Professional Documents

Culture Documents

23 - Bergmann - HV Testing On Rot Machines PDF

Uploaded by

bcqbaoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

23 - Bergmann - HV Testing On Rot Machines PDF

Uploaded by

bcqbaoCopyright:

Available Formats

HIGH VOLTAGE TESTING ON

ROTATING ELECTRICAL

MACHINES

CEPED 2013, Bali, Indonesia

Dr. Ralf Bergmann

HIGHVOLT Prftechnik Dresden GmbH

High Voltage Testing on Rotating Electrical Machines

Content:

Why spend money on HV tests?

Physical background: Machine characteristics and test

methods

Generation of continuous AC test voltages

Experience with continuous AC voltage testing

Summary

2 31/10/2013

WHY SPEND MONEY ON

ON-SITE HV TESTS

High Voltage Testing on Rotating Electrical Machines 3 31/10/2013

High Voltage Testing on Rotating Electrical Machines

Technical and Physical Point of View for

Electrical Machine Testing On-site

Manufacturing

D

a

m

a

g

e

M

i

s

t

a

k

e

T

e

s

t

i

n

g

T

e

s

t

i

n

g

D

i

a

g

n

o

s

i

s

Transportation Installation

T

e

s

t

i

n

g

Power

frequency

50/60 Hz

Operation

Power frequency

50/60 Hz

Electrical machine life

R

e

p

a

i

r

A

g

e

i

n

g

4 31/10/2013

High Voltage Testing on Rotating Electrical Machines

Necessity for Evaluation of Machine Condition

Generators are an essential part of each power plant.

Failures usually result in the generating unit going off-line during

repair, which may result in longer time periods without generation

and immense costs.

Large electric motors are usually key components of industrial or

power plants, and may be safety relevant (such as cooling water

pumps in nuclear, but also conventional power plants, for example)

Their failure may halt production, lead to losses or even accidents

Consequently an evaluation of the condition of generators and

large motors based on on-site testing is technically and

economically recommended

5 31/10/2013

High Voltage Testing on Rotating Electrical Machines

Root Causes of Generator Failures

6 31/10/2013

Mechanical 36

Bearings 3

Insulation 50

Thermal 11

Percentage of root causes of hydrogenerator failures

Hydrogenerator failures results of the survey, Study committee SC11, EG11.02 Cigre 2002

High Voltage Testing on Rotating Electrical Machines

Necessity for Evaluation of Machine Condition

7 31/10/2013

High Voltage Testing on Rotating Electrical Machines

Requirements for On-Site Testing

Test results should cover

Evaluation of the machine insulation condition and its ageing

Estimation of remaining lifetime

Finding the cause and location of problems inside the machine

Requirements for test set-up

Designed for easy and frequent transportation, assembly and

operation

Negligible ageing caused by on-site test

Load during on-site test should correspond to operational stress

Easy adoption to different test requirements as voltage, load

capacitance, dielectric losses etc.

8 31/10/2013

High Voltage Testing on Rotating Electrical Machines

Requirements for On-Site Testing

Technical point of view

System components are routine and type tested in factory

Check of transportation damages or assembling defects

Easy assembling and dismantling of the test system on-site

Lightweight, transportable and reliable

Physical point of view

Kind of testing stress operational stress AC voltage

(also recommended by IEC 60034-1 clause 9.2 for factory and on-site tests)

Acceleration of failure mechanism testing stress >operational stress

Application of diagnostic measurements, e.g. PD, C/tan

9 31/10/2013

PHYSICAL BACKGROUND:

MACHINE CHARACTERISTICS

AND TEST METHODS

High Voltage Testing on Rotating Electrical Machines 10 31/10/2013

High Voltage Testing on Rotating Electrical Machines

Tested Parameters and Test Methods used

11 31/10/2013

Tested parameter Test Method

Voltage withstand of insulation AC voltage test

1)

General ageing of insulation,

measurement of dielectric losses

Tan delta measurement during AC

voltage test

Detecting the presence of insulation

defects and their location

PD measurement during AC

voltage test

1) According IEC 60034-1 DC testing will result in different surface potential along

end winding insulation and different ageing mechanisms leading to breakdown.

In addition DC testing does not allow tan delta or sufficient PD measurement.

