Professional Documents

Culture Documents

12 59 Lipolytic Enzymesarticle27

Uploaded by

Furqoni Nurul UmmahCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

12 59 Lipolytic Enzymesarticle27

Uploaded by

Furqoni Nurul UmmahCopyright:

Available Formats

Enzyme and Microbial Technology 40 (2007) 187194

Rapid communication

Stimulation of novel thermostable extracellular lipolytic

enzyme in cultures of Thermus sp.

Alberto Domnguez

a

, Pablo Fuci nos

b

, M. Luisa R ua

b

, Lorenzo Pastrana

b

,

Mara A. Longo

a

, M. Angeles Sanrom an

a,

a

Department of Chemical Engineering, University of Vigo, Lagoas-Marcosende, 36310 Vigo, Spain

b

Department of Biochemistry, Genetics and Immunology, University of Vigo, Spain

Received 29 September 2005; received in revised form 5 September 2006; accepted 12 September 2006

Abstract

Selected organisms from the genus Thermus (T. aquaticus YT1, T. thermophilus HB8 and HB27) offer new opportunities for biocatalysis and

biotransformations as a result of the extreme stability of their enzymes. In order to favour the secretion of extracellular lipolytic enzymes the effect

of temperature and carbon source has been studied. All strains were able to grow within a wide temperature range (from 60 to 80

C) with an

optimum value of 70

C for extracellular lipolytic activity.

On the other hand, several sugars were used as carbon source in the culture medium at different concentrations (from 0.5 to 14 g dm

3

).

Supplementation of monosaccharides (glucose, fructose) and disaccharides (maltose, sucrose) was carried out in an attempt to increase biomass and

lipolytic enzyme production. The inuence of carbon source was variable, depending on the strain. Nevertheless, the addition of lowconcentrations

of mono- or disaccharides helped to improve the productivity of the process in most cases. The most signicant effects on extracellular lipolytic

activity were detected in T. thermophilus HB27 and T. aquaticus YT1 cultures, using sucrose and fructose as carbon source at an initial concentration

of 0.5 g dm

3

. Moreover, the effect of addition of lipids (olive oil, coconut oil and tributyrin) was tested. In T. thermophilus HB27 cultures, the

highest extracellular lipolytic activities were obtained when olive oil was added (70% higher than those obtained in control cultures).

2006 Elsevier Inc. All rights reserved.

Keywords: Thermostable lipolytic enzymes; Carbon source; Temperature; T. thermophilus HB8; T. thermophilus HB27; T. aquaticus YT1

1. Introduction

In recent years, there has been an increasing interest in the

study of enzymes from extremophiles, since they are not only

more thermostable but often more resistant to chemical agents

and extreme pHvalues than their mesophilic homologues [13].

Lipolytic enzymes catalyze a wide number of different reac-

tions, most of them of industrial application. In spite of their

potential interest, the available information about the production

of lipolytic enzymes by thermophilic microorganisms is scarce,

and it is mainly focused on the detection of this activity in some

bacteria isolated from hot springs, as well as the stability of the

enzymes at high temperatures [4,5].

The ability of T. thermophilus (HB8 and HB27) and T. aquati-

cus YT1 to produce signicant lipolytic activity when cultivated

Corresponding author. Tel.: +34 986 812383; fax: +34 986 812380.

E-mail address: sanroman@uvigo.es (M.A. Sanrom an).

in a complex medium has been demonstrated in our laboratory.

All enzymes were stable at 80

C over 30 min and showed a

remarkable activity on fatty acid esters with acyl chains longer

than 10 carbon atoms [6]. Two proteins with lipolytic activity

were identied in intra- and extracellular extracts from the three

Thermus strains cultures by zymogramanalysis, with molecular

weights of 34 and 62 kDa [7,8]. The culture time-course in a

basal medium has been described [8] and the inuence of some

variables (i.e. gas environment) in biomass and enzyme produc-

tion has been investigated, both in Erlenmeyer asks [8] and a

stirred tank bioreactor [9].

In previous papers [69], we have shown that enzyme produc-

tion was not fully associated to growth rate, although absolute

values of total lipolytic activity and biomass were positively

correlated. However, cell growth was relatively low, and lipoly-

tic activity appeared to be largely retained within the biomass.

Therefore, it would be interesting to nd culture conditions (i.e.

medium composition, pH, temperature, aeration), allowing to

improve growth and/or favour enzyme secretion.

0141-0229/$ see front matter 2006 Elsevier Inc. All rights reserved.

doi:10.1016/j.enzmictec.2006.09.006

188 A. Domnguez et al. / Enzyme and Microbial Technology 40 (2007) 187194

In this work, optimisation of lipolytic enzyme production by

T. thermophilus HB8, HB27 and T. aquaticus YT1 has been

attempted. The inuence of incubation temperature and the

effect of the type and concentration of carbon source in the cul-

ture medium have been studied.

2. Materials and methods

2.1. Microorganisms and culture conditions

T. thermophilus HB8, HB27 and T. aquaticus YT1 were kindly provided

by Dr. J. Berenguer (Universidad Aut onoma, Madrid, Spain).

Submerged cultures were carried out in 1000 cm

3

Erlenmeyer asks

with 200 cm

3

of medium (pH 7.5), prepared in distilled water and composed

of 8 g dm

3

casein peptone, 4 g dm

3

yeast extract and 3 g dm

3

NaCl.

Throughout this study, the basal medium was consecutively supplemented with

several concentrations (0.5, 1.5, 7 and 14 g dm

3

) of carbohydrates (glucose,

fructose, maltose and sucrose). Also, some experiments were carried out in

culture media supplemented with lipids, namely olive oil, coconut oil and

tributyrin (concentrations 1 and 10 g dm

3

). Culture inoculation and sample

preparation were realised according to Fuci nos et al. [8]. Experiments were

done in duplicate and samples were analysed in triplicate. The values in the

gures correspond to mean values with a standard deviation less than 15%.

2.2. Analytical methods

2.2.1. Cell growth determination

Cell concentration was monitored spectrophotometrically at 600 nm and the

obtained values were converted to g cell dry wt dm

3

using calibration curves

previously determined.

2.2.2. Lipolytic activity assay

It was determined using p-nitrophenyl laurate (p-NPL) as substrate following

the method described in Fuci nos et al. [7]. One activity unit was dened as the

amount of enzyme that produced 1 mol of p-nitrophenol per min under standard

assay conditions. The activities were expressed in Udm

3

.

2.2.3. Protein concentration

It was determinedaccordingtoLowryet al. [10], usingbovine serumalbumin

as standard.

2.2.4. Total carbohydrates concentration

It was determined by the phenol-sulphuric method of Dubois et al. [11],

using d-glucose as standard.

3. Results and discussion

In this work, some strategies to enhance lipolytic enzyme

production by three Thermus strains have been investigated. In

a previous paper [6], the selected strains were reported to show

remarkable activity on fatty acid esters with acyl chains longer

than 10 carbon atoms, and the activity towards these substrates

appeared to increase as substrate chain-length diminished.

Therefore, the denomination lipolytic enzyme/activity has

been utilised throughout this work, since incontrovertible attri-

bution of true lipase activity would require further investigation.

Moreover, an operational classication of enzyme activities

as intra- or extracellular has been utilised. Thus, activity

detected in the culture medium after biomass separation by

centrifugation was considered as extracellular, while that recov-

ered in solution after sonication of the buffer-resuspended cells

and elimination of cell debris was considered as intracellular.

