Professional Documents

Culture Documents

Petroleum Development Oman L.L.C.: Keywords

Uploaded by

ravi000980 ratings0% found this document useful (0 votes)

830 views21 pagesOriginal Title

SP-1176

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

830 views21 pagesPetroleum Development Oman L.L.C.: Keywords

Uploaded by

ravi00098Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 21

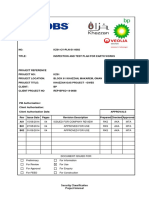

Petroleum Development Oman L.L.C.

UNRESTRICTED Document ID : SP-1176 ERD !7-!"#

$ul% "!!! &'l'n( )e% :

Non-De*truct've E+am'nat'on

,men-ment*.Supplement* to

,S/E 0P1 Co-e Sect'on 1#

2e%3or-*:

Acceptance Criteria

ASME V

Examination Personnel

Liquid Penetrant Examination

Magnetic Particle Examination

Radiographic Examination

Ultrasonic Examination

This document is the property o Petroleum !e"elopment #man$ LLC% &either the 'hole nor any part

o this document may (e disclosed to others or reproduced$ stored in a retrie"al system$ or transmitted in

any orm (y any means )electronic$ mechanical$ reprographic recording or other'ise* 'ithout prior

'ritten consent o the o'ner%

Non-Destructive Examination Version 1.0

Authorised For Issue

Signed +%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%

UER )#TT,-*

C.!/ Materials and Corrosion

The ollo'ing ta(le lists the our most recent re"isions to this document% !etails o all re"isions prior to

these are held on ile (y the issuing department%

1er*'on No. Date ,ut4or Scope . Remar)*

Version -%0 01,02,00 #TT,-1 Reormatted and updated text o ER!302304

Re"% -$ &o"% -556%

July 2000 SP-1176 i

Non-Destructive Examination Version 1.0

Contents

,ut4or'*e- &or I**ue ...................................................................................................................'

Content*.......................................................................................................................................''

1. Intro-uct'on.............................................................................................................................1

". Spec'5'cat'on 5or Non-De*truct've E+am'nat'on.................................................................."

,ppen-'+ , 6lo**ar% o5 De5'n't'on*7 Term* an- ,88rev'at'on*............................................9

,ppen-'+ 0 ,men-ment*.Supplement* to ,S/E Sect'on 1.................................................:

,rt'cle 1 - 6eneral Re;u'rement*.............................................................................................:

,rt'cle " - Ra-'o(rap4'c E+am'nat'on......................................................................................<

,rt'cle : - Ultra*on'c E+am'nat'on /et4o-* &or In-Serv'ce In*pect'on...............................=

,rt'cle < - Ultra*on'c E+am'nat'on /et4o-* &or /ater'al* ,n- &a8r'cat'on...................1!

,rt'cle 6 - L';u'- Penetrant E+am'nat'on..............................................................................1"

,rt'cle 7 - /a(net'c Part'cle E+am'nat'on............................................................................1:

,ppen-'+ C Re5erence*............................................................................................................17

U*er Comment &orm................................................................................................................1>

July 2000 SP-1176 ii

Non-Destructive Examination Version 1.0

1. Introduction

1.1 Purpose

This speciication gi"es the minimum technical requirements or &on3!estructi"e

Examination$ 'here the applica(le Code has (een designated (y the Company as ASME

7oiler and Pressure Vessel Code$ Section V )generally reerred to in this speciication as

ASME V*%

This speciication replaces ER! 02304$ &on3!estructi"e Examination$ issued in &o"em(er

-556 and gi"es amendments and supplements to ASME V%

1.2 Changes to the Specification

This speciication shall not (e changed 'ithout appro"al rom the Custodian$ the 8elding

.unctional !iscipline /ead )C.!/*$ UER )#TT,-*$ 'ho o'ns this speciication% 9 you thin:

any part o this speciication is not correct$ 'rite your comments on a copy o the User

Comments .orm% The orm is included as the last page o this speciication% Send the copy

'ith your comments and personal details to !CS%

July 2000 Page 1 SP- 1176

Non-Destructive Examination Version 1.0

2. Specification for Non-Destructive Exaination

This Speciication gi"es the minimum technical requirements or &on3!estructi"e

Examination 'here ASME V is the applica(le Code designated (y the Company )or the

applica(le Code reerenced (y a Construction Code,Speciication designated (y the

Company*%

2.1 Specification !e"uireents

The scope o this speciication is limited to the ollo'ing non3destructi"e examination )&!E*

methods+

Radiographic Examination

Ultrasonic Examination

Liquid Penetrant Examination

Magnetic Particle Examination

These &!E methods shall (e used to detect surace and internal discontinuities in (ase

materials$ 'elds$ and a(ricated parts and components%

&on3!estructi"e Examination shall (e conducted in accordance 'ith the ASME 7oiler and

Pressure Vessel Code Section V$ -55; Edition plus -555 Addenda$ as amended and

supplemented (y Appendix 7 o this speciication% The amendments and supplements gi"en

in Appendix 7 ha"e (een necessary to incorporate special P!# requirements%

The Clause num(ering in Appendix 7 ollo's that o ASME V% Clauses o ASME V that are

neither amended nor supplemented (y this speciication shall apply in their entirety%

2.2 Process De#ivera$#es

Process deli"era(les comprise rele"ant &!E reports$ produced and endorsed in accordance

'ith this speciication%

2.% Process &'ner(s !esponsi$i#it)

The o'ner o this speciication$ #TT,-$ as C.!/ 8elding$ is responsi(le or authorising all

proposed de"iations or amendments to the speciication and or the instigation o periodic

re"ie's and updates in accordance 'ith Clauses -%4 and 4%2%

2.* Perforance +eve#s , Indicators

&ot applica(le to this speciication%

2.- Perforance .onitoring

&ot applica(le to this speciication%

2./ Effective period

The requirements o this speciication shall remain in orce indeinitely unless superseded (y

an authorised re"ision%

2.0 !evie' and Iproveent

This speciication 'ill (e re"ie'ed and updated once e"ery three years% The re"ie' authority

