Professional Documents

Culture Documents

Ecuaciones para Curva de Conductores y Motores

Uploaded by

Carlos Lovera RodriguezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ecuaciones para Curva de Conductores y Motores

Uploaded by

Carlos Lovera RodriguezCopyright:

Available Formats

1

Index Terms--AC motor protection, Induction motor protection

Overcurrent protection.

I. NOMENCLATURE

I Fault current in Amps

A Conductor Transversal section in Circular

Mils

T

2

Cable Short-circuit Temperature

T

1

Cable Service Temperature

In Nominal Current in amperes

Ist Starting Current in amperes

ST Starting time assumed 3s (can be changed)

MIN

scale

Is the minimum value of decade (in amperes

or seconds on the equation)

Med Length from the minimum value of scale to

the unknown point (*)

Dim Length of a decade on hard copy catalog. (*)

(*) med and dim shall be measured in the

same unit (centimeters, inch, etc)

II. INTRODUCTION

ow voltage coordination is a very important and

fundamental tool for the analysis of an electric system in

industrial plants. The safety of the electric systems operation

depends on this analysis as well as the security of personnel

who work at or operate an industrial plant.

Protection Coordination software is very popular these days,

but sometimes these kinds of software are very expensive, or

have limitations. For example, they only work with a group of

trademarks or sometimes the report summary cannot be

customized.

The electric department of Inelectra makes Coordination

protection analysis for many clients using Microsoft Excel

worksheets in a manual way. This paper realizes an

automation of the process, using the programming module of

Microsoft Excel called Visual Basic Application (VBA). The

use of this tool is very helpful to customize any study or

analysis. In this case, it is used to develop an application to

execute Protection Coordination for Low voltage systems. The

main reason to use Microsoft Excel is because it is the most

popular electronic worksheet.

III. THE APPLICATION

Basically it consists of a Microsoft Excel Chart with data

series plotted. Each series represents curves and points related

to the study. Figure 1 shows the application screen.

Fig. 1 Application screen

IV. CURVE PARAMETERIZATION

The user can obtain curves from a hard copy catalog or

electronic files. Sometimes it is difficult or imprecise to obtain

data point.

Figure 2 shows two typical cases that can be presented in a

hard copy catalog. In case A, the current is known and time

is unknown. Time can be calculated applying the next

equation.

Current:

=

dim

10

med

Scale

MIN t (1)

In case B, the time known and the current is unknown, the

current can be calculated applying the next equation.

Time:

=

dim

10

med

Scale

MIN I (2)

Software Design for Low Voltage Protection

Coordination based on Visual Basic

Applications (VBA) for Microsoft Excel

A. Borrero, and M. Azarie

L

1-4244-0288-3/06/$20.00 2006 IEEE

2006 IEEE PES Transmission and Distribution Conference and Exposition Latin America, Venezuela

2

Fig. 2 Parameterization Chart

V. SOFTWARE OPTIONS

The user can get trip curves from any manufacturer. These

curves can be:

A. Cables Damage Curves

The application can be represented on the drawing as the cable

damage curve for copper and aluminum cables, and a different

insulation.

Fig. 3 Conductor properties dialog box

Copper conductor

+

+

=

5 . 234

5 . 234

log 0297 . 0

1

2

10

2

T

T

A

I

(3)

Aluminum conductor

+

+

=

228

228

log 0125 . 0

1

2

10

2

T

T

A

I

(4)

B. Molded Case Circuit Breaker

The application has a data base loaded, with typical trip curves

for a magnetic-only circuit breaker and thermo-magnetic

circuit breaker. The user can load another trip curve from any

other manufacturer by just obtaining points from the minimum

curve and the maximum curve.

Fig. 4 Fixed Breaker properties dialog box

Also the user can add trip curves from an adjustable circuit

breaker modifying values such as: long time pickup, long time

delay, short time pickup, short time delay and instantaneous

pickup.