Although the occurrence of cell-bound enzyme would be

possible and is not regarded here, this categorization is based on

usual industrial practice, and it is the most interesting from the

standpoint of industrial application of the described enzymes.

3.1. Effect of temperature on growth and lipolytic activity

The three studied strains were grown in shake asks,

within a wide range of temperature (from 60 to 80

C). The

cultures were stopped after 30 h of incubation, since previous

experiments indicated that, no signicant increases in lipolytic

enzyme activity were attained later in ask cultures. Besides,

cell lysis was mostly negligible at this time. Moreover, the

authors indicated that no kinetic typication of the enzymes as

primary metabolites was possible for any of the Thermus strains,

because of the lack of a good tting of the experimental lipolytic

activity production rates to the Luedecking & Piret model

[68].

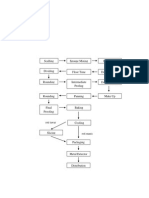

Time-course of cultures and nal biomass, intra- and

extracellular lipolytic activity are shown in Fig. 1 and Table 1,

respectively. In the three studied strains, the increase in temper-

ature seemed to have a negative effect on biomass production:

nal cell growth at 60

C was almost two-fold higher than

that at 80

C. However, this effect was more remarkable in T.

thermophilus HB8 cultures, while T. thermophilus HB27 and

T. aquaticus YT1 only showed a signicant decrease in cell

growth at temperatures above 70

C. These results are close

to those reported by Oshima and Imahori [12], who found

that the optimal growth temperature for a locally isolated T.

thermophilus strain was 70

C. When biomass production

proles (Fig. 1) are considered, it can be seen that stationary

phase is approached rather rapidly at 80

C. Similar nal

cell growth levels are attained at 60 and 70

C, although a

longer lag phase is generally observed at 60

C, as it was

foreseeable.

More signicant differences between strains were observed

for lipolytic enzyme production. Maximum intracellular

activity was very similar in all T. aquaticus YT1 cultures, with

an average value of 66 Udm

3

, and production proles were

fairly close. On the other hand, the increase in temperature had

an acute effect on T. thermophilus HB8 and HB27 intracellular

enzyme levels. Final activities of 125 and 93 Udm

3

were

obtained, respectively, operating at 80

C, about two-fold higher

than those attained at 60

C, while intermediate values were

obtained at 70

C. Although the shape of the production patterns

was somewhat similar to those of cell growth for each inde-

pendent temperature, enzyme production cannot be considered

strictly growth associated. First, the highest activity levels were

found at 80

C, which was the least favourable condition for

biomass production. Secondly, at this temperature, attainment

of maximumenzyme levels was delayed with respect to those in

cell growth. Therefore, some additional feature must be involved

in the mechanismof lipolytic enzyme production at intracellular

level.

T. thermophilus strains have been reported to produce

chaperonins, a class of proteins implicated in the folding of

other proteins. Taguchi et al. [13] recovered and puried two

A. Domnguez et al. / Enzyme and Microbial Technology 40 (2007) 187194 189

Fig. 1. Time course of cultures of Thermus strains, grown at different temperatures: () 60

C, () 70

C, and () 80

C.

intracellular chaperonins from late log phase T. thermophilus

HB8 cultures performed at 75

C, and demonstrated their ability

to promote refolding of several enzymes at high temperatures.

However, the effect of chaperonins on protein refolding is

dependent on the temperature: above 60

C spontaneous

refolding fails but if the native protein is sufciently stable, the

chaperonin induces productive refolding in an ATP-dependent

manner. At temperatures below 60

C (i.e. 50

C) spontaneous

refolding of the proteins occurs, and the chaperonin arrests this

spontaneous refolding in the absence of ATP.

It could be hypothesised that the occurrence of chaperonins

within T. thermophilus cells might contribute to the phenomena

described in this work, by favouring lipolytic enzyme folding

and therefore stability at high temperature. Since the mechanism

of chaperonin action seems to be dependent of temperature, this

could account to a certain extent for the differences observed in

intracellular lipolytic enzyme levels for T. thermophilus HB27

and HB8.

As for extracellular lipolytic activities, they were rather low

in comparison with the intracellular enzymes. In all cases, the

highest nal values were obtained when operating at 70

C. A

parabolic dependence of temperature was postulated for extra-

cellular lipolytic activity. Experimental results for nal activity

were tted to polynomic equations, and subsequently derivated

to obtain the theoretical optimum. According to this procedure,

optimal temperatures were found at 66.9, 70.6 and 70.5

C for

T. thermophilus HB8 and HB27 and T. aquaticus YT1, respec-

tively.

The lower extracellular enzyme activity at high tempera-

ture could in part be due to the secretion of specic proteases

during the last phase of the cultures. This fact was described

by Matsuzawa et al. [14] in previous studies carried out with

other Thermus strains. Also, temperature-dependent differences

in extracellular enzyme activity could be related to the occur-

rence of special enzyme secretion mechanisms in the studied

microorganisms, a hypothesis that has already been proposed

by the authors in a previous work [8] to explain the seemingly

independent dynamics of extracellular lipolytic activity and

intracellular enzyme and biomass production. Several species

of Thermus genus are able to form, under certain environmental

conditions, clusters of cells surrounded by a membrane formed

by the fusion of the individual external membranes of each cell.

These formations are usually known as rotund bodies [15]. It

might be assumed that proteins could be rstly secreted by indi-

vidual cells to this internal cavity and, from there poured into

the culture medium. Therefore, the integrity and permeability

of the external membrane of the rotund bodies might be impor-

tant to control the liberation of enzymes to the culture medium,

and these properties could be inuenced by the temperature.

Thus, the combined and opposed effects of increased release of

190 A. Domnguez et al. / Enzyme and Microbial Technology 40 (2007) 187194

T

a

b

l

e

1

F

i

n

a

l

b

i

o

m

a

s

s

a

n

d

l

i

p

o

l

y

t

i

c

e

n

z

y

m

e

p

r

o

d

u

c

t

i

o

n

b

y

t

h

e

t

h

r

e

e

T

h

e

r

m

u

s

s

t

r

a

i

n

s

,

o

p

e

r

a

t

i

n

g

a

t

d

i

f

f

e

r

e

n

t

t

e

m

p

e

r

a

t

u

r

e

s

T

e

m

p

e

r

a

t

u

r

e

(

C

)

B

i

o

m

a

s

s

(

g

d

m

3

)

E

x

t

r

a

c

e

l

l

u

l

a

r

l

i

p

o

l

y

t

i

c

e

n

z

y

m

e

(

U

d

m

3

)

I

n

t

r

a

c

e

l

l

u

l

a

r

l

i

p

o

l

y

t

i

c

e

n

z

y

m

e

(

U

d

m

3

)

T

.

t

h

e

r

m

o

p

h

i

l

u

s

H

B

8

T

.

t

h

e

r

m

o

p

h

i

l

u

s

H

B

2

7

T

.

a

q

u

a

t

i

c

u

s

Y

T

1

T

.

t

h

e

r

m

o

p

h

i

l

u

s

H

B

8

T

.

t

h

e

r

m

o

p

h

i

l

u

s

H

B

2

7

T

.

a

q

u

a

t

i

c

u

s

Y

T

1

T

.

t

h

e

r

m

o

p

h

i

l

u

s

H

B

8

T

.

t

h

e

r

m

o

p

h

i

l

u

s

H

B

2

7

T

.

a

q

u

a

t

i

c

u

s

Y

T

1

6

0

1

.

