Professional Documents

Culture Documents

Environmental Management in The Oil, Gas and Related Energy Industries in Ghana

Uploaded by

Kwame D BoatengOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Environmental Management in The Oil, Gas and Related Energy Industries in Ghana

Uploaded by

Kwame D BoatengCopyright:

Available Formats

April 2013, Volume 4, No.

2

International Journal of Chemical and Environmental Engineering

Environmental Management in the Oil, Gas and

related Energy Industries in Ghana

O-W. Achaw

a,*

, E. Danso-Boateng

b

a

Department of Chemical Engineering ,Kumasi Polytechnic, Kumasi, Ghana

b

Department of Chemical Engineering, Loughborough University, Loughborough, UK

*Corresponding AuthorE-mail:owach@hotmail.com

Abstract:

In view of the past experiences with the oil, gas and related energy industries in the West African sub-region, there is increased

apprehension among Ghanaians on how the recent oil find would impact the environment and whether the nation has the requisite

expertise and capacity to manage the oil in an environmentally friendly manner. The apprehension is further heightened by the

generally perceived weak environmental regulatory regime in the country. The study used plant and institutional visits, interviews and

questionnaires to investigate the waste management practices of four major companies in the oil, gas and related energy industries in

Ghana. It sought to find out among others the nature of waste generated by these entities, how the waste they generate are handled, to

what extent their activities impact on the environment, the sort of uses to which the waste are put, and the regulatory regime within

which they operate. The study revealed that the activities of all the companies impacted on water bodies in their catchment area. Only

two (2) out of the four (4) industries studied have comprehensive waste treatment facilities at their plants. The study further revealed

that the Environmental Protection Agency of Ghana (EPA-Ghana) has not been able to sanction those companies violating its

regulations. Unless EPA-Ghana and other relevant regulatory bodies rigorously enforce the environmental regulations of the country,

the environment of Ghana will continue suffer degradation as a result of the activities of the oil, gas and related energy industries.

Keywords: Ghana; environment; oil waste; regulatory bodies; waste management; Environmental Protection Agency

1. Introduction

The oil, gas and related energy industries, as a result of

the huge volumes of products they churn out, also

generate significant waste which when not properly

handled are known to cause a lot of damage to the

environment [1-3]. Right from the well head where the

crude oil is produced, through the refinery processes,

down to the final point of utility, potential threats to the

environment exist. At the well head, the degradation of

flora and fauna as a result of movement and activities of

heavy duty equipment is imminent [4]. Flaring of

associated gas releases combustion gases into the

atmosphere; these gases have been established to

contribute to acid rain and climate change. Also, leakages

and spillage of oil as a result of equipment failure can

sometimes lead to catastrophe onto the environment. The

much publicized April 2010 oil spillage in the Gulf of

Mexico by BP Oil Company is a case in point [5]. During

transportation and storage of crude oil and natural gas

similar hazards lurk. The 1985 Exxon Vadez accident

provides an example in this regard. Crude refinery and

natural gas processing activities produce, among others,

huge quantities of oily wastewater, lower molecular

weight hydrocarbons, heavy metals, organic and

inorganic compounds of sulfur, and the oxides of nitrogen

and carbon among others. These waste materials have

adverse implications on the environment when they are

released without treatment. The combustion of natural gas

and oil products to produce energy either for electricity

generation, operation of internal combustion engines, or

for other commercial uses results in the production of

large volumes of combustion gases. These gases

inevitably enter into the environment and contribute to

climate change. More often than not, these materials also

directly affect human health when they come into contact

with the body.

In order to control, manage or eliminate the

environmental hazards associated with the oil, gas and

related energy industries, technology and regulations are

often the preferred instruments of choice. Technology can

help minimize the occurrence of accidents and hence

damage to the environment. For instance, double hulled

ocean going tankers have mitigated the high incidence of

oil spillage into the oceans as a result of collision or

grounding [6]. Technology is also used to foster rapid

response when a threat to the environment is imminent

[7]. When pollution of the environment finally occurs,

technology is often used to restore the environment or

mitigate the impact of pollution on the environment.

Regulatory bodies on the other hand provide guidelines,

monitoring and sanctions regimes that check the industry

Environmental Management in the Oil, Gas and related Energy Industries in Ghana

117

and thus encourage, advice or compel players in the

industry to adopt measures and technologies that

minimize or eliminate threat to the environment.

In Ghana, the recent discovery of oil and gas in

commercial quantities has suddenly heightened public

awareness of the potential dangers to the environment that

the production, processing and utility of oil products can

pose. The recent spillage of toxic drilling mud [8] into the

maritime boundaries of Ghana by Kosmos Energy, an oil

exploration company, and earlier ones by Tema Oil

Refinery (a local refinery company) into the Gulf of

Guinea [9] have awakened the nation to what it stands to

lose if care is not taken even as it celebrates its oil find.

The experiences of other oil producing nations in the

West African sub-region, particularly, the Niger delta of

Nigeria, provide useful lessons in this regard [10, 11]. It

is, for instance, estimated that between 1976 and 1996, a

total of 4,835 incidents resulted in the spillage of at least

2.4 million barrels of oil, of which an estimated 1.89

million barrels were lost to the environment in the Niger

Delta of Nigeria alone.

