Professional Documents

Culture Documents

C13, C15, and C18 Engines ARD Is Disabled

Uploaded by

Raphael ThornerOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

C13, C15, and C18 Engines ARD Is Disabled

Uploaded by

Raphael ThornerCopyright:

Available Formats

C13, C15, and C18 Engines/ ARD Is Disabled

ARD Is Disabled

Use this procedure in order to troubleshoot a failed aftertreatment regeneration or use this

procedure if one of the following event codes are active. Refer to Troubleshooting, "Event

Codes" for information about event codes. For information on the engine monitoring system,

refer to Troubleshooting, "Engine Monitoring System".

Active regenerations usually occur during normal engine operation. However, engine

operation or operator desire may cause the operator to activate the force regeneration

switch. This switch signals the Engine Electronic Control Module (ECM) that a forced

regeneration is desired. The engine ECM will determine the status of the engine and the

products operating condition and determine if it is okay to begin an active regeneration. The

elapsed time is approximately 5 seconds for the engine ECM to determine if the conditions are

acceptable for an active regeneration to begin.

If conditions allow that an active regeneration may begin, the ECM will illuminate the

appropriate indicators and begin the active regeneration. If conditions will not allow an

active regeneration to begin, the ECM will illuminate the Action Lamp and annunciate one of

the following Diagnostic Trouble Codes (DTCs). The code will appear on the Messenger

Display. The code will also be displayed on Cat ET.

Note: One forced regeneration per key cycle is permitted if a failure to ignite, insufficient

temperature to complete regeneration, or loss of combustion diagnostic trouble code is

active. This determines if the regeneration can run and clear the event.

Table 1

Diagnostic Trouble Codes

J1939

Code

CDL

Code

Code Description

(code descriptions

may vary)

Comments

3483-

11

E1305

(1)

Initial Assembly

Aftertreatment #1

Procedure Required

Initial assembly of the aftertreatment system

is complete or the Engine ECM or the A5:E2

Aftertreatment Controller was replaced.

3530-

31

E1040

(2)

ARD Manually

Disabled

The regeneration system is disabled by the

Caterpillar Electronic Technician (ET).

3703-

31

E993

(2)

DPF Active

Regeneration

The regeneration system is disabled due to

the ARD Disable Switch in the operator

Inhibited Due to

Inhibit Switch

interface.

3712-

15

E1301

(1)

Aftertreatment

Regeneration Cannot

Start Due To System

Fault

There is an active fault related to the ARD

combustion air system, ARD fuel system, or

ARD ignition system.

3716-

15

E1300

(1)

Aftertreatment

Regeneration Cannot

Start Due To Low

Engine Temperature

The coolant temperature is below

40 C (104 F ) and the Diesel Particulate

Filter inlet temperature is below

50 C (122 F).

If the ambient temperature is

15 C (5 F) or below, the coolant

temperature must be

60 C (140 F) for an active regeneration to

begin.

3750-

15

E1302

(1)

Aftertreatment

Regeneration Cannot

Start Due To

Conditions Not Met

One or more conditions are not allowing an

Aftertreatment Regeneration to start, Refer

to Test Step 7.

3750-

17

E1239

(2)

DPF #1 Conditions

Not Met for Active

Regeneration

The operator did not allow a regeneration to

occur or 25 hours has elapsed since the last

successful regeneration. The operator must

respond when the DPF lamp and action lamp

is illuminated. This event will trigger a 50%

derate.

3750-

18

E1239

(3)

DPF #1 Conditions

Not Met for Active

Regeneration

The operator did not allow a regeneration to

occur or 32 hours has elapsed since the last

successful regeneration. The operator must

respond when the DPF lamp, action lamp is

illuminated and audible sound in the cab.

This event will trigger a 100% derate.

3750-

31

E1239

(1)

DPF #1 Conditions

Not Met for Active

Regeneration

The operator did not allow enough time for

regeneration to occur. The operator must

respond when the DPF lamp is illuminated.

The operator must allow the engine to idle

until the soot load is reduced to 50 percent.

Table 2

Troubleshooting Test Steps Values Results

1. Check for Diagnostic Codes that

are Active

A. Establish communication

Diagnostic

code

Result: A E1239 (1), E1239 (2),

E1239 (3), 3750-31, 3750-17 or

3750-18 diagnostic code is

present, proceed to Test Step 2.

between Cat ET and the Electronic

Control Module (ECM). Refer to

Troubleshooting, "Electronic

Service Tools", if necessary.

B. Download the "Warranty Report"

from the engine ECM before

performing any troubleshooting or

clearing diagnostic trouble codes.

