Professional Documents

Culture Documents

Dual Motor Pendulum Positioning System

Uploaded by

patmos666Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dual Motor Pendulum Positioning System

Uploaded by

patmos666Copyright:

Available Formats

6

th

International Advanced Technologies Symposium (IATS11), 16-18 May 2011, Elaz, Turkey

6

AbstractThis paper presents a new pendulum experiment

setup for educational purposes. The pendulum is actuated by the

thrusts of two motorized propellers mounted back-to-back at its

free end. It can be positioned at any desired position including the

unstable upright. Setups hardware, control system and

mathematical model are described. Performance of the system in

single-thrust and differential-thrust modes is evaluated by

hardware-in-the-loop simulation experiments featuring feedback

linearization and discrete PD control.

Keywordspendulum, propeller, brushless motor, hardware-

in-the-loop simulation

I. INTRODUCTION

he inverted pendulum is a classic benchmark system for

control design and its various implementations have been

studied excessively in the literature [1-3]. The traditional

inverted pendulum systems are actuated by moving the axis of

rotation and the aim is to balance the system in its unstable,

upright balanced position. Due to its fairly simple dynamics,

the inverted pendulum is especially suited to the dynamics and

control systems laboratories of academic institutions.

This paper describes the development and testing of a new

pendulum experiment setup, designed to aid mechanical

engineering students in system dynamics and control related

courses. Unlike traditional systems, the axis of rotation is fixed

and the pendulum is actuated by the thrust of a motorized

propeller mounted at the free end. Similar propeller actuated

pendulums for educational purposes have been reported.

References [4-6] describe experiment kits utilizing a single

brushed dc-motor powered propeller. The pendulum is

balanced against gravity in a single direction and upright

balancing is not possible. In [7], a single motorized propeller

is rotated by a positioning servo around an axis parallel to the

pendulums axis of rotation. This way, the direction as well as

the magnitude of the thrust is varied to hold the pendulum at

any desired position. Our setup features two brushless dc-

motor powered propellers mounted back-to-back at the tip of

the pendulum. This provides two point forces of variable

magnitude and opposite direction that can be used to drive and

hold the pendulum at any position including the unstable

upright. The dual motor arrangement enables differential thrust

actuation which improves the responsiveness and stability of

the system.

Figure 1: Pendulum Setup

II. SETUP DESCRIPTION

The overall design of the setup is shown in Fig.1. Two

motorized propellers are attached back-to-back to the end of

an aluminum pendulum arm. Each of them is able to provide

thrust in a single direction, therefore they are referred to as

clockwise (CW) motor and counter-clockwise (CCW) motor

regarding the moment of their thrusts with respect to the

pendulums pivot point. The pendulum arm is suspended by a

free-to-rotate overhung axle which is coupled to a 2000

counts/revolution optical incremental encoder. The housing of

the axle bearings are clamped to a laboratory desk.

Figure 2: Circuit Board

Pendulum Positioning System Actuated by Dual

Motorized Propellers

Y. Gltekin

1

and Y.Tacolu

2

1

TOBB University of Economics and Technology, Ankara, Turkey, ygultekin@etu.edu.tr

2

TOBB University of Economics and Technology, Ankara, Turkey, ytascioglu@etu.edu.tr

T

Y. Gltekin, Y. Tacolu

7

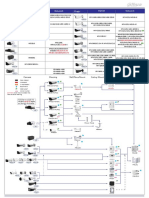

Figure 3: Control Hardware Schematic

Figure 4: Thrust vs Control Input (a) CCW motor (b) CW motor

The control algorithm has been implemented on a PC by

using MATLAB/Simulink Real Time Windows Target

(RTWT) [8]. RTWT compiles Simulink models into C or C++

code and enables the execution of hardware-in-the-loop

simulations in real-time. A custom designed circuit board

(Fig.2) interfaces the control PC to the physical system via

standard RS-232 serial protocol. It includes a Microchip

PIC16F877A microcontroller for serial communications and

PWM (Pulse Width Modulation) signal generation for the

motors, a HCTL2022 integrated circuit for decoding and

counting incremental encoder pulses, and a serial level

converter circuit [9] for translating RS-232 signals from the

control PC to TTL signals suited to the boards

microcontroller. The data exchange between the control PC

and the microcontroller takes place at every 5 ms with 2-byte

packets. The PC receives 16-bit encoder position and sends

two 8-bit motor control signals (Fig.3).

