Professional Documents

Culture Documents

Sampling Analysis Procedure - Sand Control

Uploaded by

Yougchu LuanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sampling Analysis Procedure - Sand Control

Uploaded by

Yougchu LuanCopyright:

Available Formats

Sampling analysis procedure - sand control

This article describes the sampling analysis procedure for sand control: conventional and side stream filtration method.

1 Conventional procedure

By passing the oil sample through a sieve of a given size the sand particles can be separated from the oil and collected. The sand particles collected can

be measured and related to the size of the sample to produce a sand production rate for the producing well.

1.1 Apparatus/chemicals

ASTM sieve 325 mesh (44 um or 0.045 mm)

Hand centrifuge with 10 mL graduated centrifuge tubes

Pail or bucket - for collecting crude oil filtrate

Measuring jug or cylinder (2 Litres)

Plastic wash bottle

Collecting beaker

Glass or metal rod

Demulsifier (currently in use

Detergent (e.g. Teepol concentrate)

Distilled water/clean tap water

1.2 Method

1. Sample from the well bean box 4-8 litres of crude oil in a suitable container. Note: Flush the sample point prior to sampling to eradicate any possible

particle accumulation.

2. Add 4 - 5 drops of demulsifier to the sample (see note).

3. Shake sample container vigorously before sieving to ensure all sand is suspended while decanting.

4. Sieve the oil sample with constant agitation/stirring through a clean ASTM sieve 325 which is placed on top of a collecting bucket.

5. For viscous crude or stable emulsion, which do not sieve through easily, add a known amount of detergent concentrate or demulsifier to the sample

and continue sieving with constant stirring.

Upon completion of step 5 note the total volume of oil filtrate after sieving collected in the bucket.

6. The volume of detergent used must be subtracted from the total volume of oil filtrate measured after sieving to give the actual crude oil sample being

filtered. If detergent volume is small enough, it can be ignored.

7. On completion of sieving, wash the sieve containing sand particles with detergent solution to remove traces of oil.

8. Finally wash the sand particles carefully into a clean beaker with distilled water or tap water in wash bottle.

9. Transfer all the sand particles from the beaker into a graduated 10 mL centrifuge tube via a funnel.

10. Fill to 10 mL mark with distilled or tap water. Hand centrifuge for 2 minutes.

11. Note the mass of sand collected at the bottom of the tube.

Remark: With the availability of precision electronic weighing machines, it is less cumbersome and more accurate to dry the sand and weigh it.

2 Side stream filtration method

2.1 Principle of the Method

A sample of produced fluid is passed through a series of three sieves. The residue is washed with solvents to remove excess oil, wax and water. The

volume of the residue is measured after drying. A density factor is applied and the weight of sand produced is related to a unit volume of produced fluid.

For the results obtained by this method to be meaningful, the well being sampled must be in a stable flow state. It is important that no sampling be done

until five hours after a bean change.

2.2 Apparatus

Sieve holder. 100 mesh sieve complete with dispersion plate. 200 mesh sieve. 325 mesh sieve. 3 "0" rings 2 gaskets. 1/4" metal support ring. find brush.

graduated centrifuge tube.

2.3 Chemicals

Toluene. Acetone.

2.4 Sampling

1.Aassemble the sieves in the holder with the steel ring at the base and each sieve separated by an "O" ring.

2.From the top the order of assembly is:

a)100 mesh sieve complete with dispersion plate

b)200 mesh sieve

c)325 mesh sieve

d)metal support ring.

3.The seal at either end is completed with gaskets.

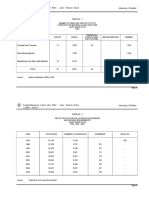

4.Referring to Fig. 760 connect the sieve holder to the flow line by means of the snap couplings.

5.Close valves A, B, C, D.

6.Open valve A fully.

7.Open valve B fully.

8.Use valve C to direct the flow to dump.

9.Continue to dump until the line at C feels warm.

10.Redirect the flow to the sieve holder through C.

11.Over a period of 10 seconds gradually open valve D fully. This gradual operation of D helps to prevent wax deposition on the sieves.

12.Sample through the sieve holder for three minutes into the container.

13.Record the THP.

14.Close valves C, B and A.

15.Remove the sieve holder.

16.Cautiously remove the sieves from the holder so as not to lose their contents.

17.Determine the volume in litres of produced fluid passed through the sieve holder during sampling.

18.Install clean sieves.

2.5 Analysis

Wash the sand in each sieve with toluene. Wash the sand in each sieve with acetone. Allow the sand to dry. Brush the dry sand from each sieve into the

same graduated centrifuge tube. Measure the volume of sand in cm3.