1.1 Objectives

This study used industrial visits, interviews, and

questionnaires to investigate the potential threats to the

environment of the anticipated exploitation of the recent

oil find in Ghana. Specifically, it sought to identify the

specific wastes produced by industries working in the

crude production, crude oil refinery, petroleum and

related products storage, and thermal power plant

facilities that utilize hydrocarbons as the main fuel. It also

sought to study the technologies available at these

industries to treat the crude oil and related products

wastes, the potential uses for the waste as well as the

regulatory regimes within which the industries operate in

Ghana in order to assess the extent of compliance of these

companies. It is anticipated that the results of this study

will inform the development of measures to curb the

potential threat to the environment that will inevitably

accompany the exploitation of crude oil and related

products in commercial quantities in Ghana.

2. Methods and Materials

Only those industries that responded to an invitation to

participate in the exercise were included in the study. The

industries covered included those in crude oil and natural

gas production, crude oil processing, petroleum and

related products storage, and thermal power production.

The national regulatory agencies, namely, the EPA-Ghana

and the Factories Inspectorate Department of the Ministry

of Employment and Social Welfare, Ghana (FID-Ghana)

were also included. The study employed industrial and

institutional visits, interviews, questionnaires, and

desktop studies for the investigation. Planned visits to the

plants were also undertaken during which a walkthrough

of the facilities were carried out with guidance from

technical personnel. During the visits, observations were

made of equipment, waste generation and handling, and

the general operations and organization of the plants. Unit

managers of the plants and departmental officers were

interviewed wherever necessary. Lastly, literature on

environmental and waste management in the crude oil

exploitation and related industries and the legislative

regime regarding environmental practices in the Ghana

were also reviewed. The results of the study were

qualitatively analyzed.

3. Results and Discussions

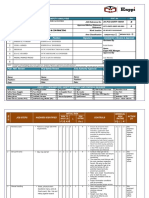

The list of companies and institutions that participated in

the study is shown in Table 1. The choice of plants and

institutions was dictated by the extent of their presence in

Ghana, but also so that a holistic view of the industry with

regard to the impact on the environment would be

achieved. The crude oil production company operates an

offshore facility in Ghana and its main product is crude

oil. The refinery company operates a complex facility that

includes a crude distillation unit, a residual catalytic

cracking unit, a Merox unit, a sulfur production facility,

an array of waste treatment units, and storage depots for

crude oil, liquefied petroleum gas, and refinery products.

The thermal power plant produces electricity from

Table 1. Relevant companies and institutions studied

hydrocarbons (petroleum and natural gas). Its facilities

include combustors, gas and steam turbines, generators,

process water treatment units and an array of waste

treatment entities. All petroleum and related products

storage facilities in Ghana are currently owned and

operated by the government. Nationwide, eight such

facilities exist whose main functions are the reception and

storage of petroleum products and distribution of same to

retailers scattered across the country. They also stock and

oversee the strategic oil reserves of the country. Also, on

Table 1 are the environmental regulatory bodies in the

country. EPA-Ghana is the main regulatory body which

by an Act of the Parliament of Ghana is mandated to

among others, monitor and enforce environmental

regulations in the country. Others bodies who play a

complementary role, especially, where environmental and

waste management in the crude oil and related industries

is concerned are the Ghana National Petroleum Company,

the Ministry responsible for shipping, and the FID-Ghana.

EPA-Ghana and FID-Ghana were included in the study.

Company/I

nstitution

Number in

Ghana

Number Visited/

Interviewed

Percentage

Coverage

(%)

Crude Oil

Production

2 1 50

Crude

Processing

1 1 100

Bulk Oil

Storage

8 1 12.5

Thermal

Power Plant

4 1 25

Monitoring

Agencies

4 2 50

Environmental Management in the Oil, Gas and related Energy Industries in Ghana

118

3.1 Waste generated by the companies

All the companies studied generated waste as shown in

Table 2. The types of waste generated by these companies

include solids, liquid effluents and gaseous emissions.

The crude processing company generated the widest array

of waste followed by the thermal power plant.

Understandably, the bulk oil storage company generated

the least amount of waste as its activities do not

necessitate the processing or conversion of materials. The

core of oil waste from this industry stemmed mostly from

leakages and occasional spillage that occur during the

discharge and loading of crude oil products. Each type of

waste generated by the industries has the potential to

impact negatively on the environment if not treated before

disposal into the environment. The potential effects of the

waste generated by the industries studied on the

environment are summarized in Table 3. The effects of

these waste are numerous and varied. Some have very

serious consequences on the environment if not checked.

Gaseous emissions like carbon dioxide and methane (off-

gas) have serious implications on climate change [12],

while others like sulfur dioxide and the oxides of nitrogen

are known to cause acid rain [13] which affects forest

cover. Oily wastewater if not treated before discharge can

affect aquatic life if it enters water bodies, or flora and

fauna if disposed onto the land. On the land the oil can

seep into aquifers and thereby adversely affect their use

for domestic purposes. The oil can also stagnate on the

land for years and render it useless for agricultural

purposes. Evaporation of hydrocarbons and other compounds

from leaked or spilled oil pollute the air and can cause

respiratory and other diseases when inhaled [14].

The location of these industries further complicates the

possible effect of the wastes they generate on the

environment. For instance, all the plants in this study are

located close to water bodies and urban centers. Thus, the

effluents from the plants if not properly managed, could

flow into the water bodies and affect aquatic life with

implications to the health and economic life of adjoining

communities. Similarly, gaseous and particulate

emissions from these plants have direct consequences on

the health of the urban population in the catchment areas

of the plants.

