Professional Documents

Culture Documents

Full Catalogue

Uploaded by

LLCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Full Catalogue

Uploaded by

LLCopyright:

Available Formats

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

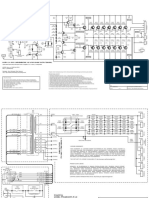

F05

1

I CHOOSE HOW I FIND

THE RIGHT TOOL!

Looking for a product reference or description,

a f a mily of tool s, a t echni cal solution ? Our cat alogue i s

speci ally designed to help you in your sear ch and

i mmedi at ely guide you towards t he infor mation you

r equi r e.

THE FACOM CATALOGUE

CONTAI NS OVER 8,000 REFERENCES !

MORE THAN 800 PAGES to help you make t he right

choi ce !

A GENUINE TOOLING

encyclopedia built around

3 DIFFERENT

TYPES OF INDEX:

SPARE PARTS I NDEX

ALPHABETICAL I NDEX

ALPHANUMERICAL I NDEX

A DOCUMENT THAT IS BOTH USEFUL AND PRACTICAL

TO

FI

PO

FI

RA

TO

SC

PL

M

HA

SA

PU

AI

M

AE

EL

EL

AU

page 878

S

P

E

C

I

A

L

I

S

T

T

O

O

L

I

N

G

G

E

N

E

R

A

L

T

O

O

L

I

N

G

W

O

R

K

S

T

A

T

I

O

N

S

a

n

d

T

O

O

L

S

T

O

R

A

G

E

page 880

page 889

Online catalogue on www.facom.com

Section

number

Technical

characteristics

Section

Chapter

Spare

part

SPECIAL

PRESENTATION

New product

Technical details

in tabular and

drawing form

1

9

S

E

C

T

I

O

N

S

d

i

v

i

d

e

d

i

n

t

o

3

C

H

A

P

T

E

R

S

Heading

Product features

Reference

Technical

focus

Description

101

.1105

1106

Pump

Cylinder

Cylinde

V

Swivel vice

Wall cabinet

Wall cabin

GENERAL TOOLING

Dimensions

mm

C

mm

P

mm

D

g

D

g

PULLERS WITH 2 SLIDING LEGS

2-LEG PULLERS FOR ENGINEERING APPLICATIONS

The design of this puller is particularly suited to cage-type ball bearings.

Pressure is distributed over the two races, and the tool can be used for both shaft and

housing fits.

Depending on ball diameter, different pairs of spherical tips should be selected from one of

the three sets available.

Positioning tips in bearing

Bend back cage

ends.

Insert appropriate tips into

ball race, then give a

quarter turn to lock.

Screw beam

rods into tips.

OPERATION

Online catalogue on www.facom.com

Comprising:

- 3 pairs of tips: 9 - 11 12.5 mm diameter

- Beam U.53K1.

Spread 40 to 110 mm diameter.

For ISO bearings 6206 to 6211, 6303 to 6307,

6403 to 6404.

Supplied in a plastic case BP.115 with tray PL.71A.

Weight 1.84 kg.

LIGHT ENGINEERING PULLER KIT

U.14 PULLERS

Puller with 2 slim legs and self-gripping spring

mechanism.

Designed for battery terminals.

For bearings 6 to 18 mm diameter.

Comprising:

- 4 expansion pullers U.49P1 to U.49P4.

- 1 slide hammer U.49L.

Plastic case BP115.

Complete with tray PL.445.

Dimensions

mm

LIGHT ENGINEERING PULLER KIT

Drill 2 diametrically

opposite holes.

M

Safety

N

E

W

P002-003 NOIR.qxd 15/09/04 09:29 Page 2

2

3

4

5

6

7

8

9

0

2

3

4

5

6

7

8

9

F05

TOOL SETS 26

FIXED WORKSHOP FURNITURE 76

PORTABLE STORAGE 90

FIXED-SIZE & ADJUSTABLE WRENCHES 110

RATCHETS, SOCKETS 148

TORQUE CONTROL 234

SCREWDRIVERS, KEYS and BITS 272

PLIERS, CIRCLIP PLIERS, LOCK-GRIP PLIERS 332

MEASURING, MARKING-OUT, METROLOGY 376

HAMMERS, IMPACT TOOLS 422

SAWING, DRILLING & CUTTING 446

PULLERS 478

AIR TOOLS 508

MAINTENANCE, PIPEWORK & RIVETING 542

AEROSPACE 564

ELECTRICITY 594

ELECTRONICS 650

AUTOMOTIVE 700

Online catalogue on www.facom.com

MOBILE WORKSHOP FURNITURE 58

P002-003 NOIR.qxd 15/09/04 09:29 Page 3

Elektronischer Katalog unter www.facom.com

F05 F05

The enti r e FACOM t ea m i s uni t ed in t he sa me obj ective: to off er

you long-l asting tool s t hat allow you to work quickly and safely.

Because we cont rol all st ages of production process f rom design t hrough

to f abri cation, we ar e abl e to continually ensur e t hat we meet t hese

commi t ment s.

Thi s new cat alogue brings toget her our enti r e r ange of product s in a

singl e document and includes all our l at est innovations such as our new

inspection l a mp using Led t echnology.

We have sought to produce a compr ehensive, pr acti cal cat alogue t hat will

serve as a TOOL for our customer s. All our new product s ar e t her efor e

syst emati cally identifi ed to give t hem added prominence.

The men and women of FACOM ar e al ways avail abl e and r eady to help.

Our demonst r ation t rucks and sal es t ea ms meet t housands of customer s

each year to pr esent our latest innovations and assi st t hem in finding t he

tool best sui t ed to t hei r needs.

The quality and intelligence of our products, plus t he quality of our

service ar e now, mor e t han ever, t he foundations on whi ch FACOM i s buil t

and will continue to guide i t s effor t s for t he year s to come.

The FACOM t ea m

A WORD FROM FACOM

QUALITY AND INTELLIGENCE

OF OUR PRODUCTS !

Online catalogue on www.facom.com

p004new 15/09/04 15:02 Page 1

2

4

8

26

16

110

868

564

872

889

880

878

876

896

FACOM :

F05 - 1

GENERAL CONTENTS

IT'S

REASSURING !

QUALITY . . . . . . . . . . . . . . . . . . . . . . . . .4 INNOVATION . . . . . . . . . . . . . . . . . . . . . . . . . 6

SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . .5 PRODUCTIVITY . . . . . . . . . . . . . . . . . . . . . . . 7

LOCAL SALES PRESENCE . . . . . . . . . . . . .8 TRAINING . . . . . . . . . . . . . . . . . . . . . . . . . .13

DISTRIBUTION NETWORK . . . . . . . . . . . .9 SPECIAL TOOLS . . . . . . . . . . . . . . . . . . . . . .14

INTERNET . . . . . . . . . . . . . . . . . . . .10 / 11 AFTER SALES SERVICE . . . . . . . . . . . . . . . . .15

TECHNICAL INFORMATION . . . . . . . . . . .12

DESIGNER and MANUFACTURER

FACOM'S VALUES

FACOM CUSTOMER SERVICE

WORKSTATIONS & STORAGE

NEW FROM FACOM

GENERAL TOOLING

STANDARDS AND SELECTION GUIDE

SPECIALIST TOOLING

SAFETY RECOMMENDATIONS

ALPHANUMERICAL INDEX

ALPHABETICAL INDEX

SPARE PARTS INDEX

FACOM GUARANTEE

YOUR FACOM CONTACTS

AT YOUR

SERVICE...

Online catalogue on www.facom.com

IT'S

PRACTICAL !

IT'S FAST !

IT'S

USEFUL !

p01.qxd 15/09/04 15:04 Page 1

2 - F05

DESIGNER

RESEARCH AND DEVELOPMENT:

THE CONSTANT SEARCH FOR

USEFUL I NNOVATIONS

The mi ssion of FACOM R & D i s to meet your t hr ee main

needs: to save time, to simplify your task and to guarantee

your safety. All of our tool s t her efor e developed to meet very

st ri ct perfor mance, st r engt h, saf ety and ergonomi c cri t eri a.

Torque driver:

Accuracy exceeds ISO 6789 requirements.

Reliable for over 50 000 operations.

Automatic release for optimum handling.

Our CAD system brings the power of the

computer to the design process.

A MANUFACTURER THAT IS

ALSO A DESIGNER,

ITS REASSURING.

12 DESIGN OFFICES

1 RESEARCH CENTRE

4 COUNTRIES

FRANCE, ITALY, UK, USA

250 ENGINEERS + TECHNICIANS

Online catalogue on www.facom.com

P02-03 noir.qxd 15/09/04 09:56 Page 2

F05 - 3

MANUFACTURER

PRODUCTION:

PROVIDI NG THE HIGHEST

LEVEL OF QUALITY

The quali ty of your tool s i s ensur ed t hrough t he

specialisation of our f actori es according to t he tool s

produced and manuf acturing t echniques used : cold forging,

hot forging, heat t r eat ment , met rology, surf ace t r eat ment ,

pl asti c inj ection, et c.

The number one producer of hand tool s in Europe,

FACOM has been producing tool s for mor e t han 8 5 year s.

Sustained investment in machines and automation

systems, has allowed i t to maint ain i t s l ead in t echnology

and cost cont rol .

A r ar e exper ti se t hat allows us to produce saf e, high-

perfor mance tool s t hat provide t he best value for money.

Heat treatment

Automated plier production

Cold-forging of pliers

Roller cabinet production robot

Screwdriver production

12 SPECIALISED PRODUCTION SITES

FRANCE, ITALY, UK, USA

Online catalogue on www.facom.com

P02-03 noir.qxd 15/09/04 09:56 Page 3

4 - F05

FACOMS VALUES / QUALITY

FACOM PRODUCTS FOR

UNBEATABLE

STRENGTH

FACOM produces tool s of a univer sal

r ecogni sed quali ty.

We const antly st rive to achi eve t he

highest standards of perfor mance,

strength and safety. We ar e ext r emely

rigorous in our choi ce of mat eri al s and

surf ace t r eat ment s. We only use manuf acturing

processes t hat we fully control.

Our obj ective: your tot al , per manent and long-l asting

sati sf action.

THE HIGHEST STANDARDS

FOR YOUR COMFORT

The st andards t hat FACOM set s i t self exceed t he

st ri ct est offi ci al st andards. Our product s undergo

int ensive t esting under extreme conditions.

The standard for FACOM is to exceed the

standards.

FOR ME,

GENUINE QUALITY

IS LASTING QUALITY !

Static resistance of the Jet roller cabinet:

800 kg (no tricks used).

FACOMS sheathed pliers are able to resist chemical

attack from a very wide range of products (illustrated:

aeronautical hydraulic fluid).