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Job Description - Drilling AssistantDocument1 pageJob Description - Drilling AssistantYougchu LuanNo ratings yet

- FINAL GRA 3 2 Fighting Fires in High Rise BuildingsDocument66 pagesFINAL GRA 3 2 Fighting Fires in High Rise Buildingsvij2009No ratings yet

- Job Description - Drilling SuperintendentDocument1 pageJob Description - Drilling SuperintendentYougchu LuanNo ratings yet

- TCP Perforating ProgrammeDocument3 pagesTCP Perforating ProgrammeYougchu LuanNo ratings yet

- Job Description - Senior Drilling SupervisorDocument1 pageJob Description - Senior Drilling SupervisorYougchu Luan100% (1)

- Biological Molecules: WaterDocument34 pagesBiological Molecules: WaterYing ShuangNo ratings yet

- CLUP LaurDocument60 pagesCLUP LaurKenneth James Arances0% (1)

- Cominox SterilClave 18-24 - User and Maintenance ManualDocument68 pagesCominox SterilClave 18-24 - User and Maintenance ManualJose Tavares100% (2)

- Test Procedure For Sand Wash SystemsDocument1 pageTest Procedure For Sand Wash SystemsYougchu LuanNo ratings yet

- Timing Requirement For Exploration Drilling OperationsDocument1 pageTiming Requirement For Exploration Drilling OperationsYougchu LuanNo ratings yet

- Wellfix DP2000 Sand Consolidation Job OutlineDocument2 pagesWellfix DP2000 Sand Consolidation Job OutlineYougchu LuanNo ratings yet

- Reporting Requirements - Drilling OperationsDocument2 pagesReporting Requirements - Drilling OperationsYougchu LuanNo ratings yet

- Material Support Base For Drillng OperationsDocument2 pagesMaterial Support Base For Drillng OperationsYougchu LuanNo ratings yet

- Production Testing RequirementsDocument2 pagesProduction Testing RequirementsYougchu LuanNo ratings yet

- Recommended Procedure For Preparation of Hec Gravel-Pack SlurryDocument3 pagesRecommended Procedure For Preparation of Hec Gravel-Pack SlurryYougchu LuanNo ratings yet

- Management of ChangeDocument2 pagesManagement of ChangeYougchu LuanNo ratings yet

- Setting Up Drilling OfficesDocument2 pagesSetting Up Drilling OfficesYougchu LuanNo ratings yet

- Preliminary Planning, Exploration Drilling, New VentureDocument2 pagesPreliminary Planning, Exploration Drilling, New VentureYougchu LuanNo ratings yet

- Production Testing - HSE RequirementsDocument3 pagesProduction Testing - HSE RequirementsYougchu Luan100% (1)

- List of Situations For Which Contingency Plans Are RequiredDocument1 pageList of Situations For Which Contingency Plans Are RequiredYougchu LuanNo ratings yet

- Job Description - Technical Assistant DrillingDocument1 pageJob Description - Technical Assistant DrillingYougchu LuanNo ratings yet

- Job Description - Technical AssistantDocument1 pageJob Description - Technical AssistantYougchu LuanNo ratings yet

- Summary Treatment of Mud ContaminantsDocument1 pageSummary Treatment of Mud ContaminantsYougchu LuanNo ratings yet

- Legal Requirements - UKDocument1 pageLegal Requirements - UKYougchu LuanNo ratings yet

- Job Description - DrillerDocument1 pageJob Description - DrillerYougchu LuanNo ratings yet

- Job Description - Drilling Engineer (Operations)Document1 pageJob Description - Drilling Engineer (Operations)Yougchu LuanNo ratings yet

- Total Hardness - Water Based Mud TestingDocument1 pageTotal Hardness - Water Based Mud TestingYougchu LuanNo ratings yet

- Solids Control Equipment - Mud CleanersDocument1 pageSolids Control Equipment - Mud CleanersYougchu LuanNo ratings yet

- Job Description - Construction SuperintendentDocument1 pageJob Description - Construction SuperintendentYougchu LuanNo ratings yet

- 1 Problems Setting The Packer: Contingency ProceduresDocument1 page1 Problems Setting The Packer: Contingency ProceduresYougchu LuanNo ratings yet

- Job Description - Completion SuperintendentDocument1 pageJob Description - Completion SuperintendentYougchu LuanNo ratings yet

- Solids Control Equipment - Flowlines and Settling TanksDocument1 pageSolids Control Equipment - Flowlines and Settling TanksYougchu LuanNo ratings yet