3

Fig. 5 Adjustable breaker properties dialog box

C. Motor Starting Curve

A low voltage motor starting curve is very difficult to obtain

from the manufacturer and a design engineer needs to obtain

this information to start the protection coordination. The

application considers seven points to construct the motor

starting curve.

TABLE I

POINTS TO CONSTRUCT MOTOR STARTING CURVE

Point Current Time

1 In 1000s

2 In ST x 1.2

3 In x 1.2 ST

4 Ist x 0.8 ST

5 Ist ST x 0.8

6 Ist 0.03s

7 Ist x 1.6 x 1.1 0.01s

Fig. 7 Motor properties dialog box

D. Transformer Damage Curves

The application can represent the transformer damage curve

based on [4]. The through-fault protection curves presented in

IEEE Std C57.12.00-2000 takes into consideration the fact

that transformer damage is cumulative, and the number of

through faults to which a transformer can be exposed is

inherently different for different applications.

TABLE II

TRANSFORMERS CATEGORY

Category kVA

One Phase

kVA

Three phase

I 5-500 15-500

II 501-1667 501-5000

III 1668-10000 5001-30000

IV > 10000 > 30000

For unbalanced faults, consider the ANSI factors and the

connection type as well, this through-fault protection curve

can be represented for ANSI factors..

Fig. 6 Transformer properties dialog box

E. Thermal Relay Operation Curve

On industrial plants, it is very common to use thermal relay

based on a bimetallic device. Its operation curve is an inverse

time type. Manufacturers often represents this curve in

multiples of a current called Ir. This current is set by the

designer and it depends on nominal load current and

restrictions made by National Electric Code.

Also plotted is the in-rush current for transformers and

nominal current.

TABLE III

TYPICAL INRUSH CURRENTS

Power

(kVA)

Time

(s)

Current

x In

500-2500 0.1 8 In

> 2500 0.1 10 12 In

4

F. Fuse melting curves

Low voltage fuse curves can be plotted from an existing data

base. Also, new manufacturers curves can be added.

Fig. 8 Fuse properties dialog box

G. Special curves

Sometimes it is required to show special data on the protection

coordination drawing. This information can be obtained from

a hard copy catalog or any computer report. The application

has an option called Dispositivo de Usuario, which allows

the user to represent any curve or any points not contained into

the group of curves mentioned from A to F.

VI. EXAMPLE

The example shows a typical one-line section. The intention of

this example is to show the low voltage coordination of a

20Hp induction motor.

Industrial plants use several numbers of induction motors, in

this example, a 20Hp motor will be connected to an existing

motor control center. The application will be used to adjust the

protective devices located into a typical full voltage non-

reverse starter. The starter is equipped with a thermal relay to

protect the motor against overloads and a molded case circuit

breaker to protect the feeder against short-circuits currents.

Fig. 8 One-line Example

First it is necessary to obtain all the required data.

- Motor: Induction type, nominal power 20Hp, 3 phase,

nominal voltage 460V, nominal current 27A (taken from table

430.150, NEC), starting current 145A (taken from table

430.151(B), NEC). Starting time assumed 3 sec.

- Feeder: Assumed length 200m, #2 AWG, insulation XLPE,

600V

- Thermal Relay: Telemecanique, Class 10, current range 23A

32A. Model: LRD-32

- Molded Case Circuit Breaker: Square-D, Only magnetic

circuit breaker, Mag-Gard Model: FAL3605016M

- Motor Control Center: Square-D, 480VAC, 3 phase +

Ground, Short-circuit withstand 65kA at 1 second.

- Main Breaker: Micro Versa trip, Circuit Breaker, 150A,

65kA, Current Sensor: 150A, Rating Plug: 60A, Long Time

Pickup: 1 x (Rating Plug), Long Time Delay Band: 4, I^2t: In,

Sort Time Pickup: 9 x (Long Time Pickup), Sort Time Delay

Band: 1, INST: None

- Transformer: 500 kVA, 4.16 kV / 0.48 kV, -Y, solid

grounded, Z = 7%

- Short circuit currents: Typical values for short circuit current

at 480V motor control centers are between 20kA and 45 kA.