C. Check and record any event codes

that are active or logged.

Result: A E993 (3) or 3703-31

diagnostic code is present,

proceed to Test Step 3.

Result: A E1040 (2) or 3530-31

diagnostic code is present,

proceed to Test Step 4.

Result: A E1300 (1) or 3716-15

diagnostic code is present,

proceed to Test Step 5.

Result: A E1301 (1) or 3712-15

diagnostic code is present,

proceed to Test Step 6.

Result: A E1302 (1) or 3750-15

diagnostic code is present,

proceed to Test Step 7.

Result: A E1305 (1) or 3483-11

diagnostic code is present,

proceed to Test Step 8.

2. A E1239 (1), E1239 (2), E1239

(3), 3750-31, 3750-17 or 3750-18

Diagnostic Code is Present.

A. The operator did not allow a

regeneration to occur or an

automatic regeneration did not occur

within the required time limit. The

operator must respond when the

DPF lamp is illuminated. Once the

DPF and action lamp are

illuminated, the operator must allow

the engine to idle until the soot load

is reduced to 50 percent.

B. Perform a "Manual DPF

Regeneration" using Cat ET.

Manual DPF

Regeneration

Result: The "Manual DPF

Regeneration" was successful.

Return the unit to service.

Result: The "Manual DPF

Regeneration" was not

successful.

Troubleshoot the active

diagnostic codes.

3. A E993 (3) or 3703-31

Diagnostic Code is Present.

Disabled

regeneration

Result: Perform a regeneration.

Refer to the Operation and

Maintenance Manual, "Diesel

A. The operator has disabled the

regeneration system and a

regeneration is necessary.

Particulate Filter Regeneration"

for the proper operation of the

regeneration system.

Return the unit to service.

4. A E1040 (2) or 3530-31

Diagnostic Code is Present.

A. The regeneration system is

disabled by Cat ET.

Regeneration

disabled by

Cat ET.

Result: Establish

communication between Cat ET

and the engine ECM. Set the

value of the "Aftertreatment

Regeneration Device" from

"Disabled" to "Enabled".

Return the unit to service.

5. Aftertreatment Regeneration

Cannot Start Due To Low Engine

Temperature

A. The engine temperature is too

low for an aftertreatment

regeneration.

Low engine

temperature

Result: Raise the coolant

temperature above

40 C (104 F ) and the Diesel

Particulate Filter inlet

temperature above

50 C (122 F). If the ambient

temperature is

15 C (5 F) or below, the

coolant temperature must be

above

60 C (140 F) for an active

regeneration to begin.

Return the unit to service.

6. Aftertreatment Regeneration

Cannot Start Due to System Fault

A. Establish communication

between the Caterpillar Electronic

Technician (ET) and the engine

Electronic Control Module (ECM).

B. Check for active faults related to

the ARD combustion air system,

ARD fuel system, or ARD ignition

system.

System Fault

Result: Troubleshoot all active

faults related to the ARD

combustion air system, ARD

fuel system, or ARD ignition

system. Clear any active codes

after correcting the faults.

Activate regeneration.

Return the unit to service.

7. Aftertreatment Regeneration

Cannot Start Due to Conditions

Not Met

A. Check for the following

conditions:

1. Soot load is too low (15%)

2. Soot load is too high (116% plus

10 minutes after getting a level 3

high soot warning)

3. The regeneration status is disabled

and the "Time to Regenerate" is

greater than 8 hours

4. Incorrect work mode conditions

(parking brake is not set,

transmission is not in neutral)

5. Engine speed and load conditions

inhibit the forced regeneration

request

6. Excessive DPF intake

temperature. This can be caused by

high engine speed and/or high load

7. Regenerations are not disabled

8. For Industrial applications, Refer

to the OEM wiring schematic to

ensure that the CEM is wired

correctly for automatic regenerations

if applicable

9. An active derate, pressure based

or temperature-based event codes

Unacceptable

conditions

Result: Correct any of the listed

conditions. Activate

regeneration.

For Industrial Applications: If

an excessive DPF intake

temperature is present, reduce

engine speed and/or load and

perform a low speed

regeneration

Return the unit to service.

8. Initial Assembly Aftertreatment

#1 Regeneration Required

A. Establish communication

between the Caterpillar Electronic

Technician (ET) and the engine

Electronic Control Module (ECM).

B. Under the "Information" menu,

select "Current Totals". Record the

"Total Operating Hours".

Total

operating

hours

Result: The "Total Operating

Hours" is less than 100 hours.