'ill (e UER )#TT,-$ C.!/ Materials and Corrosion*%

July 2000 Page 2 SP-1176

Non-Destructive Examination Version 1.0

Appendix A 1#ossar) of Definitions2 3ers and A$$reviations

The definitions, terms and abbreviations of ASME V apply, with the following additions:

De5'n't'on*

Compan% Petroleum !e"elopment #man LLC%

Contractor The party that carries out all or part o the design$ engineering$

procurement$ construction$ commissioning or management o a

pro<ect$ or operation or maintenance o a acility% The Company

may underta:e all or part o the duties o the Contractor%

Corporate &unct'onal

D'*c'pl'ne ?ea-

The person responsi(le or the discipline to 'hich the standard

(elongs%

U*er The Company$ Consultant or Contractor 'ho uses this

document%

*4all 9ndicates a requirement%

*4oul- 9ndicates a recommendation%

ma% 9ndicates a possi(le course o action

,88rev'at'on*

,S/E American Society o Mechanical Engineers

,SNT American Society or &on3destructi"e Testing

0S 7ritish Standard

C&D? Corporate .unctional !iscipline /ead

CS@IP Certiication Scheme or 8elding 9nspection Personnel

DCS !ocument Control Section )#T7,4*

D@DI !ou(le 8all !ou(le 9mage

D@SI !ou(le 8all Single 9mage

EN European Standard )Europ=ische &orm*

II@ 9nternational 9nstitute o 8elding

IAI 9mage >uality 9ndicator

ISO 9nternational #rganisation or Standardisation

/?B Megahert?

NDE &on3destructi"e Examination

PCN Personnel Certiication in &on3destructi"e Testing

T, Technical Authority$ as deined in ER!300304 and @U3424%

@PS 8elding Procedure Speciication

July 2000 Page SP- 1176

Non-Destructive Examination Version 1.0

Appendix 4 Aendents,Supp#eents to AS.E Section 5

Artic#e 1 - 1enera# !e"uireents

3-126 1enera#

Add the following:

&!E shall (e perormed only (y Company registered &!E Contractors )Category @A*% &!E

acti"ities shall (e controlled and documented in accordance 'ith SP3--2-%

Unless speciied other'ise (y the Company$ all &!E o 'elds shall (e carried out 'ith the

'eld at am(ient temperature%

3-1*6 !e"uireents

Replace existing text as follows:

All non3destructi"e examination personnel shall (e qualiied and certiicated or the method

o &!T to (e carried out in accordance 'ith 9S# 52-4$ to &!T Le"el 4 or higher% The roles

and responsi(ilities o &!T personnel shall (e as deined in the le"els o competence in 9S#

52-4% Personnel certiied to AS&T )S&T3TC3-A* Le"el 99 are accepta(le pro"ided that the

certiying Le"el 999 &!T Engineer has (een appro"ed (y the Company%

Equi"alent inspection and &!T qualiications e%g% CS89P,PC& Tester,Practitioner,

9nterpreter )8elds*$ Le"el 4$ may (e accepted at the sole discretion o the Company%

Personnel qualiied to AS&T Le"el 9 or equi"alent shall (e used only as assistant to a Le"el 99

perorming &!E%

3-1-6 Procedure

Replace paragraph c! with the following:

All &!E perormed under this speciication shall (e done to an appro"ed 'ritten procedure%

The Procedure shall (e re"ie'ed and endorsed (y the &!E ContractorBs AS&T Le"el 999

personnel (eore su(mission to the Company or appro"al%

The Contractor shall perorm a Procedure >ualiication test to the satisaction o the

Company% All qualiication tests shall (e 'itnessed (y a Company TA3A )or higher*% The

Company may engage a third party agency to carry out inspection on its (ehal% 8here an

inspection agency has 'itnessed the testing$ the agency shall also issue a Certiicate o

Conormance$ 'hich states that the testing practices 'ere in compliance 'ith ASME V and

this speciication%

8here rele"ant$ the testing o a 8PS qualiication may (e used or &!E procedure

qualiication% Pre"ious test records may also (e used to support a procedure% The procedure

shall (e re"ie'ed and appro"ed (y a Company TA34 )or higher* (eore any &!E is perormed

on each Pro<ect% At least one copy o each qualiied procedure shall (e readily a"aila(le to the

ContractorCs &!E Personnel or their reerence and use%

3-176 Eva#uation

Replace existing text with the following:

The acceptance standards or these &!E methods shall (e as stated in the reerencing Code

Section and as speciied in rele"ant Company Standards%

July 2000 Page ! SP-1176

Non-Destructive Examination Version 1.0

Artic#e 2 - !adiographic Exaination

3-226 1enera# !e"uireents

3-221 Procedure !e"uireents

3-221.1 Cop#iance 'ithout a 8ritten !adiographic Procedure.

Replace existing text with the following:

Radiography shall (e carried out to an appro"ed 'ritten procedure only% The procedure shall

(e re"ie'ed and endorsed (y the &!E ContractorBs AS&T Le"el 999 (eore su(mission to the

Company or appro"al%

3-22* S)ste of Identification

Replace existing text with the following:

Each radiograph shall ha"e the ollo'ing inormation inherent 'ithin the ilm structure to

ensure tracea(ility% This shall (e achie"ed (y using lead letters and num(ers% The inormation

shall include+3

The Contract num(er%

!ate%

8eld num(er or identiication%

Repair num(er%

8elderBs num(er%

&ominal diameter o pipe%

8all thic:ness or pipe schedule%

3-22- .onitoring Densit) #iitation of !adiographs

Replace existing text with the following:

Measurement o ilm density shall (e made (y a densitometer ha"ing a range o 0 D E% The

instrument shall (e cali(rated to manuacturerBs recommendations The cali(ration records

shall (e a"aila(le or re"ie' (y the Company%

3-2%6 E"uipent And .ateria#s

3-2%1 Fi#

3-2%1.1 Se#ection

Add the following

Ultra3ine or ine3grain high contrast ) !E$ !2 or equi"alent* ilm shall (e used in con<unction

'ith lead intensiying screens%

3-2%2 Intensif)ing Screens.