The chosen brushless dc-motors are commonly used in

model aircrafts due to their small size and high speed (~20000

rpm) and they can deliver up to 5 N thrust with 8x4

propellers. The standard drive circuit for these types of motors

is called an ESC (Electronic Speed Controller). An ESC

adjusts the speed of the motor according to a special PWM

signal where the duty cycle period has to be between 1 ms to

2ms. As in this case; when the PWM frequency is 200 Hz, the

ESCs accept duty cycles from 20% to 40%. This range of duty

cycles is expressed with 8-bit resolution. That means the

motors stop at %20 duty cycle (0) and runs at full speed at

40% duty cycle (255). Even though both motors have identical

hardware, a small difference is expected between their

performances. Thrust measurements were performed for the

entire range of duty cycles and curves are fitted to the results

by using MATLABs Basic Fitting tool (Fig.4). The curve

equations are used for analytical approximation of control

inputs corresponding to the required thrusts.

III. MATHEMATICAL MODELING AND SIMULATION

The system is a simple pendulum with a point force at its

free end (see Fig.5). By using Newtons 2nd law and

D`Alembert principle, it can be modeled as follows:

TL c gL m m L m m

B A B A

sin

2

1

3

1

2

(1)

where:

m

A

= mass of the arm (kg)

m

B

= total mass of the motor-propeller assembly attached at

point B (kg)

L = distance from the pivot O to point B (m)

m

A

= mass of the rod (kg)

= angle of the pendulum arm measured counter-

clockwise from rest (rad)

g = gravitational acceleration (m/s

2

)

c = total viscous damping coefficient (Nms/rad)

T = net thrust produced by the motorized propellers (N)

The first term of this equation is the moment of inertia of

the system. The second term is the moment due to the weight

of the pendulum assembly. The parameters m

A

, m

B

, and L are

0.21 kg, 0.16 kg and 0.6 m respectively. The third term is the

moment due to the viscous friction of the bearings and also the

aerodynamic drag caused by the propellers. An average value

for c is found to be 0.0074 Nms/rad by performing a simple

drop test while both motors are running at the same speed. The

last term of the equation is the moment about the pendulum

axle due to the net thrust of the motorized propellers.

ENCODER

DECODER

PC

ESC ESC

CCW

MOTOR

CW

MOTOR

ANGULAR POSITION

PIC16F877A

0 1 2 3 4 5

0

50

100

150

200

250

Thrust Force (N)

C

o

n

t

r

o

l

I

n

p

u

t

CCW Motor

Approximation

0 1 2 3 4 5

0

50

100

150

200

250

Thrust Force (N)

C

o

n

t

r

o

l

I

n

p

u

t

CW Motor

Approximation

(a)

(b)

Pendulum Positioning System Actuated by Dual Motorized Propellers

8

Figure 5: Pendulum Schematic

In order to cancel the non-linear term from the equation,

feedback linearization is applied in the form:

u g m m T

B A

sin

2

1

(2)

The resulting system is linear and has a fairly simple

transfer function with two real poles:

s

mL

c

s

mL

s U

s

2

2

1

(3)

where:

B A

m m m

3

1

(4)

Figure 6: Simulink Model

The Simulink model of the system is given in Fig. 6. Since

the system is already Type 1 (linearized system has 1 pole at

zero), a proportional-derivative (PD) controller is preferred. It

is known through thrust measurements (see Fig.4) that the

propellers are limited to apply just above 4.5 N of thrust.

Therefore a saturation block is also added to the model. The

system is simulated with a multiple step input from 0 to 150

in 30 increments. The proportional and derivative gains are

tuned with structured trial-and-error and selected to be 2 and

0.8 respectively. Fig.7 shows the results of the simulation.

