Professional Documents

Culture Documents

14 - Bergmann - HV TR PDF

Uploaded by

bcqbaoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

14 - Bergmann - HV TR PDF

Uploaded by

bcqbaoCopyright:

Available Formats

HIGH VOLTAGE TESTING ON

TRANSFORMERS

CEPED 2013, Bali, Indonesia

Dr. Ralf Bergmann

HIGHVOLT Prftechnik Dresden GmbH

Table of contents

Motivation and Standards

Factory Testing Latest Technology

On-Site Testing Same principle

Summary

2013-10-31 2 High Voltage Testing on Trandformers

MOTIVATION AND

STANDARDS

2013-10-31 3 High Voltage Testing on Trandformers

10/31/2013 4 High Voltage Testing on Trandformers

Motivation

Early recognition of:

Design issues

Production failures

Insulation degradation

2013-10-31 5 High Voltage Testing on Trandformers

Motivation

Transformer - Key component in electric energy system

Securing Transformers quality essential for reliability of electric

network

Extensive testing within development and testing of transformers

Routine test

Type test

Increase of old transformers in power grid

Need to verify old transformers condition

10/31/2013 6 High Voltage Testing on Trandformers

STANDARDS FOR FACTORY TESTING

Standards

Standards IEC

IEC 60076-13

Standards IEEE

IEEE C57.12.00 - C57.12.90

IEEE C57.152 (=old IEEE 62)

GOST

GOST 1526, GOST 3484, GOST 52719-2007

On-Site Testing: No separate standards.

use of same testing procedures,

possible test voltage reduction for service aged

transformers

2013-10-31 7 High Voltage Testing on Trandformers

Possible Test`s on power transformers

Measurements of winding resistance

Measurement of no-load loss and current

Dielectric tests

Temperature-rise test

Determination of sound levels

Measurement of the harmonics

of the no-load current

Measurement of insulation resistance

Measurement of turn ratio

Determination of capacitances

Tests on on-load

tap-changers

FACTORY TESTING -

LATEST TECHNOLOGY

2013-10-31 8 High Voltage Testing on Trandformers

IMPULSE VOLTAGE TEST OF

POWER TRANSFORMER

ACCORDING TO

IEC 60076-3, POS. 13-15

IEC 60060-1 2010

2013-10-31 9 High Voltage Testing on Trandformers Modern solutions of power transformer testing

10 High Voltage Testing on Trandformers

Sample of lightning impulses

Tail time

Front time

2013-10-31 Modern solutions of power transformer testing

0,9

0,3

1,0

U

B

A

0,7a

t

T

1

T

C

a

D

C

0,1a

a instant of chopping

Full lightning impulse Chopped lightning impulse

11 High Voltage Testing on Trandformers

Accuracy is important:

Correctness of wave shape

Space is expensive:

Space saving solution

Time is money:

Quick test setup increasing

output of factory

Requirements on impulse

voltage test

2013-10-31 Modern solutions of power transformer testing

Connection Point The all in one solution

Test system consists of only two

individual components:

1) Impulse generator

2) Connection Point

HV divider

Chopping gap and

Overshoot compensation

Benefits of Connection Point:

Space saving solution

Integrated overshoot compensation

Only one connection to the test object

Only one test setup is used

High Voltage Testing on Trandformers 12 2013-10-31 Modern solutions of power transformer testing