3.2 Waste handling by the companies

The manner the companies involved in the study manage

the waste they generate is shown in Table 4. The waste

management approaches can be grouped into three,

namely, waste reuse, direct waste dumping and waste

treatment prior to disposal. Mostly, the solid wastes are

not treated in any of the plants studied. They are either

sold for reuse or dumped to disposal sites. The gases and

liquid effluents however receive some treatment before

disposal in some cases. Wastes that are reused or recycled

are metal scraps, empty drums, treated oil sludge and

recovered oil. While the companies sell the metal scraps

Table 2. Types of wastes generated by companies

Industry

Waste Generated

Crude

Production

Spent chemical solutions, waste oil, plastics, toxic

drilling mud, empty drums, office and domestic

waste.

Crude

Processing

Process effluents (oily wastewater, sour water,

desalter wastewater, spent amine solution, spent

cuastic), oil free wastewater, metal scraps, spent

catalyst, charcoal bags, drums, oil sludge, sewage,

CO, CO2, H2S, SOx, NOx, NH3, off-gas, office and

domestic waste.

Bulk Oil

Storage

Waste oil, domestic and office waste.

Thermal

Power Plant

NOx, SOx, CO, CO2, particulate matter, oily

wastewater, oil free wastewater, oil-contaminated

solids, oil sludge, empty drums, office and domestic

waste.

Environmental Management in the Oil, Gas and related Energy Industries in Ghana

119

and empty drums to dealers, the recovered oil is either

recycled for use in the plant or sold to secondary users.

For instance, the refinery company recycles recovered oil

to its catalytic cracking unit. On the other hand, the

thermal power plant sells the recovered oil to secondary

users. All other solid wastes are dumped at land filling

sites or collected by municipal waste agencies. The

wastes in this category include office wastes, spent

catalysts, food waste, plastics and charcoal bags.

It is only the crude refinery and the thermal power plants

that were found to treat the process wastes prior to

disposal. The bulk oil storage facility has no waste

treatment facility neither has the crude oil production

company. The bulk oil storage facility in particular

generates relatively little oily waste which is either

collected in waste ponds or allowed to drain off or

washed into a nearby stream. The crude oil production

company on the other hand collects and ships off its oily

waste, mostly oily mud and production chemicals to

secondary agents for treatment or disposal. Associated

gas generated by the latter company is however flared on

site. All liquid effluents and gaseous emissions except

fugitive emissions receive one kind of treatment or

another prior to disposal in those companies that treat

their wastes. In these companies, elaborate waste

treatments facilities exist to treat liquid and gaseous

waste. Table 4 shows the facilities available for waste

treatment at these plants. These include comprehensive

wastewater treatment plants that deal with both oily and

non-oily wastewater, and some process effluents. The

wastewater treatment unit of the crude oil refinery plant,

for instance, combines physical, chemical and biological

processes. The corresponding facility in the thermal

power plant uses physical and chemical methods to treat

mainly oily wastewater. Other wastewater treatment.

Table 3. Potential effects of wastes generated on the environment

Waste Type Potential Effect

Scraps

Litter the landscape and limit land usage.

Empty drums

Litter the environment and obstruct movement; serves as breeding grounds for mosquitoes; leaks residual

chemicals into environment.

Sludge

Hurts aquatic life and limits surface water usage; destroys flora and fauna on land; renders land unfit for

agricultural use; disrupts economic activities such as fishing and recreation if it occurs in the sea.

Spent catalysts

If not disposed properly become nuisance to land and water bodies; associated heavy metals are poisonous.

Plastics

Litter the landscape, limit land usage and choke drainage systems.

Charcoal bags

Litter the landscape.

Particulate matter

Pollutes the air and causes respiratory diseases.

Office waste

Litters the landscape and limits land usage; could be source of fire.

Food waste

Gives bad odor and serves as breeding ground for microbial agents.

Process effluents

Pollute water bodies, aquifers, and gives bad odor; they can be sources of microbial breeding, pollution of flora

and fauna; renders land unfit for agricultural and domestic use.

Oil free wastewater

Pollutes water bodies and aquifers; are source of microbial growth.

Oily wastewater

Pollutes water bodies, adversely affects flora and fauna; affects land use and human health; disruptive of

economic activities such as agriculture, fishing and recreation.

Off-gas

Causes climate change, pollutes surrounding air, affects human health

H2S

Has very bad odor, pollutes air; is poisonous to human health.

Sour water

Has very bad odor, affects flora and fauna, pollutes water bodies and affects land use.

Sewage

Bad odor and sources of municipal diseases.

NOx/SOx

Has bad odor; causes acid rain and hence adversely affects flora, fauna and land use.

Oil-contaminated solids

Litter the landscape, can be source of fire.

Drilling mud

Pollutes water bodies and land; affects aquatic life and land usage.

Environmental Management in the Oil, Gas and related Energy Industries in Ghana

120

units in these plants include gravity separators, chemical

ponds, sour water stripping units, and neutralization

sumps among others. Gaseous emission treatments units

in the crude refinery plant include a stripping unit, and a

sulfur recovery unit that treats H

2

S, SO

2

, and NH

3

laden

effluents. Also, a flaring unit exists to combust gaseous

hydrocarbons. In both plants electrostatic particle

separating units are available to separate particulates from

gaseous streams.