0

5

1

.

0

1

1

.

0

5

3

.

9

2

7

.

6

9

1

1

.

5

7

5

1

.

1

2

5

8

.

0

1

6

3

.

0

5

7

0

0

.

7

5

1

.

0

4

1

.

1

8

4

.

5

0

3

4

.

4

0

2

7

.

2

5

7

2

.

8

8

1

.

7

9

6

8

.

7

0

8

0

0

.

4

7

0

.

6

4

0

.

6

2

1

.

6

3

1

3

.

1

6

1

4

.

6

1

1

2

4

.

7

8

9

3

.

3

3

6

4

.

3

2

enzymes to the culture medium and thermal or proteolytic deac-

tivation at high temperatures could account for the results found

in the present work.

Although maximum intracellular lipolytic activity was

obtained at 80

C in T. thermophilus HB8 cultures, the scarce

benecial effect in the other studied strains and the consequent

increase in production costs does not recommend operating at

this temperature. Besides, one of the most interesting aspects

in this eld is the enhancement of enzyme secretion, which in

this case appears to be favoured at 70

C (especially for T. ther-

mophilus HB27). Therefore, all subsequent experiments were

carried out employing 70

C as culture temperature.

3.2. Effect of the type and concentration of carbon source

A high degree of nutritional diversity has been detected in

Thermus strains (i.e. T. thermophilus HB8, T. aquaticus YT1) by

Degryse et al. [16], Alfredsson et al. [17] and Santos et al. [18].

These strains grewwell on different carbon sources, although the

presence of glucose, galactose, fructose, sucrose or maltose in

the culture mediumseemed to have a particularly positive effect.

However, the above-mentioned studies were carried out by

means of agar plate cultures, and only provided qualitative

results. Besides, they focused on the investigation of cell

growth, and no information was given on the production of

potentially interesting enzymes. In the present work T. ther-

mophilus HB8, HB27 and T. aquaticus YT1 have been grown

in submerged cultures, using a complex medium supplemented

with several concentrations (from 0.5 to 14 g dm

3

) of mono-

and disaccharides (glucose, fructose, maltose and sucrose). The

end-culture values of biomass, intra- and extracellular lipolytic

activity (after 30 h of incubation) for the three strains are

compared in Figs. 24, respectively. The data are expressed as

percentages referred to the results obtained in the basal medium

(with no additional carbon source) at 70

C, shown in Table 1.

The effect of carbon source appeared to be somewhat

strain-dependent and therefore difcult to generalise. However,

some common patterns could be established for the tested

strains. As it can be observed in Fig. 2, supplementation of

the basal medium with low concentrations (up to 1.5 g dm

3

)

of mono- or disaccharides led, in most cases, to a moderate

increase (2050%) in biomass production. Higher carbon

source concentrations did not result in further improvements in

cell growth, with the exception of T. thermophilus HB8 cultures,

in which biomass was increased two-fold and 2.5-fold when

the basal medium was supplemented with sucrose (7 g dm

3

)

or maltose (14 g dm

3

). Also, it is noteworthy that cell growth

was signicantly diminished when high levels of glucose were

added to the medium, in all the studied strains.

When intracellular lipolytic activity production was con-

sidered (Fig. 3), the general behaviour of the microorganisms

was similar to that described for cell growth. However, the

comparison of both sets of data indicated that intracellular

enzyme and biomass productions were not fully associated. The

addition of low concentrations (0.51.5 g dm

3

) of mono- and

disaccharides generally resulted in a noticeable amelioration

in enzyme production, the most promising results having been

A. Domnguez et al. / Enzyme and Microbial Technology 40 (2007) 187194 191

Fig. 2. Inuence of carbon source on biomass production by Thermus strains,

after 30 h of culture time. Carbon source: () glucose, () fructose, () maltose,

and () sucrose (100%biomass production: T. thermophilus HB8, 0.75 g dm

3

;

T. thermophilus HB27, 1.04 g dm

3

; T. aquaticus YT1, 1.18 g dm

3

).

obtained with disaccharides, and for T. thermophilus HB8.

Carbon source supplementation above this level does not

seem to be advisable, since intracellular lipolytic activities

remained mostly unaltered, or decreased. Only T. thermophilus

HB8 and HB27 showed any amelioration in intracellular

enzyme levels at high carbon source concentrations, with

three-fold and 1.6-fold rises in activity (referred to control) in

the presence of sucrose (14 g dm

3

) and maltose (7 g dm

3

),

respectively.

Finally, extracellular lipolytic enzyme concentrations were

assessed. No signicant levels of extracellular activity were

detected for T. thermophilus HB8, in any case. As for the other

two strains (Fig. 4), the general effect of carbon source supple-

mentation was similar to that previously described for biomass

Fig. 3. Inuence of carbon source on intracellular lipolytic activity production

by Thermus strains, after 30 h of culture time. Carbon source: () glucose, ()

fructose, () maltose, and () sucrose (100% lipolytic activity: T. thermophilus

HB8, 72.80 Udm

3

; T. thermophilus HB27, 81.79 Udm

3

; T. aquaticus YT1,

68.70 Udm

3

).

and intracellular enzyme. A slight enhancement in extracellular

enzyme production was obtained when low concentrations of

the different carbon sources were added. The best results were

obtained with sucrose for T. thermophilus HB27 and fructose

for T. aquaticus YT1 (both sugars at 0.5 g dm

3

).

Total carbohydrates and protein consumption were evalu-

ated in all the cultures. The assessed nutrients were not totally

depleted in any case, and most consumption occurred during

the early stages of the cultures. Low nutrients consumption

in Thermus strains has already been mentioned in previous

works [6,19,20]. No relevant information could be inferred from

these data, concerning the dynamics of cell growth and lipolytic

enzyme production on different carbon sources.

192 A. Domnguez et al. / Enzyme and Microbial Technology 40 (2007) 187194

Fig. 4. Inuence of carbon source on extracellular lipolytic activity production

by T. thermophilus HB27 and T. aquaticus YT1, after 30 h of culture time.

Carbon source: () glucose, () fructose, () maltose, and () sucrose (100%

lipolytic activity: T. thermophilus HB8, 4.50 Udm

3

; T. thermophilus HB27,

34.40 Udm

3

; T. aquaticus YT1, 27.25 Udm

3

).

To our knowledge there are few reports about the produc-

tion of thermostable lipases or esterases from thermophilic

microorganisms, and none on how it can be affected by the

choice and concentration of carbon source. However, the inu-

ence of this factor on lipolytic enzyme secretion by mesophilic

microorganisms has been investigated. The results are very dif-

ferent depending on the microorganism and the experimental

conditions employed. Generally, monosaccharides have been

reported to favour lipase production by mesophilic microor-

ganisms. So, Benjamin and Pandey [21] found that glucose

and fructose enhanced lipase activity in submerged cultures of

Candida rugosa. Dalmau et al. [22] proposed a mixture of com-

pounds as optimum carbon source for lipase production by the

same microorganism. Polysaccharides (i.e. starch) and glycerol

have been described as poor carbon sources for lipase production

by C. rugosa and Yarrowia lipolytica [2123], although they led

to good results in the case of Penicillium citrinum and Rhizopus

delemar [24,25]. Costa et al. [26] concluded that the ability of the

yeast Issatchenkia orientalis to secrete lipolytic activity in sub-

merged culture was improved by using monosaccharides (glu-

cose, fructose), although di- and polysaccharides (sucrose, lac-

tose, maltose, starch) as well as glycerol were not recommended.

