - 480V

I Wide operating temperature range

(25 to 70C).

Power quality readings

Total Harmonic Distortion (THD) for current,

voltage, and k-factor readings indicate potential

power quality problems which, unchecked,

could disrupt critical processes or damage

equipment.

Flexible communications

Communications ports come standard on all

Circuit Monitors, allowing them to be tied onto

communications networks up to 19K2 baud

without additional cards or modules. For higher

speeds, Circuit Monitors can be tied into

industrially hardened local area networks and

high speed Ethernet (TCP/IP) networks. The

networks can include a virtually unlimited

number of devices, including Circuit Monitors,

Power Meters, protective relays, and trip units

for low voltage circuit breakers, multiple

personal computers, and other compatible

devices.

CM-4000 features

4

Comprehensive metering

The PowerLogic Circuit Monitor 4000 installs on

a 3-phase circuit like a conventional watt-hour

meter, but it delivers far more information. In

fact, the Circuit Monitor 4000 performs true rms

metering to revenue class accuracy. The Circuit

Monitor offers comprehensive metering with

0.04% typical accuracy on current and voltage.

Power

quality

readings

Total Harmonic

Distortion (THD) for

current, voltage and

k-factor readings

indicate potential

power quality

problems, which

unchecked could

disrupt critical

processes or damage

equipment.

Programming capabilities

The Circuit Monitor 4000 is programmed using

simple math functions, timers and compare

statements to customise data logging, control

functions and more. Application program

examples include tracking disturbances, time of

use metering etc. Meter values can be analysed

in the Circuit Monitor and summarised in daily,

weekly and monthly reports.

Easy setup

Basic Circuit Monitor 4000 set-up can be performed through the VFD

(Vacuum Fluorescent Display), LCD (Liquid Crystal Display) or a PC

running System application software. The VFD also has an optional

optical port. The PC connects to the Circuit Monitor using either the

system network or the RS232 port. No thumbwheel or DIP switches are

involved; therefore, after installation, set-up parameters such as the unit

address, CT and VT ratios can be configured without exposing personnel

to live conductors. For security, all set up information is password

protected.

CM-4000 features

5

Flexible communications

There are two optional displays, a VFD, or a backlit LCD, both can be

mounted up to 15 metres from the Circuit Monitor. RS-485 and RS-232

communication ports are provided as standard allowing the Circuit

Monitor to be tied onto communication networks of up-to 38k4 baud

without additional cards or modules. There is an optional ECC (Ethernet

Communications Card) which provides information in web browser

format, and communication with up to 31 devices connected to the

ECCs serial port.

Alarm and relay functions

The Circuit Monitor 4000 can detect over 100 alarm situations, including

over/under conditions, status-input changes, and phase unbalance

conditions. The Circuit Monitor 4000 now allows the user to combine

alarms using Boolean style logic i.e. AND, NAND, OR and XOR logic

instructions. Each alarm condition can be set to automatically operate

one or more Circuit Monitor 4000 relays on the IOC-44 card. Multiple

alarms can be assigned to each relay. Up to three form-C, 10A

mechanical relays and one solid state output are available. When the

optional ECC is fitted it is possible to send an alarm message to an

e-mail account or a pager.

Extended memory

options

The Circuit Monitor 4000 uses its

non-volatile memory (RAM) to retain all data

and metering configuration values. There are

8MB of memory as standard, however this can

easily be expanded to 16MB, 32MB and higher.

6

CM-4000 features

On board alarm/event

logging

When an alarm occurs, the Circuit Monitor 4000

can log the event type, date and time, and the

most extreme reading during the pickup delay.

When the alarm condition drops out, the

dropout date/time and the most extreme

reading during the entire event will be logged.

The size of the event log can be user

configured.

Field upgradeable firmware

The Circuit Monitor 4000 is designed to take advantage of technological

advances. As Schneider Electric introduces more powerful versions of

each Circuit Monitor 4000, upgrade kits allow the user to install the new

capabilities without changing wiring or hardware. This is possible

because the Circuit Monitor 4000 supports downloadable firmware. The

new firmware is transmitted from a PC into the Circuit Monitor 4000 using

the RS232/485 port or the optional ECC. This means it is possible to

download upgrades at individual meters or to groups of meters over a

network. The Circuit Monitor 4000 does not even need to be

de-energised. This allows you to keep your Circuit Monitor 4000 up to

date with the latest enhancements, minimising fear of obsolescence.

Data logging

The Circuit Monitor 4000 is provided with non-volatile memory for storing

meter readings. A user can configure the size structure of up to 14

independent data logs to record metered data at intervals from 1 second

to 24 hours. Data logs can be used to record at regular intervals or report

by exception. Each data log can record up to 96 electrical parameters

(including date and time). The number of stored readings for each of the

parameters is based on the amount of memory available in the Circuit

Monitor.

7

CM-4000 features

Onboard and optional I/O

The Circuit Monitor 4000 can offer up to 25 I/O

points. This can be achieved by using an I/O

option card and an I/O extender. The I/O option

card offers four digital inputs, three output relays

and one solid state output. The I/O extender

offers up to eight I/O points, with a maximum of

four analogues. The onboard I/O for the Circuit

Monitor 4000 is limited to a standard kWH pulse

output.

Multi utility metering

The Circuit Monitor 4000 can monitor various

utilities including water, air, gas and steam.

The Circuit Monitor 4000 monitors the number

of pulses via an I/O module, and then gives a

cumulative figure side by side with electrical

parameters. The data can be displayed in any

units including cost.

Ethernet communications card

The Circuit Monitor 4000 now comes with an optional ECC (Ethernet

Communications Card). The ECC allows the Circuit Monitor 4000 to be

connected directly to an Ethernet LAN/WAN. The web pages available

enable you to see real time data onboard the Circuit Monitor 4000 using

a standard web browser. These pages can also display data of devices

daisy chained from the RS485 port of the Circuit Monitor 4000. The ECC

supports up to five customisable web pages, which allow the user to

choose which data is most relevant to them.

8

CM-4000 features

Waveform capture

The Circuit Monitor 4000 can record and display current and voltage

signals. The captured waveforms are stored in the Circuit Monitor 4000

memory for retrieval and display by PowerLogic application software.

The waveform captures are used for harmonic analysis and event

recording. Waveform captures for 255th harmonic analysis at 512

samples per cycle are triggered from the PowerLogic software.

These can be up to 60 cycles in duration. Waveform captures for event

recording can be triggered by internal alarm conditions or from external

signals, such as an over current relay.