0 10 20 30 40 50 60

0

20

40

60

80

100

120

140

160

time (s)

t

h

e

t

a

(

d

e

g

)

reference

simulation

Figure 7: Simulation Result

IV. EXPERIMENTS AND RESULTS

The Simulink model shown in Fig.6 is also used for the

experiments but the mathematical model of the system is

replaced with the physical system thanks to RTWTs

hardware-in-the-loop capabilities. The blocks shown in Fig.8

are connected to the rest of the Simulink model instead of the

blocks inside the gray Plant box of Fig.6. Using RTWT, the

sampling time of 5 ms is also achieved on the PC side and RS-

232 communications are performed with the built in Packet-

Input, Packet-Output blocks. The Thrust to Control Input

Conversion block contains a MATLAB function which

calculates control inputs to the motors corresponding to the

required thrust based on the approximate curves of the Fig.4.

The Count to Radian Conversion block converts the

instantaneous encoder count to angle in radians.

Figure 8: RTWT Model

The first experiment is performed with the same multiple

step input and controller gains as in the simulation. Only the

CCW motor is used as a thrust source. Fig.9 shows the result

of this experiment in comparison to the simulation. The system

generally performs as expected; however, two shortcomings

can be identified. Firstly, a dead-band is present when the

motor starts from rest. This is the reason for the lag at the

initial response (t=13 s) to the first step reference. Secondly,

the lack of breaking mechanism causes system to overshoot

when the motor needs to slow down rapidly. This is apparent

in the transient at the last step (t=4855 s).

-K-

c

si n

Thrust

Saturati on

pi

Target

-K-

L

1

s

1

s

PID(z)

Di screte

PID Control l er

-K-

1/

((mA/3+mB)*L^2)

-K-

(mA/2+mB)*g*L

-K-

(mA/2+mB)*g

Plant

ref

L

O

A

B

T

1

theta

T

theta

CW Motor

CCW Motor

Thrust to Control Input

Conversi on

1

2

Output to

Seri al Port

1

Input from

Seri al Port

encoder theta

Count to Radi an

Conversi on

1

T

Packet

Output

Packet

Input

Y. Gltekin, Y. Tacolu

9

0 10 20 30 40 50 60

0

50

100

150

200

time (s)

t

h

e

t

a

(

d

e

g

)

0 10 20 30 40 50 60

-20

-10

0

10

20

time (s)

s

i

m

u

l

a

t

i

o

n

-

e

x

p

e

r

i

m

e

n

t

(

d

e

g

)

simulation

experiment

Figure 9: Experiment Result - Single Thrust, Multiple Step

In the second set of experiments, the aim is to stabilize the

pendulum at the upright position ( = 180). Again a single

thrust source is active at any given time. That means, only the

CCW motor is active when the pendulum is at the right-hand-

side semi-circle (0 < < 180), and only the CW motor is

active when the pendulum is at the left-hand-side semi-circle

(180 < < 360). When the previously tuned gains are used,

the system oscillates around the reference with 18 amplitude.

The proportional gain is reduced until no further significant

reduction occurs in the oscillation amplitude. The best

performance is achieved with K

P

= 0.5, K

D

= 0.8, and it has

10 amplitude as shown in Fig.10.

0 5 10 15 20 25 30

0

20

40

60

80

100

120

140

160

180

200

time (s)

t

h

e

t

a

(

d

e

g

)

Kp=2, Kd=0.8

Kp=0.5, Kd=0.8

Figure 10: Experiment Result - Single Thrust, Upright Balance

The last set of experiments also aims upright stabilization.

This time, both motors run at all times and actuation is

achieved by differential thrust. The idea is to shorten the time

required for the motors to achieve the desired speed in order to

minimize oscillations. Fig.11 shows the results of this

experiment. Using the same controller gains as in the previous

experiment, oscillation amplitude is reduced by 50% in

differential thrust mode. The proportional gain is further

reduced until the system becomes over damped. Finally, the

pendulum is stabilized at 179 with no oscillations.

0 5 10 15 20 25 30

0

20

40

60

80

100

120

140

160

180

200

time (s)

t

h

e

t

a

(

d

e

g

)

Kp=0.5, Kd=0.8

Kp=0.2, Kd=0.8

Figure 11: Experiment Result - Differential Thrust, Upright Balance

V. CONCLUSION AND FURTHER WORK

Development and testing of a new pendulum experiment

setup for educational purposes is described. The setup features

two brushless dc-motor powered propellers mounted back-to-

back at the tip of the pendulum. Systems performance is

evaluated via hardware-in-the loop simulation experiments by

using Simulink RTWT with custom designed interface circuit.