The specific waste handling methods in the various plants

studied and the state of these units are listed on Table 5.

All the waste treatment units in the thermal power plant

function and most are in use. Only the incinerator was not

in use at the time of the study and this is because the

company sells its recovered oil instead of incinerating it.

The company therefore had no use for the incinerator as

of the time of the visit. On the other hand most of the

waste treatment plants in the refinery plant are either non-

functioning or only partly functioning. Out of the six

independent waste treatment facilities in the plant three

do not function at all. Only two are fully functioning. The

wastewater treatment plant that treated most of the

process effluents only functions partly. It presupposes that

the company disposes off its effluents and gaseous

emissions without any treatment at all or only partly

treated. Given that the plant is situated in an urban setting

and close to water bodies, this situation has serious

adverse implications for the surface water, surrounding

flora and fauna, and the health of inhabitants in the

surrounding communities.

The specific effects of the wastes generated by these

plants on the environment are shown in Table 6. Wastes

from each of the plants affect water bodies. The oil

production companys activities directly affected the open

sea, and for that matter aquatic life. Additionally, its

operations impacted negatively on fishing activities of the

local community. The bulk storage company leaked oil

into an adjoining stream and a marshy land and thereby

polluting these entities. This situation has on several

occasions elicited complaints from the adjoining

communities. Leaked and spilled oil evaporated and

polluted the surrounding air. Oily wastewater and process

effluents from the crude processing company were

disposed off into a nearby lagoon and treated wastewater

from the thermal power company was disposed off into a

nearby marshy land which drains into a stream that flows

into the sea. Again, both the crude oil refinery and

thermal power companies emitted carbon dioxide and the

oxides of nitrogen and sulfur into the environment.

These gases have been established to contribute to climate

change and acid rain. Besides, spilled or leaked petroleum

products from these plants emitted volatile organic

compounds that polluted the air. Hydrogen sulfide,

ammonia and sulfur dioxide emissions in the crude oil

processing plant polluted the air of the plant and nearby

communities and thereby affected the health of employees

and inhabitants of the communities.

3.3 Compliance with environmental regulations

All the companies studied are aware and apparently

operated according to the EPA-Ghana guidelines. This

means that effluents, emissions, and disposal of wastes

from these plants supposedly meet EPA-Ghana approved

guidelines. Furthermore, the environmental performances

of the companies are evaluated on regular basis by EPA-

Ghana. EPA-Ghana has recently introduced an evaluation

scheme dubbed AKOBEN [15] to check environmental

pollution by industry. The AKOBEN program is an

environmental performance rating and disclosure

Table 4. Waste treatment methods employed by the companies

Waste Types

Treatment Methods

Scraps Sold for reuse

Empty drums

Sold for reuse

Sludge

Landfill, sold for use as fuel or used to

make concrete

Spent catalysts Landfill

Plastics Municipal collection

Charcoal bags Municipal collection

Particulate matter

Electromagnetic separators (EPS)

Office waste

Municipal collection

Food waste

Municipal collection

Process effluents

Multi-stage wastewater treatment

(physical, chemical and/or biotreatment)

Oil free wastewater

pH adjustment followed by disposal

Oily wastewater

Gravity separation or wastewater plant

Off-gas

Flared

H2S

Stripping unit

Sour water

Stripping unit

Spent caustic solution

pH adjustment and discharge in drain

Sewage

Oxidation ponds (stabilization and

degradation by natural processes)

NOx/SOx

Not treated

Oil-contaminated solids

Landfill or municipal waste collection

Drilling chemical mud

Sent to secondary party for handling

Environmental Management in the Oil, Gas and related Energy Industries in Ghana

121

Table 5. Observed effects of wastes generated by the plants

initiative that assesses the environmental performance of

mining and manufacturing companies in the country using

a five-color rating scheme. Every year the results are

disclosed to the public with the objective to strengthen

public awareness and participation in pollution and

environmental issues. The scheme relies on public

ridicule to get companies to engage in good practices. It

was introduced in part to address EPA-Ghanas inability

to strictly enforce its regulations. This weakness has

resulted in a situation where violating companies got

away with environmental abuses without any sanction.