High Voltage Testing on Rotating Electrical Machines

Voltage withstand test

Provides information, if the machine insulation is sufficient to

withstand a certain AC voltage level

No breakdown / breakdown immediately provides a pass/fail criterion

for the test without necessity of interpretation

Type of testing stress type of operational stress

same behaviour of all types of defect during test and operation

Amount of testing stress >amount of operational stress

acceleration of failure mechanism, defects break down in minutes

that would in months during normal service

AC test voltage is basis for diagnostic measurements

12 31/10/2013

High Voltage Testing on Rotating Electrical Machines

PD measurement

Provides information about insulation defects in a stadium, when

they do not yet lead to breakdown

Requires interpretation

PD magnitude, inception and extinction voltages can be measured,

giving additional information about the severity of the problem

PD patterns and their phase resolution give information about the

type of defect and their location in the machine

The effort to find the problem is reduced, which avoids unnecessary

disassembly and shortens the time needed for further investigation

and repair

Trending can be applied to find out if and how fast problems are

increasing over time

Basis: Variable AC voltage source

13 31/10/2013

High Voltage Testing on Rotating Electrical Machines

Tan Delta measurement

Provides information about general insulation condition in a stadium,

when no breakdown occurs yet.

Requires interpretation

In combination with PD measurement, or if tan delta measurement

has been conducted before a fault it helps to determine if a machine

should be repaired or replaced

Voltage dependence (tan delta tip-up) often reveals more than the

actual tan delta value

Trending again gives valuable information about if and how fast

problems are increasing

Basis: Variable AC voltage source

14 31/10/2013

GENERATION OF

CONTINUOUS

AC TEST VOLTAGES

High Voltage Testing on Rotating Electrical Machines 15 31/10/2013

High Voltage Testing on Rotating Electrical Machines

Requirements for Test Voltage Source

Should generate AC test voltages according IEC 60034-1

Output voltage should be variable to:

Gradually increase test voltage

Measure PD inception and extinction voltage

Measure tan delta tip-up values

Should have low distortion and low PD level for sensitive

measurement

Needs to be small enough for use inside of power plants

16 31/10/2013

Technical Requirements according standards

High voltage tests on rotating machines (motor & generators)

Test Frequency range of AC source accord.

standard

Withstand voltage test 10 500 Hz

Withstand voltage test combined with

Partial discharge measurement

10 500 Hz

Power factor / tan delta measurement 45 < f < 65 Hz

Required test voltage level for AC

Withstand voltage test and Partial

Discharge Measurement

2 x U

n

+1000 V

1

Required test voltage level for Tan

Delta Measurement

1 x U

n

1

IEC 60034-1 (2004), Term: 9.2; recommended after on-site maintenance, cleaning and

drying of generators is lower, only 1,5*U

n

for withstand voltage test

U

n

rated voltage of rotating machine (ph-ph)

High Voltage Testing on Rotating Electrical Machines 17 31/10/2013

High Voltage Testing on Rotating Electrical Machines

Off-Line Voltage Test vs. On-Line Monitoring

18 31/10/2013

Feature Off-Line AC Test On-Line Monitoring

AC test voltages according IEC

60034-1

+ +

Gradual increase of test voltage

+ +

Measuring PD inception and

extinction voltage

+ +

Measuring tan delta tip-up

+ +

Low distortion and low PD level

+

Trending of PD values

+ + +

Trending of tan delta values

+ O (unusual, high effort)

Requires outage

+ +

Test equipment size

+

Different methods different tasks. One cannot replace the other.