The results found in the present work seemto indicate that the

presence of certain carbon sources in the culture medium might

have aninuence oncell growthandlipolytic enzyme production

by Thermus strains. However, the observed effects appeared to

be somehowless dramatic than those reported in some instances

for mesophilic microorganisms. This could be related to the

extreme environments in which thermophilic microorganisms

are usually found, generally characterised by lownutrients avail-

ability. Therefore, the strains are naturally conditioned to survive

in oligotrophic environments, and inhibition by excess of sub-

strates is often encountered [27].

Supplementation of the medium with low concentrations of

mono- anddisaccharides generallyresultedinimprovedbiomass

and lipolytic enzyme production. However, when high carbohy-

drate concentrations were used, no further improvements were

observed, and in some cases (i.e. glucose) strong decreases

in biomass and enzymatic activity were detected. This could

be attributed to the occurrence of Maillard reactions between

amino compounds and reducing sugars, promoted by the high

culture temperatures utilised and favoured by values of pH in

the medium between 7.5 (initial) and 8.5 (at the end of culture).

This kind of reaction is often found in cultures of thermophilic

strains and may result in products that can be inhibitory to

the microorganisms [27]. In the present case, this potentially

inhibitory effect appears to be most remarkable with monosac-

charides, and more precisely glucose. This could be due both

to the higher reactivity of this sugar towards Maillard reaction,

and a possible stronger toxic effect of the formed products. Sus-

ceptibility of disaccharides to undergo the reaction is smaller

(i.e. maltose) or nonexistent (i.e. sucrose, non-reducing sugar),

which agrees with the lesser adverse effects associated to their

presence in the culture medium.

With respect to the mechanismby which disaccharides might

be metabolised by the studied strains, the results seem to indi-

cate that they are not massively hydrolysed in the mediumbefore

being incorporated to the cells. Extracellular hydrolysis of both

disaccharides would imply the generation of glucose, which was

shown to exert a strong inhibitory effect on both biomass and

enzyme production, yet no drastic negative repercussions were

detected when high concentrations of maltose or sucrose were

considered. Therefore, either the disaccharides are hydrolysed

at approximately the uptake rate by the cells, thus maintain-

ing a concentration below the critical one for inhibition, or

they are directly up taken by the cells. The latter hypothesis

is supported by the recently ascertained genome sequence of T.

thermophilus, in which maltose/trehalose permease and ABC

transporter encoding genes were found [28]. Besides, the mal-

tose/trehalose ABC transporter was recently reported to also

recognize sucrose [29]. The genes encoding two -glucosidades,

a -glucosidase and a maltodextrin glucosidase were also found,

but there are no indications that these enzymes could be secreted

by the microorganisms to the culture medium.

Finally, the effect of the addition of lipidic compounds to the

culture mediumin biomass and lipolytic enzyme production has

been assessed in T. thermophilus HB27 cultures. This strain was

selected for this preliminary study, due to the higher enzyme

secretion levels detected in previous cultures, and the more

abundant information available on its lipolytic enzymes [7]. The

presence of lipids has been reported to be crucial for lipases and

esterases production by a number of microorganisms [30]. Thus,

A. Domnguez et al. / Enzyme and Microbial Technology 40 (2007) 187194 193

Fig. 5. Intra- and extracellular lipolytic activity production by T. thermophilus

HB27 cultures in presence of several lipidic compounds with different con-

centrations (1 and 10 g dm

3

): B, control; OO, olive oil; CO, coconut oil; TB,

tributyrin.

the basal medium was supplemented with different concentra-

tions (1 and 10 g dm

3

) of triglycerides (olive oil, coconut oil

and tributyrin). Intra- and extracellular enzyme activities after

30 h culture time are presented in Fig. 5. Tributyrin appeared

to have a strong inhibitory effect in the microorganism, while

cell growth did not undergo dramatic changes with the addition

of olive or coconut oil. On the other hand, the presence of olive

oil helped to increase lipolytic enzyme production levels, both

intra and extracellular up to 33% and 70%, respectively. As it

occurred with carbohydrates, the best results were obtained with

low concentrations of added carbon source. Therefore, it would

appear that the presence of lipids could trigger to some extent the

production of lipolytic enzymes. The occurrence of a biphasic

medium could lead to hydrophobic interactions that might alter

the permeability of the membranes surrounding the already

mentioned rotund bodies, therefore accounting for the observed

variations in enzyme secretion levels. However, further inves-

tigation is required on this topic before attempting any denite

conclusion.

4. Conclusions

According to the results obtained, it can be concluded that

the progressive increase in incubation temperature appeared to

have a negative effect on cell growth, and 70

C was selected

as an optimum for this variable, a compromise in terms of

biomass, intra- and extracellular enzyme production, and cost

optimisation.

Disaccharides (i.e. sucrose and maltose) have been estab-

lishedas goodcarbonsources allowingtoimprove growthand/or

favour enzyme secretion by these microorganisms, although the

most adequate concentration seems to depend on the strain.

On the other hand, the addition of high levels of glucose or

fructose to submerged cultures of Thermus sp. did not bring

about signicant ameliorations in lipolytic activity. Moreover,

the addition of some lipidic compounds (olive and coconut oils)

to the culture medium increased total lipolytic activity levels up

to two-fold with respect to the control culture. These promising

results encourage to realise more studies in which surfactants

or other lipidic compounds would be added to culture medium.

These compounds could help to increase the secretion of lipoly-

tic enzymes due to changes in cell wall permeability or surfactant

effects on cell bound enzyme.

Acknowledgements

This work was nanced by the Spanish Ministry of Science

and Technology and European FEDER(Project PPQ2001-3361)

and XUNTA de Galicia (Project PGIDT03PXIB30103PR).

References

[1] Hough DW, Danson MJ. Extremozymes. Biocatal Biotransfor

1999;3:3946.

[2] Schiraldi C, De Rosa M. The production of biocatalysts and biomolecules

from extremophiles. Trends Biotechnol 2002;20:51521.

[3] Pantazaki AA, Pritsa AA, Kyriadakidis DA. Biotechnologically rele-

vant enzymes from Thermus thermophilus. Appl Microbiol Biotechnol

2000;58:112.

[4] Berger JL, Lee BH, Lacroix C. Identication of new enzyme activi-

ties of several strains of Thermus species. Appl Microbiol Biotechnol

1995;44:817.

[5] Lagarde D, Nguyen HK, Ravot G, Wahler D, Reymond JL, Hills G, et al.

High-throughput screening of thermostable esterases for industrial biocon-

versions. Org Process Res Dev 2002;6:4415.

[6] Dominguez A, Sanroman A, Fuci nos P, Rua ML, Pastrana L, Longo MA.

Quantication of intra- and extra-cellular thermophilic lipase/esterase pro-

duction by Thermus sp. Biotechnol Lett 2004;26:7058.

[7] Fuci nos P, Abadin CM, Sanroman A, Longo MA, Pastrana L, Rua ML.