The designed system is an ideal aid for teaching mathematical

modeling, parameter identification and control system design

at various levels. The further work will concentrate on

development of a compact, modular and portable setup based

on the prototype presented here. Such a system can be given to

students as a take-home hands-on project.

ACKNOWLEDGMENT

Authors thank to former undergraduate students smet Fatih

ekerolu and Elgin Oktay for their efforts in building the

system hardware.

REFERENCES

[1] J. Yi, N. Yubazaki, Stabilization fuzzy control of inverted pendulum

systems, Artificial Intelligence in Engineering, vol. 14, pp. 153-163,

2000.

[2] A. Siuka, M. Schberl, Applications of energy based control methods

for the inverted pendulum, Robotics and Autonomous Systems, vol. 57,

pp. 1012-1017, 2009.

[3] J. -J. Wang, Simulation studies of inverted pendulum based on PID

controllers, Simulation Modelling Practice and Theory, vol. 19, pp.

440-449, 2011.

[4] E. T. Enikov, V. Polyzoev, J. Gill, Low-cost take-home experiment on

classical control using Matlab/Simulink Real-Time Windows Target,

in Proc. of the ASEE/PSW-2010 Conf., Reno, NV, 2010.

[5] S.-F. Yang, J.-H. Chou, A mechatronic positioning system actuated

using a micro DC-motor-driven propellerthruster, Mechatronics, vol.

19, pp. 912-926, 2009.

[6] http://prism2.mem.drexel.edu/~paul/thrustTester/thrustTester.html (last

accessed 17.02.2011)

[7] K. Craig, M. Kleinigger, Mechatronics case study: Thrust vectoring

and control of an unstable system, Dept. Mech. Eng., Rensselaer

Polytechnic Institute, Troy, NY.

[8] http://www.mathworks.com/products/rtwt/ (last accessed 17.02.2011)

[9] http://picprojects.org.uk/projects/simpleSIO/ssio.htm (last accessed

17.02.2011)

You might also like

- 500 Important Spoken Tamil Situations Into Spoken English Sentences SampleDocument7 pages500 Important Spoken Tamil Situations Into Spoken English Sentences SamplerameshdurairajNo ratings yet

- Robot - Line Follower InstructableDocument34 pagesRobot - Line Follower InstructableHery Teguh SetiawanNo ratings yet

- Head and Neck Anatomy PDFDocument346 pagesHead and Neck Anatomy PDFIrina Panciu Stefan100% (20)

- DC Power Supply DocumentationDocument4 pagesDC Power Supply DocumentationAashi BhawsarNo ratings yet

- TMS320C6748 DSP BOARD Package ContentDocument22 pagesTMS320C6748 DSP BOARD Package ContentPrangya PradhanNo ratings yet

- Mosfet Driver Theory and ApplicationsDocument28 pagesMosfet Driver Theory and ApplicationsRoga29No ratings yet

- College of Medicine & Health SciencesDocument56 pagesCollege of Medicine & Health SciencesMebratu DemessNo ratings yet

- G 26 Building Using ETABS 1673077361Document68 pagesG 26 Building Using ETABS 1673077361md hussainNo ratings yet

- Smart Irrigation System Using ArduinoDocument12 pagesSmart Irrigation System Using ArduinoAbhijeet DeshpandeNo ratings yet

- Self Balancing Two Wheeled Robot ReportDocument11 pagesSelf Balancing Two Wheeled Robot Reportnetlvr0No ratings yet

- myDAQ and myRIO DocumentationDocument22 pagesmyDAQ and myRIO DocumentationMani BalaNo ratings yet

- HEN-PFG690 SPM PDFDocument106 pagesHEN-PFG690 SPM PDFAndres Jose Amato TorresNo ratings yet

- Dye Sensitized Solar Cell: Presented By: S.Shashank ChettyDocument26 pagesDye Sensitized Solar Cell: Presented By: S.Shashank Chettyabebaw matebuNo ratings yet