The FACOM guarantee applies to all tools used under normal

conditions and allows for their repair or replacement according

to circumstances.

This guarantee is an integral part of the reputation of FACOM

tools and is the best guarantor of user satisfaction.

See

P 63

FACOMS VALUES QUALITY SECURITY INNOVATION PRODUCTIVITY

p. 4 to 7 p. 5 p. 6 p. 7

Online catalogue on www.facom.com

P04-05 noir.qxd 15/09/04 09:57 Page 4

F05 - 5

FACOMS VALUES / SAFETY

SAFETY

IS MY

NO. 1 PRIORITY

Our t wo overriding priorities ar e to const antly

protect you in your every working moment and t he safety

of your working envi ronment .

These obj ectives ar e pr esent f rom t he very st ar t of t he

design process, and influence bot h tool ergonomi cs and t he

choi ce of mat eri al s. Each product must t hen successfully

compl et e a seri es of operating, endurance and destructive

tests befor e i t can be market ed.

A comfor t abl e tool r educes t he ri sk of injury, accident

and of da mage to t he i mmedi at e envi ronment .

Jet roller cabinet: anti-shock protection on

each corner, rounded cabinet base, worktop with

retaining lip and drawer catch to prevent

accidental opening. [page 63]

You can rely on the safety of Facom

tools, whatever your working

conditions.

FACOMS VALUES QUALITY SECURITY INNOVATION PRODUCTIVITY

p. 4 to 7 p. 4 p. 6 p. 7

PROTECTION OF

THE USERS

ENVIRONMENT

USER

SAFETY

See safety

recommendations

P 872

Online catalogue on www.facom.com

P04-05 noir.qxd 15/09/04 09:57 Page 5

6 - F05

FACOM

I NNOVATES FOR I NCREASED EFFICIENCY

At Facom, t he essenti al function of innovation i s to

speed up your work, make your job easi er and ensur e your

saf ety.

Every day we t est new procedur es, new product s, new

designs, new mat eri al s and new met hods

to help you

i mprove your

effi ci ency.

GOOD INNOVATION

IS USEFUL

INNOVATION

The Facom Vision System: a cordless

inspection lamp using a new, ultra-resistant

LED-based lighting technology. Its very

powerful white light shows up every detail.

[page 17]

Hose remover DM.44.

The ideal alternative to a screwdriver and pliers.

No risk of injury !

[page 22]

The hose remover is a typical

example of a product

developed to meet a need

that was found to exist

among users.

Our researchers took account

of your requirements to

develop this new product

using our CAD system.

The tool was then thoroughly

tested in use before entering

into production.

It easily loosens and removes

hoses without damage, while at

the same time protecting the

user.

It guarantees a saving of time.

The FACOM

product development

process

Online catalogue on www.facom.com

FACOMS VALUES QUALITY SECURITY INNOVATION PRODUCTIVITY

p. 4 to 7 p. 4 p. 5 p. 7

FACOMS VALUES / INNOVATION

P06-07noir.qxd 15/09/04 09:58 Page 6

F05 - 7

FACOMS VALUES / PRODUCTIVITY

FOR ME, THE

RIGHT TOOL

MEANS GREATER

EFFICIENCY

Over and above its aesthetic

aspects, ergonomics also

contributes to the quality of

your tools, their strength, their

comfort and safety of use.

Design, for FACOM, is more than

just making things look nice !

Improved

performance

through ergonomics

We ar e const antly concerned wi t h finding new ways in

whi ch to help you i mprove your effi ci ency.

Productivi ty necessarily involves opti mi sing t he cost s of

pur chasing and using tool s. It al so i mpli es effi ci ent

organi sational solutions and work aids.

The infor mative cont ent of our ext ensive document ation

and t he continuing t r aining provided in our t r aining cent r es or

at your pl ace of work al so help you to be mor e effi ci ent .

FACOM:

the best for the best.

Series 306 torque wrench: for

maintenance and production applications.

Remains accurate to within 2% over

25 000 cycles.

Exceeds ISO 6789 specifications.

No risk of accidental alteration.

Large range of bits and accessories.

Designed for intensive use.

[page 19]

The calibration certificate: as a

COFRAC accredited organization

(No. 2-1305), FACOM is able to provide

a torquing tool calibration service.

You receive an official certificate

for each tool.

ACCREDITATION

NO. 2-1305

FORCE

TORQUE WRENCHES

CALIBRATION

The Jet roller cabinet helps you to

work faster and to find the right

tool in the right place at the right

time.

Modular, movable drawer

partitions. Easy to move.

Pictograms identifying the

drawer contents. Accessories

attach without tools.

[page 63]

Online catalogue on www.facom.com

FACOMS VALUES QUALITY SECURITY INNOVATION PRODUCTIVITY

p. 4 to 7 p. 4 p. 5 p. 6

P06-07noir.qxd 15/09/04 09:58 Page 7

8 - F05

I LIKE IT WHEN FACOM

VISITS ME !

Thei r MISSION: to be available, to li st en and to

get to know you by vi si ting you at your workpl ace.

Our OBJECTIVE: to answer your queries, provide

advice, allow you to try out tool s and help you to

sel ect t he tool s best sui t ed to your needs.

FACOM, the importance of customer contact.

Over 200 TECHNICAL &

SALES ADVISORS and

160 DEMONSTRATION TRUCKS

FACOMS GUIDI NG PRI NCIPLE IS TO BE ATTENTIVE TO

YOUR NEEDS AT ALL TI MES.

150,000 visits per year.

150,000 opportunities to l earn

your needs, analyse t hem and anti cipat e

t hem in order to provide concr et e solutions.

CUSTOMER SERVICE / LOCAL SALES PRESENCE

Online catalogue on www.facom.com

CUSTOMER LOCAL SALES DISTRIBUTION

SERVICE PRESENCE NETWORK INTERNET

p. 8 to 15 p. 10-11

P08-09 noir.qxd 15/09/04 10:02 Page 8

Catalogue lectronique sur www.facom.fr F05 - 9

THROUGH MY DISTRIBUTOR, I

HAVE ACCESS TO THE ENTIRE

FACOM RANGE !

FACOM di st ributor s ar e chosen for

t hei r professionalism, t hei r friendliness

and spi ri t of servi ce.

They ar e the int er medi ari es through whi ch

all our servi ces (delivery, wide r ange of it ems

from stock, infor mation, tool war r anty, aft er

sal es, customer advi ce, et c.) ar e made

avail abl e to our customers.

They ar e genuine partners.

The di st ributor s exhibition spaces

provide a pl ace wher e you can di scover our

tool s, touch many of t hem and obt ain

document ary infor mation.

Dealing with your distributor is like

dealing directly with FACOM.

Espace FACOM di spl ay uni t

Point-of-sale advertising industry's

European Silver Oscar in 2004

CUSTOMER SERVICE / DISTRIBUTION NETWORK

With 12 SUBSIDIARIES in Europe, Asia and North America,

and products distributed in over 100 COUNTRIES by

5,500 DISTRIBUTORS.

FACOM is always close to you and your needs.

CLOSER TO YOU !

Online catalogue on www.facom.com

TECHNICAL SPECIAL AFTER SALES

INFORMATION TRAINING TOOLS SERVICE

p. 12 p. 13 p. 14 p. 15

P08-09 noir.qxd 15/09/04 10:02 Page 9

10 - F05

CUSTOMER SERVICE / INTERNET

THE INFORMATION I WANT

WHEN I WANT IT, 24 HOURS

A DAY !

Whet her you ar e a user or a di st ributor, t he

Facom web si t e f acom. com i s avail abl e 24 HOURS a

day, 7 DAYS a week, r eady to provide infor mation,

advi ce or ot her servi ces.

JOIN 60,000 OTHER MONTHLY

VISITORS online at facom.com !

DIRECT ACCESS to your ON LINE cat alogue.

Use t he sear ch engine to i mmedi at ely find t he tool s t hat

ar e of int er est to you.

Online catalogue on www.facom.com

CUSTOMER LOCAL SALES DISTRIBUTION

SERVICE PRESENCE NETWORK INTERNET

p. 8 to 15 p. 8 p. 9

P10-11 noir.qxd 15/09/04 10:16 Page 10

F05 - 11

CUSTOMER SERVICE / INTERNET

Key figur es / hi story of FACOM

3 6 0 vi r tual vi si t of a demonst r ation

t ruck

Addr esses of all our subsidi ari es

worldwide

Download everyt hing you need:

t echni cal l eafl et s, inst ructions, pages

f rom t he cat alogue

FACOM news: dat es of t r ade f ai r s,

new product announcement s, et c.

Tr ade sections: to di scover

t he ext ent of FACOM's exper ti se

Looking for a specifi c product ?

Need a customi sed solution?

Leave us a message

in t he cont act section.

Thi s section cont ains det ail s of ALL THE SERVICES t hat

make t he diff er ence: standardisation / selection guide,

safety recommendations, torque control guide, special

automotive tools / vehicle applications guide.

The PRODUCTS of t he YEAR: a showcase of innovation

to give you t he edge.

Online catalogue on www.facom.com

TECHNICAL SPECIAL AFTER SALES

INFORMATION TRAINING TOOLS SERVICE

p. 12 p. 13 p. 14 p. 15

P10-11 noir.qxd 15/09/04 10:16 Page 11

12 - F05

CUSTOMER SERVICE / TECHNICAL INFORMATION

OVER 20,000 QUERIES DEALT WITH PER YEAR

The queri es we r eceive cover a very wide r ange of subj ect s: r equest s for t echni cal infor mation,

for assi st ance finding product s or spar e par t s, for pr acti cal tips, t echni cal document ation, et c.

Our advi sor s ar e al ways abl e to provide t he cor r ect answer wi t h t he help of numerous dat a and

infor mation bases.

Don't hesi t at e to cont act your usual FACOM r epr esent ative. See pages 896-897.

Contacting FACOM, it's as easy as a phone call.

THE SOLUTION

IS ALWAYS

JUST A PHONE

CALL AWAY!

Online catalogue on www.facom.com

CUSTOMER LOCAL SALES DISTRIBUTION

SERVICE PRESENCE NETWORK INTERNET

p. 8 to 15 p. 8 p. 9 p. 10-11

P12-13 noir.qxd 15/09/04 10:14 Page 12

F05 - 13

CUSTOMER SERVICE / TRAINING

FACOM HELPS

ME IMPROVE

MY SKILLS

TRAINING CENTRES

TO DEVELOP YOUR SKILLS

We off er ext ernal or in-house t r aining progr a mmes

in a number of ar eas including, for exa mpl e,

torque cont rol , pulling tool s, workst ation l ayout , et c.