Space reduction using Connection Point

2013-10-31 High Voltage Testing on Trandformers 13

Arrangement with Connection Point Arrangement with divider, overshoot

compensation and chopping gap

MOST COMMON LAYOUT

LAYOUT USING CONNECTION POINT

Example: Test system U

LI

=1800 kV U

SI

=1150kV

Space required = 400 m Space Required = 300 m

25% space reduction

Test object

Di vi der

Chopping

gap

Overshoot

Compensat

ion

Impulse

generator

Test object

Connecti on

poi nt

Impulse

generator

FACTORY TESTING -

APPLIED VOLTAGE TESTING

2013-10-31 14 High Voltage Testing on Trandformers

Applied Voltage Test IEC 60076-3, pos. 11

15

Transformer based AC test system

- continuously duty cycle, high feeding power

- high test system costs

Resonant test system with variable inductance

- perfect sine wave, proven/robust technology

- less feeding power, less costs

Resonant test system with variable frequency

- perfect sine wave, proven/robust technology

- small components, lowest feeding power, best price

2013-10-31 High Voltage Testing on Trandformers

Applied voltage test or separate source AC withstand voltage

test can be performed with 3 different type of test systems

16 High Voltage Testing on Trandformers

Example of Applied Voltage Test for 1200 kV

2013-10-31 Modern solutions of power transformer testing

Test of transformer for 800 kV HVDC transmission

at Siemens Nuremberg, Germany

2013-10-31 17 High Voltage Testing on Trandformers

ADVANTAGES

Compact

Easy extendable

Low power consumption

Operates according to

IEC >80% of rated voltage

Lower Investment cost

Applied Voltage Test

Variable Frequency Test System

Test system at Siemens Dresden, Germany

System Concept for Applied

Voltage Test

2013-10-31 18 High Voltage Testing on Trandformers

1 Control and feeding unit

2 Exciter transformer

3 HV reactor

4 Blocking impedance

5 Voltage divider

3

5

4

400V

50 kVA

50/60Hz

LV HV

Transformer

to be tested

FACTORY TESTING -

INDUCED AC VOLTAGE TESTING

2013-10-31 19 High Voltage Testing on Trandformers

2013-10-31 20 High Voltage Testing on Trandformers

Generation of test frequency

Solutions for Induced Voltage test

Since the test voltage Up for the induced voltage test is often higher than twice the rated

voltage, the test frequency must be at least doubled to avoid over-excitation of the iron

core.

Motor / Generator Set Static Frequency Converter

10/31/2013 21 High Voltage Testing on Trandformers

Induced AC Testing

based on Static Frequency Converter

Different frequencies for loss measurement and induced voltage

testing provided by static frequency converter

replacing several different motor-generator-sets

Fulfill all demands of standards

Efficient

Allows testing of transformers >1000 MVA

Expandable

Space-Saving

Easy to operate, intrinsically safe

ADVANTAGES

2013-10-31 22 High Voltage Testing on Trandformers

Induced AC Testing

based on Static Frequency Converter

Block diagram of transformer test system

Induced AC Testing

based on Static Frequency Converter

2013-10-31 High Voltage Testing on Trandformers 23

Transformer test system for induced voltage tests, based on static frequency converter, type WV 2000-4000/170

Static frequency

converter build in

container Cooling system Step-up transformer High voltage filter

Induced AC Testing

based on Static Frequency Converter

2013-10-31 High Voltage Testing on Trandformers Page 24

Static Frequency Converter

built in Container

2013-10-31 25 High Voltage Testing on Trandformers

THD Value < 5%

Test voltage and current waveform no-load loss measurement with THDu <3.5% and THDi =52% (150 MVA transformer)

26

Sensitive PD Measurement

High Voltage Testing on Trandformers 2013-10-31

PD Level <10 pC according to IEC 60270

ON-SITE TESTING

SAME PRINCIPLE

2013-10-31 27 High Voltage Testing on Trandformers

2013-10-31 28 High Voltage Testing on Trandformers

NO STANDARDS FOR ON-SITE TESTING

HIGHVOLT on-site test systems allow tests appropriate to standards

of factory testing

On-Site Tests:

Applied Voltage Test

Induced AC Voltage Tests

Optional: Impulse Testing

HV On-Site Testing

ON-SITE TESTING

APPLIED VOLTAGE TEST

2013-10-31 29 High Voltage Testing on Trandformers

Wide load range of power transformers 5 to 40 nF

Variable test frequency 40 to 200 Hz

Voltage 360 kV Expandable to 720 kV

Electric current 5 A

2013-10-31 30 High Voltage Testing on Trandformers

Test System for Applied Voltage Test

Resonant system with variable frequency

Standard 40 foot trailer

High Voltage Testing on Trandformers 31

Applied Voltage

Procedure and Test sequence

2013-10-31

Transportation to site

Test arrangement and connection of test object (approx. 50 min)

Start system and enter test parameters (approx. 10 min)

Start automatic test sequence

Automatic search of test frequency at 10% of U

test

(frequency shall be not less than 80% of rated frequency per IEC)