- Temp-Indicator Using AT89C52Document12 pagesTemp-Indicator Using AT89C52rakeshrakesh100% (1)

- Thermal Modeling of A Combined System of Photovoltaic Thermal PVT Solar Water HeaterDocument11 pagesThermal Modeling of A Combined System of Photovoltaic Thermal PVT Solar Water HeaterUmer AbbasNo ratings yet

- XAR Digital Alternator Regulator: Installation and Operation ManualDocument12 pagesXAR Digital Alternator Regulator: Installation and Operation ManualpeefincaNo ratings yet

- The Study of 220 KV Power Substation Equipment DetailsDocument90 pagesThe Study of 220 KV Power Substation Equipment DetailsAman GauravNo ratings yet

- 2020 02 RechargeEU Trucks PaperDocument38 pages2020 02 RechargeEU Trucks Paperpatmos666No ratings yet

- Autonomous Trucks: An Opportunity To Make Road Freight Safer, Cleaner and More EfficientDocument28 pagesAutonomous Trucks: An Opportunity To Make Road Freight Safer, Cleaner and More Efficientpatmos666No ratings yet

- En CD00201961 PDFDocument39 pagesEn CD00201961 PDFIrini Fountouli - LadopoulouNo ratings yet

- Tailored Transportation SolutionsDocument20 pagesTailored Transportation Solutionspatmos666No ratings yet

- High Risk Medications in AyurvedaDocument3 pagesHigh Risk Medications in AyurvedaRaviraj Pishe100% (1)

- Solid Waste ManagementDocument26 pagesSolid Waste ManagementPamela MendozaNo ratings yet

- Battery Maintenance Guide For DJI Enterprise DronesDocument10 pagesBattery Maintenance Guide For DJI Enterprise DronesChristiaan De Ridder100% (1)

- Lab 1-9Document36 pagesLab 1-9HassanAhmed124No ratings yet

- Wind and Solar Mobile ChargerDocument6 pagesWind and Solar Mobile ChargerIJRRRNo ratings yet

- Mobile Phone Charger ReferencesDocument13 pagesMobile Phone Charger ReferencesMohd Amirul AkmalNo ratings yet

- Dual Converter Using ThyristorsDocument1 pageDual Converter Using ThyristorsEdgefx Kits100% (1)

- Electronic Load and Other Circuit IdeasDocument6 pagesElectronic Load and Other Circuit Ideasanees_172000100% (1)

- Lab 4 Stepper Motor PDFDocument10 pagesLab 4 Stepper Motor PDFIrfan HaiderNo ratings yet

- 1.2 MARS Data Cache Simulator ToolDocument2 pages1.2 MARS Data Cache Simulator Toolamarsdd7238No ratings yet

- Low Power Nine-Bit Sigma-Delta ADC Design Using TSMC 0.18micron TechnologyDocument5 pagesLow Power Nine-Bit Sigma-Delta ADC Design Using TSMC 0.18micron Technologyeditor_ijtel100% (1)

- Siemens Safety B10 Values - Extract From IC 10-2017Document2 pagesSiemens Safety B10 Values - Extract From IC 10-2017spuntoandreaNo ratings yet

- Getting Started With Altera DE2-70 BoardDocument5 pagesGetting Started With Altera DE2-70 BoardThanh Minh HaNo ratings yet

- Data Sheet SunEdison Mono Silver SE R335BMC 39Document2 pagesData Sheet SunEdison Mono Silver SE R335BMC 39Nazeeh Abdulrhman AlbokaryNo ratings yet

- Esp32 HC-SR04Document4 pagesEsp32 HC-SR04Eric Simancas AcevedoNo ratings yet

- 100kw Grid Connected PV ModuleDocument3 pages100kw Grid Connected PV ModuleKapil DevNo ratings yet

- Mo at Source PDFDocument2 pagesMo at Source PDFcavcicNo ratings yet

- ME 5643 Final Project Report on DoodleBotDocument16 pagesME 5643 Final Project Report on DoodleBotKeshav Arora0% (1)

