Professional Documents

Culture Documents

Lifting Lug Calculation

Uploaded by

Daison PaulCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lifting Lug Calculation

Uploaded by

Daison PaulCopyright:

Available Formats

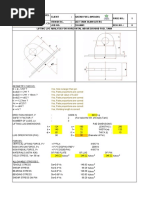

CLIENT SIEMENS PAGE NO.

: 155

ITEM DESC: ANION REGENERATION TANK

JOB NO. : 12-0827 REV. NO. : 0

LIFTING LUG ANALYSIS FOR HORIZONTAL EQUIPMENT

f

h t

45 a

t1

w

l

ERECTION WEIGHT, P : 19620 N ( 2000 Kg)

SHOCK FACTOR, F : 2

NUMBER OF LUGS : 2

LIFTING LUG DIMENSIONS: PAD DIMENSION:

h = 100 a = 200 LENGTH(l): 300

b = 100 f = 60 WIDTH(w) : 200

di= 60 t1 = 15 THICK.(t): 15

LUG ORIENTATION (PHI) : 90 D= 30 (Diameter of Pin)

FORCES :

VERTICAL LIFTING FORCE, PV = P/4*F = 19620.0 N

NOM.CIRCUM.FORCE, Pc = PV*COS(PHI)+5%PV= 981.0 N

NOM.RADIAL.FORCE, Pr = PV*COS(90-PHI) = 19620.0 N

MATERIAL : OF DOUBLER PAD SA516 GR 70 SA-36

YIELD STRESS, Ys= : 248.29 N/mm^2 248.29 N/mm^2

MATERIAL : OF PIN SA-36

YIELD STRESS, Ys= 248.29 N/mm^2

ALLOWABLE STRESSES :

TENSILE STRESS,Sa=0.6*Ys : 148.974 N/mm^2

SHEAR STRESS, Ss=0.4*Ys : 99.316 N/mm^2

BEARING STRESS, Se=0.8*Ys : 198.632 N/mm^2

BENDING STRESS, Sb=0.66*Ys : 163.8714 N/mm^2

ALLOWABLE SHEAR STRESS FOR PIN Ss=0.4*Ys : 99.316 N/mm^2

INDUCED STRESSES :

TENSILE STRESS = PV/(t1*(b-di)) = 32.70 N/mm^2 <Sa HENCE SAFE

SHEAR STRESS = PV/(2*t1*(f-ri))= 21.80 N/mm^2 <Ss HENCE SAFE

BEARING STRESS = PV/(di*t1) = 21.80 N/mm^2 <Se HENCE SAFE

BENDING STRESS = M/Z=Pc*h/(t1*a^2/6)= 0.98 N/mm^2 <Sb HENCE SAFE

SHEAR STRESS ON PIN = PV/(PI/4*D^2)= 27.76 N/mm^2 <Sb HENCE SAFE

OF LUG

TOP GREAT ENGINEERING & MARINE

PTE LTD

PROJECT : DORAD 800 MW COMBINED

CYCLE POWER PLANT

b

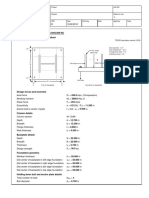

CLIENT SIEMENS PAGE NO.: 156

ITEM DESC: ANION REGENERATION TANK

SERIAL NO. : JOB NO. : 12-0827 REV. NO. : 0

LIFTING LUG ANALYSIS FOR HORIZONTAL EQUIPMENT

(as per bednar ex.10.5 page-275)

STRENGTH OF WELD (LIFTING LUG TO PAD) :