Increase the voltage up to U

test

Withstand voltage test

Decrease the voltage up to 0 V

Finish test and print test report (HIGHVOLT Suite

)

32

Summary Applied Voltage Test

Dielectric test of the main insulation

(between winding and iron core/ tank; between the winding systems)

Test voltage up to 360 kV

with additional reactor up to 720 kV

Required power supply:

400 Volt (3~), 40 kVA

Only one HV lead to connect

the transformer under test

High Voltage Testing on Trandformers 2013-10-31

ON-SITE TESTING

INDUCED AC VOLTAGE TEST

2013-10-31 33 High Voltage Testing on Trandformers

Setup for Induced Voltage Test

2013-10-31 34 High Voltage Testing on Trandformers

PD

1234

PLC

3 ~ 400V

/ 50~60 Hz

PD measuring

system

HV capaci ti ve compensati on uni t (Opti on)

Transformer

to be tested

1234

1. Frequency converter

2. Step-up transformer

3. HV filter 1

4. HV compensation (Option)

5. HV filter 2 (Option)

6. Loss measuring system

1 2 3

4

5

6

Space for

accessoiries

Design of Mobile Test System

Static

frequency

converter

Step-up transformer

Control room

HV filter 1

Power supply cable,

HV connection cable

2013-10-31 35 High Voltage Testing on Trandformers

CTs and VTs

Space for

accessories, HV

electrodes, etc.

HV test lead

High Voltage Testing on Trandformers 36

Induced voltage Procedure and Test

Sequence (IEC/ IEEE/customer specification)

2013-10-31

1. Transportation to site

2. Test arrangement and connection of test object (approx. 50 min)

3. Start system and enter test parameters U

test

and f

test

(approx. 10 min)

Typically: U

test

= 80% of U

test at factory

f

test

approx. 2 x f

rated

(between f

rated

and 200 Hz)

Choose frequency of test

= f

test

:

a) Factory test frequency i.e. 120 Hz,180 Hz, etc.

b) Or to minimize the power demand choose frequency to take

advantage of variable frequency to reach self compensation

4. Start automatic test sequence

5. Measure PD at test voltage levels specified

6. Finish test and print test report (HIGHVOLT Suite)

APPLICATION

Required for reactive power compensation during short-circuit tests,

load-loss tests and on-load tap-changer tests

SOLUTION

Capacitor bank on one trailer or in one 40-foot container

for single phase and small three phase types

Capacitor bank on 2 trailers in four 20-foot containers for larger

three phase types (3 containers for capacitors, 1 for measuring

transducers)

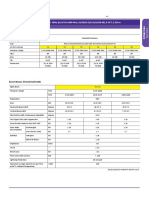

Standard types:

- up to 250 MVA test objects: 36 kV / 24 MVA, HVCC 24000/36

- up to 500 MVA test objects: 36 kV / 54 MVA, HVCC 54000/36

Capacitor Banks for Mobile Transformer Test

Systems

Principle sketch of mobile capacitor bank

HVCC 24000/36

power measurement:

current transformer / voltage transformer

CT1CT3: phase current measurement

CT4: protection against unsymmetrical currents

Compensation units can be connected to form a 3-phase

or a powerful single phase capacitor bank

HV capacitive

compensation units

40 ft trailer

cable drums

All transformers

up to highest

ratings can be

tested on site

Higher power by

mobile capacitive

compensation

banks is

available

Mobile capacitor bank HVCC 24000/36

inside a 40ft container

40

Output voltage: Up to 80 kV

Output power: 1000 kVA / 620 kW

Power supply: 400 V (3~)

- 750 kVA mains supply or

- 1200 kVA diesel generator

Only 3 HV cables to connect

the transformer under test

Easy set up:

Within 1 hour ready to test

Summary Induced Voltage Test

High Voltage Testing on Trandformers 2013-10-31

EXAMPLES OF TESTED

TRANSFORMERS

2013-10-31 41 High Voltage Testing on Trandformers

42

Test of a 500 MVA Single Phase Trans-

former in a Nuclear Power Station

High Voltage Testing on Trandformers 2013-10-31

Test of 1phase main transformer with WV 620-1000/80

Power supply by mobile diesel generator

43

Parallel connection of up to 3 test systems (total: 1.9 MW/3 MVA)