Add the following:

Lead intensiying screens shall (e used on all @amma ray exposures and all F3ray exposures

requiring more than -40 :V% The thic:ness o the screens )(oth ront and (ac:* shall (e

0%-41mm%

July 2000 Page " SP- 1176

Non-Destructive Examination Version 1.0

3-2%% Iage 9ua#it) Indicator :I9I; Design

Replace existing text incl"ding table! with the following:

8ire type penetrameters shall (e used to determine radiographic sensiti"ity% The

penetrameters shall (e selected and utilised in accordance 'ith E& E643-% The selected 9>9

model shall co"er the 'ire thic:ness ranges listed in the ta(le (elo'%

@all t4'c)ne** IAI Ran(e EN :6" - 1#

G 1mm

1 to -2mm

-; to E1mm

H E1mm

-4 3 -;

-0 3 -6

06 3 -4

0- 3 02

3-2/6 Ca#i$ration

3-2/1 Source Si<e

Add the following:

9ridium -54 sources shall ha"e a physical si?e o not greater than AxAmm%

3-206 Exaination

3- 202 !adiation Energ)

3-202.1 =-radiation.

Add the following:

F3ray Radiography shall (e carried out using 400$ 410 or A00 :V equipment$ the po'er

supply (eing pro"ided (y a generator%

7attery operated F3ray equipment may also (e used 'ith prior appro"al o the Company% A

ully charged spare (attery pac: shall al'ays (e a"aila(le on site as replacement%

3-202.2 1aa !adiation.

Add the following:

8here examination using @amma radiation is permitted$ the source shall (e 9ridium -54%

The maximum strength shall (e A0 curies in accordance 'ith the limitation in the P!# /SE

Manual%

Sources o higher strength shall not (e used on site 'ithout 'ritten appro"al rom the

Company%

3-276 Eva#uation

3-272 !adiographic Densit)

3-272.1 Densit) +iitations.

Replace existing text with the following:

July 2000 Page 6 SP-1176

Non-Destructive Examination Version 1.0

.or @amma ray exposures the ilm density shall (e (et'een 4 and A%1 measured in the portion

o ilm (eing interpreted% 8hen F3ray is used then the density shall (e (et'een -%; and A%1%

Vie'ing conditions shall conorm to the requirements o E& 411;0 )identical to 9S# 11;0*%

3-27% I9I Sensitivit)

Add the following:

Radiographic Sensiti"ity shall (e equal to or (etter than that speciied in the applica(le code%

.or the !8!9 technique$ the diameter o 'ires employed shall (e (ased on the nominal

dou(le 'all thic:ness o the specimen%

.or the !8S9 technique$ the diameter o 'ire shall (e (ased on the nominal single 'all

thic:ness o the specimen%

.or 'eldments$ the thic:ness o external 'eld reinorcement and internal 'eld protrusion

shall (e included in the sensiti"ity calculation%

3-27- 1eoetric >nsharpness +iitations

Replace existing text as follows:

The geometric unsharpness shall not exceed the ollo'ing "alues+

Material Thic:ness )mm* Ug Max )mm*

G 10

10 D 21

21 3 -00

H -00

0%1

0%21

-%00

-%20

3-27/ Eva#uation $) .anufacturer

Add the following:

Radiographs shall (e interpreted and the report endorsed (y a radiographer qualiied to a

minimum o 9S# 52-4 &!T Le"el 4 , AS&T Le"el 99 or PC&,ERS qualiied radiographic

interpreter and then su(mitted to the Company TA3A or appro"al%

3-2?6 Docuentation

3-2?1 !adiographic 3echni"ue Docuentation Detai#s

Replace existing text with the following:

All radiographs shall (e accompanied (y a test report% As a minimum the report shall include

the ollo'ing inormation+

- 8eld identiication num(er

- RadiographerCs identity

- 8elderCs num(er)s*

- !ate o exposure

- Code , speciication

- Location o ilm

July 2000 Page 7 SP- 1176

Non-Destructive Examination Version 1.0

- Type o ilm

- Radiographic procedure num(er

- 8hether original 'eld or repair

- /eat treatment condition

- 8all Thic:ness)es*

- Radiographic technique

- 9>9 type and si?e

- Sensiti"ity achie"ed

- @eometric unsharpness

- !ensity achie"ed

- Location and type o any la's disco"ered

- Conclusion 3 accept or re<ect 'ith respect to applica(le speciication%

July 2000 Page # SP-1176

Non-Destructive Examination Version 1.0

Artic#e * - >#trasonic Exaination .ethods For In-Service

Inspection

3-*26 1enera#

3-*22 Personne# !e"uireents

Replace second sentence of existing text as follows:

Personnel perorming this examination shall (e qualiied to 9S# 52-4 &!T Le"el 4 or

equi"alent in accordance 'ith Section T3-E0 o this speciication% Additional testing o

personnel$ using appropriate test pieces and procedures$ should (e considered to "eriy the

minimum deect si?e and nature o deects that can (e detected%

3-*%6 E"uipent.