Online catalogue on www.facom.com

TECHNICAL SPECIAL AFTER SALES

INFORMATION TRAINING TOOLS SERVICE

p. 14 p. 15

P12-13 noir.qxd 15/09/04 10:14 Page 13

14 - F05

CUSTOMER SERVICE / SPECIAL TOOLS

When your work involves very speci ali sed appli cations, t he only

option i s to design custom tool s.

FACOM's engineer s will exa mine wi t h you t he best way to

customi se your tool s or obt ain a par ti cul ar fini sh.

Together we will design the tools of tomorrow.

Don't hesi t at e to cont act your usual FACOM r epr esent ative. See

pages 896-897.

NEED A CUSTOMISED

TOOL?

JUST CALL FACOM !

Online catalogue on www.facom.com

CUSTOMER LOCAL SALES DISTRIBUTION

SERVICE PRESENCE NETWORK INTERNET

p. 8 to 15 p. 8 p. 9 p. 10-11

P14-15 noir.qxd 15/09/04 10:09 Page 14

F05 - 15

CUSTOMER SRVICE CLIENTS / AFTER SALES SERVICE

WITH FACOMYOU'RE

GUARANTEED A REAL

AFTER SALES SERVICE.

When you buy a FACOM product , t he guar ant ee cover s

much mor e t han just i t s quali ty. That i s our fi r st

commi t ment .

It al so ext ends to t he tool in use. Our r epl acement or

r epai r poli cy will t hus ensur e your complete satisfaction,

even if your tool i s sever al year s old!

We have al so int roduced fixed rates for repairing tools

t hat ar e subj ect to wear (e. g. : ai r tool s, et c.). These

r epai r s ar e guar ant eed for a period of 6 mont hs f rom

t he ti me of compl etion.

With FACOM, you are guaranteed peace of mind.

Be on the safe side:

Torque control

services

Online catalogue on www.facom.com

TECHNICAL SPECIAL AFTER SALES

INFORMATION TRAINING TOOLS SERVICE

p. 12 p. 13

ACCREDITATION

NO. 2-1305

FORCE

TORQUE WRENCHES

CALIBRATION

As a COFRAC accredited (No.

2-1305) organisation, FACOM

is able to:

inspect or calibrate your

torque control tools,

calibrate your torque meters,

preset your production tools.

Calibration certificates and

inspection reports are drawn up

for each tool.

P14-15 noir.qxd 15/09/04 10:09 Page 15

1952

1960

1964

1968

1987

1992

1946

16 - F05

FACOM is the first company to offer its customers a total

guarantee on its tools, on condition only that they are used

under normal conditions.

Patent application for large capacity,

powerful 500 SERIES LOCK-GRIP PLIERS.

First reversible ratchet using the patented 72-tooth

mechanism providing a 5 interval.

New U.306 pullers system consisting of a single body and

changeable inside or outside pullers (2 or 3 legs) secured

in position by means of a locknut.

A highly versatile, very safe tool. Patented.

1

ST

DEMONSTRATION TRUCK

TOTAL GUARANTEE

500 SERIES LOCK-GRIP PLIERS

REVERSIBLE RATCHET 151

PULLERS U.306

IVE ALWAYS KNOWN FACOM

TO BE INVENTIVE !

I DISCOVER

MORE ABOUT

FACOM

EVERY DAY !

Creation of oil-filter wrench U.46 which for the first time

allows filters to be removed with one hand. Patented.

OIL-FILTER WRENCH U.46

The first modular system for storing tools in the drawers

of roller cabinets, chests and workbenches.

Access to tools is greatly improved and missing tools are

more easily recognised.

MODULAR STORAGE

FACOM launches its first demonstration trucks.

An effective, innovative way to listen to users and

provide better advice by meeting them directly

where they work.

Online catalogue on www.facom.com

P16-17noirqxd 15/09/04 10:39 Page 16

1918 1924 1929

F05 - 17

NEW PRODUCTS

Powerful, directional 500 LUX beam

No risk of burns

Extremely solid

Splash water protected

5 hours continuous operation in cordless version

Highly portable

Long-life

Led technology

Protection

class IP 64

5 hours continuous

operation in cordless

version

Impact, dropping,

crushing and

solvent-resistant structure

FACOM VISION SYSTEM INSPECTION LAMP WITH LED TECHNOLOGY

ITS REALLY

SOLID

Cr eation of FACOM. Fi r st tool : Fi r st Facom cat alogue. Incr eased 500 product references

wrench 101 wrench (railway maintenance) r ange and fi r st oppor tuni ty of choi ce First series of Vanadium wrenches.

Ref. 779.CL Page 832

ADVANTAGES

Online catalogue on www.facom.com

P16-17noirqxd 15/09/04 10:39 Page 17

1945 1948 1950

18 - F05

Ref. K.152, K...HB Page 205

COMPACT 3/ 4 REVERSIBLE RATCHET + 3/ 4 OGV SOCKETS

IT ALLOWS ME TO

REACH EVERYWHERE !

ADVANTAGES

Lighter and more manoeuvrable

Increased accessibility

Two-handed grip for high torques

Secure connection between ratchet and sockets or

accessories

New monobloc

ratchet with a

compact head and

narrower sockets

Push-button socket locking/

release mechanism

Ergonomic

handle

Ergonomic

aluminium-

coated grips

Opening

adjustment knob

Progressive release

trigger mechanism

Solutions for Fi r st r at chet wr enches An incr easingly

all torque probl ems compr ehensive r ange

Ref. T5.L65 Page 366

LOCK-GRIP PLIERS

ITS LIKE

A THIRD HAND !

One-handed clamping and release action

Smooth-action release trigger

Good finger clearance between lever and work surface

Sheaths resistant to weld spatter

Capacity 65 or 100 mm diameter

ADVANTAGES

Online catalogue on www.facom.com

P18-19noir.qxd 15/09/04 10:57 Page 18

1950 1953 1956

F05 - 19

NEW PRODUCTS

Comfort

grip

Increased

contact

surface

Unobstructed access

to worm screw for

ease of adjustment

Tapered jaw tips

Very high accuracy

mechanism

(+/- 2% at factory)

Torque

pre-setting

device locks in

position

Delivered

with inspection

report

Cr eation of ISORYL scr ewdriver. Tool stor age r ange Int roduction of specifi c tool s

An i mprovement over wood handl es (cases, chest s, cabinet s) for automotive appli cations

Ref. 113A... Page 141

THE WORM SCREW ADJUSTMENT

IS EASY TO REACH !

Better transfer of load

to the hand

Easy to adjust on the nut

Better access

Shaped for easy cleaning

ADJUSTABLE WRENCH

ADVANTAGES

Ref. series 306 Page 241

SERIES 306 WRENCH

IT PROVIDES LONG-

LASTING ACCURACY !

Performance exceeds ISO6789 specifications

Durable accuracy

No risk of accidentally altering settings

Large range of bits and accessories

ADVANTAGES

Online catalogue on www.facom.com

P18-19noir.qxd 15/09/04 10:57 Page 19

1960 1964 1968

20 - F05

Wide scale

range 10-1,100 N.m

Designed for

workshop use

For testing torque

wrenches

7

th

cat alogue FACOM becomes t he No. 1 50 demonstration trucks

produced in 100,000 copi es hand tool producer in Fr ance in Europe

TORQUE METER

The meter imposes the ISO 6789 testing procedure.

Four operating modes according to the type of tool

(ISO, PEAK, STORAGE or TRACKING)

Print-out of Inspection Reports using a standard

printer directly connected to the meter

Optimised investment

Very strong

IVE DECIDED

TO GO ISO !

Ref. E.5000 Page 268

ADVANTAGES

MULTI-IMPACT TOOLS

Installing and reinstalling hard or fragile parts

Ideal for maintenance

Operator protection and comfort

Easy-to-install tips

IT AVOIDS DAMAGING

THE PARTS, AND PROTECTS

THE USER TOO !

Ref. 217.GJ1 Page 433

ADVANTAGES

Online catalogue on www.facom.com

Concept of

interchangeable tips

of differing materials

High-strength

threaded

connection Ergonomic

shock-absorbing

sheathed handle

P20-21noir.qxd 15/09/04 10:32 Page 20

1973 1978 1985

F05 - 21

NEW PRODUCTS

m

Bi-material nylon +

PVC mesh design

Injected

polypropylene

case

Anti-slip studs

Closed by

clip-fastened

strap

Designed for

stacking

que

250,000 copi es of FACOM assi st ance vehi cl e fi r st New compr essor U77:

t he cat alogue i ssued appear s at motor r acing t r acks tot al saf ety

Heavy-duty

hinges

High impact and solvent-resistance

Lightweight

Not harmful for the working environment

Anti-slip studs

Can be stacked for easy storage

BP SERIES PLASTIC CASES

ITS REALLY

TOUGH !

Ref. BP.109 Page 107

ADVANTAGES

Guaranteed durability

Spaces designed to suit tool sizes

Comfort of use

Folds to a compact size

Fast and safe

NEW GENERATION ROLL BAGS

I ALWAYS HAVE

IT ON ME !

Ref. 2013.M Page 55

ADVANTAGES

Online catalogue on www.facom.com

s

P20-21noir.qxd 15/09/04 10:32 Page 21

1987 1988 1990

22 - F05

Compact,

ergonomic handle

Moving jaw

controlled by

multi-thread

adjustment

screw

Instant access to diagnostic

functions and automatic range

selection in AC and DC

Gripping pins

120,000 user visits New gener ation "Chrono" New pat ent ed OGV pat t ern socket s and

each year r ange of roll er cabinet s wr enches t hat prot ect tool s and nut s

HOSE REMOVER

Easily loosens and removes hoses

Covers all makes of car (from 24 to 53 mm)

Avoids damage to the hose

Can be operated with one hand

Protects the user

AT LAST, JUST THE

TOOL I NEEDED !

Ref. DM.44 Page 714

ADVANTAGES

AUTOMOTIVE DIGITAL MULTIMETER

Simple and quick to operate

Automotive-specific functions:

Lambda probe and injection time

Can detect very small values of leakage

current (0.02 A)

Option: compact current clamp

IVE NEVER SEEN A METER

THATS SO EASY TO USE !