The weakness stems in part from of a generally weak

regulatory regime in Ghana. Another important factor that

restrains the EPA-Ghana from enforcing its regulations is

economics, specifically, the monopoly enjoyed by some

of the companies in the Ghanaian market. For instance,

the oil processing company is the only one in the country

that processes and supplies crude oil products. Thus, if it

were made to shut down for non-compliance of

environmental regulations, it could lead to a sudden

shortage of certain petroleum products in the country- a

situation which would have serious economic and

political ramifications in the country. Consequently, such

companies are able to flout environmental regulations

with impunity. Indeed, in this study, the crude oil

processing company was found to have flouted the EPA-

Ghana regulations on emissions and effluent discharge

levels, yet it had not been cited by the EPA-Ghana for

violation of its regulations. Thus, in order to make up for

its inability to enforce its rules, EPA-Ghana is seeking to

use public opinion through the AKOBEN disclosure

schemes to bring pressure to bear on the companies to

comply with its regulations. The performance of the

companies investigated in this study, on the basis of a

number of regulatory variables of the EPA-Ghana, is

shown on Table 7. Significantly, none of the companies

had been cited for violation of environmental regulations

by the EPA-Ghana as of the time of the study. However

data from the companies themselves indicated that two of

them had actually violated EPA-Ghana rules on gaseous

emissions and effluent discharge levels. It is noteworthy

in this regard that the refinery company, for instance,

operated its Residual Fluid Catalytic Unit (RFCU), even

though its wastewater treatment unit was not fully

functioning. This meant that process effluents from

Industries

Waste types

Effect on environment

Crude production

Waste crude oil

Aquatic life of the sea

Affected fishing activities

Spent chemicals

Aquatic life of the sea

Combustion

gases

Climate change, acid rain

Crude refinery

Oily water Affected nearby lagoon

NOx, SOx Acid rain

CO2 Climate change

Spent caustic

Nearby lagoon

Process effluents

Nearby lagoon

Leaked/spilled

oil

Polluted surrounding air

Bulk oil storage

Waste oil

Marshy land/stream

Leaked/spilled

oil

Polluted surrounding air

Thermal plant

Wastewater

Drained into a marshland

and a stream

CO2

Climate change

NOx, SOx

Acid rain

Leaked/spilled

oil

Polluted surrounding air

Table 6. Performance of companies as per some regulatory guidelines

Monitoring Parameter

Industry

Crude Production

Crude Refinery

Bulk Oil Storage Plant

Thermal Power

Standards used

EPA & ISO1400

EPA & Insurance EPA EPA & World Bank

Monitoring Agency

EPA

EPA

EPA

EPA

Frequency of monitoring by EPA

Monthly

Quarterly

Regularly

Regularly

Environmental permit

Yes

Yes Yes Yes

Recent accidents

None

Yes None None

Breach of regulations

Yes

Yes Yes None

Community Complaints

Yes

Yes

Yes

None

Environmental Officer

Yes

Yes

Yes

Yes

Regular Reports to EPA-Ghana

Yes

Yes

Yes

Yes

Environmental Management in the Oil, Gas and related Energy Industries in Ghana

122

the RFCU were only partially treated before discharge

into the environment. Indeed, a condition for the

operation of the RFCU is that the wastewater treatment

plant be functional. Yet, in spite of the quarterly visits by

the EPA-Ghana, the company had not been cited for

violation of the environment as of the time of the study.

Among the companies studied, only one, namely the

refinery plant, had had a major accident that impacted

significantly on the environment. All the companies have

internal personnel in the form of environmental officers

who monitor the internal activities and advised

management on environmental compliance and waste

management related issues. These officers also prepare

and submit regular environmental reports to the EPA-

Ghana and the company management. Records from the

companies showed that the FID-Ghana had not visited

any of the companies as of the time of the study. FID-

Ghana, on the other hand complained that lack of logistics

hindered its ability to deliver on its mandate. This has created a

situation where some companies are violating environmental

regulations without been being brought to book..

4. Conclusion

Waste management practices of the oil, gas and related

energy industries in Ghana were examined in this study.

Results of the study reveal that the operations of all the

companies involved in the study negatively affected the

environment. The activities of the oil production

company, the crude oil refinery company and the

petroleum products storage company have already had

adverse impact on water bodies. Only two of the

companies had facilities in place to treat the waste they

generate. It was observed that only the thermal power

plant managed its operations such that it did not elicit any

complaints from communities in its catchment area. Only

one out of the four (4) companies studied had had a major

oil spillage that had significant adverse effect on

environment. Among the regulatory agencies only the

EPA-Ghana monitored the activities of the companies on

regular basis. The activities of two (2) of the industries

were found to consistently violate the environmental

regulations of Ghana. Therefore, unless the EPA-Ghana

rigorously enforces its environmental regulations the

activities of these industries will continue to degrade the

environment of Ghana.

REFERENCES

[1] F. Aguilera, J. Mendez, E. Pasaro, and B. Laffon, Review on the

effects of exposure to spilled oils on human health, Journal of

Applied Toxicology, 30(4), pp. 291-301, 2010.

[2] [2] E&P Forum/UNEP, Environmental management in oil and

gas exploration and production: An overview of issues and

management approaches, UNEP IE/PAC Technical Report 37 /

E&P Forum Report, vol. 2:72/254, 1997.

[3] [3] K.T. OReilly, R.I. Magaw, and W.G. Rixey, Predicting the

effectof hydrocarbon and hydrocarbon-impacted soil on

groundwater, (2001) Retrieved January, 2011, from

www.api.org/ehs/groundwater/upload/14_Bull.pdf.

[4] [4] I.O. Asai, S.I. Jeged, D.A. Jegede, O.K. Ize-Iyamu, and E.B.

Akpasubi, Effects of petroleum exploration and production

operations on the heavy metal groundwater in the Niger Delta,

International Journal of Physical Sciences, 2(10), pp. 271-275,

2007.

[5] [5] S. Bristol, Deepwater horizon MC252 Gulf incident oil

budget, 2010. Retrieved June, 2011, from

http://www.usgs.gov/foia/budget/08-02-2010.

[6] [6] O.T. Gudmestad, Water waves and floating bodies in the

perspective of arctic offshore engineering, In 20th International

Workshop on Water Waves and Floating Bodies, Longyearbyen

Spitsbergen, Norway, 2005.