- Wind Turbine MPPT Regulator v2.3 120120Document36 pagesWind Turbine MPPT Regulator v2.3 120120EdwinDuranJr.100% (1)

- Nexys2 ISE 12 - 2 Decoder TutorialDocument15 pagesNexys2 ISE 12 - 2 Decoder TutorialVale Conde CuatzoNo ratings yet

- ON - Semiconductor KA78R05CTU Datasheet PDFDocument18 pagesON - Semiconductor KA78R05CTU Datasheet PDFKhaled KamelNo ratings yet

- Electrical Power ProjectDocument12 pagesElectrical Power ProjectsrnkaNo ratings yet

- DIY Mega ESR Tester InfoDocument36 pagesDIY Mega ESR Tester InfoBenjamin DoverNo ratings yet

- Magnetic Induction and ResonanceDocument16 pagesMagnetic Induction and ResonanceKim Won Kuk100% (1)

- Particle Swarm Optimization: Function, Which Maps The Search Space To The Function Space. Since A Function Has Only OneDocument5 pagesParticle Swarm Optimization: Function, Which Maps The Search Space To The Function Space. Since A Function Has Only OneMeltem YaktubayNo ratings yet

- Tri-Band Miniature GPS Array With A Single-Fed CP Antenna ElementDocument4 pagesTri-Band Miniature GPS Array With A Single-Fed CP Antenna ElementHo Quang SonNo ratings yet

- Finite Element Method Magnetics - FEMM 4.2 Electrostatics TutorialDocument7 pagesFinite Element Method Magnetics - FEMM 4.2 Electrostatics TutorialKamila KNo ratings yet

- Huawei Weather StationDocument10 pagesHuawei Weather StationSneyder CelinNo ratings yet

- CNC by SourabhDocument7 pagesCNC by SourabhsaurabhNo ratings yet

- DIY Squid HatDocument22 pagesDIY Squid Hatkailani_ishitaNo ratings yet

- Major ReportDocument43 pagesMajor ReportPrashant BaliaNo ratings yet

- Clap Switch CircuitDocument5 pagesClap Switch CircuitSabid Uddin100% (2)

- RC CarDocument11 pagesRC CarJade Panzo SalaspeNo ratings yet

- Sony DXC 3000aDocument14 pagesSony DXC 3000aOnceUponAThing100% (1)

- Dice Project 00Document10 pagesDice Project 00HarshaNo ratings yet

- CIP-1000 Operation MaualDocument15 pagesCIP-1000 Operation MaualAngel Santos SantosNo ratings yet

- Fuzzy Logic and Phase-Locked Loop for Precise DC Motor Speed ControlDocument6 pagesFuzzy Logic and Phase-Locked Loop for Precise DC Motor Speed ControlMuhammad IkhsanNo ratings yet

- Trnsys 2004 PDFDocument32 pagesTrnsys 2004 PDFKhuleedShaikhNo ratings yet

- Moto 360 Smartwatch Teardown PDFDocument14 pagesMoto 360 Smartwatch Teardown PDFPhone 4uNo ratings yet

- ESP8266 DHT11 Humidity Temperature Data LoggerDocument6 pagesESP8266 DHT11 Humidity Temperature Data LoggersaravananNo ratings yet

- Muammer YILDIZ - : Update - 5-2010Document43 pagesMuammer YILDIZ - : Update - 5-2010bento broli100% (1)

- Anki A Unified Control Strategy For Three-Phase Inverter PDFDocument16 pagesAnki A Unified Control Strategy For Three-Phase Inverter PDFRavi KumarNo ratings yet

- Sepic Converter Based DC Motor Speed ControlDocument18 pagesSepic Converter Based DC Motor Speed ControlCrispNo ratings yet

- Power Factor Measurement & Correction: Prepared By: Guided byDocument29 pagesPower Factor Measurement & Correction: Prepared By: Guided bySunil PillaiNo ratings yet

- EE Lab Manuls Fast NuDocument70 pagesEE Lab Manuls Fast NuMuhammad SaadNo ratings yet

- A Study of Synchronous Motor Drive Using SFCDocument4 pagesA Study of Synchronous Motor Drive Using SFCBrian GuevaraNo ratings yet