Sag/swell and transient detection

The Circuit Monitor 4000 can continuously monitor for sags, swells and

transients (lasting as little as 1 microsecond) on any metered voltage or

current. These features can help detect and analyse troublesome voltage

disturbances that can cause costly equipment down time. The Circuit

Monitor detects sags and swells based on user-defined setpoints and

delays (in cycles). When the Circuit Monitor 4000 detects a voltage or

current disturbance, it performs an event capture to record the

disturbance. The capture is configurable for 16, 32, 64, 128 and 512

samples per cycle resolution. It is performed using the patented

waveform capture sampling technique that samples all current and

voltage signals simultaneously. The user selects the number of pre event

cycles required. Thus the event capture shows the circuit both before and

after the disturbance. The event can be date and time stamped to the

millisecond, and recorded in the event log.

9

Sequence of events

Events can be reconstructed to the millisecond

with time stamps. Time between monitoring can

be kept in synch by using GPS (1msec) or

Ethernet (5 msec).

CM-4000 features

Installation and control power options

In addition to current and voltage inputs, the Circuit Monitor 4000

requires control power. The Circuit Monitor 4000 operates in a wide

range of voltages 90-305Vac and 100-300V dc. The Circuit Monitor 4000

has its very own wiring error detection, and can diagnose various wiring

faults such as swapped CT polarities.

10

CM-2000 features

Alarm and relay functions

Circuit Monitors can detect over 100 alarm situations, including

over/under conditions, status input changes, and phase unbalance

conditions. Each alarm condition can be set to automatically operate one

or more Circuit Monitor relays. Multiple alarms can be assigned to each

relay. Up to three form-C, 10A mechanical relays and one solid-state

output are available.

On board alarm/event

logging

When an alarm occurs, the Circuit Monitor can

log the event type, date and time, and the most

extreme reading during the pickup delay. When

the alarm condition drops out, the dropout

date/time and the most extreme reading during

the entire event will be logged. The size of the

event log can be user configured.

Data logging

Circuit Monitors are available with non-volatile

memory for storing meter readings. A user can

configure the size and structure of up to 14

independent data logs to record metered data

at intervals from 1 minute to 24 hours. Data

logs can be used to record at regular intervals

or report by exception. Each data log can

record up to 100 electrical parameters

(including date and time). The number of stored

readings for each of the parameters is based

on the amount of memory available in the

Circuit Monitor.

11

CM-2000 features

Waveform capture

The Circuit Monitor can sample, record, and display current and voltage

signals. The captured waveforms are stored in the Circuit Monitor

memory for retrieval and display by PowerLogic application software. The

waveform captures are used for harmonic analysis and event recording.

Waveform captures for up to 63rd harmonic analysis at 128 samples per

cycle are triggered from the front of the monitor or via the network from a

PC. These can be up to 30 cycles in duration. Waveform captures for

event recording can be triggered by internal alarm conditions or from

external signals, such as an overcurrent relay. These 64 samples per

cycle event recordings can be up to 60 cycles in duration.

Sag/swell detection

The Circuit Monitor can continuously monitor for sags and swells on any

metered voltage or current. This feature can help detect and analyse

troublesome voltage disturbances that can cause costly equipment down

time. The Circuit Monitor detects sags and swells based on user-defined

setpoints and delays (in cycles). When the Circuit Monitor detects a

voltage or current disturbance, it performs an event capture to record the

disturbance. This capture is configurable for 12, 24, 36, 48, or 60 cycles

at 64 samples per cycle. It is performed using the patented waveform

capture sampling technique that samples all current and voltage signals

simultaneously. The user selects the number of pre-event cycles, ranging

from 2 to 10 cycles. Thus, the event capture shows the circuit both

before and after the disturbance. The event can be date and time

stamped to the millisecond, and recorded in the event log.

12

CM-4000

Typical Wiring Diagram (1)

3 phase, 4 wire star connection

Dimensions mm

Side View

121.9

4.1

133.1

End View

61.9

87.1

107.4

Millimeters

Top View

219.7

207.5

6.2

6.2

139.7

152.2

202.9

118.4

231.4

6.9

203.2

80.6

39.9

Top View

Side View

kWh pulse

Control power VT, 120

or 240V ac.

Secondary, 50 VA

Star VT

13

Specifications

Current Inputs (Each Channel)

I Nominal Current 5 A ac

I Metering Range 0-10 A ac

I Withstand 15 A 50 A 10 sec per hour

continuous 500 A 1 sec per hour

I Burden Less than 0.15 VA

I Input Impedance Less than 0.1 Ohm

Voltage Inputs (Each Channel)

I Nominal Full

I Scale 347 V ac L-N, 600 V ac L-L

I Metering Over-range 50%

I Input Impedance Greater than 2 M Ohm

I Metering Frequency

I Range 4567 Hz, 350450 Hz

Accuracy

I Complies with ANSI C12.20 2 class for revenue

meters; wire seal protects revenue settings

Typical

I Power and Energy 0.04% of reading

Specified

I Current 0.04% of reading + .025%

of full scale

I Voltage 0.04% of reading + .025%

of full scale

I Power 0.075% of reading + .025%

of full scale

I Power Factor +.002 for |pf|>.5

I Frequency +.01 Hz at 45-67 Hz

( When tested in accordance with ANSI C12.20 typical reference

performance.)

Sampling

I Continuous fast sample

and meter 512 samples/cycle

Harmonic Resolution

I Metered Values 255th harmonic

Waveform Capture

I Steady State Manual initiation

512 samples/cycle,

255th harmonic

I Disturbance Manual or alarm initiation

512 samples/cycle for 12

cycles to 64 samples/cycle

for 96 cycles. Adjustable

number of pre-alarm cycles

I Adaptive Manual or alarm initiation

512 samples/cycle for 2

seconds to 16 samples/

cycle for 64 seconds.

Capture for set time or while

in alarm. Adjustable

number pre-alarm cycles

Disturbance Detection

I Continuously monitors for sags, swells, and other

short-term variations

I 128 samples/cycle

I Responds in less than 1/2 cycle

I On detection: Alarm, log, save waveform

Transient Detection (optional)

I Continuously sample voltage inputs at 4 MHz

(66,666 samples/cycle)

I On detection: Alarm, log, save waveform

I/O

I Standard kWh pulse

I Standard kWh pulse output: up to 240 Vac,

300 Vdc, 3750 Vrms isolation

I 96 mA maximum

I I/O Option Card (Optional)

I Four digital inputs

I Three output relays (10A load max.)

I One solid-state output (96 mA max.)

I I/O Extender (Optional)

I Eight I/O points. Up to four may be analog.

I Plug-in I/O modules for maximum flexibility.

Logging

I 8Mb non-volatile memory, field expandable to

32+ Mb

I 14 data logs, up to 96 parameters each

I Event log date/time stamps to millisecond

I Record selected parameters at 100 msec interval

during events

I Min/max log of all real-time readings

I Log min/max/average of selected parameters each

interval Interval length 11440 minutes

I Default logging loaded at factory, begins on device

power up

Alarming

I Each alarm individually configured with pickup and

dropout setpoints and delays

I Each alarm can be assigned one of four priority

classes

I Supports multiple alarms for a single quantity to

create alarm levels. Assign different actions based

on the severity level of the alarm.