High Voltage Testing on Rotating Electrical Machines

Technical Solutions for HV AC Test Voltage

Generation

T

R

L

C

T

H

C

H

C

L

MD

C

C

AC

ACTC

Compensated

transformer

ACRL

Resonant test system with tuned

inductance as series resonant circuit

T

R

L

H

T

E

C

H

C

L

MD

C

C

AC

T

R

T

E

L

H

C

H

C

L

MD

C

C

AC

ACRL

Resonant test system with tuned

inductance as parallel resonant circuit

FC T

E

L

H

C

H

C

L

MD

C

C

AC

ACRF

Resonant test system

with tuned frequency

AC

f

19 31/10/2013

High Voltage Testing on Rotating Electrical Machines

Parameters of Typical Test Objects

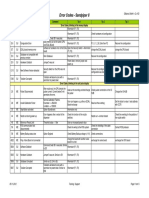

20 31/10/2013

Parameter Small turbo

generator

Large turbo

generator

Small hydro

generator

Medium hydro

generator

Rated voltage 13.8 kV 27 kV 6.3 15

Rated power 112 MVA 1300 MVA 12.5 MVA 270 MVA

Test voltage 28.6 kV 55 kV 13.6 kV 31 kV

Test

capacitance

494 nF up to 1.5 F 675 nF 1185 nF

Test current at

50 Hz

4.44 A 25.9 A 2.88 A 18.0 A

Test power at

50 Hz

127 kVA 1425 kVA 39 kVA 395 kVA

Generators of same power and voltages may differ in capacitance by

factor 3 depending on the design

number of stator bars, geometry, insulation thickness etc.

High Voltage Testing on Rotating Electrical Machines

Comparisons of different AC Test Systems

Mode of on-site test

system

ACTC

compensated transformer

ACRL

variable inductance

ACRF

variable frequency

Frequency 50 / 60 Hz 50 / 60 Hz 20 to 300 Hz

Quality factor of

resonance

(5)

40 to 60 80 to 200

(limited by tan delta of machine)

Power supply Single / two phase Single / two phase Three phases

Specific weight 15 to 20 kg/kVA 3 to 10 kg/kVA 0.5 to 2 kg/kVA

Sufficient for

Small motors and

generators

Test power 500 kVA

All motors and

generators

All motors and

generators

21 31/10/2013

EXPERIENCE WITH

CONTINUOUS

AC VOLTAGE TESTING

Particular Tests

High Voltage Testing on Rotating Electrical Machines 22 31/10/2013

High Voltage Testing on Rotating Electrical Machines

Variable Frequency Test System for Testing of

Rotating Machines Installed in a Van

Control and feeding unit

Test voltage lead

Exciting transformer

HV resonant reactor

23 31/10/2013

High Voltage Testing on Rotating Electrical Machines

Voltage range: 3050100 kV

Current range: 102550 A

Frequency: 20300 Hz

On-site Resonant Test System Based on

Variable Frequency

Application: Rotating machines

Medium voltage cables

Capacitor banks

24 31/10/2013

High Voltage Testing on Rotating Electrical Machines

Voltage range: 3050100 kV

Current range: 102550 A

Frequency: 20300 Hz

On-site Resonant Test System Based on

Variable Inductance, mounted in Container

Tests: Voltage withstand test

PD measurement

Tan delta measurement

25 31/10/2013

High Voltage Testing on Rotating Electrical Machines

Application: Test of Turbo Generator

26 31/10/2013

Generator test in

Power plant of

Ruien, Belguim

Cortesy of

Laborelec, Belgium

High Voltage Testing on Rotating Electrical Machines

Application: Test in Hydro Power Plant

27 31/10/2013

Compagnie Nationale du Rhone,

Usine de Bourg les Valence

5 x 33 MVA, 10.5 kV, installed 1968

SUMMARY

High Voltage Testing on Rotating Electrical Machines 28 31/10/2013

High Voltage Testing on Rotating Electrical Machines

Summary

On-site testing of rotating machines should be done with AC

test voltages

Same behavior of defects as under operating conditions

Variable test voltage for overvoltage tests and voltage dependent

measurements available

Separate source testing can reveal more information than on-

line monitoring, but is also more complex

Both methods complement each other and have their valid application

Resonant test systems with variable inductance or frequency

are the best solution

Easy transportability and handling

Low demand on feeding power

29 31/10/2013

TOP QUALITY:

MADE BY YOU

CERTIFIED BY HIGHVOLT

High Voltage Testing on Rotating Electrical Machines 30 31/10/2013

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Power Factoring Surge ArrestersDocument2 pagesPower Factoring Surge Arrestersdacow22No ratings yet

- Test Voltages For CablesDocument3 pagesTest Voltages For CablesMahmoud EidNo ratings yet

- Application Note: Determining Harmonic DirectionDocument5 pagesApplication Note: Determining Harmonic DirectionAnton MatzNo ratings yet