FILLET WELD THROAT, L1 = 4.2 mm

FILLET LEG SIZE (WFp) = 6 mm

TOTAL WELD LENGTH (Wl) = 430 mm

LINEAR SECT.MOD.(Z)=2*a^2/6= 13333.33 mm^2

UNIT FORCES DUE TO CIRCUMFERENTIAL FORCES

BENDING(f1) = Pc*h/Z = 7.36 N/mm

SHEAR (f2) = Pc/Wl = 2.28 N/mm

UNIT FORCES DUE TO RADIAL FORCES

SHEAR (f3) = Pr/Wl = 45.63 N/mm

REQUIRED WELD SIZE DUE TO COMBINED LOAD

f = sqrt[(f1+f2)^2+f3^2] = 46.63 N/mm

WELD EFFICIENCY = 0.55 (E)

WELD STRENGTH(49%of 0.9Sy)= 109.50 N/mm^2 (Sw)

fw = Sw.E = 60.22 N/mm^2

REQUIRED THROAT SIZE (WFc)= f/fw = 0.77 mm

AS WFp>WFc, PROVIDED WELD FILLET SIZE IS SUFFICIENT

STRENGTH OF WELD (LIFTING LUG PAD TO SHELL) :

FILLET WELD THROAT, L1 = 4.242 mm

FILLET LEG SIZE (WFp) = 6 mm

TOTAL WELD LENGTH (Wl) = 1000 mm

LINEAR SECT.MOD.(Z)=2*l^2/6= 30000.00 mm^2

UNIT FORCES DUE TO CIRCUMFERENTIAL FORCES

BENDING(f1) = Pc*(h+t)/Z = 3.76 N/mm

SHEAR (f2) = Pc/Wl = 0.98 N/mm

UNIT FORCES DUE TO RADIAL FORCES

SHEAR (f3) = Pr/Wl = 19.62 N/mm

REQUIRED WELD SIZE DUE TO COMBINED LOAD

f = sqrt[(f1+f2)^2+f3^2] = 20.18 N/mm

WELD EFFICIENCY = 0.55

WELD STRENGTH (49%of 0.9Sy)= 109.50 N/mm^2

fw = Sw.E = 60.22 N/mm^2

REQUIRED THROAT SIZE (WFc)= f/fw = 0.34 mm

AS WFp>WFc, PROVIDED WELD FILLET SIZE IS SUFFICIENT

TOP GREAT ENGINEERING & MARINE

PTE LTD

PROJECT : DORAD 800 MW COMBINED

CYCLE POWER PLANT

You might also like

- Lifting Lug CalculationsDocument6 pagesLifting Lug CalculationsYash RamiNo ratings yet

- Mathcad - Spreader Beam Design Calculations As Per DNV 5th VerDocument29 pagesMathcad - Spreader Beam Design Calculations As Per DNV 5th VerAbderraoufAffes100% (3)

- Lifting Lug Calculation ParametersDocument3 pagesLifting Lug Calculation Parametersdhirendarji83% (6)

- Lifting LugsDocument2 pagesLifting LugsAdi Cahyoko82% (11)

- Lifting Lug CalculationDocument7 pagesLifting Lug CalculationErin JohnsonNo ratings yet

- Lifting LugDocument24 pagesLifting LugMas Arman Tewo100% (6)

- Lifting Lug Excel SheetDocument8 pagesLifting Lug Excel Sheetshazan67% (3)

- Guideline Lifting Lug DesignDocument10 pagesGuideline Lifting Lug Designye-kyaw-aung80% (10)

- Lifting LugsDocument3 pagesLifting Lugssatyenlala100% (3)

- Lifting Beam CalculationDocument2 pagesLifting Beam Calculationராபர்ட் ஆன்றோ ரெனி100% (4)

- Lifting Lug Design Calcs As 4100Document2 pagesLifting Lug Design Calcs As 4100Ede Jaimes100% (2)

- Lifting Lug Calculation-1Document1 pageLifting Lug Calculation-1dtgpand100% (4)

- Vitec Equipments PVT LTD Filename: Spreader Beam CalculationDocument48 pagesVitec Equipments PVT LTD Filename: Spreader Beam CalculationDarshan PanchalNo ratings yet