I Response time: Standard, 1 sec.; High speed, 100

msec., Disturbance, less than 1/2 cycle: Transient,

1 microsecond

I Boolean alarms combine up to four other alarms

with NAND, NOT, OR, and XOR

Feature Addition

I Platform can be updated with new features by

firmware download

I Downloads can be done via RS-485, RS-232, or

optional Ethernet ports

I Downloads can be done at individual meter or to

groups of meters over network

Control Power

I Universal AC or DC

I Nominal Range 120/249 Vac

I Operating Range 90305 Vac

I Burden 50 VA

I Frequency. 4567 Hz, 350450 Hz

I Ride Through 0.1 sec at 120 Vdc

I DC Control Power

I Operating Range 100300 Vdc

I Burden 30W

I Ride Through 0.1 sec at120 Vdc

Operating Temperature

I Meter options -25C to +70C

I VFD Display -25C to +70C

I LCD Display. -25C to +60C

( May require de-rating when used with some external I/O or non-

recommended mounting orientations.)

Operating Environment

I Humidity 595% relative humidity

(non-condensing)

I Pollution Degree 2

I Installation Category II

Regulatory/Standards Compliance

I Emissions FCC Part 15 Class A/CE

I Discharge IEC 1000-4-2 level 3

I Transient IEC 1000-4-4 level 3

I Surge IEC 1000-4-3 level 4

I Dielectric UL508, CSA C22.2

I Radiated IEC 1000-4-3 level 3

I Accuracy ANSI C12.20 class .2

IEC 687 class .2

I Europe CE per EN 61010

14

CM-4000

Communications

I All communication ports may be used

simultaneously

RS-485 (Standard)

I Modbus or Jbus protocol

I 2-wire or 4-wire connection

I Up to 10,000 feet cabling at 9600 Baud

I Up to 38K4 Baud

RS-232 (Standard)

I Modbus or Jbus protocol

I Up to 38K4 Baud

I Direct Connect to PC or modem

Optical Port (Optional)

I Included on VFD display

I Up to 38K 4Baud

Ethernet (Optional)

I Modbus/TCP/IP Protocol

I 10/100BaseT and 100BaseFL connections

I Up to 100M Baud

Modbus Master (Optional, with Ethernet)

I Connect up to 31 Modbus or POWERLOGIC

downstream devices

I Up to 38K4 Baud

Web Server

I Web server functionality provided by the Ethernet

Communications Card (ECC)

I View data from the Circuit Monitor and devices

connected to the ECCs serial port using a

conventional web browser

I View data from individual devices, multiple

devices, and comparison summaries

I Default pages provided; custom pages can be

created by the user

Display (Optional)

I Two versionsbacklit LCD and Vacuum

Fluorescent (VFD)

I Proximity sensor turns on VFD display

I User selects English, French, or Spanish

I Mount up to 50 feet from Circuit Monitor

I Mounts over most through-door circuit breakers;

requires rear clearance only for cable

15

Ordering information

Circuit monitor 4000 series

Catalogue number Description

CM4000MG Instrumentation, logging, wavecap, programmable c/w 2 card slots

CM4000TMG As 4000 with high speed transient detection and capture

Input/output modules

Catalogue number Description

IOC-44 Field installable I/O card with 4 status inputs, 3 relay outputs, and 1 pulse output

IOX-0044 I/O Extender Module with 4 analog inputs and 4 analog outputs (4-20mA)

IOX-0404 I/O Extender Module with 4 status inputs and 4 analog outputs (4-20mA)

IOX-08 I/O Extender Module with 8 status inputs

IOX I/O Extender Module with no pre-installed I/O

DI120AC 120V ac 1 input for IOX

DI240AC 240V ac 1 input for IOX

DI32DC 32V dc 1 input for IOX (0.2mS turn on - polarised)

DO120AC 120V ac 1 output for IOX

DO240AC 240V ac 1 output for IOX

DO60DC 60V ac 1 output for IOX

DO200DC 200V dc 1 output for IOX

AI05 0-5V dc analog 1 input for IOX

AI420 4-20mA dc analog 1 input for IOX

AO420 4-20mA dc analog 1 output for IOX

ECC-21 Ethernet Communications Card; 100 Mb Fibre or 10/100 Mb UTP Ethernet port and 1

RS-485 master port

CVM Current/Voltage Module

CVM-T Current/Voltage Module with high speed transient detection

CMDLCMG Display module, backlit LCD

CMDVFMG Display module, vacuum fluorescent, IR port, proximity sensor

OCIVF I/R communications interface for CMVDF

CAB-4 4 foot display cable

CAB-12 12 foot display cable

CAB-30 30 foot display cable

CM-2000

Typical Wiring Diagram (1) Dimensions mm

AO

BO

N

DISC

SW

CO

CT

CPT

(120 o 240 VAC

14 V A)

(1) IN-

(2) IN+

(3) IC-

(4) IC+

(5) IB-

(6) IB+

(7) IA-

(8) IA+

(9) VN IN

(10) VC IN

(11) VB IN

(12) VAIN

N (27)

G (26)

L (25)

o AMMETER (A)

o VOLTMETER, L-L (V)

o VOLTMETER, L-N (V)

o WATTMETER (W)

o VARMETER (VAr)

o VA METER (VA)

o POWER FACTOR METER

o FREQUENCY METER (Hz)

o DEMAND AMMETER (A)

o DEMAND POWER (W)

o DEMAND POWER (VA)

o WATTHOUR METER

o VARHOUR METER

o THD, CURRENT (%)

o THD, VOLTAGE (%)

o K-FACTOR

CIRCUIT MONITOR

[CT Primary]

[PT Primary]

[Sys. Type]

[Dmd. Int.]

[WH/Pulse]

[Address]

[Baud Rate]

[Nom. Freq.]

[Reset]

[Reset]

[Reset]

[Reset]

[Reset]

[Rst. Min/Max]

[Set Password]

[Accept]

3-PHASE

A (A-B)

B (B-C)

C (C-A)

N

SELECT

METER

[Value]

METERS

MIN

MAX

ALARM

[Setup]

Kilo

Mega

PHASE

MODE

Optical

Comm Port

187

23

80

263

129

21

116

14

222

305

Top View

Front View

mm

v

o

l

t

a

g

e

/

p

o

w

e

r

o

p

t

i

o

n

a

l

M

o

d

u

l

e

(1) 3-Phase, 4-Wire star with

optional metered neutral.

Other system types supported).