[7] [7] C.R. Chase, and G. Roberts, Advanced detection technology

for early warning- the key to oil spill prevention, International Oil

Spill Conference, Savannah, Georgia USA, 2008.

[8] [8] Ghana News Agency, Kosmos refuses to pay fine for oil

spill off Ghana, 2010. Retrieved August, 2011, from

www.ghanaweb.com/GhanaHomePage/NewsArchive/artikel.php?I

D=190803.

[9] [9] The Ghanaian Journal, TOR records second oil spillage in a

month, 2008. Retrieved August 2011, from

www.theghanaianjournal.com/2008/02/29/tor-records-second-oil-

spillage-in-a-month.

[10] United Nations Environmental Programme, Environmental

Assessment of Ogoniland, 2011. Retrieved February 2012, from

http://postconflict.unep.ch/publications/OEA/UNEP_OEA.pdf.

[11] J. Vidal, Nigeria on alert as Shell announces worst oil spill in a

decade, 2011. Retrieved January 2011, from

http://www.guardian.co.uk/environment/2011/dec/22/nigerian-

shell-oil-spi.

[12] M. Lancaster, Green Chemistry: An Introductory Text. The Royal

Society of Chemistry Publishing, Cambridge: UK, 2002.

[13] C.T. Driscoll, K.M. Driscoll, M.J. Mitchell, and D.J. Raynal,

Effect of acid rain deposition on forest and aquatic ecosystems in

New York State, Environmental Pollution, 123, pp. 327-336,

2003.

[14] H.J. Rudd, and N.A. Hill, Measures to reduce emissions of VOCs

during loading and unloading of ships in the EU. European

Commission - Directorate General Environment

AEAT/ENV/R/0469, p. 2, 2001.

[15] Environmental Protection Agency of Ghana, AKOBEN rating

and disclosure programme, 2010. Retrieved June 2011, from

www.epaghanaakoben.org/.

You might also like

- JSA - EDDY CURRENRT - AmendedDocument1 pageJSA - EDDY CURRENRT - AmendedMahmoud Abdel DayemNo ratings yet

- Safe Working at Heights Part 1 - KG - 310519Document15 pagesSafe Working at Heights Part 1 - KG - 310519eugene stevensNo ratings yet

- Bolt TorquingDocument2 pagesBolt TorquingREHAN IQBALNo ratings yet

- Attachment 7 Scaffolding PermitDocument2 pagesAttachment 7 Scaffolding PermitAviects Avie JaroNo ratings yet

- SHEQ Stevedore & Cargo Handling SupervisorsDocument12 pagesSHEQ Stevedore & Cargo Handling Supervisorssheldon cramer100% (1)

- JSEA FOR DISMNTLING OF MACHINES (Central Work Shop)Document16 pagesJSEA FOR DISMNTLING OF MACHINES (Central Work Shop)B&R HSE BALCO SEP SiteNo ratings yet

- 1 45Document3 pages1 45nsadnan0% (1)

- Acf-Mra-064 - SCDocument1 pageAcf-Mra-064 - SCFateh AliyaNo ratings yet

- Roofing ActivitiesDocument1 pageRoofing ActivitiesMark BeebakheeNo ratings yet

- Carpentry Forming Framing or Wood WorkingDocument1 pageCarpentry Forming Framing or Wood WorkingPrakash PavuralaNo ratings yet

- FUSHAN TECH SAFETY PROCEDUREDocument11 pagesFUSHAN TECH SAFETY PROCEDUREhoangmtbNo ratings yet

- Civil Engineer with 18 Years ExperienceDocument4 pagesCivil Engineer with 18 Years Experiencepasser byNo ratings yet

- JHA for Unloading Product from Ship at Port of SalalahDocument4 pagesJHA for Unloading Product from Ship at Port of SalalahSreekumar100% (1)

- Acf-Mra-063 - UaDocument1 pageAcf-Mra-063 - UaFateh AliyaNo ratings yet

- 14 M Behavioural Based Safety MGMT UpdatedDocument5 pages14 M Behavioural Based Safety MGMT UpdatedSri NivasNo ratings yet

- Demolition of Hvac System - Isd Security Building #07Document12 pagesDemolition of Hvac System - Isd Security Building #07Izaaz AhamedNo ratings yet

- HSE RequirementDocument10 pagesHSE Requirementyudiyana16No ratings yet

- RA - SandblastingDocument2 pagesRA - Sandblasting721917114 47No ratings yet

- Contractor Ehs Risk Assessment For NDT TestingDocument6 pagesContractor Ehs Risk Assessment For NDT TestingBernard PenuliarNo ratings yet

- Reynaldo Darcera: Project Management Contractor Near-Miss at Worksite ReportDocument15 pagesReynaldo Darcera: Project Management Contractor Near-Miss at Worksite ReportAyaz AhmadNo ratings yet

- Upgrade Wastewater Treatment Facilities Hazard ID PlanDocument14 pagesUpgrade Wastewater Treatment Facilities Hazard ID PlanDarius DsouzaNo ratings yet

- Machinery and equipment repair maintenance checklistDocument18 pagesMachinery and equipment repair maintenance checklistpradeepgamage4513No ratings yet

- Guidelines Flagmen - Banksmen (English)Document1 pageGuidelines Flagmen - Banksmen (English)Pirlo PoloNo ratings yet

- Presentation: "Emergency Preparedness"Document63 pagesPresentation: "Emergency Preparedness"vidhya sagarNo ratings yet