- Lift Lug SpreadsheetDocument2 pagesLift Lug Spreadsheetpgarrett775814233100% (1)

- Engineering Design of Lifting LugsDocument1 pageEngineering Design of Lifting LugsadammzjinNo ratings yet

- Spreader Beam CalculationDocument2 pagesSpreader Beam Calculationhombre.muerto595977% (13)

- Lifting LugDocument7 pagesLifting LugSajal KulshresthaNo ratings yet

- Lifting Lug Calcs (Frame)Document5 pagesLifting Lug Calcs (Frame)Mudasir MughalNo ratings yet

- Lifting Lug CalculationDocument5 pagesLifting Lug CalculationEm Mar100% (2)

- (B) Schematic Diagram of 2 Nos Lugs With No Tailing Lug: .0 Lifting Lug Design CalculationDocument7 pages(B) Schematic Diagram of 2 Nos Lugs With No Tailing Lug: .0 Lifting Lug Design CalculationArt G. Enzi100% (1)

- Lug Design (XLS)Document4 pagesLug Design (XLS)Bhartendu Patni100% (1)

- Design of Padeye CalcDocument3 pagesDesign of Padeye CalcBolarinwa89% (9)

- Design of lifting lug for 8MT load capacityDocument2 pagesDesign of lifting lug for 8MT load capacityKeyurNo ratings yet

- Spreader Beam BLOCK EDocument23 pagesSpreader Beam BLOCK Evaminos85% (13)

- Spreader BeamDocument2 pagesSpreader Beamwisnu_bayusakti75% (4)

- Lifting Lug Calculations KodDocument2 pagesLifting Lug Calculations Kodanu radhaNo ratings yet

- Lifting Lug Calculation 4april2018Document2 pagesLifting Lug Calculation 4april2018Diosdado Mingi Jr.No ratings yet

- Large Moment ExampleDocument5 pagesLarge Moment ExampleAmro Ahmad AliNo ratings yet

- Calculation of Beam/Column Splice: HB-300x300x10x15Document5 pagesCalculation of Beam/Column Splice: HB-300x300x10x15amachmouchiNo ratings yet

- Lifting Lug Analysis: (As Per Bednar Ex.10.5 Page-275) Strength of Weld (Lifting Lug To Pad)Document1 pageLifting Lug Analysis: (As Per Bednar Ex.10.5 Page-275) Strength of Weld (Lifting Lug To Pad)jagannadha varmaNo ratings yet

- Lifting (Carbon Vessel)Document1 pageLifting (Carbon Vessel)jagannadha varmaNo ratings yet

- Spreader BeamDocument7 pagesSpreader BeamAnonymous sfkedkymNo ratings yet

- Column Base Plate Design (Bs5950-1:2000) : Project Job RefDocument4 pagesColumn Base Plate Design (Bs5950-1:2000) : Project Job RefronyNo ratings yet

- Mckoi Design ArmatureDocument11 pagesMckoi Design ArmatureMarko Antonio MccoyNo ratings yet

- Design of Beam to Column ConnectionDocument13 pagesDesign of Beam to Column ConnectionGautam SharmaNo ratings yet

- Column Base Plate DesignDocument4 pagesColumn Base Plate Design_jessecaNo ratings yet

- TRUNNION CALCULATION SHEETDocument1 pageTRUNNION CALCULATION SHEETAtty Atty100% (1)

- Davit CalcDocument6 pagesDavit Calcrustamriyadi100% (1)

- Chequered PlateDocument23 pagesChequered Platesaravanan428680% (10)

- Lifting Beam DesignDocument4 pagesLifting Beam DesignAnonymous XAqiBJ100% (4)

- 30m 24sq.m SQ 100kpaDocument20 pages30m 24sq.m SQ 100kpamanohargudNo ratings yet