I

n

p

u

t

/

O

u

t

p

u

t

O

p

t

i

o

n

a

l

M

o

d

u

l

e

Side View with Modules

CTS

Fuses

Star

Connection

Fuses

LOAD

Fuses

Fuses

Communication

Voltage

Current

C

o

n

t

r

o

l

P

o

w

e

r

PowerLogic

LINE

Technical specification

I Current Inputs (each channel):

I Current Range: 07.4 A

I Nominal Current: 5 A

I Voltage Inputs (each channel):

I Voltage Range: 0180 Vac

I Freq. Range (50/60 Hz): 4565 Hz

I Freq. Range (400 Hz): 350440 Hz

I Harmonic Response (Voltage, Current):

I Freq. 45 Hz65 Hz: 64th Harmonic

I Freq. 350 Hz440 Hz: 3rd Harmonic

I Accuracy:

I Current, voltage: +/- 0.20%

I Power, energy: +/- 0.40%

I Power Factor: +/- 0.005

I Frequency 50/60 Hz: +/- 0.01 Hz

I Frequency 400 Hz: +/- 0.5 Hz

Control Power Input Specifications

I Input Range, ac: 100264 Vac

I Frequency Range: 47440 Hz

I Input Range, dc: 100350 Vdc

Temp. Range (operating)

I -25 to 70C

Weight

I Circuit Monitor (without options) 3.2 kg

Ordering Information

Type Description

3020 CM-2350-MG Disturbance monitoring, 100k extended

memory, plus CM-2250 features

3020 IOM-11-MG I/O Module: 1 status in, 1 pulse out

3020 IOM-18-MG I/O Module: 8 status in, 1 pulse out

3020 IOM-44-MG I/O Module: 4 status in, 1 pulse out, 3 relay out

3020 IOM-4411-20-MG I/O Module: 4 status in, 1 pulse out, 3 relay out,

1 analog in, 1 analog out (4-20 mA)

3020 IOM-4411-01-MG I/O Module: 4 status in, 1 pulse out, 3 relay out,

1 analog in, 1 analog out (0-1 mA)

3020 IOM-4444-20-MG I/O Module: 4 status in, 1 pulse out, 3 relay out,

4 analog in, 4 analog out (4-20 mA)

3020 IOM-4444-01-MG I/O Module: 4 status in, 1 pulse out, 3 relay out,

4 analog in, 4 analog out (0-1 mA)

3090 OCI-2000-MG Optical communications interface

3090 VPM-277-C1-MG Voltage/power module for direct connect up to

415/230V circuits

3090 CMA-100 Circuit Monitor mounting adapter to reduce rear

clearance requirements

3090 SMA-220 Circuit Monitor surface mounting enclosure with

hinged cover

3090 RTM-317-MG Ride Through Module

16

17

Power meter

The PowerLogic Power Meter is cost effective,

high performance meter. It can operate as a stand-alone

device or as part of a PowerLogic system.

Features

Economical Metering Solution

I A single, economical electronic device that

replaces a full complement of analog

meters

I Accurate true rms metering of distorted

currents and voltages up to the 31st

harmonic

I THD readings for each metered phase of

current and voltage to assist in

measurement of power quality data

I Neutral current monitoring to detect

overload neutrals

I Individual machine load monitoring

I Available feeder capacity monitoring (peak

demand current)

I Load monitoring for predictive

maintenance/troubleshooting

I Departmental kWh cost allocation

I Remote meter reading and data logging

from a personal computer using

PowerLogic System Manager software and

RS-485 communications.

Ease of Installation

I Display mounts in panel cutout of many

analog meters

I Separate meter and display modules allows

flexible mounting options (model PM-600

and higher)

I Easy retrofit into existing power equipment

I Standard IEC dimensions, 144 x 144 mm

(PM-100)

Direct Connect Up to 600V

I No VTs required up to 600V

I No separate control power required on up

to 600 V circuits

Communications Options

I PowerLogic communications for integration

with a PowerLogic Power Monitoring

System

I Modbus RTU communication for integration

with other systems

I Energy pulse initiator for communication to

energy management systems

2-Line LCD Display

I Mounts back-to-back or up to 15 metres

from Power Meter module (PM-600,

PM-620, PM-650)

I Use as a portable power meter

programmer (PM-600, PM-620, PM-650)

I Simultaneous display of phase A, B, C

quantities

I Provides setup and display of metering

information

I Provides optical isolation from 600 V

metering connection

Designed for Reliability

I Tested for compliance with UL, and NOM,

CSA requirements

I CE mark

I Testing in accordance with stringent IEC

1000 series of electrical tests

I FCC compliant (Class A)

I Vibration and temperature tested

Instrumentation Summary

Real-Time Readings

I Current (per phase, N, G, 3-phase)

I Current (neutral, N)

I Voltage (L-L, L-N)

I Real Power (per phase, 3-phase)

I Reactive Power (per phase, 3-phase)

I Apparent Power (per phase, 3-phase)

I Power Factor (per phase, 3-phase)

I Frequency

Demand Readings

I Demand Current (per-phase present, peak)

I Average Power Factor (3-phase total)

I Demand Real Power (3-phase total)

I Demand Reactive Power (3-phase total)

I Demand Apparent Power (3-phase total)

I Coincident Readings

I Predicted Demands

I Advanced demand option (Synch to

comms, sliding block calculation

Energy Readings

I Accumulated Energy, Real

I Accumulated Energy, Reactive

I Accumulated Energy, Apparent

I Bi-directional Readings

Other monitoring functions

I Energy pulse relay output

I RS-485 PowerLogic and Modbus RTU

communications

I THD, voltage & current (A, B, C)

I Date/time stamping (Peak demands, power

up/restart, resets)

I Onboard alarms (Under/over conditions,

phase unbalance conditions)

I Min/max readings (Frequency, current,

voltage, power, power factor, THD)

I Data and event logs

18

Power meter

19

Power meter

Powerful functionality

The Power Meter accepts inputs from standard 5A CTs and has full scale

input of 10A. The voltage inputs can be directly connected to 3 phase

circuits of 600V and below without the need for VTs. For higher voltage

circuits, the Power Meter accepts a full range of VT primary values with

control power derived from the VTs or from a separate source of ac or dc

control power. Setup and resets are password protected and are easily

done through the Power Meter display or via the network using System

Manager software. PowerLogic or Modbus RTU protocols can be

selected. All readings are scaled to their actual values without the need

for a multipler.

Advanced functionality

In addition to the basic metering functions, the Power Meter increases its

value to you with advanced functionality features.

Power Quality Readings

Total Harmonic Distorsion (THD) for current and

voltage readings indicate potential power

quality problems, which unchecked, could

disrupt critical processes or damage equipment.

Min/Max readings

Min/max readings provide measurements of

extreme meter values needed for maintenance

purposes. These readings can be viewed and

reset from the display. Min/max resets are

password protected.