Ref. 714 Page 823

ADVANTAGES

Online catalogue on www.facom.com

Multimeter designed

for automobile

maintenance

P22-23noir.qxd 15/09/04 11:05 Page 22

1992 1992 1993

I

N

D

U

S

T

R

I

A

L

D

E

S

I

G

N

JANUS

1994

AWARD

F05 - 23

NEW PRODUCTS

Easier to carry,

reduces fatigue

Hands free

Anti-tilt system

Airline approved

Optimum tool storage

Runoff resistant

Covers 80% of MacPherson assemblies

50% cost reduction

Speeds up fork set installation and removal

Suitable for use on new generation springs

Compatible with conventional forks,

suitable for all makes.

ge

Large storage

area

Large diameter

wheels

Seals

mounted

between lid

and bin

3-position

trolley

Injected

composite

material

New body with spacer

allowing 2 different fork

positions

Interchangeable forks

New system of hinged

multiple diameter

forks

SPRING COMPRESSOR WITH MULTIPLE-DIAMETER FORKS

WORKSTATION TROLLEY + CASE

nd New AEROSPACE and MICROTECH

scr ewdriver wins t he Point-of-Sal e adver ti sing indust rys European

MICROTECH

r anges Janus de lindustrie

award Golden Oscar for t he F92 cat alogue l aunch

MY WORKSTATION GOES

WHERE I GO !

I REALLY SAVE TIME !

Ref. U.89M2JM Page 760

Ref. BV.29P + BV.C1 Page 98

ADVANTAGES

ADVANTAGES

Online catalogue on www.facom.com

ned

P22-23noir.qxd 15/09/04 11:05 Page 23

1994 1994 1994

I

N

D

U

S

T

R

I

A

L

D

E

S

I

G

N

JANUS

1994

AWARD

24 - F05

High strength

drawer slides

Carry tray

Very large

diameter wheels

(160 mm)

Bumpers on all

four corners and

rounded cabinet

base

Non-protruding

large-diameter wheels

(125 mm), 2 fixed, 2 castors

with brake

Fold-down

steering

handle

Drawer release mechanism

incorporated within

the handle

Cr eation of sl eeve case JP9 New ERGOTWIST

Janus de lindustrie award

for storing hexagon keys bi-mat eri al scr ewdriver for hacksaw f r a me 601

Ultra-heavy-duty worktop of galvanized steel

on a 24 mm thick wooden base

Static resistance 1 tonne

Drawer capacity up to 40 kg

Enables you to move your tools close to a

vehicle or machine and avoid endless to-ing

and fro-ing.

HEAVY MECHANICAL WORKSTATION

ITS ALREADY BEEN LOADED

TO OVER A TONNE !

Ref. JET.TS6 (red) - JET.TS6G (grey) Page 74

ADVANTAGES

JET ROLLER CHEST

Protects the operator and his environment

Catch to prevent accidental drawer opening

Compact design

Easy to store

Easily crosses obstacles (large diameter wheels)

I DECIDE WHERE

I WORK !

Ref. JET. CR4 (red) - JET. CR4G (grey)

Page 73

ADVANTAGES

Online catalogue on www.facom.com

P24-25noir.qxd 15/09/04 11:24 Page 24

1996 2001 2005

F05 - 25

NEW PRODUCTS

Quick single-handed opening

Ambidextrous

Liner lock safety catch and

2 stage release

Comfortable

Durable

Supplied with a leather case

ors

Ergonomic monobloc brushed

stainless steel handle

Thumbscrew

2 stage liner lock

release

Universal

hanging hook

4 large diameter

wheels, including

2 castors with a

brake

Stainless

steel blade

12C27

Galvanized steel worktop

Corner

bumpers

Panel with system for

securing hammers and

dressers.

Other tools can be

freely hung using the

CKS system

PANEL-BEATING / BODY REPAIR WORKSTATION

FACOM KNIFE

T5 new concept t rigger-r el ease FACOM, offi ci al suppli er of Cat alogue FO5,

lock-grip pli er s Scuderi a FERRARI al ways innovative

THE FIRST WORKSTATION DESIGNED

SPECIFICALLY FOR BODY

REPAIR PERSONNEL!

I ALWAYS HAVE IT

ON ME!

Ref. 840LE Page 475

Ref. CR.T4 Page 801

ADVANTAGES

ADVANTAGES

Online catalogue on www.facom.com

Two pull-out trays with non-slip mats giving access

to a bin for storing heavy tools

Very large storage capacity

Easy to maintain, high strength

Very manoeuvable

P24-25noir.qxd 15/09/04 11:24 Page 25

S

E

R

V

A

N

T

E

2

9

1

5

N E W. . .

26 - F05 On-line catalogue available on www.facom.com

2013.M

(page 55)

DRIVERS KIT

2061.EM41A

(page 49)

SET OF TOOLS WITH

CONTAINER CASE

section 01 EN-VALIDEE 10/09/04 13:32 Page 26

Tool sets

WORKSTATI ONS AND TOOL STORAGE

BUILDING MAINTENANCE AND

GENERAL SERVICING SETS

Fitting and maintenance 52

Plumbing and sanitation 53

Refrigeration and

Air-conditioning 54

ELECTROMECHANICAL ENGINEERING

Electromechanical

engineering 46

Office equipment and

computer servicing 50

PLANT AND EQUIPMENT

MAINTENANCE SETS

Park and garden equipment 40

Handling equipment 41

Farming equipment 42

Construction plant 44

MECHANICAL ENGINEERING SETS

28

DRIVERS SETS

55

FACOM MODULAR SYSTEM

56

l

For electrical tool sets, see section 17, p 627 - 648.

l

For electronic tool sets, see section 18, p 694.

For standards, selection guide - safety recommendations, see p 868. F05 - 27

section 01 EN-VALIDEE 10/09/04 13:32 Page 27

Description Qty F

WORKSTATIONS AND TOOL STORAGE

28 - F05 On-line catalogue available on www.facom.com

MECHANICAL ENGINEERING

512-PIECE MECHANICAL TOOL SET

CM.160A

Metric and inch set supplied loose, as below.

D: 113 kg.

F Qty Description

40.JE18 18 Combination wrenches 6 to 24 mm

40.JU12 12 Combination wrenches 1/4" to 15/16"

40 6 Combination wrenches 26 to 30 and 32 mm

40LA 4 Long combination wrenches 33, 35, 36, 38 mm

39.JE10T 10 Roll set of short combination wrenches: 3.2 to 11 mm

44.JE12 12 Open-end wrenches 6 to 32 mm

31.JE6T 6 Roll set of low profile open-end wrenches 8 to 19 mm

43.JE5T 5 Roll set of flare-nut wrenches 7 to 19 mm

113A 2 Adjustable wrenches 6" and 10"

115A.100 1 Pin wrench

S.440AP 29

L 1/2" socket set 8 to 32 mm and accessories

(in a case)

S.40U 7 Rack socket-set: 3/8" to 21/32"

S.41U 6 Rack socket-set: 11/16" to 1"

S.141A 1 Long hinged handle L 1/2"

R.425AP 26

L 1/4" socket set 5.5 to 14 mm and accessories

(in a case)

R.40U 11 11-piece rack socket-set 3/16" to 9/16"

K.432E 16

L 3/4" truck socket set 30 to 55 mm and accessories

(in a case)

NS.500A 26 L1/2" impact socket set 8 to 27 mm and accessories

NS.265M 21 Impact screwdriver set with bits

S.306A200 1 Torque wrench 40 to 200 Nm with ratchet

AZ 3

Screwdrivers for slotted heads 3.5x75 - 4x100 -

5.5x100 mm

AZF 2 Screwdrivers for slotted heads 6.5x100 - 8x200 mm

AZFH.10X200 1 Screwdriver for slotted heads with hexagonal shoulder

AZP 3 Screwdrivers for Phillips J heads no. 0-1-2

AZPH.3X150 1 Screwdriver for Phillips head no. 3 with hexagonal shoulder

AZD 3 Screwdrivers for PozidrivJ heads no. 0-1- 2

AZDH.3X150 1 Screwdriver for Pozidriv head no. 3 with hexagonal shoulder

AY.VE 3

1000V insulated screwdrivers for slotted heads

3.5x100 - 4x100 - 6.5x100 mm

APY.VE 2

1000V insulated screwdrivers for Phillips J heads:

1x100 - 2x125

701A 1 Multifunction tester

AV.HT1B 1 Voltage tester screwdriver 90 to 480V

AF 1 Screw starter for slotted heads

AZB 2

Short screwdrivers for slotted heads 4x40 and 6.5x40

mm

AZPB 2

Short screwdrivers for PhillipsJ heads 1x40 and 2x40

mm

82H.JP9 9 Sleeve set of hexagonal keys: 1.5 to 10 mm

83SH.JP9 9 Sleeve set of spherical head hex keys: 1.5 to 10 mm

89.JP8 8 TorxJ keys no. 10 to 45

82H.JU10 10 Wallet set of hexagonal keys 1/16" to 3/8"

84E.J1 5 Set of nut spinners, in a case

AEF.J1 5 Micro-Tech screwdriver set

94A.JE13T 13 Roll set of nut spinners 3.2 to 14 mm

187.18CPE 1 Sheathed combination pliers

192.16CPE 1 Sheathed "piano wire" diagonal cutters

180.CPE 1 Sheathed multigrip pliers

182A.CP 1 "Mammoth" multigrip pliers

185.20CPE 1 Sheathed straight half-round nose pliers

195.CPE 1 Sheathed angled half-round nose pliers

189.17CPE 1 Sheathed round-nose pliers

188.16CPE 1 Sheathed flat-nose pliers

495.22EL 1 Heavy-duty end nippers

191A.18EL 1 Compound-leverage end nippers

T5.L65 1 Trigger-release lock-grip pliers (with aluminium sheathing)

501 1 Large-capacity lock-grip pliers

507A 1 Compact lock-grip pliers

114.8 1 Lock-grip wrench

521.200 Sliding jaw lock-grip clamp

169E 3 Inside-circlip pliers 13 - 18 - 23

167E 3 Outside-circlip pliers 13 - 18 - 23

405.12MT 1 Precision diagonal cutters

401.MT 1 Extra-long flat-nose precision pliers

403.MT 1 Precision angled half-round nose pliers

800A 1 Tape measure 2m

234 1 Scriber

DELA.1051.05 1 Rule 300 mm

804 1 Feeler gauge 19 blades

311A.50 1 Level with protractor dial

809.J2 8 Measuring and scribing instrument kit

603E 1 Hacksaw frame

660A.8 10 Bimetal saw blades

STG 5 File set

235.1 1 Square punch

883B 1 Right-cut scroll shears

237.A 1 Thread restoring tool

270.A 1 Spark-plug brush

996.5 1 Steel cable cutters

990.A1 1 Bolt cropper

881 1 Multi-purpose serrated shears

887A 1 Nibbler

231 1 Three-square scraper

222.J19 19 Box set of drill-bits 1 to 10 mm

221.227J2 41 Tap and die set (in a case)