The assumed value is 38kA.

After completing all the required data, the designer engineer is

ready to star the study. Start by filling in the general

information: project name, elements to coordinate, date,

project number, revision, document number, one-line drawing

5

number, one-line image file, client image file, time and

currents limits to plot.

Fig. 9 General properties dialog box

VII FINALREPORT

Figure 10 shows the final report for the current study. From

the report it is possible to verify that the 20 Hp new motor is

successfully added to a system. The settings for the thermal

relay are appropriate to allow the motor start. And the setting

for the circuit breaker provides an integral protection against

high currents until the real short circuit level (38kA). The

motors feeder is totally protected and the existing settings for

the motor control center main breaker keeps selectivity with

the downstream circuit breaker

Thermal Relay: Ir = 33.75A (Class 10)

Breaker: In = 20A, A, Trip 1300%

VIII. CONCLUSIONS ANDFUTURE WORK

This paper has discussed one of many protection coordination

studies. Protective and damage curves are shown in different

colors and the user can manage the labels, colors, line width,

one-line figure and add any other note or drawing.

This application can be performed to be used in medium

voltage systems. It is a starting point of motivation for many

design engineers to maximize the potential of the information

tools.

As a future work, the incorporation of a new module that will

verify the coordination and selectivity between protective

devices or curves has been contemplated.

The migration of this application to be used online into the

INELECTRAs Intranet and will be accessible for all

engineers who work in Inelectra, S.A.C.A.

IX. REFERENCES

[1] IEEE, (2001) IEEE Recommended Practice for Protection

and Coordination of industrial and Commercial Power

Systems 242, ANSI/IEEE

[2] IEEE, (1990) IEEE Recommended Practice for Power

System Analysis 399, ANSI/IEEE

[3] NFPA, (2005) National Electric Code, NFPA-70.

X. BIOGRAPHIES

Alfredo Borrero was born in Caracas -

Venezuela, on December 21, 1976. He

graduated from the Simon Bolivar

University.

His employment experience includes

Inelectra, S.A.C.A., working in

hydrocarbon industry.

Michel Azarie was born in Anzotegui -

Venezuela, on July 16, 1983. He graduated

from the Universidad de Oriente.

His employment experience included

Inelectra, S.A.C.A., as engineer assistance

6

0.001

0.010

0.100

1.000

10.000

100.000

1000.000

10 100 1000 10000 100000 1000000

Current (Amp.)

T

i

m

e

(

s

e

c

.

)

20HP/480V/3F

MOTOR 1

REL TRMICO

Clase 10

REL MAGNTICO

AJUSTE - 1300

CONDUCTOR

CALIBRE: 2 - ICC: 38KA

M-VERSATRIP

S:150- RT:60

LTC: 1- LTD:4

I^2t In- STC:9- STD:1

INST: None

ICC TRIFSICA

Valor: 38 KAmp.

TX 1-TR3F-500KVA

CURVA DE DAOS

TX 1-TR3F-500KVA

1er Pico

TX 1-TR3F-500KVA

2do Pico

TX 1-TR3F-500KVA

CURVA DE DAOS - ANSI

TX 1-TR3F-500KVA

CORRIENTE NOMINAL

Fig.10 Final report for current study

You might also like

- Micom Agile P841: Grid SolutionsDocument8 pagesMicom Agile P841: Grid SolutionsTaQuangDucNo ratings yet

- Communication Training ReportDocument33 pagesCommunication Training ReportkakagoNo ratings yet