Alarm/Relay Functions

The PM650 has on-board alarms. Alarm

functions include over/under conditions for

voltage, current, frequency, and phase

unbalances. In addition, these alarms can be

assigned to operate the solid state output.

Event logging

When an alarm condition occurs, the PM650

Power Meter logs the event in nonvolatile

memory. These events can be viewed from the

display or PowerLogic software.

Data Logging

As part of a comprehensive power system, the PM650 expands metering

capabilities with data logging. Values are stored in nonvolatile memory,

preserving critical data for the interval between logging updates via

communications with the system computer. All metered values are

available for recording at user defined intervals, offering total flexibility.

A typical log configuration is recording demand readings for kW, kVAR,

and kVA, at hourly intervals, storing 3 days of information.

The meter is pre-configured from the factory to log values.

PowerLogic system compatability

The Power Meter supports standard PowerLogic RS-485

communications up to 19k 2Baud with communications links up to 3300

m. A meter can quickly be installed into any existing PowerLogic system.

The Power Meter has been fully integrated into the latest PowerLogic

application software, System Manager. SMS software enables users to

manage their electrical distribution systems by providing tabular and

graphical data displays, alarms, real time and historical time trend tables

and graphs, and reports. Power Meter setup and reset operations and

wiring diagnostics can also be performed from a remote personal

computer using System Manager software.

PowerLogic power monitoring devices and systems assist in equipment

monitoring for cost allocation, troubleshooting, predictive maintenance,

planning, and more. The lower installed cost of the Power Meter makes it

possible for facilities to monitor many smaller, less critical feeder circuits

enabling whole facility power monitoring.

20

Power meter

21

Power meter

Basic metering solutions and more

The PowerLogic Power Meter is designed for use in basic power

metering applications. It can replace conventional metering devices such

as ammeters, voltmeters, and watt-hour meters while providing powerful

capabilities not offered by analog metering. The Power Meters true rms

readings (31st harmonic response) accurately reflect non-linear circuit

loading more than conventional analogue metering devices. The Power

Meter calculates the neutral current, which can assist in identifying

overloaded neutrals due to either unbalanced single phase loads or

triplen harmonics.

Circuits can be closely monitored for available

capacity by keeping track of the peak average

demand current. Accurate circuit loading

information is essential to get the most out of

existing power equipment while maintaining

power system reliability.

The Power Meter provides a full complement of

accurate true rms metering values through its

display, or via the standard RS-485

communication port to a PowerLogic Power

Monitoring and Control System. Refer to the

tables for information about the metering values

reported by each model. A relay output is

included to communicate energy and demand

information to third party energy management

systems.

Mounting flexibility

The Power Meters small size and variety of

mounting configurations allow it to be readily

installed in new equipment or retrofit into

existing equipment. The Power Meter module

can be mounted onto a 35mm DIN rail, or it can

be mounted on any flat surface using its four

mounting feet. For added simplicity in retrofit

installations, the panel mounting hole patterns

for both the Power Meter module and the

Power Meter display match the conventional

ammeter/voltmeter spacing so the meter and

the display can be mounted back-to-back on

opposite sides of a panel surface. In metering

installations of 600 V and below,

the Power Meter provides additional savings in

both cost and mounting space by eliminating

the need for VTs and control power

transformers.

Versatile display

The optional Power Meter display for models

PM600, PM620, PM650 mounts in the same

space as conventional meters and is connected

to the Power Meter module with backlit

communication cable. With the backlit 2-line by

16-character LCD display, the user can view

metering data, and access the password

protected meter setup and resets menus. Since

the Power Meter display can be mounted up to

15 m away from the Power Meter module,

power metering can now be installed in tight

equipment spaces without sacrificing

convenient and affordable local display.

The communications port on the Power Meter

display is optically isolated from the 600V

metering connections.

22

Power meter

23

Power meter

(1) 3-Phase, 4-Wire star. (Other system types supported.)

Dimensions mm

Typical Wiring Diagram(1)

A

B

C

N

LOAD

NOTE: CONTROL POWER

CAN BE DRAWN FROM FUSED

VOLTAGE INPUTS L-L OR L-N

OR AN EXTERNAL SOURCE

L1-L2 100-300 VDC

90-600 VAC

FUSES

TOP

A B C N

9 10 11 12

PULSE

OUTPUT

19

20

21

CURRENT

VOLTAGE

CONTROL

POWER

8

L2 7

L1 6

COMMS

DISPLAY

CONNECTOR

22

A- B-

C-

13 14 15

16 17 18

+IN 5

IN 4

+OUT 3

OUT 2

SHLD 1

A+ B+ C+

Model PM-600, PM-620, PM-650

LINE

Technical specification

Metering Specifications

I Current Inputs:

I Current Range: 010A

I Nominal Current: 5 A

I Overcurrent Withstand: 500 A, 1 second

I Voltage Inputs:

I Voltage Range: 20600 Vac/115-500V*

I Frequency Range (50/60 Hz), 4565 Hz

I Accuracy:

I Current, voltage: 0.25% / 1%*

I Power, energy: 0.50% / 1.5%*

I Power Factor: 1.00% / 1.5%*

I Frequency: 50/60 Hz, 0.02 Hz

Control Power Input Specifications

I Input Range, ac 90600 Vac / 115-500 Vac*

I Frequency Range: 4565 Hz

I Input Range, dc 100300 Vdc / NA*

Temp. Range (operating)

I PM-100: -20 to 55C

I Meter Module: 0 to 60C

I Meter Display: 0 to 55C

Weight

I PM-100: 0.3 kg

I PM-600, 620, 650: 0.5 kg

I Power Meter Display: 0.2 kg

* PM-100

Ordering Information

Type Description

3020 PM600-MG Power Meter Module, Basic Instrumentation

3020 PM620-MG Power Meter Module, Basic Instrumentation,

plus Demand, THD, Date/Time Stamping,

Neutral Current

3020 PM650-MG Power Meter Module, Min/Max, Alarms, Event

and Data Storage, plus PM-620 Features

3020 PMD32-MG Power Meter Display with 0.3 m Cable

3020 SC104-MG Optional 1.2 m Cable

3020 SC112-MG Optional 3.6 m Cable

3020 SC130-MG Optional 9 m Cable

24

Power meter

Dimensions mm

Typical Wiring Diagram(1)

Model PM-100

14

14

17

P

F

P

Param.