Parallel Operation for Testing

up to 1200 MVA Transformers

High Voltage Testing on Trandformers 2013-10-31

Summary

Testing power transformers up to 1200 MVA

According to IEC and IEEE standards

Waveform distortion THD <5%

Partial discharge (PD) noise level <10 pC (with 2

nd

HV filter)

Free adjustable frequency 40 to 200 Hz (self compensation)

Modular design allows for future expansion

Easy and fast test set up

2013-10-31 High Voltage Testing on Trandformers 45

YOU DELIVER QUALITY

OUR EQUPIMENT PROVES IT

High Voltage Testing on Trandformers 47 2013-10-31

You might also like

- Haefely - V Type Impulse GeneratorDocument11 pagesHaefely - V Type Impulse GeneratorAno035No ratings yet

- Transformer Testing SafetyDocument8 pagesTransformer Testing SafetyAvoor KhanNo ratings yet

- High Voltage Testing of TransformerDocument18 pagesHigh Voltage Testing of TransformerDinesh mor100% (1)

- Transformer test report summaryDocument1 pageTransformer test report summaryRey-an A. MorenoNo ratings yet

- 1000 KV Power TransformerDocument4 pages1000 KV Power TransformeralpcruzNo ratings yet

- Battery Monitoring BasicsDocument52 pagesBattery Monitoring BasicsKnwn StrngrNo ratings yet

- Electrical Books: Oil Type or Oil Inmersed Power TransformerDocument6 pagesElectrical Books: Oil Type or Oil Inmersed Power TransformerHector BonillaNo ratings yet

- Insulators: Properties, Types and EfficiencyDocument18 pagesInsulators: Properties, Types and EfficiencyGurpreet UppalNo ratings yet

- Power System Analysis: Merger TestDocument8 pagesPower System Analysis: Merger TestAnonymous mNQq7ojNo ratings yet

- A Presentation ON Overhead Line Insulators Faculty: Gunjan VarshneyDocument67 pagesA Presentation ON Overhead Line Insulators Faculty: Gunjan VarshneyGunjan VarshneyNo ratings yet

- Cts and Vts TheoryDocument20 pagesCts and Vts Theorymvpradeep87No ratings yet

- Lighting Arrester - Electrical Notes & ArticlesDocument14 pagesLighting Arrester - Electrical Notes & Articlesbramhanand vermaNo ratings yet

- Arcing HornDocument2 pagesArcing HornSureshraja9977100% (1)

- TEST ELKİTABI - Manual Turquia EnsaiosDocument23 pagesTEST ELKİTABI - Manual Turquia EnsaiosruimauricioferreiraNo ratings yet

- 60 - Surge ArrestersDocument69 pages60 - Surge ArrestersJorge Baque100% (1)

- Advc Operational GuideDocument184 pagesAdvc Operational GuidegovindarulNo ratings yet

- Digital Low Resistance Ohmmeter TestingDocument36 pagesDigital Low Resistance Ohmmeter Testingdacow22100% (1)

- 1LAB000113 Test Book Intro Table Contents 2010Document16 pages1LAB000113 Test Book Intro Table Contents 2010jayaprasadviNo ratings yet

- Testing of Power TransformerDocument15 pagesTesting of Power TransformerL.n. Giri100% (1)

- Product: Complete Diagnostic SolutionsDocument8 pagesProduct: Complete Diagnostic SolutionsbhpNo ratings yet

- Bizu Teste Trafo Power Transformer Testing Brochure ENUDocument32 pagesBizu Teste Trafo Power Transformer Testing Brochure ENUdiogoufrn-1No ratings yet

- Impulse Voltage Testing of Power TransformersDocument10 pagesImpulse Voltage Testing of Power TransformerssameekNo ratings yet

- Stator Winding Fault Diagnosis in Three-PhaseDocument7 pagesStator Winding Fault Diagnosis in Three-PhaseitcmiguelNo ratings yet

- Impulse Testing of TransformersDocument20 pagesImpulse Testing of TransformersSantosh VardhanNo ratings yet