Identication of extracellular lipases/esterases produced by Thermus ther-

mophilus HB27: partial purication and preliminary biochemical charac-

terisation. J Biotechnol 2005;117:23341.

[8] Fuci nos P, Dominguez A, Sanroman MA, Longo MA, Rua ML, Pastrana L.

Production of thermostable lipolytic activity by Thermus species. Biotech-

nol Prog 2005;21:1198205.

[9] Dominguez A, Pastrana L, Longo MA, Rua ML, Sanroman MA. Lipoly-

tic enzyme production by Thermus thermophilus HB27 in a stirred tank

bioreactor. Biochem Eng J 2005;26:959.

[10] Lowry OH, Rosebrough NJ, Farr AL, Randall RJ. Protein measurement

with the Folin phenol reagent. J Biol Chem 1951;193:26575.

[11] Dubois M, Giles UA, Hamilton JK, Rebers PA, Smith F. Colorimetric

method for determination of sugars and related substances. Anal Chem

1956;28:3506.

[12] Oshima T, Imahori K. Description of Thermus thermophilus combination

nova, a non-sporulation thermophilic bacterium from a Japanese thermal

spa. Int J Syst Bacteriol 1974;24(1):10212.

[13] Taguchi H, Konishi J, Ishii N, Yoshida M. Achaperoninfroma thermophilic

bacterium, Thermus thermophilus, that controls refoldings of several ther-

mophilic enzyme. J Biol Chem 1991;266(33):224118.

194 A. Domnguez et al. / Enzyme and Microbial Technology 40 (2007) 187194

[14] Matsuzawa H, Hamaoki M, Ohta T. Production of thermophilic extracellu-

lar proteases (aqualysins I and II) by Thermus aquaticus YT-1, an extreme

thermophile. Agric Biol Chem 1983;47(1):258.

[15] Becker RJ, StarzykMJ. MorphologyandrotundbodyformationinThermus

aquaticus. Microbios 1984;41:11529.

[16] Degryse E, Glansdorff N, Pierard A. A comparative analysis of extreme

thermophilic bacteria belonging to the genus Thermus. Arch Microbiol

1978;117(2):18996.

[17] Alfredsson GA, Baldursson S, Kristjansson K. Nutritional diversity among

Thermus spp. isolated from Icelandic hot springs. Syst Appl Microbiol

1985;6(3):30811.

[18] Santos MA, Williams RAD, Da Costa MS. Numerical taxonomy of

Thermus isolates from hot springs in Portugal. Syst Appl Microbiol

1989;12:3105.

[19] Sonnleitner B, Cometta S, Fiechter A. Growth kinetics of Thermus ther-

mophilus. Eur J Appl Microbiol Biotechnol 1982;15:7582.

[20] Cometta S, Sonnleitner B, Fiechter A. The growth behaviour of Ther-

mus aquaticus in continuous cultivation. Eur J Appl Microbiol Biotechnol

1982;15:6974.

[21] Benjamin S, Pandey A. Optimisation of liquid media for lipase production

by Candida rugosa. Bioresour Technol 1996;55:16770.

[22] Dalmau E, Montesinos JL, Lotti M, Casas C. Effect of different carbon

sources on lipase production by Candida rugosa. Enzyme Microb Technol

2000;26:65763.

[23] Corzo G, Revah S. Production and characteristics of the lipase

from Yarrowia lipolytica 681. Bioresour Technol 1999;70(2):

17380.

[24] Haas MJ, Bailey DG. Glycerol as carbon source for lipase pro-

duction by the fungus Rhizopus delemar. Food Biotechnol 1993;7:

4953.

[25] Sztajer H, Maliszewska I. The effect of culture conditions on lipoly-

tic productivity of Penicillium citrinum. Biotechnol Lett 1989;11:

8958.

[26] Costa M, Deive FJ, Longo MA. Lipolytic activity in submerged

cultures of Issatchenkia orientalis. Process Biochem 2004;39(12):

210914.

[27] Holst O, Manelius A, Krahe M, M arkl H, Raven N, Sharp R. Thermophiles

and fermentation technology. Comp Biochem Physiol 1997;118A:

41522.

[28] Henne A, Br uggemann H, Raasch C, Wiezer A, Hartsch T, Liesegang H,

et al. The genome sequence of the extreme thermophile Thermus ther-

mophilus. Nature Biotechnol 2004;22:54753.

[29] Silva Z, Sampaio MM, Henne A, Boehm A, Gutzat R, Boos W, et al.

The high-afnity maltose/trehalose ABC transporter in the extremely ther-

mophilic bacterium Thermus thermophilus HB27 also recognizes sucrose

and palatinose. J Bacteriol 2005;187:12108.

[30] Sharma R, Chisti Y, Banerjee U. Production, purication, characterisation,

and applications of lipases. Biotechnol Adv 2001;19:62762.

You might also like

- Thermal and Energetic Studies of Cellular Biological SystemsFrom EverandThermal and Energetic Studies of Cellular Biological SystemsA. M. JamesNo ratings yet

- Research Article: Lipase Activity Among Bacteria Isolated From Amazonian SoilsDocument5 pagesResearch Article: Lipase Activity Among Bacteria Isolated From Amazonian Soilsyaniy_2No ratings yet

- Improvements in Titer, Productivity, and Yield Using Solka-Floc For Cellulase ProductionDocument16 pagesImprovements in Titer, Productivity, and Yield Using Solka-Floc For Cellulase Productionguime27No ratings yet

- Articulo 1Document8 pagesArticulo 1Andre PaRdo DGNo ratings yet

- Kinetics of Ethanol Fermentation With High Biomass Concentration Considering The Effect of TemperatureDocument13 pagesKinetics of Ethanol Fermentation With High Biomass Concentration Considering The Effect of TemperatureJhon Fernando NiñoNo ratings yet

- Experiments Enzymes: Science Technology ActionDocument2 pagesExperiments Enzymes: Science Technology ActionHartini HassanNo ratings yet

- 13 67 Lipase DOtensionDocument7 pages13 67 Lipase DOtensionNena Och Exha Part IINo ratings yet

- Acido LacticoDocument9 pagesAcido LacticoJuan Victor ChampeNo ratings yet

- The Exometabolome of Clostridium Thermocellum Reveals Overflow Metabolism at High Cellulose LoadingDocument11 pagesThe Exometabolome of Clostridium Thermocellum Reveals Overflow Metabolism at High Cellulose LoadingMaruf MuhammadNo ratings yet

- DONAJIDocument8 pagesDONAJImartinNo ratings yet

- Paper 1 Bio 1 LabDocument4 pagesPaper 1 Bio 1 Labheidia92No ratings yet

- The Effect of Coconut Water On Adipocyte Differentiation and Lipid Accumulation in 3T3-L1 CellsDocument6 pagesThe Effect of Coconut Water On Adipocyte Differentiation and Lipid Accumulation in 3T3-L1 CellsHàn Mẫn PhươngNo ratings yet

- A18v46n1 Amilase PentingDocument6 pagesA18v46n1 Amilase Pentingfitri_anaNo ratings yet

- Bio 101 Sample Lab ReportDocument3 pagesBio 101 Sample Lab ReportRavinderenPichan67% (3)

- Comparison of Several Methods For Effective Lipid Extraction From MicroalgaeDocument3 pagesComparison of Several Methods For Effective Lipid Extraction From MicroalgaeRahul GogiaNo ratings yet