- Sor-Landscape-Ppe5 29 Dec. 2020Document1 pageSor-Landscape-Ppe5 29 Dec. 2020haniNo ratings yet

- Al-Khalij 3X450 MW Power Plant Project Job Safety Analysis WorksheetDocument3 pagesAl-Khalij 3X450 MW Power Plant Project Job Safety Analysis WorksheetMustafa hse JafferNo ratings yet

- Thinner B MSDS PDFDocument4 pagesThinner B MSDS PDFEKO PURWANTONo ratings yet

- Hazard Identification and Risk Analysis in Mining: Case Studies of an Iron Ore and Coal MineDocument84 pagesHazard Identification and Risk Analysis in Mining: Case Studies of an Iron Ore and Coal MineZarimi Ac100% (1)

- Procedure For OffloadingDocument10 pagesProcedure For OffloadingStansilous Tatenda Nyagomo100% (1)

- Job: Assembling of Internal Floating Roof.: Job Safety Analysis FormDocument3 pagesJob: Assembling of Internal Floating Roof.: Job Safety Analysis FormDilshad ali100% (1)

- Ramapo College Vehicle Fueling SOPDocument1 pageRamapo College Vehicle Fueling SOPAnees EkNo ratings yet

- Fundamental HSE Management TrainingDocument8 pagesFundamental HSE Management TrainingIGede SumantraNo ratings yet

- He0Alth, Safety and Environment Ola/Uber/Cab Drivers: Submitted byDocument22 pagesHe0Alth, Safety and Environment Ola/Uber/Cab Drivers: Submitted byRohan NandiNo ratings yet

- Mom For Table To Drill MeetingDocument2 pagesMom For Table To Drill MeetingChaudhary Wasim MurtazaNo ratings yet

- Method Statement For Light Beacons and Buoys C04Document93 pagesMethod Statement For Light Beacons and Buoys C04Olugbemiga James OlalekanNo ratings yet

- Hse Plan 3Document14 pagesHse Plan 3YcRij SeYerNo ratings yet

- Hazard IdentificationDocument1 pageHazard IdentificationMohamad Zakwan Zach ZakariaNo ratings yet

- JP Jo Interview QuestionsDocument10 pagesJP Jo Interview QuestionsMuhammad MehboobNo ratings yet

- কিণকেকত্র সুরো ও টনরাপত্তার ১০৫ টি টিপকDocument111 pagesকিণকেকত্র সুরো ও টনরাপত্তার ১০৫ টি টিপকJubair Ibna JubarajNo ratings yet

- Ocp BatchingDocument1 pageOcp BatchingAarya Mishra TiwariNo ratings yet

- Safety Alert 12 2017 Drill Collar DroppedDocument1 pageSafety Alert 12 2017 Drill Collar DroppedChandrasekhar SonarNo ratings yet

- Fire Response PlanDocument4 pagesFire Response PlanArchana GaonkarNo ratings yet

- Igc3-The Health and Safety Practical ApplicationDocument21 pagesIgc3-The Health and Safety Practical ApplicationSamuel P SNo ratings yet

- Nebosh IGC 3 Observation Sheet 00218445 FinalDocument13 pagesNebosh IGC 3 Observation Sheet 00218445 FinalNahaz HydroseNo ratings yet

- OHS&W Plant Specific Hazard IdentificationDocument3 pagesOHS&W Plant Specific Hazard IdentificationJulio Best SetiyawanNo ratings yet

- Carpentry Work PDFDocument2 pagesCarpentry Work PDFcityofdarwingisNo ratings yet

- Industrial Safety Program TemplateDocument20 pagesIndustrial Safety Program TemplateanasNo ratings yet

- Employee Wwelfare ProjectDocument11 pagesEmployee Wwelfare ProjectVijay KishanNo ratings yet

- SAFETY WALKAROUND CHECKLIST FOR HAND TOOLSDocument3 pagesSAFETY WALKAROUND CHECKLIST FOR HAND TOOLSdidikNo ratings yet

- Loss of Working Day Due To RainDocument3 pagesLoss of Working Day Due To RainMuhammadGaniNo ratings yet

- 24-Hours Near Miss ReportDocument1 page24-Hours Near Miss ReportHaleemUrRashidBangashNo ratings yet

- Building De-Dusting JSADocument3 pagesBuilding De-Dusting JSAJayesh J PillaiNo ratings yet

- Health Safety & Environment: Deco InteriorsDocument2 pagesHealth Safety & Environment: Deco InteriorsSusan SeseNo ratings yet

- Noise and Hearing Conservation TrainingDocument1 pageNoise and Hearing Conservation TrainingRabialtu SulihahNo ratings yet

- Pera JackhammerDocument7 pagesPera Jackhammerjumansyahamid1988No ratings yet

- Devadas CV - 2014Document4 pagesDevadas CV - 2014loveson709No ratings yet

- Work at Heigh at Night SafetyDocument49 pagesWork at Heigh at Night SafetyKhuda BukshNo ratings yet

- Dosecc Health ManualDocument62 pagesDosecc Health ManualRachmad HazanNo ratings yet

- Workplace Vocabulary for Esl Students: With Exercises and TestsFrom EverandWorkplace Vocabulary for Esl Students: With Exercises and TestsNo ratings yet