3-*%1 Instruent !e"uireents

3-*%1.1 3)pe

Add the following:

The speciic ultrasonic unit )ma:e and model*$ pro(e type and cali(ration (loc:s to (e used

shall (e speciied in the procedure or Company appro"al% Cali(ration (loc:s should (e 9983

V-$ 9983V4 or step 'edge type%

3-*-6 Procedure !e"uireents

Replace the first sentence of the existing text with the following:

Ultrasonic Examination shall (e carried out to an appro"ed 'ritten procedure% The procedure

shall (e re"ie'ed and endorsed (y the &!E ContractorBs AS&T Le"el 999 (eore su(mission to

the Company or Appro"al%

Procedures shall (e qualiied in accordance 'ith Section T3-10 o this speciication%

3-*?6 !ecords

3-*?* !eport

Add the following:

8hen corrosion monitoring o piping systems and static equipment is carried$ out the data

shall (e entered in the report ormat sho'n in Attachment - o this speciication to acilitate

entry o the data into the PACER 3 Corrosion Management System%

Iey points monitored shall (e identiied on rele"ant isometric dra'ings or piping systems

and on schematic diagrams or static equipment%

!etailed s:etches o any corrosion or other deects noted shall (e recorded and attached 'ith

the ultrasonic inspection report%

July 2000 Page $ SP- 1176

Non-Destructive Examination Version 1.0

Artic#e - - >#trasonic Exaination .ethods For .ateria#s And

Fa$rication

3--26 1enera# !e"uireents

3--22 8ritten Procedure !e"uireents

Replace first sentence of existing text with the following:

Ultrasonic Examination shall (e carried out to an appro"ed 'ritten procedure% The procedure

shall (e re"ie'ed and endorsed (y the &!E ContractorBs AS&T Le"el 999 (eore su(mission to

the Company or appro"al%

Procedures shall (e qualiied in accordance 'ith Section T3-10 o this speciication%

3--%6 E"uipent and Supp#ies

Add the following:

See also Section T3EA- o this speciication%

3--*6 App#ications

3--*1 .ateria# Product Fors

3--*1.1 P#ate

Add the following:

>uality grades o erritic steel plate and general lamination chec:s shall (e carried out as per

7S 1556%

9n edge testing scanning shall co"er -00J o the area in a (and o minimum 10 mm rom the

cut edge%

3--*2 8e#ds

3--*2.0 Exaination of 8e#ds

3--*2.0.2 Scanning

Add the following:

&ominal pro(e angle 'ill (e E1$ 60 and 20% Each 'eld shall (e examined 'ith at least t'o

dierent pro(e angles%

Selection o pro(e angle shall (e dependent on local 'eld geometry% A third pro(e angle may

(e used at the discretion o the technician or 'hen required (y the company%

3--?6 !eports And !ecords

3--?% Exaination !ecords

Replace the existing text with the following:

July 2000 Page 10 SP-1176

Non-Destructive Examination Version 1.0

.or each ultrasonic examination the ollo'ing inormation shall (e identiied and recorded+

Ultrasonic procedure num(er

!ate o examination

Examination personnel 9dentity$ le"el and signature%

Ultrasonic examination equipment%

Cali(ration sheet identity

8eld identiication and location

8elding process

&!E speciication%

Surace condition%

Acceptance criteria%

8all thic:ness and length o 'eld examined%

/eat treatment condition%

#riginal or repair 'eld%

Map or record o discontinuities assessed%

Conclusion 3 accept or re<ect according to Speciication%

July 2000 Page 11 SP- 1176

Non-Destructive Examination Version 1.0

Artic#e / - +i"uid Penetrant Exaination

3-/26 1enera#

3-/21 Procedure

3-/21.1 Initia# Procedure

Replace the first sentence of the existing text with the following:

Liquid Penetrant Examination shall (e carried out to an appro"ed 'ritten procedure% The

procedure shall (e re"ie'ed and endorsed (y the &!E ContractorBs AS&T le"el 999 (eore

su(mission to the Company or appro"al%

3-/%6 E"uipent

3-/%1 Penetrant .ateria#s

Add the following:

All penetrant material shall (e aerosol applied%

The ma:e and (rand o the penetrant$ de"eloper and cleaner to (e used shall (e speciied

indi"idually in the procedure or Company appro"al%

3-/*6 !e"uireents

3-/*1 Contro# of Containants

Add the following to the end of the first paragraph:

The required certiication shall (e a"aila(le or re"ie' (y the Company%

3-/-6 Procedure , 3echni"ue

3-/-1 3echni"ues

#elete the first paragraph "p to the colon and replace with the following:

&ormally a colour contrast )daylight "isi(le* penetrant shall (e used 'ith the penetrant

processes listed% .luorescent penentrants shall (e used only on special applications 'ith the

prior appro"al o the Company%

3-/?6 Docuentation , !ecords

3-/?6.1

Add the following:

The test report shall (e prepared and contain as a minimum the ollo'ing inormation+

Procedure num(er

!ate o examination

Examination personnel identity$ le"el and signature%

8eld identiication

Material

Technique

Type o consuma(le

July 2000 Page 12 SP-1176

Non-Destructive Examination Version 1.0

Acceptance criteria , standard

Si?e and location o any deect ound

Acceptance or re<ection 'ith respect to acceptance standard

July 2000 Page 1 SP- 1176

Non-Destructive Examination Version 1.0

Artic#e 0 - .agnetic Partic#e Exaination.

3-026 1enera#

Replace the first sentence of the existing text with the following:

This procedure is intended to (e limited to applications 'here la's (rea: the surace o

erromagnetic materials%

9t should not (e assumed that magnetic particle examination is capa(le o detecting su(3

surace discontinuities%

3-0-6 Procedure , 3echni"ue

Add the following:

Magnetic particle examination shall (e carried out to an appro"ed 'ritten procedure% The

procedure shall (e re"ie'ed and endorsed (y the &!E ContractorBs AS&T le"el 999 (eore

su(mission to the Company or appro"al%

3-0-1 .ethod of Exaination.

Replace the existing text with the following:

Examination shall (e done using the continuous magnetic lo' method (y the application o a

permanent yo:e magnet unless prior appro"al is o(tained rom the Company or other

methods% The magnet shall remain in position 'hile the examination medium is applied and

'hile excess examination medium is (eing remo"ed%

3-0-2 3echni"ues and .ateria#s.

Add the following to the first paragraph:

8hen liquid in: is used as the testing media$ the suraces to (e examined shall (e painted

'ith a contrasting paint or strippa(le lacquer appro"ed (y the Company%

Replace the second paragraph incl"ding listed items! with the following:

Magneti?ation shall (e carried out (y the yo:e technique%

3-0-% .agneti<ing Fie#d Ade"uac) and Direction.