- Microprocessor-Based Robust DC Servo Motor ControlDocument7 pagesMicroprocessor-Based Robust DC Servo Motor ControlVikas PatelNo ratings yet

- Sliding Mode Observer For Torque Control in Sensorless BLDC MotorDocument5 pagesSliding Mode Observer For Torque Control in Sensorless BLDC MotorIOSRjournalNo ratings yet

- Simulation of Some Power System, Control System and Power Electronics Case Studies Using Matlab and PowerWorld SimulatorFrom EverandSimulation of Some Power System, Control System and Power Electronics Case Studies Using Matlab and PowerWorld SimulatorNo ratings yet

- Community Data rpt04 15 Reduced SizeDocument72 pagesCommunity Data rpt04 15 Reduced Sizepatmos666No ratings yet

- List of Accredited Ppa PortDocument13 pagesList of Accredited Ppa Portpatmos666No ratings yet

- Case No COMP/M.2844 - Linde / Komatsu / Komatsu Forklift: REGULATION (EEC) No 4064/89 Merger ProcedureDocument6 pagesCase No COMP/M.2844 - Linde / Komatsu / Komatsu Forklift: REGULATION (EEC) No 4064/89 Merger Procedurepatmos666No ratings yet

- Minimizing The Carbon Footprint of Material Handling Equipment: Comparison of Electric and LPG ForkliftsDocument12 pagesMinimizing The Carbon Footprint of Material Handling Equipment: Comparison of Electric and LPG Forkliftspatmos666No ratings yet

- High TransportDocument110 pagesHigh Transportpatmos666No ratings yet

- Test 154PLDocument78 pagesTest 154PLpatmos666No ratings yet

- RA No 8794Document2 pagesRA No 8794Art AranetaNo ratings yet

- Guide to Standard Truck Trailer DimensionsDocument15 pagesGuide to Standard Truck Trailer DimensionsMauro63No ratings yet

- Request For Proposal (RFP)Document26 pagesRequest For Proposal (RFP)patmos666No ratings yet

- The Japan CrashDocument55 pagesThe Japan Crashpatmos666No ratings yet

- Webb County Accounts Payable: Check RegisterDocument309 pagesWebb County Accounts Payable: Check Registerpatmos666No ratings yet

- F 9301Document4 pagesF 9301HOMERO JARAMILLO CATEMAXCANo ratings yet

- Best Practice Guidelines For Safe Un Loading of Road Freight VehiclesDocument66 pagesBest Practice Guidelines For Safe Un Loading of Road Freight VehiclesJUAN ANTONIO MOLINANo ratings yet

- Eolic - Win Powe - JPDocument56 pagesEolic - Win Powe - JPpatmos666No ratings yet

- Oregon DOT Motor Carrier Newsletter Highlights Transportation UpdatesDocument19 pagesOregon DOT Motor Carrier Newsletter Highlights Transportation Updatespatmos666No ratings yet

- Processes 08 00887Document10 pagesProcesses 08 00887patmos666No ratings yet

- PDFDocument32 pagesPDFAnamae LabasoNo ratings yet

- European ProccesDocument99 pagesEuropean Proccespatmos666No ratings yet

- Artificial Intelligence Research CenterDocument20 pagesArtificial Intelligence Research Centerpatmos666No ratings yet

- Artificial Intelligence:: A Rival For Humans, or A Partner?Document1 pageArtificial Intelligence:: A Rival For Humans, or A Partner?patmos666No ratings yet

- Handbook 2020 10 - 16Document75 pagesHandbook 2020 10 - 16patmos666No ratings yet

- Indian School Al Wadi Al Kabir: Rounding Off Numbers & Roman NumeralsDocument3 pagesIndian School Al Wadi Al Kabir: Rounding Off Numbers & Roman Numeralspatmos666No ratings yet

- Teams Medical Missions: PartnershipDocument4 pagesTeams Medical Missions: Partnershippatmos666No ratings yet

- Finite Elements for Solving PDEs on Evolving SurfacesDocument30 pagesFinite Elements for Solving PDEs on Evolving Surfacespatmos666No ratings yet