- NR ScadaDocument1 pageNR Scadavishuraj2007No ratings yet

- Active Disturbance Rejection Control for Nonlinear Systems: An IntroductionFrom EverandActive Disturbance Rejection Control for Nonlinear Systems: An IntroductionNo ratings yet

- ATP Petersen Coil PracticalExerciseDocument33 pagesATP Petersen Coil PracticalExerciseGesiel SoaresNo ratings yet

- Automation Systems For Sliding Gates Antriebe Für Den SchiebetoreDocument16 pagesAutomation Systems For Sliding Gates Antriebe Für Den SchiebetorejovandjNo ratings yet

- THYNE-1 Product DescriptionDocument36 pagesTHYNE-1 Product DescriptionSting DâuNo ratings yet

- Toshiba Grz100 Xrio Converter Manual Enu Tu2.20 v1.000Document9 pagesToshiba Grz100 Xrio Converter Manual Enu Tu2.20 v1.000RaúlEmirGutiérrezLópezNo ratings yet

- Full Text Analysis of Power Flow of Nigerian 330kv Grid SystemDocument8 pagesFull Text Analysis of Power Flow of Nigerian 330kv Grid SystemOgunranti RasaqNo ratings yet

- Investigation+of+Magnetizing+Inrush+Current+in+a+Single PhasetransformerDocument6 pagesInvestigation+of+Magnetizing+Inrush+Current+in+a+Single PhasetransformerpcelisNo ratings yet

- RLC 1st ManualDocument141 pagesRLC 1st Manualjaved shaikh chaandNo ratings yet

- Sepam Ansi 49Document9 pagesSepam Ansi 49jaikolangaraparambilNo ratings yet

- Qualitrol-Hathaway DFR-1200 Master ProtocolDocument14 pagesQualitrol-Hathaway DFR-1200 Master ProtocolJOSENo ratings yet

- Firmware ManualDocument146 pagesFirmware ManualBhaskar AddepalliNo ratings yet

- Slup 224Document191 pagesSlup 224marcosscaratoNo ratings yet

- 8 Candidate Quiz Buzzer Using 8051Document33 pages8 Candidate Quiz Buzzer Using 8051prasadzeal0% (1)

- ML023030070 USNRC Power Plant Engineering 3Document170 pagesML023030070 USNRC Power Plant Engineering 3MutahirrasoolNo ratings yet

- SIP5 7UM85 V07.30 Manual C027-2 enDocument1,756 pagesSIP5 7UM85 V07.30 Manual C027-2 enMarioyfernanda Guerra MuruaNo ratings yet

- Switchgear Battery Sizing by HandDocument4 pagesSwitchgear Battery Sizing by HandNia KurniawatiNo ratings yet

- PM172EH ModbusDocument54 pagesPM172EH ModbusRanajit Goswami100% (1)

- 3 C&S - ALL Low Voltage Components - MCB - MCCB Etc 19.04Document78 pages3 C&S - ALL Low Voltage Components - MCB - MCCB Etc 19.04mksharma1978No ratings yet

- SEL Client Exercise: Hands-On RTAC SessionDocument19 pagesSEL Client Exercise: Hands-On RTAC SessionMichael DavisNo ratings yet

- P220 PDFDocument12 pagesP220 PDFSatya VasuNo ratings yet

- Powerflex 7000 Medium Voltage Ac Drives: Troubleshooting GuideDocument122 pagesPowerflex 7000 Medium Voltage Ac Drives: Troubleshooting GuideahilsergeyNo ratings yet

- A8000 To SCC 104 ConfigurationDocument6 pagesA8000 To SCC 104 ConfigurationAjith MerinNo ratings yet

- UPFC Detailed Model MATLAB and SimulinkDocument3 pagesUPFC Detailed Model MATLAB and SimulinkEdilberto MJNo ratings yet

- Bangladesh Electricity Distribution Code Draft 2012 BERCDocument153 pagesBangladesh Electricity Distribution Code Draft 2012 BERCAbdullah Bin ManzurNo ratings yet