- Transformer Exciting Current TestDocument32 pagesTransformer Exciting Current TestJNo ratings yet

- Introduction to Electric Power Systems: History, Generation, Transmission, Smart GridDocument17 pagesIntroduction to Electric Power Systems: History, Generation, Transmission, Smart GridsohaibNo ratings yet

- AC Voltage ControllersDocument21 pagesAC Voltage ControllersgilmartNo ratings yet

- Power TransformersDocument37 pagesPower TransformersGanesuni HarishNo ratings yet

- Advanced Transformer ParallelingDocument6 pagesAdvanced Transformer ParallelingnicholasleeNo ratings yet

- Test On TransformerDocument13 pagesTest On TransformerGurvinder Singh Virdi100% (2)

- Upptcl Intern PDFDocument24 pagesUpptcl Intern PDFnischaljain07No ratings yet

- VT Guard Pro Protects VTs from Harmful Ferroresonance EffectsDocument4 pagesVT Guard Pro Protects VTs from Harmful Ferroresonance EffectsAdemir DzanicNo ratings yet

- Telenor BDVDocument15 pagesTelenor BDVShahid IqbalNo ratings yet

- Testing NotesDocument12 pagesTesting NotesJigar TakoliaNo ratings yet

- Transformer Oil TestDocument10 pagesTransformer Oil TestAnkit KumarNo ratings yet

- 1000 KVA Type Test From ERDA, IndiaDocument9 pages1000 KVA Type Test From ERDA, IndiasaikatNo ratings yet

- Testing and Monitoring of High Voltage Equipment InsulationDocument43 pagesTesting and Monitoring of High Voltage Equipment InsulationGOKUL GNo ratings yet

- Statcom - Meeting The Grid CodeDocument8 pagesStatcom - Meeting The Grid CodeVinod DhanushNo ratings yet

- Cable Installation Manual For Power and Control CablesDocument102 pagesCable Installation Manual For Power and Control CablesWashington VásquezNo ratings yet

- Protect Electrical Equipment from Over VoltagesDocument16 pagesProtect Electrical Equipment from Over VoltagesSweqZNo ratings yet

- Transformer Tech TestingDocument60 pagesTransformer Tech TestingCiel Aire100% (1)

- Insulation Resistance of Power TransformerDocument16 pagesInsulation Resistance of Power TransformerMELVIN100% (3)

- DGA Ebook WebDocument16 pagesDGA Ebook Webjulio cesar silvaNo ratings yet

- Transformer Oil LeaksDocument2 pagesTransformer Oil Leaksoreinoso2009No ratings yet

- Validating Surge TestDocument9 pagesValidating Surge Testquality10No ratings yet

- Power Transformer Testing and Commissioning PDFDocument6 pagesPower Transformer Testing and Commissioning PDFEric Stanton100% (1)

- Tapcon 260 procedure guideDocument18 pagesTapcon 260 procedure guideMuhammad NasirNo ratings yet

- REM615 Appl 756885 ENlDocument168 pagesREM615 Appl 756885 ENlwilsonpamintuNo ratings yet

- Matrix Converter - Reading NotesDocument4 pagesMatrix Converter - Reading NotesAnsar NiaziNo ratings yet

- Lightning Protection in Power SystemsDocument26 pagesLightning Protection in Power SystemsAnikaNo ratings yet

- A.C Powers and Power FactorDocument23 pagesA.C Powers and Power FactoremgNo ratings yet

- Transformer TestingDocument4 pagesTransformer TestingNarendra DuvediNo ratings yet

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsFrom EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsNo ratings yet

- VSC-FACTS-HVDC: Analysis, Modelling and Simulation in Power GridsFrom EverandVSC-FACTS-HVDC: Analysis, Modelling and Simulation in Power GridsNo ratings yet

- Transformer TestingDocument24 pagesTransformer Testingmuaz_aminu142264% (14)

- Transformer Testing GuideDocument25 pagesTransformer Testing Guideask4vinod100% (1)

- High Voltage Test of 8D-GIS With "Power VT": Answers For EnergyDocument2 pagesHigh Voltage Test of 8D-GIS With "Power VT": Answers For EnergyNina Milan JokanovicNo ratings yet