- 2D Finite Elements With Displacement Interpolated Embedded Localization Lines: The Analysis of Fracture in Frictional MaterialsDocument16 pages2D Finite Elements With Displacement Interpolated Embedded Localization Lines: The Analysis of Fracture in Frictional Materialspatmos666No ratings yet

- The Galerkin Finite Element MethodDocument50 pagesThe Galerkin Finite Element MethodSayan KumarNo ratings yet

- Advanced Finite Element LecturesDocument47 pagesAdvanced Finite Element LecturesPeter MattewsNo ratings yet

- Beckman DxI 800 Prolactin Assay Superiority for Monomeric ProlactinDocument5 pagesBeckman DxI 800 Prolactin Assay Superiority for Monomeric Prolactindoxy20No ratings yet

- Kerala Electricity Regulatory Commission Schedule of TariffDocument36 pagesKerala Electricity Regulatory Commission Schedule of TariffvjtheeeNo ratings yet

- GT ĐỀ 04Document39 pagesGT ĐỀ 04Cao Đức HuyNo ratings yet

- 2 - Alaska - WorksheetsDocument7 pages2 - Alaska - WorksheetsTamni MajmuniNo ratings yet

- Is Revalida ExamDocument11 pagesIs Revalida ExamRodriguez, Jhe-ann M.No ratings yet

- Dahua Pfa130 e Korisnicko Uputstvo EngleskiDocument5 pagesDahua Pfa130 e Korisnicko Uputstvo EngleskiSaša CucakNo ratings yet

- Thank You For Taking The Week 3: Assignment 3. Week 3: Assignment 3Document3 pagesThank You For Taking The Week 3: Assignment 3. Week 3: Assignment 3DhivyaNo ratings yet

- Philip Rance EAH Philo of ByzantiumDocument3 pagesPhilip Rance EAH Philo of ByzantiumstoliNo ratings yet

- Gante Iris PPT Pe p006Document20 pagesGante Iris PPT Pe p006Donna Ville GanteNo ratings yet

- ARES SC4 Service Manual (HP-300UA)Document20 pagesARES SC4 Service Manual (HP-300UA)mike_net8903No ratings yet

- NASA Technical Mem Randum: E-Flutter N78Document17 pagesNASA Technical Mem Randum: E-Flutter N78gfsdg dfgNo ratings yet

- P&id BoilerDocument1 pageP&id BoilerBagus AryowibowoNo ratings yet

- MPC-006 DDocument14 pagesMPC-006 DRIYA SINGHNo ratings yet

- Abiotic and Biotic Factors DFDocument2 pagesAbiotic and Biotic Factors DFgiselleNo ratings yet

- A Feature Selection Based On The Farmland Fertility Algorithm For Improved Intrusion Detection SystemsDocument27 pagesA Feature Selection Based On The Farmland Fertility Algorithm For Improved Intrusion Detection SystemsRashed ShakirNo ratings yet

- Advanced Composite Materials Design EngineeringDocument19 pagesAdvanced Composite Materials Design EngineeringpanyamnrNo ratings yet

- Takara 2012Document57 pagesTakara 2012Deepak Ranjan SahooNo ratings yet

- Workload Assessment in Railway ControlDocument8 pagesWorkload Assessment in Railway ControlbbeeNo ratings yet

- SDE1 V1 G2 H18 L P2 M8 - SpecificationsDocument1 pageSDE1 V1 G2 H18 L P2 M8 - SpecificationsCleverson SoaresNo ratings yet

- Hexagon MI GLOBAL S DataSheet Letter EN NAFTA Rel5Document22 pagesHexagon MI GLOBAL S DataSheet Letter EN NAFTA Rel5dudecastro1542No ratings yet

- Cars Ger Eu PCDocument157 pagesCars Ger Eu PCsergeyNo ratings yet

- AS 1418.2 Cranes, Hoists and Winches Part 2 Serial Hoists and WinchesDocument31 pagesAS 1418.2 Cranes, Hoists and Winches Part 2 Serial Hoists and WinchesDuy PhướcNo ratings yet

- Whatever Happens, Happens For Something Good by MR SmileyDocument133 pagesWhatever Happens, Happens For Something Good by MR SmileyPrateek100% (3)