- Climate Change ArticleDocument7 pagesClimate Change ArticleRay SmithNo ratings yet

- 9.2.1.a Most Organisms Are Active in A Limited Temperature RangeDocument10 pages9.2.1.a Most Organisms Are Active in A Limited Temperature RangeTroy SouthwellNo ratings yet

- Bacteria GC 1Document6 pagesBacteria GC 1Sundaram PattaruNo ratings yet

- Industrial Microbiology Lab 1 (BTC4205)Document23 pagesIndustrial Microbiology Lab 1 (BTC4205)Jerry CaldwellNo ratings yet

- High Cell Density Cultivation and High Recombinant Protein Production of Escherichia Coli Strain Expressing Uricase PDFDocument6 pagesHigh Cell Density Cultivation and High Recombinant Protein Production of Escherichia Coli Strain Expressing Uricase PDFdivya_jspandianNo ratings yet

- Biomass and Lipid Productivities of Chlorella Vulgaris Under Autotrophic, Heterotrophic and Mixotrophic Growth ConditionsDocument7 pagesBiomass and Lipid Productivities of Chlorella Vulgaris Under Autotrophic, Heterotrophic and Mixotrophic Growth ConditionsKomathi BalasupramaniamNo ratings yet

- Growthof Zymomonas CP4 OnmannitolDocument8 pagesGrowthof Zymomonas CP4 OnmannitolThuy Anh BuiNo ratings yet

- Hsu Et - Al 2007Document4 pagesHsu Et - Al 2007Nguyen PhungNo ratings yet

- Accelerated Shelf-Life Testing of An Intermediate Moisture Food in Air and in An Oxygen-Free AtmosphereDocument7 pagesAccelerated Shelf-Life Testing of An Intermediate Moisture Food in Air and in An Oxygen-Free AtmospherefreeloadtailieuNo ratings yet

- Reference Method For Water Holding Capacity AssessmentDocument5 pagesReference Method For Water Holding Capacity AssessmentFaysa UtbaNo ratings yet

- Predictive Modelling and Validation of Listeria Innocua Growth at Superatmospheric Oxygen and Carbon Dioxide ConcentrationsDocument13 pagesPredictive Modelling and Validation of Listeria Innocua Growth at Superatmospheric Oxygen and Carbon Dioxide ConcentrationsCarlos CeballosNo ratings yet

- 1.0 AbstractDocument26 pages1.0 AbstractEreenNo ratings yet

- Isolation and Optimization of Lipase Producing Bacteria From Oil Contaminated SoilsDocument4 pagesIsolation and Optimization of Lipase Producing Bacteria From Oil Contaminated SoilsMuhamad RidzuanNo ratings yet

- Study 2010Document7 pagesStudy 2010hoplittaNo ratings yet

- Kelompok 1 PDFDocument8 pagesKelompok 1 PDFAmeliaNo ratings yet

- Research Journal of Pharmaceutical, Biological and Chemical SciencesDocument7 pagesResearch Journal of Pharmaceutical, Biological and Chemical SciencesMaslakhatun NisakdiyahNo ratings yet

- Combination of Microfiltration and Heat Treatment For Esl Milk ProductionDocument9 pagesCombination of Microfiltration and Heat Treatment For Esl Milk ProductionRaul Blas TelloNo ratings yet

- 2Document6 pages2nurul9535No ratings yet

- Enhancement of Antioxidant Mechanisms and ReductioDocument10 pagesEnhancement of Antioxidant Mechanisms and Reductioanto.dellabadiaNo ratings yet

- Oroxylum Indicum (L.) Kurz Extract Inhibits Adipogenesis and Lipase Activity in VitroDocument14 pagesOroxylum Indicum (L.) Kurz Extract Inhibits Adipogenesis and Lipase Activity in Vitrohasemana hasemanaNo ratings yet

- Improvement of Yarrowia Lipolytica Lipase ProductionDocument4 pagesImprovement of Yarrowia Lipolytica Lipase ProductionjuanNo ratings yet

- The Effect of High Pressure On Microbial Population, Meat Quality and Sensory Characteristics of Chicken Breast Fillet PDFDocument7 pagesThe Effect of High Pressure On Microbial Population, Meat Quality and Sensory Characteristics of Chicken Breast Fillet PDFhuangymNo ratings yet

- FulltextDocument6 pagesFulltextRoqayya AsslamNo ratings yet

- BOUALLAGUI - 2003 - Effect of Temperature On The Performance of An AnaerobicDocument6 pagesBOUALLAGUI - 2003 - Effect of Temperature On The Performance of An AnaerobicThobiasNo ratings yet

- Optimization of A Fed-Batch Fermentation Process For Production of Bleomycin by Streptomyces Mobaraensis ATCC 15003Document6 pagesOptimization of A Fed-Batch Fermentation Process For Production of Bleomycin by Streptomyces Mobaraensis ATCC 15003jmrozo3No ratings yet

- DeletDocument15 pagesDeletErmias AbelnehNo ratings yet

- Extremophiles As A Source For Novel EnzymesDocument6 pagesExtremophiles As A Source For Novel EnzymesandreafonnegraNo ratings yet

- Cellulase Enzyme Production by Streptomyces SP Using Fruit Waste As SubstrateDocument5 pagesCellulase Enzyme Production by Streptomyces SP Using Fruit Waste As SubstrateHamka NurkayaNo ratings yet

- Hydrogen Production From Food Waste in Anaerobic Mesophilic and Thermophilic AcidogenesisDocument9 pagesHydrogen Production From Food Waste in Anaerobic Mesophilic and Thermophilic AcidogenesisĐêmTrắngNo ratings yet

- Roduction of Asiaticoside From Centella Entella Asiatica Rban Cells in BioreactorDocument5 pagesRoduction of Asiaticoside From Centella Entella Asiatica Rban Cells in BioreactorSyed Muazzam Shah PutraNo ratings yet

- Uquiche 2019Document8 pagesUquiche 2019Ommi Samuel G SNo ratings yet

- Ethanol ProductionDocument20 pagesEthanol Productionkakakukoa100% (1)

- The Micro Lora Involved in Aerobic-Thermophilic Sludge StabilizationDocument8 pagesThe Micro Lora Involved in Aerobic-Thermophilic Sludge StabilizationAlex ZomNo ratings yet

- Ba VariableDocument8 pagesBa VariableDavid SantosNo ratings yet

- Streptomyces Flavogriseus hs1 Isolation and Characterization of Extracellular Proteases and Their Compatibility With Laundry DetergentsDocument9 pagesStreptomyces Flavogriseus hs1 Isolation and Characterization of Extracellular Proteases and Their Compatibility With Laundry DetergentsMaruf MuhammadNo ratings yet

- Advances in Mechanisms and Modi Fications For Rendering Yeast ThermotoleranceDocument8 pagesAdvances in Mechanisms and Modi Fications For Rendering Yeast ThermotoleranceEsteban Gonzàlez RodriguezNo ratings yet

- Fungal EnzymesDocument9 pagesFungal EnzymesYui Bioscience PalsanNo ratings yet

- Yarrowia Lipolytica Growth Under Increased Air Pressure: in Uence On Enzyme ProductionDocument9 pagesYarrowia Lipolytica Growth Under Increased Air Pressure: in Uence On Enzyme ProductionNelma GomesNo ratings yet