138,5

138,5

42,5

5

136,

(2)

(1)

13 11 9 7

V1 V2 V3 N

6 5 4 3 2 1

K2 K1

S1S2S1S2S1

S1

S2

S1

S2

S1

S2

PM300

(A) TD+

(B) TD-

(A') RD+

(B') RD

L1 L2 L3 N

(4)

14 16 17 18

RC

S2

3 2 1

MX

protection

15 / 6300A

Ordering Information

Type Description

PM -100 Power M eter, stand-alone

shunt release

170

140

140

51

25

Selection guide

Current

Voltage, L-L

Voltage, L-N

Real Power (kW)

Reactive Power (kVAR)

Apparent Power (kVA)

Power Factor

Frequency

Real Energy (kWh)

Reactive Energy (kVARh)

Apparent Energy (kVAh)

Energy Accumulation

Modes

kWh pulse Output

Communications

Communications Wiring

Front Display

THD, Voltage & Current

Current Demand

Power Demand

(kWd, kVARd, kVAd)

Date/time stamping

Predicted Power Demand

Advanced Demand

Options

I/O Points (Max. Available)

Onboard Alarms

Min/Max Readings

Data and Event Logs

Downloadable Firmware

Waveform Capture

Sag/Swell

Programmable logic

Sequence of Events

Recording (SER)

HTML

Transient Detection

Revenue Accuracy, ANSI

Accuracy (of Reading)

Harmonic Response

UL Listed

CUL

CSA, CE, NOM

Voltage Input

CTs Included

Feature Value

Power Meters

PM600 PM620 PM650

A, B, C, N

A-C, C-B, C-A

A-N, B-N, C-N

A, B, C, total

A, B, C, total

A, B, C, total

A, B, C, total

3 total

3 total

3 total

Signed, Absolute,

energy in, energy out

Ethernet (E)

Modbus RTU (M)

POWERLOGIC (P)

2-wire, 4-wire

A, B, C

A, B, C, present & peak

3 total, present & peak

kW, kVAR, kVA

Synch to comms,

sliding block calculation

Under/over conditions.

phase unbalance conditions

Frequency, current, voltage,

power, power factor, THD

Samples per cycle

Detection/recording

On-board

GPS clock sync

Power/Energy

Current/Voltage

Based on sample rate

2-wire,

4-wire

2-wire,

4-wire

2-wire,

4-wire

M

P

M

P

M

P

Opt Opt Opt

.5%

.25%

.5%

.25%

.5%

.25%

C12.16 C12.16 C12.16

1

31 31 31

600 600 600 Direct connect max

Neutral not available.

Phase loss only.

3 power only. Per phase power

unavailable.

Phase power factor calculated

based on simulated neutral voltage.

With addition of IOM.

With addition of Ethernet

Communications Module.

Ethernet Communications Card

Min/max real power only.

With addition of VT's unit can

monitor up to 1.7MV.

Revenue metering security switch

and tab for wire seal.

Waveform capture up to 63rd

harmonic.

High sample rate available with

CVMT option module.

Circuit Monitors

CM2350

4-wire

E

P

128

.4%

.2%

16

C12.16

31

180

CM4000 CM4000T

2-wire,

4-wire

E

M

512

Opt

Opt

2-wire,

4-wire

E

M

Opt

Typically

0.04%

25 25

C12.20

255

600 600

Typically

0.04%

C12.20

255

4MH

z

PM100

No communications

26

27

Schneider Electric Ltd, Merlin Gerin PowerLogic Systems

Cheney Manor, Swindon, Wiltshire SN2 2QG. Tel: (01793) 500482 Fax: (01793) 500428.

Internet address: http://www.schneider.co.uk

in electrical distribution,

Expertise

Schneider Electric

control andautomation

Schneider Electric is the leading UK and world expert in the development

and manufacture of products for the distribution and industrial applications of

electricity. In the UK, Schneider Electric operates from 16 industrial and

commercial sites, with 2,500 people, and achieves an annual turnover in

excess of 270 million.

Offering a full range of products and services for panel builders, OEMs,

contractors, specifiers and the electrical supply industry for commercial and

industrial applications.

Schneider Electric is committed to supporting its customers at every stage of

a project. Our 180 sales engineers, is the largest dedicated sales force in the

UK electrical industry.

Our sales engineers are skilled at assessing individual requirements and

combined with the expert support of our product specialists, will develop the

most effective and economical solution.

Local support

nationwide on one number 0870 608 8 608

Fax 0870 608 8 606

Leading names in electrical distribution, control and automation

Greater London

2nd floor 408 Strand,

London WC2R 0NE.

Email Address

WebmasterGB@schneider.co.uk

Local customer support centres

Scotland Unit 11000,

Academy Business Park,

Gower Street, Glasgow,

G51 1PR. Email Address

WebmasterGB@schneider.co.uk

South West 190 Park Avenue,

Aztec West, Almondsbury,

Bristol, BS12 4SS.

Email Address

WebmasterGB@schneider.co.uk

North West 8 Brindley Road,

City Park Business Village,

Cornbrook, Manchester,

M16 9HQ. Email Address

WebmasterGB@schneider.co.uk

Telemecanique is a UK

market leader and world expert

in industrial control and

automation. It provides complete

solutions, with its range of

components, programmable

logic controllers, variable speed

drives and communications

software. In addition, it offers

power distribution through

prefabricated Canalis

busbar

trunking.

Modicon a leading brand

and marketer of high

technology programmable

controllers (PLCs) and motion

control systems used in

industrial automation. Its

international catalogue include

PLCs, numerical controllers,

specialised programming

and software, fieldbus

communication networks and

interface terminals.

Square D is a total quality

organisation and its business is

to put electricity to work

productively and effectively,

protecting people, buildings and

equipment. Its low voltage

electrical distribution equipment,

systems and services are used

world wide in commercial

applications.

Merlin Gerin is one of the

foremost experts of electrical

distribution products and systems.

Its comprehensive array of

extra-high, medium and low

voltage products and systems is

designed to manage and protect

electrical installations, ensure

safety and provide power supply

reliability and continuity.

Regional product showrooms

North Schneider Electric Limited, 123 Jack Lane, Hunslet, Leeds, LS10 1BS.

Midlands Schneider Electric Limited, University of Warwick Science Park, Sir William Lyons Road, Coventry, CV4 7EZ.

Schneider Electric Limited, Fordhouse Road, Wolverhampton, WV10 9ED.