- Multi LVL DC DC BoostDocument9 pagesMulti LVL DC DC BoostDurga PrathibhaNo ratings yet

- ASAT ConfigPro TrainingDocument99 pagesASAT ConfigPro Trainingrommel76100% (1)

- Feeder Protection Relay REF 610 REF 610: Operator's Manual - ANSI VersionDocument68 pagesFeeder Protection Relay REF 610 REF 610: Operator's Manual - ANSI VersionwiyatnoNo ratings yet

- Frequently Asked Questions (FAQ) About TETRA, SCADA, Telemetry and TelecontrolDocument5 pagesFrequently Asked Questions (FAQ) About TETRA, SCADA, Telemetry and TelecontroltrsghstrhsNo ratings yet

- Excitation CIGREA1 10Document6 pagesExcitation CIGREA1 10ucb2_ntpcNo ratings yet

- Ground Fault LocationDocument8 pagesGround Fault Locationzbyszko201234No ratings yet

- Zab Abb Unitrol 1010 1020 e RevaDocument12 pagesZab Abb Unitrol 1010 1020 e RevaGavinsiauNo ratings yet

- Protection Techniques With Renewable Resources and Smart Grids-A Survey 2015 PDFDocument23 pagesProtection Techniques With Renewable Resources and Smart Grids-A Survey 2015 PDFbdsrlNo ratings yet

- Abb Elr48pDocument2 pagesAbb Elr48pMUHAMMAD FAHMI0% (1)

- Modeling and Simulation in XENDEE: IEEE 34 Node Test FeederDocument12 pagesModeling and Simulation in XENDEE: IEEE 34 Node Test Feedercarlos cervantesNo ratings yet

- Siemens 7SJ512 V3.2 Template Manual ENU TU2.20 V1.100Document13 pagesSiemens 7SJ512 V3.2 Template Manual ENU TU2.20 V1.100RaúlEmirGutiérrezLópezNo ratings yet

- 22 - Altenhuber - Guidance For The Application of Low Voltage FusesDocument10 pages22 - Altenhuber - Guidance For The Application of Low Voltage FusesRagowo Tri WicaksonoNo ratings yet

- Reference DAPPER PDFDocument124 pagesReference DAPPER PDFangel lozadaNo ratings yet

- Siemens Power Engineering Guide 7E 54Document1 pageSiemens Power Engineering Guide 7E 54mydearteacherNo ratings yet

- Reg316 4eDocument980 pagesReg316 4ejgerand100% (1)

- Complex Short Circuit MVA Method For Power PDFDocument4 pagesComplex Short Circuit MVA Method For Power PDFluisNo ratings yet

- Scope: Surge Arrester Leakage Current AnalyserDocument6 pagesScope: Surge Arrester Leakage Current AnalyserEMD NSPCLNo ratings yet

- Catalogo Contactores en Vacio MitsubichiDocument16 pagesCatalogo Contactores en Vacio MitsubichiWalter CataldoNo ratings yet

- Low Power Boost Converter For Portable Applications by Eddy Wells and Mark JordanDocument9 pagesLow Power Boost Converter For Portable Applications by Eddy Wells and Mark JordanberbouNo ratings yet

- Three Winding Transformer Test System-EPRI-2017-Rev4Document18 pagesThree Winding Transformer Test System-EPRI-2017-Rev4Jorge TorresNo ratings yet

- 2017 Simulation of Three-Phase Transformerless Online UPS Using MATLAB-SIMULINK-IJAERDV04I0569640 PDFDocument7 pages2017 Simulation of Three-Phase Transformerless Online UPS Using MATLAB-SIMULINK-IJAERDV04I0569640 PDFTài Nguyễn Minh NhậtNo ratings yet

- BHB Sicamdm EngDocument228 pagesBHB Sicamdm EngMạc DavidNo ratings yet

- Motors and The NECDocument7 pagesMotors and The NECjonathandacumosNo ratings yet