830A.10 1 Ratchet tool-holder

830A.10L 1 Long ratchet tool-holder

AS.12LTP180T2 12 Wallet set of 12 needle files, 180 mm

245.J2 26 Set of gasket punches in a case

200A 2 Riveting hammers, 24 and 32 mm

208A.32CB 1 Plastic-tip mallet

212A.40 1 Dead-blow hammer

247.G 5 Sheathed nail sets: 2 - 3 - 4 - 6 - 8 mm

249.G 5 Sheathed drift punches: 2 - 3 - 4 - 6 - 8 mm

265.20 1 Constant-profile cape chisel

254A.10 1 Precision cape chisel

263.18 1 Flat chisel

256.4 1 Precision centre punch 4 mm

257.G 1 Automatic centre punch

134.18 1 Pipe wrench

138.30 1 Strap wrench, 4"

238A.32 1

239.EA 1

239 1

Y.RIV1 1

374A.20 1

269 1

777A.230 1

U.306A140 1

U.306G2 3

U.306M 1

U.306A1 1

U.302 1

285.JS10 10

840.1 1

841 1

162 1

844.R 1

449.Z3A 1

848B.100 1

661626 1

827B 1

834.R2 1

Pipe cutter, 3 to 32 mm and 1/8" to 1 1/4"

Inch dies

"Refrigeration" flaring tool (in a case)

Riveting kit

Double-action oil can

Crowbar

Inspection lamp

3-leg puller d 7 to 140 mm

Legs for inside application

Slide hammer

Nut/washer subassembly

3-leg puller 6 to 80 mm

Set of stud extractors

Electricians knife with wire stripper

Electricians scissors

Automatic wire stripper/cutter

Retractable utility knife

Terminal crimping kit

Instant-heat 100 W soldering iron

Reel of solder wire

Magnetic retriever

Articulated mirror

1

section 01 EN-VALIDEE 10/09/04 13:32 Page 28

On-line catalogue available on www.facom.com F05 - 29

Supplied with set of hooks CKS.2230-160.

D: 423 kg.

MECHANICAL ENGINEERING

SET CM.160A

WITH 8-DRAWER ROLLER CABINET

JET.8G AND CHEST C4-2G

JET8.M160A

D: 239 kg.

SET CM.160A WITH WORKBENCH

2230.BB1 AND CABINET 2210

4

0

%

2230.BBM160A

1

0

%

WORKSTATIONS AND TOOL STORAGE

section 01 EN-VALIDEE 10/09/04 13:32 Page 29

MECHANICAL ENGINEERING

F Qty Description

40.JE18 18 Combination wrenches 6 to 24 mm

40 6 Combination wrenches 26 to 30 and 32 mm

40L 4 Long combination wrenches 33, 35, 36, 38 mm

39.JE10T 10 Roll set of short combination wrenches 3.2 to 11 mm

44.JE12 12 Open-end wrenches 6 to 32 mm

43.JE5T 5 Roll set of flare-nut wrenches 7 to 19 mm

31.JE6T 6 Roll set of low profile open-end wrenches 8 to 19 mm

113A.C 2 Adjustable wrenches 6" and 10"

115A.100 1 Pin wrench

S.440AP 29

L 1/2" socket set 8 to 32 mm and accessories

(in a case)

S.141A 1 Long hinged handle L 1/2"

R.425AP 26

L 1/4" socket set 5.5 to 14 mm and accessories

(in a case)

K.432E 16

L 3/4" truck socket set 30 to 55 mm and accessories

(in a case)

S.306A200 1 Torque wrench 40 to 200 Nm with ratchet

AZ 3

Screwdrivers for slotted heads 3.5x75 - 4x100 -

5.5x100 mm

AZF 2 Screwdrivers for slotted heads 6.5x100 - 8x200 mm

AZFH.10X200 1 Screwdriver for slotted heads with hexagonal shoulder

AZP 3 Screwdrivers for PhillipsJ heads no. 0 - 1 - 2

AZPH.3X150 1 Screwdriver for Phillips head no. 3 with hexagonal shoulder

AZD 3 Screwdrivers for PozidrivJ heads no. 0 - 1 - 2

AZDH.3X150 1 Screwdriver for Pozidriv head no. 3 with hexagonal shoulder

AY.VE 3

1000V insulated screwdrivers for slotted heads

3.5x100 - 4x100 - 6.5x150 mm

APY.VE 2

1000V insulated screwdrivers for PhillipsJ heads

1x100 - 2x125 mm

701A 1 Multifunction tester

AV.HT1B 1 Voltage tester screwdriver 90 to 480V

AF 1 Screw starter for slotted heads

82H.JP9 9 Sleeve set of hexagonal keys 1.5 to 10 mm

83SH.JP9 9 Sleeve set of spherical head hex keys: 1.5 to 10 mm

89.JP8 8 TorxJ keys no. 10 to 45

AEF.J1 5 Micro-Tech screwdriver set

187.18CPE 1 Sheathed combination pliers

192.16CPE 1 Sheathed "piano wire" diagonal cutters

180.CPE 1 Sheathed multigrip pliers

182A.CP 1 "Mammoth" multigrip pliers

185.20CPE 1 Sheathed straight half-round nose pliers

195.CPE 1 Sheathed angled half-round nose pliers

189.17CPE 1 Sheathed round-nose pliers

188.16CPE 1 Sheathed flat-nose pliers

495.22EL 1 Heavy-duty end nippers

191A.18EL 1 Compound-leverage end nippers

501 1 Large-capacity lock-grip pliers

507A 1 Compact lock-grip pliers

521.200 1 Sliding jaw lock-grip clamp

F Qty Description

T5.L65 1 Trigger-release lock-grip pliers (with aluminium sheathing)

169E 3 Inside-circlip pliers 13 - 18 - 23

167E 3 Outside-circlip pliers 13 - 18 - 23

405.12MT 1 Precision diagonal cutters

800A 1 Tape measure 2m

234 1 Scriber

DELA.1051.05 1 Rule 300 mm

804 1 Feeler gauge 19 blades

603E 1 Hacksaw frame

660A.8 10 Bimetal saw blades

STG 5 File set

235.1 1 Square punch

883B 1 Right-cut scroll shears

237.A 1 Thread restorer

270.A 1 Spark-plug brush

996.5 1 Steel cable cutters

881 1 Multi-purpose serrated shears

231 1 Three-square scraper

222.J19 19 Box set of drill-bits 1 to 10 mm

221.227J2 41 Tap and die set (in a case)

830A.10 1 Ratchet tool-holder

830A.10L 1 Long ratchet tool-holder

200A 2 Riveting hammers 24 and 32 mm

208A.32 1 Heavyweight mallet

212A.40 1 Dead-blow hammer

247.G 5 Sheathed nail sets: 2 - 3 - 4 - 6 - 8 mm

249.G 5 Sheathed drift punches: 2 - 3 - 4 - 6 - 8 mm

265.20 1 Constant-profile cape chisel

254A.10 1 Precision cape chisel

263.18 1 Flat chisel

256.4 1 Precision centre punch 4 mm

257.G 1 Automatic centre punch

134.18 1 Pipe wrench

Y.RIV1 1 Riveting kit

374A.20 1 Double-action oil can

269 1 Crowbar

U.306A140 1 3-leg puller d 7 to 140 mm

U.306G2 3 Legs for inside application

U.306M 1 Slide hammer

U.306A1 1 Nut/washer subassembly

840.1 1 Electricians knife with wire stripper

841 1 Electricians scissors

162 1 Automatic wire stripper/cutter

844.R 1 Retractable utility knife

827B 1 Magnetic retriever

834.R2 1 Articulated mirror

8145A 1 Vernier caliper to 1/10 mm

673838 1 Pre-insulated terminal crimping pliers

329-PIECE MECHANICAL TOOL SET

CM.150A

Metric set supplied loose, as below.

D: 97,5 kg.

" Service plus "

This symbol means that 20% extra container space remains

available when the tools are in place

2

0

%

2

0

%

30 - F05 On-line catalogue available on www.facom.com

WORKSTATIONS AND TOOL STORAGE

section 01 EN-VALIDEE 10/09/04 13:32 Page 30

On-line catalogue available on www.facom.com F05 - 31

SET CM.150A WITH 7-DRAWER ROLLER

CABINET JET.7G AND

JET.C4-2G CHEST

JET7.M150A

D: 218, 5 kg.

SET CM.150A WITH WORKBENCH 2230.BB1

AND CABINET 2210

2230.BBM150A

Supplied with a set of hooks CKS.2230-150.

D: 407,5 kg.

5

0

%

3

0

%

MECHANICAL ENGINEERING

WORKSTATIONS AND TOOL STORAGE

section 01 EN-VALIDEE 10/09/04 13:33 Page 31

MECHANICAL ENGINEERING

F Qty Description

40.JE18 18 Combination wrenches 6 to 32 mm

40 6 Combination wrenches 26 to 30 and 32 mm

39.JE10T 10 Roll set of short combination wrenches: 3.2 to 11 mm

44.JE12 12 Open-end wrenches 6 to 32 mm

113A.10C 1 Adjustable wrench 10"

S.440AP 29

L 1/2" socket set 8 to 32 mm and accessories

(in a case)

R.425AP 26

L 1/4" socket set 5.5 to 14 mm and accessories

(in a case)

AZ 3

Screwdrivers for slotted heads 3.5x75 - 4x100 -

5.5x100

AZF 2 Screwdrivers for slotted heads 6.5x100 - 8x200 mm

AZFH.10X200 1 Screwdriver for slotted heads with hexagonal shoulder

AZP 3 Screwdrivers for PhillipsJ heads no. 0 - 1 - 2

AZPH.3X150 1 Screwdriver for Phillips head no. 3 with hexagonal shoulder

AZD 3 Screwdrivers for PozidrivJ heads no. 0 - 1 - 2

AZDH.3X150 1 Screwdriver for Pozidriv head no. 3 with hexagonal shoulder

AY.VE 3

1000V insulated screwdrivers for slotted heads

3.5x100 - 4x100 - 6.5x150

APY.VE 2

1000V insulated screwdrivers for PhillipsJ heads 1x100

- 2x125

701A 1 Multifunction tester

AV.HT1B 1 Voltage tester screwdriver 90 to 480V

82H.JP9 9 Sleeve set of hexagonal keys 1.5 to 10 mm

89.JP8 8 TorxJ keys no. 10 to 45

187.18CPE 1 Sheathed combination pliers

192.16CPE 1 Sheathed "piano wire" diagonal cutters

180.CPE 1 Sheathed multigrip pliers

185.20CPE 1 Sheathed straight half-round nose pliers

188.16CPE 1 Sheathed flat-nose pliers

F Qty Description

495.22EL 1 Heavy-duty end nippers

501 1 Large-capacity lock-grip pliers

T5.L65 1 Trigger-release lock-grip pliers (with aluminium sheathing)

169E 3

Trigger-release lock-grip pliers (with aluminium shea-

thing)

167E 3 Outside-circlip pliers 10 - 25, 18 - 60 and 32 - 100 mm

800A 1 Tape measure 2m

234 1 Scriber

DELA.1051.05 1 Rule 300 mm

804 1 Feeler gauge 19 blades

603E 1 Hacksaw frame

660A.8 10 Bimetal saw blades

STG 5 File set

235.1 1 Square punch

270.A 1 Spark-plug brush

200A 2 Riveting hammers 24 and 32 mm

208A.32CB 1 Plastic-tip mallet

247.G 2 Sheathed nail sets 2 and 4 mm

249.G 2 Sheathed drift punches 2 and 4 mm

254A.10 1 Precision cape chisel

263.18 1 Flat chisel

256.4 1 Precision centre punch 4 mm

134.18 1 Pipe wrench

Y.RIV1 1 Riveting set

374A.20 1 Double-action oil can

840.1 1 Electricians knife with wire stripper

841 1 Electricians scissors

834.R2 1 Articulated mirror

184-PIECE MECHANICAL TOOL SET

CM.140A

Supplied loose, as below.