You might also like

- 2000kva Power ModuleDocument8 pages2000kva Power ModuleIrfan SaeedNo ratings yet

- ANSI Symbols PDFDocument15 pagesANSI Symbols PDFlisused100% (1)

- Asco Series 300 Power Transfer SwitchesDocument16 pagesAsco Series 300 Power Transfer SwitchesCCR PLTU TENAYANNo ratings yet

- ATU 500 Owner ManualDocument24 pagesATU 500 Owner ManualBudi ArdyanNo ratings yet

- Logix Pro All LabsDocument78 pagesLogix Pro All LabsJonathan Damn Dawn100% (3)

- Animation Career GuideDocument14 pagesAnimation Career Guideeditoraptech50% (2)

- Software Installation Rev9Document84 pagesSoftware Installation Rev9Gabriel Ian Bada AroboNo ratings yet

- Feedback 35 001 USB MentorDocument2 pagesFeedback 35 001 USB MentorBreno LizardoNo ratings yet

- Riello Multiplus Ups Series 100 120 ManualDocument45 pagesRiello Multiplus Ups Series 100 120 ManualJorgeErnestoCartagenaNo ratings yet

- Submittal - LS Power Chambersburg - G3096 - 5.15.20Document419 pagesSubmittal - LS Power Chambersburg - G3096 - 5.15.20kohatian27796105100% (2)

- Compact Nsx100-630 User ManualDocument148 pagesCompact Nsx100-630 User Manualsoud98No ratings yet

- Compute-It: Computing KS3Document159 pagesCompute-It: Computing KS3GamePlay Aslan ggNo ratings yet

- Basler Elect Excitation System Upgrade Frame6UG09Document53 pagesBasler Elect Excitation System Upgrade Frame6UG09Ksureshki SureshNo ratings yet

- Nfpa 110 Type 10 Requirements For Emergency Power Systems: PowerhourDocument61 pagesNfpa 110 Type 10 Requirements For Emergency Power Systems: PowerhourDomingo RuizNo ratings yet

- AC Generator Synchronising Principles: Performance CriteriaDocument38 pagesAC Generator Synchronising Principles: Performance CriteriaWong TerbiumNo ratings yet

- Technical Data SheetDocument14 pagesTechnical Data SheetRavi Ranjan VermaNo ratings yet

- Medium Voltage System: Nguyen The Vinh - Consultant EngineerDocument40 pagesMedium Voltage System: Nguyen The Vinh - Consultant EngineerNguyễn Nhật ÁnhNo ratings yet

- May2012 PDFDocument121 pagesMay2012 PDFAlex LeungNo ratings yet

- 8991 3488 00 Diagrams and Drawings PDFDocument56 pages8991 3488 00 Diagrams and Drawings PDFLuis GutierrezNo ratings yet

- 8991 3488 00 Diagrams and Drawings PDFDocument56 pages8991 3488 00 Diagrams and Drawings PDFLuis GutierrezNo ratings yet

- DVR2000E Training - SECT #2 (Hardware Install)Document13 pagesDVR2000E Training - SECT #2 (Hardware Install)Anonymous uEt1sNhU7lNo ratings yet

- Grid Protection Brochure 2017Document10 pagesGrid Protection Brochure 2017SachinNo ratings yet

- Masterpact: Installation RecommendationsDocument16 pagesMasterpact: Installation RecommendationsAsif ShahNo ratings yet

- T&D Septiembre 2014 PDFDocument103 pagesT&D Septiembre 2014 PDFjegva7875No ratings yet

- Dunkerque Project Sheet (Alstom and Standardkessel)Document2 pagesDunkerque Project Sheet (Alstom and Standardkessel)peter34567100% (1)

- Prf1 PRD PF Surgearrest-M9dp80aenDocument8 pagesPrf1 PRD PF Surgearrest-M9dp80aenBudy AndikaNo ratings yet

- Npt35 Avr Ufro ControlDocument11 pagesNpt35 Avr Ufro ControlAbrahan BermudezNo ratings yet

- Installation Guide for Distribution Boards, DIN Rail Equipment, Enclosures and ConnectionsDocument215 pagesInstallation Guide for Distribution Boards, DIN Rail Equipment, Enclosures and ConnectionsRaileanu CristianNo ratings yet

- PrismaDocument26 pagesPrismaGoran MladenovicNo ratings yet

- DSE8660 Wiring DiagramDocument2 pagesDSE8660 Wiring DiagramYasser JaviNo ratings yet

- Avr CubicleDocument28 pagesAvr CubicleJITPLNo ratings yet

- Amtech Basler Offers Solution For Replacing ABB1000-15 With DECS200 Digital Excitation SystemDocument4 pagesAmtech Basler Offers Solution For Replacing ABB1000-15 With DECS200 Digital Excitation SystemRamakrishnan AlagarsamyNo ratings yet

- DEIFDocument6 pagesDEIFnhocti007No ratings yet

- Automation Solution Guide: From The Needs, Choose An Architecture, Then A Technology To Lead To A ProductDocument20 pagesAutomation Solution Guide: From The Needs, Choose An Architecture, Then A Technology To Lead To A ProductdenisonocNo ratings yet

- Digital Voltage Regulator: FeaturesDocument8 pagesDigital Voltage Regulator: Featuresvictor.ciprianiNo ratings yet

- Rückenbreite Bis 10 MM (1 Blatt 0,106 MM) : Hardware and EngineeringDocument94 pagesRückenbreite Bis 10 MM (1 Blatt 0,106 MM) : Hardware and EngineeringAdilson DominguesNo ratings yet

- Furse GuideDocument4 pagesFurse GuidefndprojectNo ratings yet

- Power Magazine June 2017Document68 pagesPower Magazine June 2017Suresh CNo ratings yet

- 5210Document55 pages5210bahmanNo ratings yet

- InteliLite MRS 16 DatasheetDocument4 pagesInteliLite MRS 16 DatasheetPeter CardonaNo ratings yet

- A EG3200 Section 7 Analog Manager (NXPowerLite)Document42 pagesA EG3200 Section 7 Analog Manager (NXPowerLite)Halit YalçınkayaNo ratings yet

- Prisma Technical GuideDocument61 pagesPrisma Technical Guidenooruddinkhan1No ratings yet

- Automation and Relay Functions - Catalogue 2003.12Document273 pagesAutomation and Relay Functions - Catalogue 2003.12Sarah RichardNo ratings yet

- West Control STGDocument5 pagesWest Control STGKathiravanRskNo ratings yet

- Compact Merlin Gerin - STRDocument1 pageCompact Merlin Gerin - STRAlexandre MorenoNo ratings yet

- Merlin Gerin LV Switchgear, Fusegear & Electrical DistributionDocument31 pagesMerlin Gerin LV Switchgear, Fusegear & Electrical DistributionIppiNo ratings yet

- GE UPS SLD 225-500kvaDocument1 pageGE UPS SLD 225-500kvashivaramNo ratings yet

- Altivar 28 Speed Controller Setup GuideDocument49 pagesAltivar 28 Speed Controller Setup GuidegilamadaNo ratings yet

- Derating Stamford PDFDocument1 pageDerating Stamford PDFPowerTechNo ratings yet

- Reactive power regulators and protectionsDocument5 pagesReactive power regulators and protectionsSalmanNo ratings yet

- Control fire dampers with Halton's FD-CON-2 unitDocument2 pagesControl fire dampers with Halton's FD-CON-2 unitkevinNo ratings yet

- Esr-48-40a C DeltaDocument2 pagesEsr-48-40a C Deltasam100% (2)