- NDPLDocument27 pagesNDPLkaushal895No ratings yet

- Motor Pump Protection RelaysDocument6 pagesMotor Pump Protection RelaysSufyan HashmiNo ratings yet

- Tsewg Tp-11 Ufc 3-500-10n Best PracticesDocument7 pagesTsewg Tp-11 Ufc 3-500-10n Best PracticeshopkitNo ratings yet

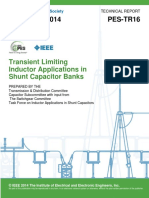

- Transient Limiting Inductor Applications in Shunt Capacitor BanksDocument60 pagesTransient Limiting Inductor Applications in Shunt Capacitor BanksBen ClarkNo ratings yet

- Smart GridDocument44 pagesSmart GriddaminhvienNo ratings yet

- Fdocuments - in Pscad-ModelingDocument21 pagesFdocuments - in Pscad-ModelingniteshNo ratings yet

- PG Rec EnglishDocument61 pagesPG Rec Englishromaoj671No ratings yet

- Power System Protection CoordinationDocument142 pagesPower System Protection Coordinationemogan100% (5)

- Calmec Conductor Tabla4Document1 pageCalmec Conductor Tabla4Carlos Lovera RodriguezNo ratings yet

- Definition and Classification of Power System Stability: IEEE/CIGRE Joint Task Force On Stability Terms and DefinitionsDocument15 pagesDefinition and Classification of Power System Stability: IEEE/CIGRE Joint Task Force On Stability Terms and DefinitionsCarlos Lovera RodriguezNo ratings yet

- Quad 405 Current Dumping Audio Amplifer DCDDocument3 pagesQuad 405 Current Dumping Audio Amplifer DCDmetinprivat01No ratings yet

- Startup Directory PDFDocument320 pagesStartup Directory PDFbillroberts981No ratings yet

- Internship Training & ReportDocument52 pagesInternship Training & ReportKooi YK100% (1)

- Ajp - 3.14 Joint ProtectionDocument78 pagesAjp - 3.14 Joint Protectionghoster33100% (1)

- Reading Test 1. Online: Is ScheduledDocument5 pagesReading Test 1. Online: Is ScheduledThanh LêNo ratings yet

- Energy Modeling GuidelinesDocument32 pagesEnergy Modeling GuidelinesBrian MayNo ratings yet

- Section 6 QuizDocument33 pagesSection 6 QuizImas Rohayati100% (2)

- Computer Graphics Mini ProjectDocument24 pagesComputer Graphics Mini ProjectVarjith100% (1)

- Sap Hana and TableauDocument6 pagesSap Hana and Tableauusd30547100% (1)

- Direct and Inverse KinematicsDocument25 pagesDirect and Inverse KinematicsMyagmarbayar NerguiNo ratings yet

- Module 2 - Physical Presentation of Reports LettersDocument14 pagesModule 2 - Physical Presentation of Reports Lettersashutoshsk5120% (1)

- 96mar Coyne PDFDocument103 pages96mar Coyne PDFdanto yuliardiNo ratings yet

- 190-01499-00 - F - Pilot GuideDocument34 pages190-01499-00 - F - Pilot GuideFordiNo ratings yet

- Input Output ModelsDocument4 pagesInput Output ModelsMaheen KhanNo ratings yet

- Chapter: 8.11 World Wide Web (WWW) Topic: 8.11.1 World Wide Web (WWW)Document4 pagesChapter: 8.11 World Wide Web (WWW) Topic: 8.11.1 World Wide Web (WWW)ETL LABSNo ratings yet

- Jochen Hartmann, Juliana Huppertz, Christina Schamp, Mark HeitmannDocument19 pagesJochen Hartmann, Juliana Huppertz, Christina Schamp, Mark Heitmann23520017 Widya Puteri AuliaNo ratings yet