- Expt 11 Lab ReportDocument11 pagesExpt 11 Lab ReportGracechel PormildaNo ratings yet

- Miles 1997Document10 pagesMiles 1997Amey N MajlekarNo ratings yet

- Optimization of Feeding Strategy For The Ergosterol Production by Yeasts Saccharomyces CerevisiaeDocument17 pagesOptimization of Feeding Strategy For The Ergosterol Production by Yeasts Saccharomyces CerevisiaeDarwin CastellanosNo ratings yet

- Abu-Khudir Et Al, 2019Document16 pagesAbu-Khudir Et Al, 2019pavimathuNo ratings yet

- A Growth Kinetic Model of Cultures On Cheese Whey As SubstrateDocument6 pagesA Growth Kinetic Model of Cultures On Cheese Whey As Substratewp_dessyNo ratings yet

- PeptidoBioactivo EscamasTilapia 2021 P1BDocument10 pagesPeptidoBioactivo EscamasTilapia 2021 P1BDenis Huanca De La CruzNo ratings yet

- E Ects of High Isostatic Pressure On MushroomsDocument6 pagesE Ects of High Isostatic Pressure On MushroomsNedric ManceraNo ratings yet

- Mix MarketingDocument1 pageMix MarketingFurqoni Nurul UmmahNo ratings yet

- GAMEDocument16 pagesGAMEFurqoni Nurul UmmahNo ratings yet

- Tugas SAFADocument3 pagesTugas SAFAFurqoni Nurul UmmahNo ratings yet

- Diagram Alir Sari RotiDocument1 pageDiagram Alir Sari RotiFurqoni Nurul UmmahNo ratings yet

- Kajian Karakterikstik Fisikokimia Tepung Instan Beberapa Varietas Jagung (Zea Mays L.)Document1 pageKajian Karakterikstik Fisikokimia Tepung Instan Beberapa Varietas Jagung (Zea Mays L.)Furqoni Nurul UmmahNo ratings yet

- Submerged Yeast Fermentation of Cheese Whey For Protein Production and Nutritional Profile AnalysisDocument5 pagesSubmerged Yeast Fermentation of Cheese Whey For Protein Production and Nutritional Profile AnalysisFurqoni Nurul UmmahNo ratings yet

- Fermentative Behavior of Saccharomyces Strains During Guava Psidium Guajava L Must Fermentation and Optimization of Guava Wine Production 2157 7110.1000118Document9 pagesFermentative Behavior of Saccharomyces Strains During Guava Psidium Guajava L Must Fermentation and Optimization of Guava Wine Production 2157 7110.1000118Furqoni Nurul UmmahNo ratings yet

- 12 82 Antifungal CompoundDocument8 pages12 82 Antifungal CompoundFurqoni Nurul UmmahNo ratings yet

- (Tulisan) (Efektivitas Penggunaan Daging Biji Picung Pangium Edule Reinw Untuk Pengawetan Ikan Selar Como Caranx Mate C.V. Segar)Document1 page(Tulisan) (Efektivitas Penggunaan Daging Biji Picung Pangium Edule Reinw Untuk Pengawetan Ikan Selar Como Caranx Mate C.V. Segar)Furqoni Nurul UmmahNo ratings yet

- Fermentative Behavior of Saccharomyces Strains During Guava Psidium Guajava L Must Fermentation and Optimization of Guava Wine Production 2157 7110.1000118Document9 pagesFermentative Behavior of Saccharomyces Strains During Guava Psidium Guajava L Must Fermentation and Optimization of Guava Wine Production 2157 7110.1000118Furqoni Nurul UmmahNo ratings yet

- 12 90 FlavorsDocument20 pages12 90 FlavorsFurqoni Nurul UmmahNo ratings yet

- (Tulisan) (Penangkapan Calon Induk Tuna Madidihang Thunnus Albacares Dalam Upaya Pengembangan Budidaya Ikan Tuna Di Gondol Bali)Document1 page(Tulisan) (Penangkapan Calon Induk Tuna Madidihang Thunnus Albacares Dalam Upaya Pengembangan Budidaya Ikan Tuna Di Gondol Bali)Furqoni Nurul UmmahNo ratings yet

- (Tulisan) (Efektivitas Penggunaan Daging Biji Picung Pangium Edule Reinw Untuk Pengawetan Ikan Selar Como Caranx Mate C.V. Segar)Document1 page(Tulisan) (Efektivitas Penggunaan Daging Biji Picung Pangium Edule Reinw Untuk Pengawetan Ikan Selar Como Caranx Mate C.V. Segar)Furqoni Nurul UmmahNo ratings yet

- Jurnal Agrikultura 2009, 20 (3) : 191-197 Penggunaan Traktor Roda Dua Pada Lahan Padi, Saeful BachreinDocument0 pagesJurnal Agrikultura 2009, 20 (3) : 191-197 Penggunaan Traktor Roda Dua Pada Lahan Padi, Saeful BachreinFurqoni Nurul UmmahNo ratings yet

- ScienceDocument4 pagesScienceAnonymous oi8giUfWVuNo ratings yet

- Slice of PizzaDocument10 pagesSlice of Pizzaseidujude10No ratings yet

- Carbohydrates SummaryDocument9 pagesCarbohydrates SummaryHarold NagunaNo ratings yet

- Biochemistry Answer Key-BLUE PACOPDocument26 pagesBiochemistry Answer Key-BLUE PACOPChengD100% (1)

- Experiment 4Document2 pagesExperiment 4DARREN JOHN MUUWILNo ratings yet

- CarbohydrateDocument43 pagesCarbohydrateJhoanna Rein DuzonNo ratings yet

- Case Report: Komal Tariq, MD Saira Tariq, MBBS Amanda M. Denney Queen, MDDocument5 pagesCase Report: Komal Tariq, MD Saira Tariq, MBBS Amanda M. Denney Queen, MDDekdesNo ratings yet

- Comparative Study of Rate of FermentationDocument31 pagesComparative Study of Rate of FermentationAkash0% (1)

- Physiology of HomeostasisDocument17 pagesPhysiology of HomeostasisRamadan PhysiologyNo ratings yet

- Optimisation of Enzymatic Hydrolysis of Apple PomaceDocument13 pagesOptimisation of Enzymatic Hydrolysis of Apple PomaceDea Inthay WulanNo ratings yet

- CarbohydratesDocument35 pagesCarbohydratesRaincel Mae WarnacNo ratings yet

- January 2022 MSDocument23 pagesJanuary 2022 MSShaheer KhanNo ratings yet

- Carbohydrates Isomerism ImpDocument20 pagesCarbohydrates Isomerism ImpSurajit BhattacharjeeNo ratings yet

- CCEA GCSE Biology Past Papers June 2017 Paper 1 Higher Tier SDocument7 pagesCCEA GCSE Biology Past Papers June 2017 Paper 1 Higher Tier Sjpcy2403No ratings yet

- Primal Testosterone EbookDocument44 pagesPrimal Testosterone Ebook7nvzs8wn24No ratings yet

- Pentosan PDFDocument54 pagesPentosan PDFCinthia StephensNo ratings yet

- 10.1007@978 3 642 79856 65 PDFDocument63 pages10.1007@978 3 642 79856 65 PDFFernanda SilvaNo ratings yet

- 10thedition Spring 2022Document107 pages10thedition Spring 2022UMAR FARIDINo ratings yet