- Hydrogen-Induced Cracking (HIC) : Failures in Sour Gas EnvironmentsDocument1 pageHydrogen-Induced Cracking (HIC) : Failures in Sour Gas EnvironmentsMurugananthamParamasivamNo ratings yet

- CV Gulfam (Nebosh Chemical Engineer)Document4 pagesCV Gulfam (Nebosh Chemical Engineer)Gulfam ShahzadNo ratings yet

- Upsurge of Money Ritual Among Youths in Nigeria and National SecurityDocument7 pagesUpsurge of Money Ritual Among Youths in Nigeria and National SecurityEditor IJTSRDNo ratings yet

- Safe-Scav HSDocument2 pagesSafe-Scav HSyfcozNo ratings yet

- Instant Download Discovering The Scientist Within Research Methods in Psychology 1st Edition Lewandowski Test Bank PDF ScribdDocument32 pagesInstant Download Discovering The Scientist Within Research Methods in Psychology 1st Edition Lewandowski Test Bank PDF Scribdemmaperezmdczjgmdnfrb100% (16)

- Feasibility Report On Diesel Hydro-Treater (DHT) Unit and Associated FacilitiesDocument29 pagesFeasibility Report On Diesel Hydro-Treater (DHT) Unit and Associated FacilitiesDivyansh Singh ChauhanNo ratings yet

- Material Balance in Multi-Unit SystemsDocument43 pagesMaterial Balance in Multi-Unit SystemsAcademicBMNo ratings yet

- OISD-RP-182 Guidelines Workover StimulationDocument46 pagesOISD-RP-182 Guidelines Workover StimulationArvind Bharadwaj100% (1)

- The Role of Bioremediation in Water Quality ManagementDocument9 pagesThe Role of Bioremediation in Water Quality ManagementInternational Aquafeed magazineNo ratings yet

- Dimethyl Ethers & Poly Ethylene Glycol: Advantages of Physical and Chemical SolventsDocument5 pagesDimethyl Ethers & Poly Ethylene Glycol: Advantages of Physical and Chemical SolventssatishchemengNo ratings yet

- AGT ExamDocument5 pagesAGT ExamAmirul Aizad Bin KamaruzamanNo ratings yet

- Biology 3: Synthesis Paper Microbial Presence Assessment in Winogradsky Columns Using Different Nutrient SourcesDocument7 pagesBiology 3: Synthesis Paper Microbial Presence Assessment in Winogradsky Columns Using Different Nutrient SourcesRieNo ratings yet

- Industrial Waste Management IntroductionDocument11 pagesIndustrial Waste Management IntroductionusmansherdinNo ratings yet

- API MSPS Chapter 17-6 - Guidelines For Determining The Fullness of Pipelines Between Vessels and Shore Tanks PDFDocument9 pagesAPI MSPS Chapter 17-6 - Guidelines For Determining The Fullness of Pipelines Between Vessels and Shore Tanks PDFthongNo ratings yet

- Iron sulfides in amine plants: friend or foeDocument31 pagesIron sulfides in amine plants: friend or foewaheedNo ratings yet

- Give The Operational Definitions of The Following Cycles: A. Biogeochemical CycleDocument2 pagesGive The Operational Definitions of The Following Cycles: A. Biogeochemical CycleDesiree G. SacasanNo ratings yet

- 1 s2.0 S0360319912017181 MainDocument8 pages1 s2.0 S0360319912017181 MainNafees VakilNo ratings yet

- NamitaDocument15 pagesNamitanamitaboharaNo ratings yet

- FM0554 Permit To WorkDocument16 pagesFM0554 Permit To WorkRhona Lyn PastorfideNo ratings yet

- Sulfur Species in Oilfield Production - The Good, the Bad and the UglyDocument20 pagesSulfur Species in Oilfield Production - The Good, the Bad and the UglyaseNo ratings yet

- H2S Health EffectsDocument2 pagesH2S Health EffectsDidi WiranataNo ratings yet

- 6c Photosynthesis and Respiration ChemistryDocument13 pages6c Photosynthesis and Respiration Chemistryapi-298247873No ratings yet

- Dow SruDocument15 pagesDow SruAJAY1381No ratings yet

- Protreat Hydro EngrgDocument6 pagesProtreat Hydro EngrgAmitkumar SinghNo ratings yet

- UEAnal. Ch-4Document12 pagesUEAnal. Ch-4DilekNo ratings yet

- Detection of Mercaptans, Hydrogen Sulfide, Elemental Sulfur and Peroxides - Doctor Test MethodDocument4 pagesDetection of Mercaptans, Hydrogen Sulfide, Elemental Sulfur and Peroxides - Doctor Test MethodMuhannad NasifNo ratings yet

- Environmental Challenges During DrillingDocument46 pagesEnvironmental Challenges During Drillingrishibarathi100% (1)

- Decontamination and Cleaning Manual L1 05 Contractors and ServicesDocument39 pagesDecontamination and Cleaning Manual L1 05 Contractors and ServicesJose DavalilloNo ratings yet

- PRACTICA 3: Remoción de Impurezas - Etapa 1ADocument7 pagesPRACTICA 3: Remoción de Impurezas - Etapa 1AOsmar Monja LopezNo ratings yet

- Manual de Reparacion Glycol-PumpDocument34 pagesManual de Reparacion Glycol-PumpFer A. Molina CéspedesNo ratings yet