3-0-%.1

Replace the first paragraph with the following:

8hen it is necessary to "eriy the adequacy or direction o the magneti?ing ield$ this shall (e

done (y means o a 7urmah3Castrol Strip positioned on the surace to (e examined% This

indicator consists o a crac:ed strip o Mu3metal encased in thin copper%

8hen using this indicator$ a suita(le lux or ield strength is indicated 'hen a clearly deined

line o magnetic particles orm across the copper ace o the indicator$ 'hen the examination

medium is applied simultaneously 'ith the magneti?ing orce

3-0/6 Ca#i$ration of e"uipent

3-0/2 +ifting Po'er of @oAes

Replace existing text as follows:

July 2000 Page 1! SP-1176

Non-Destructive Examination Version 1.0

The Magneti?ing orce o the yo:es used shall (e chec:ed prior to start o a ne' contract or

'hene"er a yo:e has (een damaged$ (ut as a minimum once e"ery A0 days% Records o

"eriication shall (e a"aila(le or re"ie' (y the Company%

Each permanent magnet yo:e shall ha"e a liting po'er o at least --:gs at the maximum

pole spacing that 'ill (e used% 9 a magnet ails to lit the test (loc: satisactorily$ then the

magnet shall (e returned or re3magneti?ation and the num(er logged%

3-006 Exaination

3-00/ @oAe 3echni"ue

3-00/.2 .agneti<ing Procedure.

Replace existing text, incl"ding $ote, with the following:

.or this technique permanent magnet yo:es shall (e used%

3-0?6 !ecords

Add the following:

Each report shall contain the ollo'ing inormation as a minimum +3

Procedure num(er

Examination personnel identity$ le"el and signature

8eld identiication

Method o magneti?ation

!ate o inspection

Type o inspection medium

Applied magnetic ield strength

/eat treatment condition o 'eld

8hether original 'eld or repair )# or R*

.la's detected and locations

Acceptance criteria , Speciication

Conclusions + Acceptance or re<ection 'ith respect to the speciication

July 2000 Page 1" SP- 1176

Non-Destructive Examination Version 1.0

Attachent 1 - >#trasonic Inspection !eport For

Petroleum Development Oman

!ate+

Ultrasonic 9nspection Report &o% Sheet o

Title+

9nspector+ Location+

Tag &o%+ Ser"ice+

7aseline 9nspection+ Kes,&o Total Line !istance )m%*+

Pro(e Type+ 9n Ser"ice K,&$ )i & see Ser"ice !escription%*+

Pro(e !iameter+ Couplant Type+

Min% Allo'a(le Thic:ness+ Retirement Action Thic:ness+

Equipment Type L Method+

!escription o Plant+

9nspection Point

9dentity$ !iameter and

Chainage%

)rom maniold or gl$

rom 'ell i oil,'ater*

Iey Point

TML

Minimum

Thic:ness

)mm*

Maximum

Thic:ness

)mm*

Required

&ominal

8all

)as per Piping

Class*

Actual

&ominal 8all

Additional 9normation

)!eect Si?e etc%*

Remar:s and Comments+

Ser"ice !escription + PR#!%,LTS!%,STS!%,A7!%

#perating Pressure+ Maximum #perating Pressure +

July 2000 Page 16 SP-1176

Non-Destructive Examination Version 1.0

Appendix C !eferences

9n this speciication$ reerence is made to the ollo'ing pu(lications% Unless speciically designated (y

date$ the latest edition o each pu(lication shall (e used together 'ith any amendments%

PDO Stan-ar-*

Technical Authorities System

&on3!estructi"e Examination )Amendments,Supplements to ASME Section V*

@uideline or @ranting Technical Authority System

Speciication or >uality Assurance o !esign$ Construction and Engineering

8or:s

/ealth$ Saety and En"ironmental Manual

ER!300304

ER!302304

@U3424

SP3--2-

/SE Manual

,mer'can Stan-ar-*

ASME 7oiler and Pressure Vessel Code$ 3 Section V$ &on3!estructi"e

Examination$ -55; Edition including -555 Addenda

&on3!estructi"e Examination$ Recommended Practice or &on3!estructi"e

Examination Personnel >ualiication and Certiication

ASME V

AS&T S&T3TC3-A

0r't'*4 an- European Stan-ar-*

Speciication or acceptance le"els or internal imperections in steel plate$ strip and

'ide lats$ (ased on ultrasonic testing

&on3destructi"e Testing D 9mage >uality o Radiographs D Part -+ 9mage >uality

9ndicators )8ire Type* D !etermination o 9mage >uality Value

&on3destructi"e Testing D 9ndustrial Radiographic 9lluminators D Minimum

Requirements )9S# 11;0+ -5;1*

7S 1556

E& E643-

E& 411;0

Internat'onal Stan-ar-*

&on3!estructi"e Testing 3 >ualiication and Certiication o Personnel 9S# 52-4

July 2000 Page 17 SP- 1176

Non-Destructive Examination Version 1.0

>ser Coent For

U*er Comment &orm

9 you ind something that is incorrect$ am(iguous or could (e (etter in this document$ 'rite your comments

and suggestions on this orm% Send the orm to the !ocument Control Section )!CS*% They ma:e a record o

your comment and send the orm to the correct C.!/% The orm has spaces or your personal details% This

lets !CS or the C.!/ as: you a(out your comments and tell you a(out the decision%

Proce-ure Deta'l* Title+ 9ssue !ate+

&um(er+

Page &um(er+ /eading &um(er+ .igure &um(er+

Comment*:

Su((e*t'on*:

U*erC* per*onal -eta'l*

&ame+ Re%

9nd%+

Signature+ !ate+

Phone+

Document Control Sect'on ,ct'on*

Comment

&um(er+

!ate+ C.!/

Re% 9nd%+

Recd%+ To C.!/+

C&D? ,ct'on*

Recd%

!ate+

Dec'*'on:

Re<ect+

Accept$ re"ise at next issue+

Accept$ issue temporary amendment

9nits%+ Re%

9nd%+

!ate+

Comments+

#riginator

Ad"ised+

!ate+ 9nits%+ !ocument

Control

Section

Ad"ised+

!ate+ 9nits%+

July 2000 Page 1# SP-1176

You might also like

- QA/QC Guidelines Objectives & ScopeDocument20 pagesQA/QC Guidelines Objectives & ScopeFurqanam196100% (2)

- Water Chilled Centrifugal UnitsDocument40 pagesWater Chilled Centrifugal UnitskdpmansiNo ratings yet

- DCVG Surveys Training Manual - GX Version PDFDocument73 pagesDCVG Surveys Training Manual - GX Version PDFlaz_kNo ratings yet

- PR 1051Document28 pagesPR 1051Arsalan AhmadNo ratings yet

- Thin-Walled Pressure Vessel TheoryDocument9 pagesThin-Walled Pressure Vessel Theoryondoy4925No ratings yet

- Itp PipingDocument15 pagesItp PipingEkhy Transmisi100% (1)

- Blyton Enid Noddy 5 Well Done Noddy! 1952Document71 pagesBlyton Enid Noddy 5 Well Done Noddy! 1952carlosathinopolos75% (12)

- SP-1246 Part 1 Technical RequirementsDocument27 pagesSP-1246 Part 1 Technical RequirementsBurning TrainNo ratings yet

- SP-1174 - 2004 EditionDocument47 pagesSP-1174 - 2004 EditionSatish Kulkarni100% (2)

- Saddle Design at Operating ConditionDocument17 pagesSaddle Design at Operating ConditionGanesh Bhardwaj100% (2)

- Impact TestingDocument27 pagesImpact Testingapi-3764139100% (2)

- 15156-2-2003 (BS en Iso)Document50 pages15156-2-2003 (BS en Iso)mayav1No ratings yet

- Pre Commiss. Check List Chilled Water PumpsDocument3 pagesPre Commiss. Check List Chilled Water PumpsARUL SANKARAN100% (1)

- Paint DefectsDocument129 pagesPaint Defectsmohammad100% (6)

- 22 Equipment Unloading, Storing, Installation and ErectionDocument8 pages22 Equipment Unloading, Storing, Installation and ErectionAkhilesh KumarNo ratings yet

- MARRI EDUCATIONAL SOCIETY’S GROUP OF INSTITUTIONSDocument17 pagesMARRI EDUCATIONAL SOCIETY’S GROUP OF INSTITUTIONSNatarajan SaravananNo ratings yet

- ASME Code General ReviewDocument33 pagesASME Code General Reviewaike_5No ratings yet

- Surface Preaparation and Painting SpecificiationDocument21 pagesSurface Preaparation and Painting Specificiationvishnu300022No ratings yet

- Nasa STD 5005dDocument76 pagesNasa STD 5005dvominhthaiNo ratings yet

- Petroleum Development Oman L.L.C.Document20 pagesPetroleum Development Oman L.L.C.Mano100% (1)

- Fatigue Crack Tolerance Design For Stainless Steel by Crack Growth Analysis-Grupo 3Document36 pagesFatigue Crack Tolerance Design For Stainless Steel by Crack Growth Analysis-Grupo 3sebastianNo ratings yet

- SP-2092 - GRP Specification Qualification and ManufacturingDocument47 pagesSP-2092 - GRP Specification Qualification and Manufacturingchandana kumar100% (2)

- Aviation Maintenance Technician Handbook—Powerplant (2024): FAA-H-8083-32BFrom EverandAviation Maintenance Technician Handbook—Powerplant (2024): FAA-H-8083-32BNo ratings yet

- Factory Acceptance Test & Inspection Test Report Pneumatic Ball Valve KSB Document No: PMT-INS-FIPBV-001 Rev: DDocument6 pagesFactory Acceptance Test & Inspection Test Report Pneumatic Ball Valve KSB Document No: PMT-INS-FIPBV-001 Rev: Dbayu dewantoNo ratings yet

- S.O.P For Hydro-Test: Ipcl-Gandhar Complex WI/GC-C&I/6.3/001 GC Maintenance Manual Hydro Test OF5Document7 pagesS.O.P For Hydro-Test: Ipcl-Gandhar Complex WI/GC-C&I/6.3/001 GC Maintenance Manual Hydro Test OF5கோகுல் இராNo ratings yet

- NDT MatrixDocument2 pagesNDT MatrixPanagiotis Chatzakos100% (1)

- GEE ElectrodeDocument17 pagesGEE ElectrodeSatyamEngNo ratings yet

- Flange Joint Box-UpDocument1 pageFlange Joint Box-UpJR MohanNo ratings yet

- Fundamentals of Professional WeldingDocument213 pagesFundamentals of Professional Weldingapi-3856939No ratings yet

- 04 Issued For Company Review RKS AKA MTA 04 Approved For Use RKS AKA MTA 04 Approved For Use RKS AKA MTADocument4 pages04 Issued For Company Review RKS AKA MTA 04 Approved For Use RKS AKA MTA 04 Approved For Use RKS AKA MTAjay2kay5793No ratings yet

- Flange Management Procedure FixDocument13 pagesFlange Management Procedure FixNaza Gavaputri100% (1)

- Operation Manual Blow Moulding Full UpdatedDocument111 pagesOperation Manual Blow Moulding Full UpdatedRiyoko Fillex100% (5)

- What Is Design Interpretation?Document17 pagesWhat Is Design Interpretation?Qaisir MehmoodNo ratings yet

- Coating Faults AADocument82 pagesCoating Faults AAAbrianto Akuan100% (5)

- BSB Rupture Disk With Safety Relief ValvesDocument8 pagesBSB Rupture Disk With Safety Relief ValvesChitikala RajeshNo ratings yet

- W P Ss 004Document12 pagesW P Ss 004BETLAHORENo ratings yet

- A4-Jgs1ep-Epc1-Qp-016 Rev. B (Flange Management Procedure)Document20 pagesA4-Jgs1ep-Epc1-Qp-016 Rev. B (Flange Management Procedure)Darrel Espino Aranas100% (1)