- Condition Monitoring of Instrument Transformers - POWERGRID ExperienceDocument36 pagesCondition Monitoring of Instrument Transformers - POWERGRID ExperiencebcqbaoNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- DOE Diagnostic Testing of Underground Cable Systems CDFI - Phase - 1 - Final-ReportDocument323 pagesDOE Diagnostic Testing of Underground Cable Systems CDFI - Phase - 1 - Final-ReportGustavo AguayoNo ratings yet

- ArresterWorks Facts-001 Arrester Lead LengthDocument11 pagesArresterWorks Facts-001 Arrester Lead Lengthnshj196No ratings yet

- Zero Lead Length Configuration PDFDocument2 pagesZero Lead Length Configuration PDFfourwheelerNo ratings yet

- Monitor Lightning Arresters OnlineDocument5 pagesMonitor Lightning Arresters OnlineJoshi DhvanitNo ratings yet

- Test Voltages For CablesDocument3 pagesTest Voltages For CablesMahmoud EidNo ratings yet

- Test Procedure of Surge ArresterDocument6 pagesTest Procedure of Surge Arrestersmi1989100% (3)

- Diagnostic AG en US1Document5 pagesDiagnostic AG en US1bcqbaoNo ratings yet

- Arrester Disconnector PDFDocument7 pagesArrester Disconnector PDFipraoNo ratings yet

- 2 - 14 Experiences EuroDoble MeetingsDocument22 pages2 - 14 Experiences EuroDoble Meetingsbcqbao100% (1)

- Testing of High Voltage CablesDocument7 pagesTesting of High Voltage CablesYogi Rungi100% (2)

- IEEE Guide For Fault Locating Techniques On Shielded Power Cable SystemsDocument37 pagesIEEE Guide For Fault Locating Techniques On Shielded Power Cable SystemsbcqbaoNo ratings yet

- Be On Guard For Effective Testing: 5 KV and 10 K Insulation TestingDocument8 pagesBe On Guard For Effective Testing: 5 KV and 10 K Insulation TestingKarthikNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Western Mining Electric Association Presentation on Transformer Testing and Maintenance ServicesDocument51 pagesWestern Mining Electric Association Presentation on Transformer Testing and Maintenance ServicesPrabhu Koppal100% (1)

- IM-1 Doble Case Studies LewandDocument21 pagesIM-1 Doble Case Studies LewandbcqbaoNo ratings yet

- Above1kV UG en V04Document36 pagesAbove1kV UG en V04Amal MohanNo ratings yet

- Diagnostic AG en US1Document5 pagesDiagnostic AG en US1bcqbaoNo ratings yet

- 5kV DiagnosticTestingDocument41 pages5kV DiagnosticTestingkl_tsoNo ratings yet

- Mineral Insulating OilDocument96 pagesMineral Insulating OilnbhawyaNo ratings yet

- IM-1 Doble Case Studies LewandDocument21 pagesIM-1 Doble Case Studies LewandbcqbaoNo ratings yet

- Oil Revised)Document78 pagesOil Revised)shhansikaNo ratings yet

- SF6 Technical PaperDocument2 pagesSF6 Technical PaperbcqbaoNo ratings yet

- Guide To Low Resistance Booklet-CROPICODocument39 pagesGuide To Low Resistance Booklet-CROPICObcqbaoNo ratings yet

- Efficient Method To Accelerate Resistance Measurement of Transformer LV WindingDocument8 pagesEfficient Method To Accelerate Resistance Measurement of Transformer LV WindingbcqbaoNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Structure of SolidsDocument22 pagesStructure of SolidsNicole Anne Borromeo100% (1)

- LSA47 3-Install&MaintenDocument28 pagesLSA47 3-Install&MaintenCao HieuNo ratings yet

- User Manual Ns King - SPH King: 7.5/10/12kVA (1-Phase In/Output) 7.5/10/15/20kVA (3-Phase Input/1-Phase Output)Document44 pagesUser Manual Ns King - SPH King: 7.5/10/12kVA (1-Phase In/Output) 7.5/10/15/20kVA (3-Phase Input/1-Phase Output)a.elwahabNo ratings yet