D: 34,5 kg.

32 - F05 On-line catalogue available on www.facom.com

WORKSTATIONS AND TOOL STORAGE

section 01 EN-VALIDEE 10/09/04 13:33 Page 32

On-line catalogue available on www.facom.com F05 - 33

SET CM.140A WITH 7-DRAW ROLLER CABINET

JET.7G

3

0

%

JET7.M140A

D119,5 kg.

178-PIECE INCH TOOL SET WITH ENGINEERS

HAMMER

CU.140A

As CM.140A, but with inch sizes replacing metric

tools (as detailed below).Supplied loose

D: 30,6 kg.

F Qty Description

40.JU17 17 Combination wrenches 1/4" to 1 1/4"

39.JU10T 10 Roll set of short combination wrenches: 1/8" to 7/16"

44.JU8T 8 Open-end wrenches 1/4"x5/16" to 1"1/8

44 3

Open-end wrenches: 7/16"x1/2", 9/16"x5/8" and

11/16"x3/4"

S.440AUP 24

Socket set L 1/2" : 3/8" to 1 1/4" and accessories

(in a case)

R.425AUP 26

L 1/4" socket set 7/32" to 9/16", bits

and accessories (in a case)

82H.JU10 10 Wallet set of hexagonal keys 1/16" to 3/8"

800A.EX 1 Tape measure 2m/6 ft

804.U 1 Precision feeler gauges to 1/10000"

202A 2 Engineers hammers 1/2" and 1"

SET CM.140A WITH 4-DRAWER

CHEST BT.64

5

%

2074.M140A

SET CM.140A WITH WORKBENCH 2230.BB1,

CABINET 2210

2230.BBM140A

Supplied with set of hooks CKS.2230-140.

D: 269,5 kg.

6

0

%

D: 63,7 kg.

MECHANICAL ENGINEERING

WORKSTATIONS AND TOOL STORAGE

section 01 EN-VALIDEE 10/09/04 13:33 Page 33

WORKSTATIONS AND TOOL STORAGE

34 - F05 On-line catalogue available on www.facom.com

MECHANICAL ENGINEERING

F Qty Description

40.JE18 18 Combination wrenches 6 to 24 mm

44.JE12 12 Open-end wrenches 6 to 32 mm

113A.10C 1 Adjustable wrench 10"

S.440AP 29

L 1/2" socket set 8 to 32 mm and accessories

(in a case)

R.425AP 26

L 1/4" socket set 5.5 to 14 mm and accessories

(in a case)

AZ 3 Screwdrivers for slotted heads 3.5x75 - 4x100 -5.5x100

AZF 2 Screwdriver for slotted heads 6.5x100 - 8x200 mm

AZP 3 Screwdrivers for PhillipsJ heads no. 0 - 1 - 2

AZD 3 Screwdrivers for PozidrivJ heads no. 0 - 1 - 2

AY.VE 2

1000V insulated screwdrivers for slotted heads 4x100 -

6.5 x150 mm

APY.VE 2 1000V insulated screwdrivers for PhillipsJ heads no. 1 and 2

AV.HT1B 1 Voltage tester screwdriver 90 to 480V

82H.JP9 9 Sleeve set of hexagonal keys 1.5 to 10 mm

89.JP8 8 TorxJ keys no. 10 to 45

187.18CPE 1 Sheathed combination pliers

192.16CPE 1 Sheathed "piano wire" diagonal cutters

F Qty Description

180.CPE 1 Sheathed multigrip pliers

185.20CPE 1 Sheathed straight half-round nose pliers

188.16CPE 1 Sheathed flat-nose pliers

501 1 Large-capacity lock-grip pliers

169E 2 Inside-circlip pliers 13 - 18

167E 2 Outside-circlip pliers 13 - 18

800A 1 Tape measure 2m

603E 1 Hacksaw frame

660A.8 10 Bimetal saw blades

STG 5 File set

235.1 1 Square punch

200A.32 1 Riveting hammer 32 mm

208A.32CB 1 Plastic-tip mallet

247.G 2 Sheathed nail sets 2 - 4 mm

249.G 2 Sheathed drift punches 2 - 4 mm

254A.10 1 Precision cape chisel

263.18 1 Flat chisel

256.4 1 Precision centre punch 4 mm

840.1 1 Electricians knife with wire stripper

137-PIECE INCH TOOL SET WITH ENGINEERS HAMMER

CU.130A

As CM.130A, but with inch sizes replacing metric

tools (as below).

Supplied loose.

D: 30,7 kg.

F Qty Description

40.JU12 12 Combination wrenches 1/4" to 15/16"

44.JU8T 8 Roll set of open-end wrenches 1/4"x5/16" to 1 1/8"x1 1/4"

44 3 Open-end wrenches 7/16"x1/2", 9/16"x5/8" and 11/16"x3/4"

S.440AUP 24

L 1/2" socket set 3/8" to 1 1/4" and accessories

(in a case)

F Qty Description

R.425AUP 26

L 1/4" socket set 7/32" to 9/16", bits

and accessories (in a case)

82H.JU10 10 Wallet set of hexagonal keys 1/16" to 3/8"

800A.EX 1 Tape measure 2m/6 ft

220A.1" 1 Engineers hammer

148-PIECE MECHANICAL TOOL SET

CM.130A

Metric set supplied loose, as below.

D: 21,7 kg.

section 01 EN-VALIDEE 10/09/04 13:33 Page 34

On-line catalogue available on www.facom.com F05 - 35

D: 50,9 kg.

3

0

%

SET CM.130A IN 4 DRAWER

CHEST BT.64

2074.M130A

1

5

%

SET CM.130A WITH ROLLER CHEST

2092A

2092.M130A

SET CM.130A

WITH 6-DRAWER ROLLER CABINET JET.6G

JET6.M130A

D: 102,7 kg.

SET CM.130A WITH 6-DRAWER ROLLER

CABINET JET.6G

2082.M130A

Supplied with set of hooks CKS.2082-130.

D: 57,5 kg.

2

0

%

4

0

%

D: 54,2 kg

MECHANICAL ENGINEERING

WORKSTATIONS AND TOOL STORAGE

section 01 EN-VALIDEE 10/09/04 13:33 Page 35

MECHANICAL ENGINEERING

128-PIECE METRIC MECHANICAL TOOL SET

CM.120A

Metric set supplied loose, as below.

D: 20,2 kg.

F Qty Description

40.JE14 14 Combination wrenches 7 to 24 mm

44.JE12 12 Open-end wrenches 6 to 32 mm

113A.10C 1 Adjustable wrench 10"

RS.440E 54 1/4" and 1/2" sockets and accessories (in a case)

AZ 3

Screwdrivers for slotted heads 3.5x75 - 4x100 -

5.5x100

AZF 2 Screwdrivers for slotted heads 6.5x150 - 8x200 mm

AZP 3 Screwdrivers for PhillipsJ heads no. 0 - 1 - 2

AZD 3 Screwdrivers for PozidrivJ heads no. 0 - 1 - 2

AY.4X100VE 1 1000V insulated screwdriver for slotted heads 4 mm

APY.1X100VE 1 1000V insulated screwdriver for Phillips heads no. 1

82H.JP9 9 Sleeve set of hexagonal keys 1.5 to 10 mm

187.18CPE 1 Sheathed combination pliers

192.16CPE 1 Sheathed "piano wire" diagonal cutters

180.CPE 1 Sheathed multigrip pliers

F Qty Description

188.16CPE 1 Sheathed flat-nose pliers

501 1 Large-capacity lock-grip pliers

169E.18 1 Inside-circlip pliers

167E.18 1 Outside-circlip pliers

800A 1 Tape measure 2m

603E 1 Hacksaw frame

660A.8 10 Bimetal saw blades

STG 5 File set

235.1 1 Square punch

200A.32 1 Riveting hammer 32 mm

208A.32CB 1 Plastic-tip mallet

247.G 2 Sheathed nail sets 2 - 4 mm

249.G 2 Sheathed drift punches 2 - 4 mm

256.4 1 Precision centre punch 4 mm

840.1 1 Electricians knife with wire stripper

93-PIECE INCH TOOL SET WITH ENGINEERS HAMMER

CU.120A

As CM.120A, but with inch sizes replacing metric

tools. No L 1/4" sockets and acessories (as below)

Supplied loose

D: 18,9 kg.

36 - F05 On-line catalogue available on www.facom.com

WORKSTATIONS AND TOOL STORAGE

1 Sheathed straight half-round nose pliers 185.20CPE

F Qty Description

40.JU12 12 Combination wrenches 1/4" to 15/16"

44.JU8T 8 Open-end wrenches 1/4"x5/16" to 1"1/8

S.440AUP 24

L 1/2" socket set 3/8" to 1 1/4" and accessories (in a

case)

F Qty Description

82H.JU10 10 Wallet set of hexagonal keys 1/16" to 3/8"

800A.EX 1 Tape measure 2m/6 ft

2002A.1" 1 Engineering hammer

section 01 EN-VALIDEE 10/09/04 13:33 Page 36

On-line catalogue available on www.facom.com F05 - 37

1

0

%

2070.M120A

SET CM.120A WITH 2-DRAWER CHEST

BT.62A

SET CM.120A WITH ROLLER CHEST

2092A

2092.M120A

SET CM.120A WITH 5-DRAWER ROLLER

CABINET JET.5G

JET5.M120A

5

0

%

SET CM.120A

WITH CABINET 2082

3

0

%

2082.M120A

Supplied with set of hooks CKS.2082-120.