- 03 CalDocument56 pages03 Calnatarajan RavisankarNo ratings yet

- Analyzing stresses on new lifting lugDocument4 pagesAnalyzing stresses on new lifting lugdharwinNo ratings yet

- Column Base Plate DesignDocument5 pagesColumn Base Plate Design_jessecaNo ratings yet

- Efficient lighting load scheduleDocument6 pagesEfficient lighting load schedulemuqtar4uNo ratings yet

- Lifting LugDocument2 pagesLifting LugSACHIN PATELNo ratings yet

- Bracing Connection DesignDocument5 pagesBracing Connection DesignnileshmadankarNo ratings yet

- 吊耳计算Document4 pages吊耳计算huangjlNo ratings yet

- Lifting LugDocument8 pagesLifting LugAzwan ShahNo ratings yet

- ComputationDocument19 pagesComputationDaryl BalgosNo ratings yet

- Pad-eye Design for 5 Mton Lifting LoadDocument2 pagesPad-eye Design for 5 Mton Lifting LoadPaulo MoreiraNo ratings yet

- Lifting Lug Design-MrDocument5 pagesLifting Lug Design-MrMiguelRagasNo ratings yet

- Footing Design SheetDocument11 pagesFooting Design SheetGowri Shankar0% (1)

- Footing Design SheetDocument11 pagesFooting Design SheetAntonius Ajalah100% (1)

- Welding Calculations For Base PlateDocument116 pagesWelding Calculations For Base PlateSyedZainAli100% (2)

- Thrust Block CalculationsDocument5 pagesThrust Block CalculationsNiño Erick Castañares86% (7)

- Brace TR W6X25Document6 pagesBrace TR W6X25mihai_serban13No ratings yet

- Hyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationFrom EverandHyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationNo ratings yet

- materials: SectionDocument30 pagesmaterials: SectionDaison PaulNo ratings yet

- ManasaN SureshN 2018 AStudyonImpactofBankniftyDerivativesTradingonSpotMarketVolatilityinIndia AAFSJ2211-9Document10 pagesManasaN SureshN 2018 AStudyonImpactofBankniftyDerivativesTradingonSpotMarketVolatilityinIndia AAFSJ2211-9shibaditya mazumdarNo ratings yet

- Preparation: Inspection Before WeldingDocument3 pagesPreparation: Inspection Before WeldingDaison PaulNo ratings yet

- Purchase Spec. For Tubes (Sa179)Document5 pagesPurchase Spec. For Tubes (Sa179)Daison PaulNo ratings yet

- PURCHASE SPEC. FOR BOLTS&NUTS (SA320M Gr.L7 & SA194M Gr.4)Document4 pagesPURCHASE SPEC. FOR BOLTS&NUTS (SA320M Gr.L7 & SA194M Gr.4)Daison PaulNo ratings yet

- Purchase Spec. For Tubes (Sa213 TP321)Document5 pagesPurchase Spec. For Tubes (Sa213 TP321)Daison PaulNo ratings yet

- Purchase Spec. For Tubes (Sa179)Document5 pagesPurchase Spec. For Tubes (Sa179)Daison PaulNo ratings yet

- materials: SectionDocument30 pagesmaterials: SectionDaison PaulNo ratings yet

- Purchase Spec. For Nozzles Swage (Sa106b)Document4 pagesPurchase Spec. For Nozzles Swage (Sa106b)Daison PaulNo ratings yet

- Purchase Spec. For Tubes (Sa789 S31803)Document6 pagesPurchase Spec. For Tubes (Sa789 S31803)Daison PaulNo ratings yet

- PURCHASE SPEC. FOR PLATES-WELD OVERLAY (SA516 Gr.70 + SA240 316L)Document4 pagesPURCHASE SPEC. FOR PLATES-WELD OVERLAY (SA516 Gr.70 + SA240 316L)Daison PaulNo ratings yet