- PR-1272 Standard Welding PQRs For On-Plot PipingDocument10 pagesPR-1272 Standard Welding PQRs For On-Plot Pipinghappale2002No ratings yet

- 510 Exam Preparation Study MaterialDocument213 pages510 Exam Preparation Study MaterialMohammed Abdul Sayeed100% (6)

- User Manual of CIPDocument81 pagesUser Manual of CIPMuhammad Arslaan100% (1)

- Function Test Procedure1Document6 pagesFunction Test Procedure1armin heidari100% (1)

- Specification 401 Rev 1129803527. 2 Unfired Pressure VesselDocument8 pagesSpecification 401 Rev 1129803527. 2 Unfired Pressure VesselariessuperNo ratings yet

- 00 Saip 74 - CuiDocument8 pages00 Saip 74 - CuiAbdelrahman HosnyNo ratings yet

- ESAB Puls Mig Welding Hand BookDocument20 pagesESAB Puls Mig Welding Hand BookLeonardo De La HudiNo ratings yet

- Aise TR9 91Document123 pagesAise TR9 91Juan Carlos Lasdica100% (3)

- Approved Coating Systems for Oil and Gas FacilitiesDocument23 pagesApproved Coating Systems for Oil and Gas FacilitiesMohammad Aamir Perwaiz100% (1)

- Coating Failure Presentation 01 PDFDocument32 pagesCoating Failure Presentation 01 PDFravi00098No ratings yet

- Valves and PipingDocument118 pagesValves and PipingMahdi Daly100% (1)

- Procedure For Test Header CertificationDocument16 pagesProcedure For Test Header CertificationAdeoye OgunlamiNo ratings yet

- A.3.10 JP152-300-DQP-05.81-90014-02 Gross Leak TestingDocument7 pagesA.3.10 JP152-300-DQP-05.81-90014-02 Gross Leak TestingJabel Oil Services Technical DPT100% (1)

- AdweaDocument12 pagesAdweaUnni Cyriac100% (1)

- City Gas Distribution PDFDocument80 pagesCity Gas Distribution PDFMoga Jagdish100% (1)

- SP 1246part 4 2003 Pdo Painting SpecDocument38 pagesSP 1246part 4 2003 Pdo Painting SpecMuthu KumaranNo ratings yet

- Mounded Storage of LPG With A Floating FoundationDocument112 pagesMounded Storage of LPG With A Floating FoundationMarco Dos Santos NevesNo ratings yet

- 20 Welding RevisedDocument104 pages20 Welding Revisedravi00098No ratings yet

- 20 Welding RevisedDocument104 pages20 Welding Revisedravi00098No ratings yet

- Standard Codes Followed in LPG IndustriesDocument41 pagesStandard Codes Followed in LPG Industriesaarunsnair100% (2)

- Reference (Woodside - Standards)Document23 pagesReference (Woodside - Standards)shankarmech04@gmail.com100% (1)

- Kou2003 PDFDocument6 pagesKou2003 PDFGe EffgenNo ratings yet

- SCP004-MS30-QA-PLN-00002 A01 - ITP Cleaning and GaugingDocument4 pagesSCP004-MS30-QA-PLN-00002 A01 - ITP Cleaning and GaugingAbdulkadir Berk MalkoçNo ratings yet

- Intermediate Well Control Equipment Inspection Criteria: Equipment Group: Choke Line Coflexip Type HoseDocument2 pagesIntermediate Well Control Equipment Inspection Criteria: Equipment Group: Choke Line Coflexip Type HoseKaleem UllahNo ratings yet

- Chapter 5 - Conclusion & RecommendationDocument4 pagesChapter 5 - Conclusion & RecommendationMohamad Shukri0% (1)

- EDG Commissioning - Activity ReportDocument3 pagesEDG Commissioning - Activity ReportmohamedNo ratings yet

- Leak TestingDocument5 pagesLeak Testingogie_0513No ratings yet

- KR Parco Ps6 Ms 0001 M.S For ConcreteDocument11 pagesKR Parco Ps6 Ms 0001 M.S For ConcretebulzaeNo ratings yet

- ITP's and ITR's A Necessary - Monster - PDFDocument5 pagesITP's and ITR's A Necessary - Monster - PDFshastri85No ratings yet

- Building Services Construction SpecififcationDocument7 pagesBuilding Services Construction SpecififcationRoshin99No ratings yet

- Form No. 102B - Solenoid ValveDocument1 pageForm No. 102B - Solenoid ValveVictor NairNo ratings yet

- SP-1108 (ESOP-01) Issue of PDO Electrical Safety Rules andDocument2 pagesSP-1108 (ESOP-01) Issue of PDO Electrical Safety Rules andaslam.ambNo ratings yet

- MOS HDPE Lining General Rev.8 - 1-4-2019 DG PDFDocument13 pagesMOS HDPE Lining General Rev.8 - 1-4-2019 DG PDFahmadNo ratings yet

- Answers - Questionnaire-Bonder06-TT+LaminationDocument6 pagesAnswers - Questionnaire-Bonder06-TT+Laminationchandana kumarNo ratings yet

- GE Oil & Gas Supplier Quality RequirementsDocument40 pagesGE Oil & Gas Supplier Quality RequirementsMohamed Bin IerousNo ratings yet

- Welding Specification UpdatesDocument13 pagesWelding Specification UpdatesRaja GanesanNo ratings yet

- Sea Water Cooling Project Phase II Visual Inspection ReportDocument1 pageSea Water Cooling Project Phase II Visual Inspection ReportjahaanNo ratings yet

- Aa - Req - 000131 - Quality Requirements Third Party Design VerificationDocument11 pagesAa - Req - 000131 - Quality Requirements Third Party Design Verificationjonodo89No ratings yet

- Hoist Monorail Pre Commissioning ITPDocument7 pagesHoist Monorail Pre Commissioning ITPmetroroadNo ratings yet

- TET-DG-5001 - Basic Design Criteria v1.1Document190 pagesTET-DG-5001 - Basic Design Criteria v1.1Gajendra HoleNo ratings yet