D: 53,9 kg.

4

0

%

D: 39,2 kg. D: 52,7 kg.

D: 89,2 kg.

MECHANICAL ENGINEERING

WORKSTATIONS AND TOOL STORAGE

section 01 EN-VALIDEE 10/09/04 13:33 Page 37

MECHANICAL ENGINEERING

84-PIECE MECHANICAL TOOL SET

CM.110A

Supplied loose, as below.

D: 15 kg.

F Qty Description

40.JE14 14 Combination wrenches 7 to 24 mm

113A.10C 1 Adjustable wrench 10"

RS.430E 30 1/4" and 1/2" sockets and accesories (in a case)

AZ 3

Screwdrivers for slotted heads 3.5x75 -

4x100 - 5.5x100 mm

AZF 2 Screwdrivers for slotted heads: 6.5x150 - 8x200 mm

AZP 3 Screwdrivers for PhillipsJ heads no. 0 - 1 - 2

AZD.2X125 1 Screwdrivers for PozidrivJ heads

AY.4X100VE 1 1000V insulated screwdriver for slotted heads 4 mm

82H.JP9 9 Sleeve set of hexagonal keys 1.5 to 10 mm

187.18CPE 1 Sheathed combination pliers

192.16CPE 1 Sheathed "piano wire" diagonal cutters

180.CPE 1 Sheathed multigrip pliers

185.20CPE 1 Sheathed straight half-round nose pliers

F Qty Description

188.16CPE 1 Sheathed flat-nose pliers

501 1 Large-capacity lock-grip pliers

169E.18 1 Inside-circlip pliers

167E.18 1 Outside-circlip pliers

800A 1 Tape measure 2m

603E 1 Hacksaw frame

660A.8 10 Bimetal saw blades

235.1 1 Square punch

200A.32 1 Riveting hammer 32 mm

208A.32CB 1 Plastic-tip mallet

247.G 2 Sheathed nail sets 2 - 4 mm

249.G 2 Sheathed drift punches 2 - 4 mm

256.4 1 Precision centre punch 4 mm

840.1 1 Electricians knife with wire stripper

84-PIECE INCH TOOL SET WITH ENGINEERS HAMMER

CU.110A

As CM.110A, but with inch sizes replacing metric tools (as below).Supplied loose.

D: 14.75 kg.

F Qty Description

40.JU12 12 Combination wrenches 1/4" to 15/16"

S.440AUP 24

L 1/2" socket set 3/8" to 1 1/4" and accessories

(in a case)

SET CM.110A

WITH JET.CR4G ROLLER CHEST

CR4.M110A

D: 86 kg.

5

0

%

F Qty Description

82H.JU10 10 Wallet set of hexagonal keys 1/16" to 3/8"

800A.EX 1 Tape measure 2m/6 ft

220A.1" 1 Engineers hammer

SET CM.110A

IN 5-TRAY BOX BT.11A

2050.M110A

D: 19,5 kg.

N

E

W

38 - F05 On-line catalogue available on www.facom.com

WORKSTATIONS AND TOOL STORAGE

section 01 EN-VALIDEE 10/09/04 13:34 Page 38

F Qty Description

192.16CPE 1 Diagonal cutters

On-line catalogue available on www.facom.com F05 - 39

N

E

W

CM.100A

Supplied loose, as below. D: 10,4 kg.

F Qty Description

40.JE14 14 Combination wrenches 7 to 24 mm

S.430ADP 26

Socket set 10 to 32 mm and accessories

(in a case)

AZ 3

Screwdrivers for slotted heads 3.5x75 - 4x100 -

5.5x100 mm

AZF 2 Screwdrivers for slotted heads 6.5x100 - 8x200 mm

AZP 3 Screwdrivers for PhillipsJ heads no. 0 -1 - 2

AY.4X100VE 1 1000V insulated screwdriver for slotted heads 4 mm

187.18CPE 1 Sheathed combination pliers

180.CPE 1 Sheathed multigrip pliers

800A 1 Tape measure 2m

603E 1 Hacksaw frame

660A.8 10 Bimetal saw blades

200A.32 1 Riveting hammer 32 mm

247.G 2 Sheathed nail sets 2 - 4 mm

249.G 2 Sheathed drift punches 2 - 4 mm

56-PIECE INCH TOOL SET WITH ENGINEERS

HAMMER

CU.100A

As CM.100A, but with inch sizes replacing metric

tools (see below). Supplied loose.

D: 14.9 kg.

F Qty Description

40.JU12 12 Combination wrenches 1/4" to 15/16"

S.440AUP 24

L 1/2" socket set 3/8" to 1 1/4" and accessories

(in a case)

202A.1" 1 Engineers hammer

800A.EX 1 Tape measure 2m/6 ft

SET CM.100A

WITH 5-TRAY BOX BT.11A

4

0

%

2050.M100A

39-PIECE MECHANICAL TOOL SET

CM.LT3

Supplied loose, as below.

D: 4,65 kg.

F Qty Description

40.JE9 9 Combination wrenches 7 to 19 mm

75.JN10 10 Open-socket wrenches 8 to 19 mm

AZ 2 Round-blade screwdrivers 3.5x100 - 5.5x150 mm

AZD 2 Screwdrivers for PozidrivJ heads no. 1 and 2

82H.JP9 9 Sleeve set of hexagonal keys 1.5 to 10 mm

192.16G 1 Diagonal cutters

187.18G 1 Combination pliers

170A 1 Multigrip pliers

200.F32 1 Riveting hammer

249 2 Drift punches 4 - 6 mm

263.18 1 Flat chisel

SET CM.LT3

WITH 2-TRAY BOX BT.6A

2060.LT3

SET CM.LT3

WITH 5-TRAY BOX BT.11A

2050.LT3

5

0

%

1

5

%

D: 7,8 kg. D: 9,5 kg.

D: 14,9 kg.

N

E

W

MECHANICAL ENGINEERING

WORKSTATIONS AND TOOL STORAGE

60-PIECE METRIC MECHANICAL TOOL SET

section 01 EN-VALIDEE 10/09/04 13:34 Page 39

WORKSTATIONS AND TOOL STORAGE

40 - F05 On-line catalogue available on www.facom.com

PARK AND GARDEN SETS

Mowers,

Mini-tractors,

Bush trimmers,

Chainsaws.

SERVICE AND REPAIR OF:

Set contains metric and inch tools

to cover all popular makes.

118-PIECE TOOL SET

CM.JA

Supplied loose, as below.

D: 18,4 kg.

F Qty Description

40.JE18 18 Combination wrenches 6 to 24 mm

40.JU12 12 Combination wrenches 1/4" to 15/16"

34.JT8 8 Minature open-end wrenches 3.2 to 8 mm

75.JE16 16 Open-socket wrenches 8 to 24 mm

75.JU10 10 Open-socket wrenches 5/16" to 7/8"

75 4 Open-socket wrenches 6 and 7 mm, 1/4" and 15/16"

AZ 4

Screwdrivers for slotted heads 3.5x75 - 4x100 -

5.5x100 - 6.5x150 mm

AZF 2 Svcrewdrivers for slotted heads 8x150 - 10x200 mm

AZP 3 Screwdrivers for PhillipsJ heads no. 1 - 2 - 3

82H.JP9 9 Sleeve set of hexagonal keys 1.5 to 10 mm

82H.JU10 10 Wallet set of hexagonal keys 1/16" to 3/8"

188.20CPE 1 Sheathed flat-nose pliers

195.CPE 1 Sheathed angled half-round nose pliers

192.18CPE 1 Sheathed diagonal cutters

170A 1 Multigrip pliers

500 1 Lock-grip pliers

179E 2 Inside-circlip pliers d 13 - 18

177E 2 Outside-circlip pliers d 13 - 18

200A 2 Riveting hammers 26 and 40 mm

248.JT7 7 Long drift punches 2 to 6 - 8 - 10 mm

256.4 1 Precision centre punch 4 mm

262A.18 1 Constant profile chisel

800A 1 Tape measure 2m

804 1 Feeler gauge 19 blades

2046.JA

SET CMJA

WITH 5-TRAY BOX BT.13A

3

0

%

D: 23,9 kg.

PLANT AND EQUIPMENT MAINTENANCE SETS

section 01 EN-VALIDEE 10/09/04 13:34 Page 40

On-line catalogue available on www.facom.com F05 - 41

378A 1 Side-lever gease gun

194.17VE 1 1000V insulated wire stripper

Full set of tools for any warehouse or site without a workshop.

REPAIR AND MAINTENANCE OF COMBUSTION ENGINE OR

ELECTRIC MOTOR DRIVEN HANDLING PLANT

For multimeter, see

section 17.

For tools for internal combustion

engines, see section 19

HANDLING EQUIPMENT SETS

F Qty Description

40.JE11 11 Combination wrenches 7 to 19 mm

42 3 Flare nut wrenches 11x13 - 14x17 - 19x22 mm

113A.12C 1 Adjustable wrench 12"

RS.430E 30 1/4" and 1/2" sockets and accessories (in a case)

AZ 3

Screwdrivers for slotted heads 4x100 - 5.5x100 -

6.5x150 mm

AZF.8X150 1 Screwdriver for slotted heads 8 mm

AY.VE 2 1000V insulated screwdrivers 3.5x100 - 5.5x150 mm

AZP 3 Screwdrivers for PhillipsJ heads no. 1 - 2 - 3

APY.1X100VE 1 1000 V insulated screwdriver for Phillips - heads no. 1

83H.JP9 9 Sleeve set of hexagonal keys 1,5 to 10 mm

192.16G 1 Diagonal cutters

391.16VE 1 1000V insulated cutting pliers

170A 1 Multigrip pliers

185.20G 1 Half-round nose pliers

187.16G 1 Combination pliers

187.18VE 1 1000V insulated combination pliers

177E 2 Outside-circlip pliers 13 - 18

179E 2 Inside-circlip pliers 13 - 18

501 1 Large-capacity lock-grip pliers

803.300M 1 Rule

F Qty Description

805.1 1 Vernier caliper

601 1 Hacksaw frame

DRD.MD250EM 1 Half-round second-cut file 250 mm

RD.MD200EM 1 Round second-cut file 200 mm

249 3 Drift punches 3, 4 and 6 mm

263.20 1 Chisel

200A.32 1 Riveting hammer 32 mm

374A.20 1 Double-action oil can

276 1 Contact-point file

449.Z3A 1 Set of terminals, pliers and accessories (in a case)

783A 1 Lug and post cleaner

784B 1 Acid hydrometer

405.10MT 1 Heavy-duty diagonal cutters

AEF.J1 5 Micro-Tech screwdriver set

840.1 1 Electricians knife with wire stripper

827.1 1 Magnetic retriever

834.R2 1 Articulated mirror

237.A 1 Thread restorer

102-PIECE TOOL SET

CM.MAN

Supplied loose, as below. D: 19,7 kg.