- Power Factoring Surge ArrestersDocument2 pagesPower Factoring Surge Arrestersdacow22No ratings yet

- Condition Monitoring of Instrument Transformers - POWERGRID ExperienceDocument36 pagesCondition Monitoring of Instrument Transformers - POWERGRID ExperiencebcqbaoNo ratings yet

- Application Note: Determining Harmonic DirectionDocument5 pagesApplication Note: Determining Harmonic DirectionAnton MatzNo ratings yet

- 2 - 14 Experiences EuroDoble MeetingsDocument22 pages2 - 14 Experiences EuroDoble Meetingsbcqbao100% (1)

- ArresterWorks Facts-001 Arrester Lead LengthDocument11 pagesArresterWorks Facts-001 Arrester Lead Lengthnshj196No ratings yet

- Monitor Lightning Arresters OnlineDocument5 pagesMonitor Lightning Arresters OnlineJoshi DhvanitNo ratings yet

- Zero Lead Length Configuration PDFDocument2 pagesZero Lead Length Configuration PDFfourwheelerNo ratings yet

- Arrester Disconnector PDFDocument7 pagesArrester Disconnector PDFipraoNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Testing of High Voltage CablesDocument7 pagesTesting of High Voltage CablesYogi Rungi100% (2)

- DOE Diagnostic Testing of Underground Cable Systems CDFI - Phase - 1 - Final-ReportDocument323 pagesDOE Diagnostic Testing of Underground Cable Systems CDFI - Phase - 1 - Final-ReportGustavo AguayoNo ratings yet

- IEEE Guide For Fault Locating Techniques On Shielded Power Cable SystemsDocument37 pagesIEEE Guide For Fault Locating Techniques On Shielded Power Cable SystemsbcqbaoNo ratings yet

- Test Voltages For CablesDocument3 pagesTest Voltages For CablesMahmoud EidNo ratings yet

- Test Procedure of Surge ArresterDocument6 pagesTest Procedure of Surge Arrestersmi1989100% (3)

- Test Voltages For CablesDocument3 pagesTest Voltages For CablesMahmoud EidNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Oil Revised)Document78 pagesOil Revised)shhansikaNo ratings yet

- SF6 Technical PaperDocument2 pagesSF6 Technical PaperbcqbaoNo ratings yet

- Diagnostic AG en US1Document5 pagesDiagnostic AG en US1bcqbaoNo ratings yet

- Above1kV UG en V04Document36 pagesAbove1kV UG en V04Amal MohanNo ratings yet

- Efficient Method To Accelerate Resistance Measurement of Transformer LV WindingDocument8 pagesEfficient Method To Accelerate Resistance Measurement of Transformer LV WindingbcqbaoNo ratings yet

- Be On Guard For Effective Testing: 5 KV and 10 K Insulation TestingDocument8 pagesBe On Guard For Effective Testing: 5 KV and 10 K Insulation TestingKarthikNo ratings yet

- IM-1 Doble Case Studies LewandDocument21 pagesIM-1 Doble Case Studies LewandbcqbaoNo ratings yet

- Diagnostic AG en US1Document5 pagesDiagnostic AG en US1bcqbaoNo ratings yet

- 5kV DiagnosticTestingDocument41 pages5kV DiagnosticTestingkl_tsoNo ratings yet

- Mineral Insulating OilDocument96 pagesMineral Insulating OilnbhawyaNo ratings yet

- Guide To Low Resistance Booklet-CROPICODocument39 pagesGuide To Low Resistance Booklet-CROPICObcqbaoNo ratings yet

- Western Mining Electric Association Presentation on Transformer Testing and Maintenance ServicesDocument51 pagesWestern Mining Electric Association Presentation on Transformer Testing and Maintenance ServicesPrabhu Koppal100% (1)

- IM-1 Doble Case Studies LewandDocument21 pagesIM-1 Doble Case Studies LewandbcqbaoNo ratings yet

- Techtopics No. 125Document2 pagesTechtopics No. 125paijo klimpritNo ratings yet

- Toshiba Tecra A11 FHNSY1 A5A002688010 PDFDocument131 pagesToshiba Tecra A11 FHNSY1 A5A002688010 PDFvinuNo ratings yet