- Composition and in Vitro Digestibility of Monosaccharide Constituents of Selected Byproduct FeedsDocument5 pagesComposition and in Vitro Digestibility of Monosaccharide Constituents of Selected Byproduct FeedsCamila NevesNo ratings yet

- List of Common Antidotes Nurses Should Know - NurseslabsDocument14 pagesList of Common Antidotes Nurses Should Know - NurseslabsKc Mea Paran Borja100% (1)

- Costa Rica GlucoseDocument91 pagesCosta Rica GlucoseAnthony HarderNo ratings yet

- Biologically Important Molecules Chemical Tests LabDocument8 pagesBiologically Important Molecules Chemical Tests LabJames DaurayNo ratings yet

- CARBOHYDRATESDocument21 pagesCARBOHYDRATESMilimo JingsawNo ratings yet

- Dubois AssayDocument7 pagesDubois AssayIlyes DammakNo ratings yet

- The Chemical Basis of LifeDocument68 pagesThe Chemical Basis of LifeDiane Christel LundayNo ratings yet

- Metabolic Pathways of CarbohydratesDocument9 pagesMetabolic Pathways of Carbohydratesgelary sousaNo ratings yet

- Catalog # URS-10: 100 Strips Per BoxDocument4 pagesCatalog # URS-10: 100 Strips Per BoxLey100% (1)

- Laboratory Report Of: Analysis of Food (FST 606)Document13 pagesLaboratory Report Of: Analysis of Food (FST 606)biokimia 2018No ratings yet

- MRPLDocument113 pagesMRPLTTTNo ratings yet

- Biology Teachers' Manual PDFDocument72 pagesBiology Teachers' Manual PDFAndrewNo ratings yet

- The Molecule of More: How a Single Chemical in Your Brain Drives Love, Sex, and Creativity--and Will Determine the Fate of the Human RaceFrom EverandThe Molecule of More: How a Single Chemical in Your Brain Drives Love, Sex, and Creativity--and Will Determine the Fate of the Human RaceRating: 4.5 out of 5 stars4.5/5 (517)

- When the Body Says No by Gabor Maté: Key Takeaways, Summary & AnalysisFrom EverandWhen the Body Says No by Gabor Maté: Key Takeaways, Summary & AnalysisRating: 3.5 out of 5 stars3.5/5 (2)

- Why We Die: The New Science of Aging and the Quest for ImmortalityFrom EverandWhy We Die: The New Science of Aging and the Quest for ImmortalityRating: 4 out of 5 stars4/5 (4)

- A Brief History of Intelligence: Evolution, AI, and the Five Breakthroughs That Made Our BrainsFrom EverandA Brief History of Intelligence: Evolution, AI, and the Five Breakthroughs That Made Our BrainsRating: 4.5 out of 5 stars4.5/5 (6)

- 10% Human: How Your Body's Microbes Hold the Key to Health and HappinessFrom Everand10% Human: How Your Body's Microbes Hold the Key to Health and HappinessRating: 4 out of 5 stars4/5 (33)

- Gut: the new and revised Sunday Times bestsellerFrom EverandGut: the new and revised Sunday Times bestsellerRating: 4 out of 5 stars4/5 (393)

- Undeniable: How Biology Confirms Our Intuition That Life Is DesignedFrom EverandUndeniable: How Biology Confirms Our Intuition That Life Is DesignedRating: 4 out of 5 stars4/5 (11)

- Gut: The Inside Story of Our Body's Most Underrated Organ (Revised Edition)From EverandGut: The Inside Story of Our Body's Most Underrated Organ (Revised Edition)Rating: 4 out of 5 stars4/5 (411)

- Tales from Both Sides of the Brain: A Life in NeuroscienceFrom EverandTales from Both Sides of the Brain: A Life in NeuroscienceRating: 3 out of 5 stars3/5 (18)

- The Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionFrom EverandThe Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionRating: 4 out of 5 stars4/5 (812)

- All That Remains: A Renowned Forensic Scientist on Death, Mortality, and Solving CrimesFrom EverandAll That Remains: A Renowned Forensic Scientist on Death, Mortality, and Solving CrimesRating: 4.5 out of 5 stars4.5/5 (397)

- Buddha's Brain: The Practical Neuroscience of Happiness, Love & WisdomFrom EverandBuddha's Brain: The Practical Neuroscience of Happiness, Love & WisdomRating: 4 out of 5 stars4/5 (216)

- Return of the God Hypothesis: Three Scientific Discoveries That Reveal the Mind Behind the UniverseFrom EverandReturn of the God Hypothesis: Three Scientific Discoveries That Reveal the Mind Behind the UniverseRating: 4.5 out of 5 stars4.5/5 (52)

- The Other Side of Normal: How Biology Is Providing the Clues to Unlock the Secrets of Normal and Abnormal BehaviorFrom EverandThe Other Side of Normal: How Biology Is Providing the Clues to Unlock the Secrets of Normal and Abnormal BehaviorNo ratings yet

- Who's in Charge?: Free Will and the Science of the BrainFrom EverandWho's in Charge?: Free Will and the Science of the BrainRating: 4 out of 5 stars4/5 (65)

- A Series of Fortunate Events: Chance and the Making of the Planet, Life, and YouFrom EverandA Series of Fortunate Events: Chance and the Making of the Planet, Life, and YouRating: 4.5 out of 5 stars4.5/5 (62)

- Fast Asleep: Improve Brain Function, Lose Weight, Boost Your Mood, Reduce Stress, and Become a Better SleeperFrom EverandFast Asleep: Improve Brain Function, Lose Weight, Boost Your Mood, Reduce Stress, and Become a Better SleeperRating: 4.5 out of 5 stars4.5/5 (15)

- Seven and a Half Lessons About the BrainFrom EverandSeven and a Half Lessons About the BrainRating: 4 out of 5 stars4/5 (109)

- Why We Sleep: Unlocking the Power of Sleep and DreamsFrom EverandWhy We Sleep: Unlocking the Power of Sleep and DreamsRating: 4.5 out of 5 stars4.5/5 (2083)

- Lymph & Longevity: The Untapped Secret to HealthFrom EverandLymph & Longevity: The Untapped Secret to HealthRating: 4.5 out of 5 stars4.5/5 (13)

- Human: The Science Behind What Makes Your Brain UniqueFrom EverandHuman: The Science Behind What Makes Your Brain UniqueRating: 3.5 out of 5 stars3.5/5 (38)

- Good Without God: What a Billion Nonreligious People Do BelieveFrom EverandGood Without God: What a Billion Nonreligious People Do BelieveRating: 4 out of 5 stars4/5 (66)

- The Rise and Fall of the Dinosaurs: A New History of a Lost WorldFrom EverandThe Rise and Fall of the Dinosaurs: A New History of a Lost WorldRating: 4 out of 5 stars4/5 (595)

- Moral Tribes: Emotion, Reason, and the Gap Between Us and ThemFrom EverandMoral Tribes: Emotion, Reason, and the Gap Between Us and ThemRating: 4.5 out of 5 stars4.5/5 (115)

- The Consciousness Instinct: Unraveling the Mystery of How the Brain Makes the MindFrom EverandThe Consciousness Instinct: Unraveling the Mystery of How the Brain Makes the MindRating: 4.5 out of 5 stars4.5/5 (93)