SET CM.MAN WITH

4-DRAWER ROLLER CHEST

JET.CR4G

CR4.MAN

D: 90,7 kg.

4

0

%

N

E

W

PLANT AND EQUIPMENT MAINTENANCE SETS

WORKSTATIONS AND TOOL STORAGE

section 01 EN-VALIDEE 10/09/04 13:34 Page 41

42 - F05 On-line catalogue available on www.facom.com

SET CM.AG4

WITH 5-TRAY BOX BT.13A

2146.MAG4

550 x 220 x 215 mm.

D: 18,9 kg.

29-PIECE METRIC TOOL SET WITH 3-TRAY BOX BT.9

2145.MAG1

470 x 220 x 170 mm.

D: 12,2 kg.

F Qty Description

44.JE8 8 Open-end wrenches 8 to 24 mm

75.JN8 8 Socket wrenches 8 to 24 mm

113A.6C 1 Adjustable wrench

113A.12C 1 Adjustable wrench 12"

AR 3

Isoryl screwdrivers with round blade 3.5x75 - 6.5x150

and 8x200 mm

170A 1 Multigrip pliers

192.20G 1 Diagonal cutters

54-PIECE METRIC TOOL SET

CM.AG4

Supplied loose.

D: 13,4 kg.

F Qty Description

40.JE9 9 Set of combination wrenches 8 to 19 mm

113A.6C 1 Adjustable wrench

113A.15C 1 Adjustable wrench

S.429EP 18

"Standard" sockets and accessories

10 to 32 mm (in a case)

AZ.4X100 1 Round-blade screwdriver

AZFH 2 Hexagonal-blade screwdrivers6.5x150 - 8x175 mm

AZP 2 Screwdrivers for PhillipsJ heads no. 1 and 2

AZD 2 Screwdrivers for PozidrivJ heads no. 1 and 2

82H 5 Set of hexagonal keys 4 - 5 - 6 - 8 - 10 mm

180 1 Multigrip pliers

187.16G 1 Combination pliers

495.22EL 1 Heavy-duty end nippers

500 1 Lock-grip pliers

603E 1 Hacksaw frame

840.2 1 Knife

200A.40 1 Riveting hammer

249 2 Drift punches 4 and 6 mm

263.20 1 Chisel

269 1 Crowbar

131A.18 1 "Stillson" pipework wrench, 60 mm, 2"

DRD.MD200EM 1 Half-round second-cut file 200 mm

187.20G 1 Combination pliers

800A 1 Tape measure 2m

603E 1 Hacksaw frame

200A.42 1 Riveting hammer 42 mm

263.18 1 Flat chisel

374A.20 1 Double-action oil can

FARMING EQUIPMENT SETS

PLANT AND EQUIPMENT MAINTENANCE SETS

WORKSTATIONS AND TOOL STORAGE

section 01 EN-VALIDEE 10/09/04 13:34 Page 42

On-line catalogue available on www.facom.com F05 - 43

150-PIECE METRIC AND INCH TOOL SET WITH CHEST BT.66

2174.MAG5

670 x 415 x 361 mm.

D: 77,4 kg.

F Qty Description

40.JE24 24 Combination wrenches 6 to 32 mm

75.JE16 16 Open-socket wrenches 8 to 32 mm

75 4 Angled socket wrenches 26 - 27 - 30 and 32 mm

113A.6C 1 Adjustable wrench

113A.15C 1 Adjustable wrench

S.151 1 Ratchet L 1/2"

S.110 1 Speed brace

S.120A 1 Sliding tee

S.240A 1 Universal joint

S.210 - S.215 2 Extension

S 22

"Standard" sockets: 8 to 19, 21 to 24, 26 to 30 and 32

mm

K.151B 1 Reversible ratchet L 3/4"

K.210B - K.215B 2 Extension

K.120B 1 Sliding tee

K 12

Set of "truck" sockets: 30 - 32 - 33 - 34 - 36 - 38 - 41 - 42

- 46 - 50 - 54 - 55 mm

AZ 2 Screwdrivers for slotted heads 3.5x75 and 4x100 mm

AZFH 5

Screwdrivers for slotted heads 5.5x125 - 6.5x150 -

8Ex175 - 10x200 and 12x250 mm

AZD 3 Screwdrivers for PozidrivJ heads no. 1 - 2 - 3

83H.JP9 9 Sleeve set of hexagonal keys 1,5 to 10 mm

180.CPE 1 Sheathed multigrip pliers

182A.CP 1 "Mammouth" multigrip pliers

192.16CPE 1 Sheathed "piano wire" diagonal cutters

187.16CPE 1 Sheathed combination pliers

F Qty Description

495.22EL 1

475A.J1 2

501 1

801A 1

234 1

805.1 1

603E 1

660A.10 10

990.A00 1

882A 1

844.D 1

PAM.MD200 1

RD.MD200 1

RAB.DRDMD250 1

TRO.5,6EM 1

200A 2

249.JT7 7

247 6

262A.20 1

269 1

121A.1' 1

Y.RIV1 1

449I 1

701A 1

U.46PL 1

PLANT AND EQUIPMENT MAINTENANCE SETS

WORKSTATIONS AND TOOL STORAGE

Heavy-duty end nippers

Reversible circlip pliers in a roll

Large-capacity lock-grip pliers

Tape measure

Scriber

Vernier caliper

Hacksaw frame

Bimetal saw blades

"Compact" bolt cropper

Scroll shears

Knife

Flat second-cut file 200 mm

Round second-cut file 200 mm

Half-round second-cut rasp 250 mm

Round file for chainsaw

Riveting hammers 32 and 50 mm

Wallet set of drift punches 2 to 10 mm

Nail sets 2 to 6 and 8 mm with wallet N.38A-6C

Chisel

Crowbar

Pipework wrench

Riveting kit

Crimping pliers

Multifunction tester

Large-capacity oil-filter wrench.

section 01 EN-VALIDEE 10/09/04 13:34 Page 43

44 - F05 On-line catalogue available on www.facom.com

CONSTRUCTION PLANT SETS

151-PIECE METRIC TOOL SET

CM.V9

Supplied loose, see below.

D: 40,9 kg.

F Qty Description

40.40LAJE26 26

Standard 8 to 18 mm and long 19 to 38 mm combina-

tion wrenches

44.JE8 8 Open-end wrenches 8 to 24 mm

R.425A 26

"Radio" socket set 5.5 to 14 mm, with screwdriver

bits and accessories

S.141A 1 Long hinged handle L 1/2"

S.208 1 Extension L 1/2"

S.232B 1 Coupler L 1/2", L 3/4"

S.440E 28

"Standard" sockets 8 to 32 mm and accessories with

storage tray

K.230B 1 Coupler L3/4" to L 1/2"

K.151B 1 Reversible ratchet L 3/4"

K.120B 1 Sliding tee

K.210B - K.215B 2 Extensions

K 12

"Truck" socket set: 30 - 32 - 33 - 34 - 36 - 38 - 41 - 42 -

46 - 50 - 54 - 55

AR 2 Round-blade screwdrivers 3.5x75 and 4x100 mm

AG 3

Forged-blade screwdrivers 5.5x150 - 6.5x150 and

8x200 mm

AP 2 Screwdrivers for PhillipsJ heads no. 1 - 2

AD 2 Screwdrivers for PozidrivJ heads no. 1 - 2

82.JL10 10 Wallet set of hexagonal keys 2 to 10 mm

F Qty Description

180.CPE 1 Sheathed multigrip pliers

192.16CPE 1 Sheathed "piano wire" diagonal cutters

187.20CPE 1 Combination pliers

188.20CPE 1 Sheathed flat-nose pliers

501 1 Large-capacity lock-grip pliers

T5.L100 1 Large-capacity lock-grip pliers

800A 1 Tape measure 2m

804 1 Feeler gauge 19 blades

804.P 1 Precision feeler gauges to 1/100 mm

603E 1 Hacksaw frame

660A.10 10 Bimetal saw blades

200A 2 Riveting hammers 28 and 40 mm

208A.32CB 1 Plastic-tip mallet

249 2 Drift punches 4 and 6 mm

247 2 Nail sets 4 and 6 mm

256.6 1 Centre punch

263.20 1 Chisel

252.10 1 Chisel

827B 1 Magnetic retriever

276 1 Contact-point file

270A.MA 1 Wire brush

SET CM.V9

WITH SITE CHEST BT.28

2068.MV9

615 x 398 x 392 mm.

D: 91,9 kg.

3

0

%

PLANT AND EQUIPMENT MAINTENANCE SETS

WORKSTATIONS AND TOOL STORAGE

section 01 EN-VALIDEE 10/09/04 13:34 Page 44

187.18CPE Sheathed combination pliers 1

On-line catalogue available on www.facom.com F05 - 45

145-PIECE INCH TOOL SET FOR EARTH MOVING PLANT

CU.V12

Supplied loose, see below.

D: 44,3 kg.

F Description

40.JU17T Roll set of combination wrenches 1/4" to 1 1/4"

40.LA Long combination wrenches 1 1/8", 1 5/16" and 1 3/8"

44

Open-end wrenches 3/8x7/16 - 1/2x9/16 - 5/8x11/16 -

3/4x13/16 to 1 1/8"x1 1/4"

34 Open-end wrenches 3/8", 7/16", 1/2", 9/16"

55.JU10 Offset ring wrenches 1/4" to 1 1/4"

113A.8C Adjustable wrench

S.145 Long hinged handle L 1/2"

S.232B Coupler L 1/2", L 3/4"

S.440AUP

L 1/2" socket set 3/8" 1 1/4" and accessories

(in a case)

K.140A Hinged handle

K.230B Coupler L3/4" to L 1/2"

K.151B Reversible ratchet L 3/4"

K.210B - K.215B Extensions

K.120B Sliding tee

K

"Truck" socket set 1 1/4" - 1 5/16" - 1 7/16" - 1 1/2" - 1 5/8" -

1 11/16" - 1 13/16" to 2" - 2 3/16" - 2 1/4"

K.125A Tommy bar

AZFH Power screwdrivers for slotted heads 6.5x150 and 8x175 mm

AR

Isoryl screwdriver with round blade 4x100 - 5.5x150 - 6.5x150

mm

AP Screwdrivers for PhillipsJ heads no. 0 to 4