- MECH3660 5660 Quiz 1 Automation Solution 2014Document5 pagesMECH3660 5660 Quiz 1 Automation Solution 2014Margaret AustenNo ratings yet

- PowerElectronics Class6Document26 pagesPowerElectronics Class6Keyur PatelNo ratings yet

- Flight Radar 24 Instruction SetDocument7 pagesFlight Radar 24 Instruction SetRafael CamposNo ratings yet

- Wireless LAN Calculator GuideDocument5 pagesWireless LAN Calculator Guidejavierdb2012No ratings yet

- CCPilot XL - Technical Manual - For CCpilot XL 3.0Document31 pagesCCPilot XL - Technical Manual - For CCpilot XL 3.0Sme SacNo ratings yet

- Mainboard Msi - 7024 - 1.4Document26 pagesMainboard Msi - 7024 - 1.4Ho Thanh BinhNo ratings yet

- Intelligent-Lab™ Milligram Balance: SeriesDocument2 pagesIntelligent-Lab™ Milligram Balance: SeriesKevin LeonardoNo ratings yet

- E-Viscous Fan Circuit Diagram20.15 - E694Document6 pagesE-Viscous Fan Circuit Diagram20.15 - E694Varun Korivi100% (1)

- Single phase 1.0 Amp bridge rectifiers DB101 THRU DB107Document2 pagesSingle phase 1.0 Amp bridge rectifiers DB101 THRU DB107Sam SureshNo ratings yet

- Power Stage Designer™: User's GuideDocument29 pagesPower Stage Designer™: User's GuideChiến TrầnNo ratings yet

- SIMPLEX6100SPECDocument4 pagesSIMPLEX6100SPECdcstrohbuschNo ratings yet

- Antenna Spec SheetDocument4 pagesAntenna Spec SheetBrianNo ratings yet

- Linear Circuit AnalysisDocument19 pagesLinear Circuit AnalysisMowheadAdelNo ratings yet

- N310 Manual (En) V01Document111 pagesN310 Manual (En) V01Jayesh Gohil100% (1)

- Mxcat 3Document49 pagesMxcat 3Mon MontejoNo ratings yet

- Simatic Net Profibus Network Manual System ManualDocument350 pagesSimatic Net Profibus Network Manual System ManualAlejandro Fernández SalasNo ratings yet

- Document Mini Project No 1.117Document8 pagesDocument Mini Project No 1.117rahmat100% (1)

- FUJITSU AMILO 1420 M Service Manual PDFDocument178 pagesFUJITSU AMILO 1420 M Service Manual PDFelprimNo ratings yet

- Ficha Tecnica UPS NETPRODocument29 pagesFicha Tecnica UPS NETPROGeovanny PiguaveNo ratings yet

- ECNG 2001 Communication Systems I (Semester II 2015/2016) Midterm (10%)Document7 pagesECNG 2001 Communication Systems I (Semester II 2015/2016) Midterm (10%)JellyJelloNo ratings yet

- Capacitance and Inductance MeasurementDocument24 pagesCapacitance and Inductance MeasurementDina GaranNo ratings yet

- 8096 MicrocontrolDocument11 pages8096 MicrocontrolSujitha Karthik Kumar100% (1)

- Huawei Dualband Co-BCCH Cell IntroductionDocument18 pagesHuawei Dualband Co-BCCH Cell IntroductionPaul Kabeya100% (2)

- Report & Discrimination SLDDocument10 pagesReport & Discrimination SLDAnonymous SOQFPWBNo ratings yet

- Vivekanandha College of Engineering For WomenDocument14 pagesVivekanandha College of Engineering For Womendhanushsri saravanakumarNo ratings yet

- MOC3021 FairchildSemiconductorDocument7 pagesMOC3021 FairchildSemiconductorRonaldReyesNo ratings yet

- Guideline For Dummies 2G - CDR Fast AnalyzeDocument12 pagesGuideline For Dummies 2G - CDR Fast AnalyzePutihPutihLompatLompat100% (1)

- IC Applications and Active Filter TransformationsDocument12 pagesIC Applications and Active Filter Transformationsmsk 31No ratings yet