- Purchase Spec. For Plates-Weld Overlay (CS + 304L)Document3 pagesPurchase Spec. For Plates-Weld Overlay (CS + 304L)Daison PaulNo ratings yet

- Purchase Spec. For Tubes (Sa789 S31803)Document6 pagesPurchase Spec. For Tubes (Sa789 S31803)Daison PaulNo ratings yet

- Purchase Spec. For Plates-Weld Overlay (CS + S31803)Document7 pagesPurchase Spec. For Plates-Weld Overlay (CS + S31803)Daison PaulNo ratings yet

- Purchase Spec. For Pipes (Sa312 TP316L)Document5 pagesPurchase Spec. For Pipes (Sa312 TP316L)Daison PaulNo ratings yet

- PURCHASE SPEC. FOR PLATES-CLADDED&FORMING (SA516 Gr.70 + SA240 316L)Document3 pagesPURCHASE SPEC. FOR PLATES-CLADDED&FORMING (SA516 Gr.70 + SA240 316L)Daison PaulNo ratings yet

- PURCHASE SPEC. FOR BOLTS&NUTS (SA320M Gr.L7 & SA194M Gr.4)Document4 pagesPURCHASE SPEC. FOR BOLTS&NUTS (SA320M Gr.L7 & SA194M Gr.4)Daison PaulNo ratings yet

- Purchase Spec. For Plates-Copper Alloy (SB171 Uns C46400)Document4 pagesPurchase Spec. For Plates-Copper Alloy (SB171 Uns C46400)Daison PaulNo ratings yet

- PURCHASE SPEC. FOR PLATES-WELD OVERLAY (SA516 Gr.70 + SA240 316L)Document4 pagesPURCHASE SPEC. FOR PLATES-WELD OVERLAY (SA516 Gr.70 + SA240 316L)Daison PaulNo ratings yet

- PURCHASE SPEC. FOR PLATES-CLADDED (SA266 Gr.2 + S31803)Document6 pagesPURCHASE SPEC. FOR PLATES-CLADDED (SA266 Gr.2 + S31803)Daison PaulNo ratings yet

- ASME Clad Steel Plate SpecDocument6 pagesASME Clad Steel Plate SpecDaison Paul100% (1)

- Purchase Spec. For Plates-Copper Alloy (SB171 Uns C46400)Document4 pagesPurchase Spec. For Plates-Copper Alloy (SB171 Uns C46400)Daison PaulNo ratings yet

- Purchase Spec. For Plates (Sa36)Document5 pagesPurchase Spec. For Plates (Sa36)Daison PaulNo ratings yet

- PURCHASE SPEC. FOR PLATES-CLADDED&FORMING (SA516 Gr.70 + SA240 316L)Document3 pagesPURCHASE SPEC. FOR PLATES-CLADDED&FORMING (SA516 Gr.70 + SA240 316L)Daison PaulNo ratings yet

- Purchase Spec. For Plates (Sa240 304L)Document3 pagesPurchase Spec. For Plates (Sa240 304L)Daison PaulNo ratings yet

- Purchase Spec. For Pipes (Sa790)Document5 pagesPurchase Spec. For Pipes (Sa790)Daison PaulNo ratings yet

- Purchase Spec. For Pipes (Sa790m S31803)Document4 pagesPurchase Spec. For Pipes (Sa790m S31803)Daison PaulNo ratings yet

- SEO-Optimized Title for Welded Stainless Steel Pipe SpecificationDocument8 pagesSEO-Optimized Title for Welded Stainless Steel Pipe SpecificationDaison PaulNo ratings yet

- Purchase Spec. For Tubes-Nonferrous (SB111 Uns C71500)Document6 pagesPurchase Spec. For Tubes-Nonferrous (SB111 Uns C71500)Daison PaulNo ratings yet

- Purchase Spec. For Pipes (Sa312 TP316L)Document5 pagesPurchase Spec. For Pipes (Sa312 TP316L)Daison PaulNo ratings yet