- D000062002 E650 S4 ZxD400xT Technical DataDocument14 pagesD000062002 E650 S4 ZxD400xT Technical DataFeodor RadilovNo ratings yet

- Auriga UPS - User Manual - DT0475 Rev.003Document45 pagesAuriga UPS - User Manual - DT0475 Rev.003Hong Lan TranNo ratings yet

- Decs 250Document12 pagesDecs 250Paulo LeiteNo ratings yet

- 5parameter ListDocument86 pages5parameter ListIsradani MjNo ratings yet

- Netcol5000-A025 In-Row Air Cooled Smart Cooling Product Quick Guide (300 MM Width)Document34 pagesNetcol5000-A025 In-Row Air Cooled Smart Cooling Product Quick Guide (300 MM Width)Myo Min HeinNo ratings yet

- BB Series User Manual V0 (2) .0Document28 pagesBB Series User Manual V0 (2) .0a.elwahabNo ratings yet

- MV Trafo SB - SMC - STP TI US - en 10 PDFDocument6 pagesMV Trafo SB - SMC - STP TI US - en 10 PDFVictor ToledanoNo ratings yet

- Option N Modbus TCP IPDocument32 pagesOption N Modbus TCP IPJosé Miguel Echeverria HerediaNo ratings yet

- THYRISTORSDocument19 pagesTHYRISTORSajo zinzoNo ratings yet

- Intro To Power Management PDFDocument37 pagesIntro To Power Management PDFbajarfileNo ratings yet

- UPS Easy 3S OperationDocument48 pagesUPS Easy 3S Operationacodr83No ratings yet

- Advanced Power Technology and Services J.S.C. Advanced Power Technology and Services J.S.CDocument10 pagesAdvanced Power Technology and Services J.S.C. Advanced Power Technology and Services J.S.CQuang NgocNo ratings yet

- E-Terra: A Concentration of Technology and Performance For Large-Scale Smart Grid DeploymentDocument4 pagesE-Terra: A Concentration of Technology and Performance For Large-Scale Smart Grid DeploymentLija ManojNo ratings yet

- MGE PDU MonitoringDocument7 pagesMGE PDU MonitoringomarpatNo ratings yet

- Motorkennlinie Motor Characteristic Caractéristique Du MoteurDocument1 pageMotorkennlinie Motor Characteristic Caractéristique Du MoteurLuis GutierrezNo ratings yet

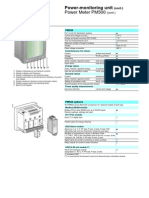

- PM500 power monitoring unit functionsDocument2 pagesPM500 power monitoring unit functionsElard HuamaniNo ratings yet

- Cerro ColoradoDocument22 pagesCerro ColoradoLuis GutierrezNo ratings yet

- Despertador SonyDocument2 pagesDespertador SonyLuis GutierrezNo ratings yet

- 22 March FloodlightDocument8 pages22 March FloodlightLuis GutierrezNo ratings yet

- Question Text: Marks 17.00/20.00 Grade 85.00 Out of 100.00Document11 pagesQuestion Text: Marks 17.00/20.00 Grade 85.00 Out of 100.00Yoo Jung100% (1)

- Universiti Teknologi Mara Final Examination: Confidential CS/APR 2011/CSC159/428/ITC150Document12 pagesUniversiti Teknologi Mara Final Examination: Confidential CS/APR 2011/CSC159/428/ITC150Izza NasirNo ratings yet

- History of Printing in NigeriaDocument8 pagesHistory of Printing in Nigeriabaituliman66630% (1)

- NCM 110 Transes 2ND SemDocument27 pagesNCM 110 Transes 2ND SemTherese Melchie SantuyoNo ratings yet

- SiminarDocument19 pagesSiminaramitmanuNo ratings yet

- Question List covers computer processing, memory, I/O devicesDocument37 pagesQuestion List covers computer processing, memory, I/O devicesNitasha GoyalNo ratings yet

- English For Skills 1 PDFDocument70 pagesEnglish For Skills 1 PDFMaya Ernie100% (1)

- What Is ProgrammingDocument3 pagesWhat Is ProgrammingjeffNo ratings yet

- ABB Review 2 2019 en 72dpiDocument41 pagesABB Review 2 2019 en 72dpiYashveer TakooryNo ratings yet

- Unit 11 12 13 14Document21 pagesUnit 11 12 13 14George BanucuNo ratings yet

- Characterstic of Comp-1Document7 pagesCharacterstic of Comp-1FaizSheikhNo ratings yet

- 10.01.2022 Domestic Data Entry OperatorDocument18 pages10.01.2022 Domestic Data Entry Operatorkhajapeer rNo ratings yet

- Course Outline (Computing Fundamentals)Document3 pagesCourse Outline (Computing Fundamentals)Michelle ElapeNo ratings yet

- Workshop Logistics, Materials, and Equipment ChecklistDocument2 pagesWorkshop Logistics, Materials, and Equipment ChecklistnaturewisdomNo ratings yet

- Datesheet Sep 2019Document2 pagesDatesheet Sep 2019Achint KaurNo ratings yet

- Quantum Vol1Document274 pagesQuantum Vol1grgchary100% (4)

- Introduction To Computers - Languages: Department of Computer and Information Science, School of Science, IUPUIDocument16 pagesIntroduction To Computers - Languages: Department of Computer and Information Science, School of Science, IUPUIRaajula AmarnathNo ratings yet

- Importance of ICT SkillsDocument17 pagesImportance of ICT SkillsMonjit SonarNo ratings yet

- Module Ii: Ethics For It Workers and It Users: I AcknowledgeDocument11 pagesModule Ii: Ethics For It Workers and It Users: I AcknowledgeMhel Annie CompasNo ratings yet

- It Workshop Lab Manual: Csi Wesley Institute of Tech &SCDocument82 pagesIt Workshop Lab Manual: Csi Wesley Institute of Tech &SCmr copy xeroxNo ratings yet

- International Journal of Control Theory and Computer Modelling (IJCTCM)Document2 pagesInternational Journal of Control Theory and Computer Modelling (IJCTCM)ijctcmjournalNo ratings yet

- Yamaha USB-MIDI Driver Installation GuideDocument8 pagesYamaha USB-MIDI Driver Installation GuideTeo IonelNo ratings yet

- Computer in Our Daily LifeDocument16 pagesComputer in Our Daily LifeZꪖʀᥴʜTɀꪗ.No ratings yet

- Starting Forth PDFDocument166 pagesStarting Forth PDFnitetrkrNo ratings yet

- DownloadDocument185 pagesDownloadJOSHUA CLUTARIONo ratings yet

- Ch-1 Intro of CADDocument31 pagesCh-1 Intro of CADHaider AliNo ratings yet