- NF79115240802810 ETicket-1Document3 pagesNF79115240802810 ETicket-1Aftab AlamNo ratings yet

- SIC CodeDocument424 pagesSIC CodeZohra MerchantNo ratings yet

- CMPE 011 Reviewer MidtermsDocument5 pagesCMPE 011 Reviewer MidtermsJohn Rave Manuel GonzalesNo ratings yet

- The Impact of E-Media On Customer Purchase IntentionDocument4 pagesThe Impact of E-Media On Customer Purchase IntentionEditor IJACSANo ratings yet

- Cisco Catalyst 9300 24-Port Data: S.No Product DescriptionDocument6 pagesCisco Catalyst 9300 24-Port Data: S.No Product DescriptionUmAiR ANo ratings yet

- Oracle HCM Cloud OverviewDocument35 pagesOracle HCM Cloud OverviewAngelVillalobosNo ratings yet

- R7410102 Finite Element Methods in Civil EngineeringDocument4 pagesR7410102 Finite Element Methods in Civil EngineeringsivabharathamurthyNo ratings yet

- Captiva Control MotorDocument52 pagesCaptiva Control Motorsertex_jo71% (7)

- EpayDocument17 pagesEpayShrinivas PrabhuneNo ratings yet

- Oracle Fusion Middleware 11g Build Applications With Adf IIDocument4 pagesOracle Fusion Middleware 11g Build Applications With Adf IIMohamedNo ratings yet

- Summative Test 3 (Tle 7 & 8)Document4 pagesSummative Test 3 (Tle 7 & 8)JoelmarMondonedoNo ratings yet

- NTT Docomo Inc. - Group 9 - EOS BDocument9 pagesNTT Docomo Inc. - Group 9 - EOS BManas DasNo ratings yet

- Catalog PDFDocument8 pagesCatalog PDFforwirelessNo ratings yet

- 90203-1104DEC E Cont Operations PDFDocument414 pages90203-1104DEC E Cont Operations PDFelmacuarro5No ratings yet

- Oil: An Overview of the Petroleum IndustryFrom EverandOil: An Overview of the Petroleum IndustryRating: 4.5 out of 5 stars4.5/5 (3)

- Well Integrity for Workovers and RecompletionsFrom EverandWell Integrity for Workovers and RecompletionsRating: 5 out of 5 stars5/5 (3)

- Advanced Production Decline Analysis and ApplicationFrom EverandAdvanced Production Decline Analysis and ApplicationRating: 3.5 out of 5 stars3.5/5 (4)

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Case Studies of Material Corrosion Prevention for Oil and Gas ValvesFrom EverandCase Studies of Material Corrosion Prevention for Oil and Gas ValvesNo ratings yet

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchFrom EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchRating: 4 out of 5 stars4/5 (10)

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideFrom EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideRating: 2 out of 5 stars2/5 (1)

- From Vision to Version - Step by step guide for crafting and aligning your product vision, strategy and roadmap: Strategy Framework for Digital Product Management RockstarsFrom EverandFrom Vision to Version - Step by step guide for crafting and aligning your product vision, strategy and roadmap: Strategy Framework for Digital Product Management RockstarsNo ratings yet

- Autodesk Fusion 360: A Power Guide for Beginners and Intermediate Users (3rd Edition)From EverandAutodesk Fusion 360: A Power Guide for Beginners and Intermediate Users (3rd Edition)Rating: 5 out of 5 stars5/5 (2)

- Asphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsFrom EverandAsphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsNo ratings yet

- Hydrocarbon Fluid Inclusions in Petroliferous BasinsFrom EverandHydrocarbon Fluid Inclusions in Petroliferous BasinsNo ratings yet

- Asset Integrity Management for Offshore and Onshore StructuresFrom EverandAsset Integrity Management for Offshore and Onshore StructuresNo ratings yet