- Solids Control Equipment - Desanders and DesiltersDocument2 pagesSolids Control Equipment - Desanders and DesiltersYougchu LuanNo ratings yet

- Water Cycle With Google MapsDocument5 pagesWater Cycle With Google MapsGrayson AllensworthNo ratings yet

- Sample/practice Exam 2010, Questions and Answers Sample/practice Exam 2010, Questions and AnswersDocument14 pagesSample/practice Exam 2010, Questions and Answers Sample/practice Exam 2010, Questions and AnswersEilyza Aballa100% (1)

- Module 4-Green Building: Leed NBC Griha Ishrae Igbc Zero Energy BuildingsDocument117 pagesModule 4-Green Building: Leed NBC Griha Ishrae Igbc Zero Energy BuildingsAmrutha PavithranNo ratings yet

- Coleman Above Gound Steel Frame PoolDocument12 pagesColeman Above Gound Steel Frame PoolSam IamNo ratings yet

- 05 Water SupplyDocument6 pages05 Water SupplyMukhammadjonNo ratings yet

- The Landscapes of Spain's Coasts and Islands: Unit OutlineDocument6 pagesThe Landscapes of Spain's Coasts and Islands: Unit OutlineIsabel M Moya SeguraNo ratings yet

- BCIAP infiltration gallery design manual part 4 guideDocument45 pagesBCIAP infiltration gallery design manual part 4 guideEddie BurnsNo ratings yet

- Learners Academy: Chemistry - XI (Chap - 02, Test - 02 - Liquid)Document2 pagesLearners Academy: Chemistry - XI (Chap - 02, Test - 02 - Liquid)Umaid Ali KeerioNo ratings yet

- Curriculum Vitae: Personal Information Mohamed Nazeer IbrahimDocument5 pagesCurriculum Vitae: Personal Information Mohamed Nazeer IbrahimjennyNo ratings yet

- What is pH? Understanding Acidic and Basic SolutionsDocument18 pagesWhat is pH? Understanding Acidic and Basic SolutionsDanielle GunterNo ratings yet

- GebremariamDocument10 pagesGebremariamnasridin abdiNo ratings yet

- E-MSDS-051 Acido Clorhidrico Al 0.2 NDocument6 pagesE-MSDS-051 Acido Clorhidrico Al 0.2 Nnpsm92No ratings yet

- A Comparison of Some Methods of EstimatiDocument8 pagesA Comparison of Some Methods of EstimatiElfarricha SamiNo ratings yet

- Water Scarcity in Small Towns: A Case Study of DeogharDocument29 pagesWater Scarcity in Small Towns: A Case Study of DeogharAngelo Gardiola MaglinaoNo ratings yet

- SIR Brochure FinalDocument14 pagesSIR Brochure Finalankitmehta131No ratings yet

- Fossil Powerplant Water Treatment BrochureDocument3 pagesFossil Powerplant Water Treatment BrochuresamarthNo ratings yet

- Technical Publication No. 85-5 A Guide To Scs Runoff ProceduresDocument112 pagesTechnical Publication No. 85-5 A Guide To Scs Runoff ProceduresBernard OwusuNo ratings yet

- Chemical Magic ExperimentsDocument4 pagesChemical Magic ExperimentsAleckz MinaNo ratings yet

- The Effect and Impact of Uncontrolled Pollution On AutosavedDocument8 pagesThe Effect and Impact of Uncontrolled Pollution On AutosavedCedric PacerNo ratings yet

- Aggrey 2008Document9 pagesAggrey 2008arif setiawanNo ratings yet

- Finefocus 800: Instruction ManualDocument64 pagesFinefocus 800: Instruction ManualMURAT ORMANNo ratings yet

- Environmental Engineering: Engr. Zaid YahyaDocument22 pagesEnvironmental Engineering: Engr. Zaid YahyaZaid Yahya100% (1)

- Design and Operation of An Ultrafiltration Plant For The Production of Drinking Water Out of The River ScheldtDocument7 pagesDesign and Operation of An Ultrafiltration Plant For The Production of Drinking Water Out of The River ScheldtNuyul FaizahNo ratings yet

- Reading Material Passage 1: Questions 1-10: Read The Following PassageDocument2 pagesReading Material Passage 1: Questions 1-10: Read The Following PassageDương Thị Mỹ MỹyNo ratings yet

- Line DiagramDocument3 pagesLine Diagramvaranasirk1No ratings yet

- Astm D4952 - 09Document2 pagesAstm D4952 - 09Muhannad NasifNo ratings yet