- ACME AHX Water-Cooled Condenser - 06.10 PDFDocument3 pagesACME AHX Water-Cooled Condenser - 06.10 PDFhappale2002No ratings yet

- DSM Carbon Footprint StudyDocument12 pagesDSM Carbon Footprint StudyAbdul Rahman100% (1)

- Transient Stability Improvement of Power System Using UpfcDocument18 pagesTransient Stability Improvement of Power System Using UpfcMuhammadWaqarNo ratings yet

- Notes on Heat Transfer Methods and EquationsDocument6 pagesNotes on Heat Transfer Methods and Equationsjme733k9100% (1)

- Hybrid Safety and Service Procedures: Automotive Technology, Fifth EditionDocument40 pagesHybrid Safety and Service Procedures: Automotive Technology, Fifth EditionSkyAnimal ChannelNo ratings yet

- EV Technology QPDocument3 pagesEV Technology QPvcetnaac c6No ratings yet

- Small, High Efficiency, Recuperated Ceramic Turboshaft EngineDocument1 pageSmall, High Efficiency, Recuperated Ceramic Turboshaft EngineU.S. Naval Research LaboratoryNo ratings yet

- HexaneDocument3 pagesHexaneIan RidzuanNo ratings yet

- Currents in The OceanDocument51 pagesCurrents in The OceanseabirchNo ratings yet

- WASHING-Pearl GlobalDocument8 pagesWASHING-Pearl Globalkanchanp93No ratings yet

- Catalase TestDocument2 pagesCatalase TestsekaralingamNo ratings yet

- Innovation SiemensDocument11 pagesInnovation SiemensOviri Charles Umude-IgbruNo ratings yet

- An Impedance Source Multi-Level Three Phase Inverter With Common Mode Voltage Elimination and Dead Time CompensationDocument18 pagesAn Impedance Source Multi-Level Three Phase Inverter With Common Mode Voltage Elimination and Dead Time CompensationRadu GodinaNo ratings yet

- Sennheiser Digital 9000 System Manual 2017 ENDocument126 pagesSennheiser Digital 9000 System Manual 2017 ENAnder ANo ratings yet

- Convair Traveler Vol. X 1958-59Document180 pagesConvair Traveler Vol. X 1958-59TateNo ratings yet

- Rotational Motion Engineering Mechanics IIT KanpurDocument67 pagesRotational Motion Engineering Mechanics IIT KanpurNitin SharmaNo ratings yet

- TeraWulf's Nuclear Bitcoin Plant Is Just One Piece of The Green Mining Puzzle - DecryptDocument16 pagesTeraWulf's Nuclear Bitcoin Plant Is Just One Piece of The Green Mining Puzzle - DecryptpipeNo ratings yet

- Development of Smart Solar-Powered Waste Bin Segregation Using Image ProcessingDocument7 pagesDevelopment of Smart Solar-Powered Waste Bin Segregation Using Image ProcessingBriely BrizNo ratings yet

- Lecture 3.0 Metal Cutting ProcessDocument34 pagesLecture 3.0 Metal Cutting ProcessHemant TrivediNo ratings yet

- LV Rating Factors in GroundDocument3 pagesLV Rating Factors in GroundChris MostertNo ratings yet

- Pyro-Bloc M Module Manual DD 31052016Document20 pagesPyro-Bloc M Module Manual DD 31052016thoavitNo ratings yet

- Aeroshell Ascender: Performance, Features & Benefits Main ApplicationsDocument3 pagesAeroshell Ascender: Performance, Features & Benefits Main ApplicationsRicardo LacskoNo ratings yet

- AERMOTORDocument12 pagesAERMOTORSharid PickeringNo ratings yet

- Installation: Residential/Light Commercial Generator SetsDocument64 pagesInstallation: Residential/Light Commercial Generator SetsJackNo ratings yet

- VCO Based ADCDocument3 pagesVCO Based ADCBlake PayriceNo ratings yet

- Daewoo 4603Document42 pagesDaewoo 4603David LovatoNo ratings yet

- Training Document: 120 113 304 f Gilbarco GmbH + Co. KG Error Codes - Sandpiper IIDocument5 pagesTraining Document: 120 113 304 f Gilbarco GmbH + Co. KG Error Codes - Sandpiper IICharlie ShowNo ratings yet