- ONGC Effluent Plant Pipe Installation GuideDocument14 pagesONGC Effluent Plant Pipe Installation GuideNithin Mathai100% (1)

- Effect of Welding Parameters on PE Weld QualityDocument22 pagesEffect of Welding Parameters on PE Weld Qualityvipul anandNo ratings yet

- Abacus FoundationsDocument9 pagesAbacus FoundationsNath GunasekeraNo ratings yet

- Hydro Testing Procedure - ZVV-JASH-R0Document5 pagesHydro Testing Procedure - ZVV-JASH-R0manojNo ratings yet

- Material Approval: Sub Contractor Submission Date Name of Material Sample Supplier Specification DetailsDocument1 pageMaterial Approval: Sub Contractor Submission Date Name of Material Sample Supplier Specification DetailsM Helmi Yunan PanggabeanNo ratings yet

- Iraq Gates Contracting Company: Kaz 12.2 Rehabilitation ProjectDocument8 pagesIraq Gates Contracting Company: Kaz 12.2 Rehabilitation ProjectAhmedNo ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument14 pagesNational Oil Corporation: Rev Date Description Checked ApprovedRochdi SahliNo ratings yet

- ASME B31.3 Process Piping: 13. Inspection, Examination & TestingDocument37 pagesASME B31.3 Process Piping: 13. Inspection, Examination & TestingMohamed Al-OdatNo ratings yet

- Railway Welding InspectionDocument16 pagesRailway Welding InspectionQuality MSIPLNo ratings yet

- ASME BOILER & PRESSURE VESSEL ACCREDITATION GUIDE FOR REVIEW TEAMSDocument11 pagesASME BOILER & PRESSURE VESSEL ACCREDITATION GUIDE FOR REVIEW TEAMSPramod AthiyarathuNo ratings yet

- Cswip Plant Inspector Competence/Experience Log: Level 2 PrequalificationDocument16 pagesCswip Plant Inspector Competence/Experience Log: Level 2 PrequalificationSigit BintanNo ratings yet

- NDT ProceduresDocument7 pagesNDT ProceduresDavid DaemmejNo ratings yet

- Barbara Delinsky-The Wedding Night PDFDocument217 pagesBarbara Delinsky-The Wedding Night PDFravi00098No ratings yet

- Stainless Pocket GuideDocument36 pagesStainless Pocket GuidePukhraj DagaNo ratings yet

- Hotel Sales Strategies To Effectively Increase RevenueDocument38 pagesHotel Sales Strategies To Effectively Increase Revenueravi00098No ratings yet

- Con AirDocument156 pagesCon Airravi00098No ratings yet

- Practices PipeDocument4 pagesPractices PipeParag Naik100% (2)

- NDT Radio Graphy Notes PDFDocument18 pagesNDT Radio Graphy Notes PDFravi00098No ratings yet

- 009 The Great Airport MysteryDocument67 pages009 The Great Airport Mysteryomar omarNo ratings yet

- RadioGraph Book 1Document33 pagesRadioGraph Book 1Vicky SinghNo ratings yet

- Welding of Duplex SSDocument20 pagesWelding of Duplex SSHermansyah PutraNo ratings yet

- PaintCure PDFDocument8 pagesPaintCure PDFmahendraNo ratings yet

- Welding Reference To Sec-IXDocument22 pagesWelding Reference To Sec-IXVijayananda AnandaNo ratings yet

- An Introduction To RadiographyDocument52 pagesAn Introduction To RadiographyAmit PalaliyaNo ratings yet

- W Section 2 Tig Welding Saf Fro General Catalogue3005009245853932523Document18 pagesW Section 2 Tig Welding Saf Fro General Catalogue3005009245853932523ravi00098No ratings yet

- Weld Chart 1Document4 pagesWeld Chart 1ravi00098No ratings yet

- Measure Optical Density of X-Ray FilmsDocument2 pagesMeasure Optical Density of X-Ray FilmsthisisghostactualNo ratings yet

- Schubert PDFDocument66 pagesSchubert PDFdattu33No ratings yet

- Elcometer 456 User Manual PDFDocument76 pagesElcometer 456 User Manual PDFchaparal100% (1)

- Husain Al Muslim Saudi Aramco PDFDocument34 pagesHusain Al Muslim Saudi Aramco PDFravi00098No ratings yet

- Welding Power SourcesDocument6 pagesWelding Power SourcesM.IBRAHEEMNo ratings yet

- AVIS-FFS Approach & MethodologyDocument7 pagesAVIS-FFS Approach & MethodologymksharmaNo ratings yet

- Che f412 Midsem Test PedDocument2 pagesChe f412 Midsem Test PedPratik ChavanNo ratings yet

- Pressure Vessel Formulas Thin Thick WallsDocument4 pagesPressure Vessel Formulas Thin Thick Wallstunglq0411No ratings yet

- Basics of Pressure Vessel FabricationDocument50 pagesBasics of Pressure Vessel Fabricationavik100% (1)

- 02 - UNIT-II - Part I PDFDocument72 pages02 - UNIT-II - Part I PDFsrajan gupta100% (1)

- Astm D 942 PDFDocument5 pagesAstm D 942 PDFChandra ManiNo ratings yet

- SM 001 SRV SpecDocument5 pagesSM 001 SRV Specvardan_vardanNo ratings yet

- Design of Vertical Pressure Vessel Using ASME Codes: September 2018Document13 pagesDesign of Vertical Pressure Vessel Using ASME Codes: September 2018liftline engineersNo ratings yet

- Design Fatigue AssessmentDocument15 pagesDesign Fatigue AssessmentIdris SiddiquiNo ratings yet

- Design Calculation of Nozzle Junction Based On ASME Pressure Vessel Design CodeDocument7 pagesDesign Calculation of Nozzle Junction Based On ASME Pressure Vessel Design CodebiniamNo ratings yet

- Asme Pressure Vessel Joint EfficiencyDocument4 pagesAsme Pressure Vessel Joint EfficiencynasrpkNo ratings yet