Complete an "Aftertreatment

System Functional Test" using

Cat ET to clear the E1305 or

3483-11 code.

Result: The "Total Operating

Hours" is greater than 100

hours.

Complete an "Ash Service

Regeneration" using Cat ET to

clear the E1305 or 3483-11

code.

Posted by MANOLO at 9:34 PM

You might also like

- Cat C15 SDP Testing and Adjusting Manual 2 PDFDocument138 pagesCat C15 SDP Testing and Adjusting Manual 2 PDFDragan Krsmanovic100% (2)

- Acert Technology For Off-Highway C15 Engines: Caterpillar ConfidentialDocument62 pagesAcert Technology For Off-Highway C15 Engines: Caterpillar ConfidentialMilorad ZelenovicNo ratings yet

- Diagnostic Trouble Code Charts for 6.0L Diesel EnginesDocument28 pagesDiagnostic Trouble Code Charts for 6.0L Diesel EnginesRogério MorenoNo ratings yet

- Icon Pro StarDocument1 pageIcon Pro Staramateur123456100% (1)

- Cat Messenger ManualDocument68 pagesCat Messenger ManualElisabeth Gornik100% (3)

- CAT Programming ManualDocument258 pagesCAT Programming ManualAnggraini Sari100% (2)

- C7 Serv1824Document31 pagesC7 Serv1824Marcus VeniciusNo ratings yet

- Injector Solenoid Circuit - Test (RENR5096)Document7 pagesInjector Solenoid Circuit - Test (RENR5096)Josip MiškovićNo ratings yet

- Injection Actuation PressureDocument20 pagesInjection Actuation Pressureabdelrhmangbr8682% (11)

- 2004 EPA certified Caterpillar engine ratings and uprate familiesDocument4 pages2004 EPA certified Caterpillar engine ratings and uprate familiesJohn DollNo ratings yet

- Access Cummins Engine Controllers without Wiring HarnessDocument5 pagesAccess Cummins Engine Controllers without Wiring Harnesstecnicogato27No ratings yet

- ET - Getting Started GuideDocument65 pagesET - Getting Started GuideDnl Mrc Rjs Schmpk90% (21)

- Fault Code: 1664 - SPN: 4796 - FMI: 31: ISX CM871Document4 pagesFault Code: 1664 - SPN: 4796 - FMI: 31: ISX CM871Andi KastrawanNo ratings yet

- Cylinder Cut Out Test PDFDocument14 pagesCylinder Cut Out Test PDFFrank Asman100% (1)

- Files PDFDocument1 pageFiles PDFIvanNo ratings yet

- Timing Calibration PDFDocument8 pagesTiming Calibration PDFbahman100% (1)

- CAN Bus Failure On Engine's Display - Blog - TeknisiDocument7 pagesCAN Bus Failure On Engine's Display - Blog - TeknisimkNo ratings yet

- REHS3819-02 Procedure For Troubleshooting and Cleaning The Oil Rail System For The HEUIDocument8 pagesREHS3819-02 Procedure For Troubleshooting and Cleaning The Oil Rail System For The HEUImoises100% (2)

- Caterpillar Acert Engine Diagnostic CodesDocument6 pagesCaterpillar Acert Engine Diagnostic CodesNoel Salazar100% (1)

- C13, C15, and C18 Engines ARD Fuel Pressure Is HighDocument10 pagesC13, C15, and C18 Engines ARD Fuel Pressure Is HighRaphael Thorner100% (1)

- Sensor Electrical Connectors C15 PDFDocument4 pagesSensor Electrical Connectors C15 PDFHerrera Salazar Visnu100% (1)

- CAT DELETES ARD DISABLE STEPSDocument2 pagesCAT DELETES ARD DISABLE STEPSdauvin100% (1)

- Acceleration Is Poor or Throttle Response Is PoorDocument5 pagesAcceleration Is Poor or Throttle Response Is PoorNay SoeNo ratings yet

- 0042-11 Injection Actuation Pressure Output FaultDocument1 page0042-11 Injection Actuation Pressure Output FaultHamilton Miranda100% (3)

- CATERPILLAR FLASH FILES REFERENCE - 29352d1282876866-Wash-File-Cat-Ecm-Adem4-Adem2-Flash-File PDFDocument237 pagesCATERPILLAR FLASH FILES REFERENCE - 29352d1282876866-Wash-File-Cat-Ecm-Adem4-Adem2-Flash-File PDFKhaled Kamel100% (1)

- Injector Trim File InstallDocument2 pagesInjector Trim File InstallnobodymagdesignNo ratings yet

- Cat Data Link - Test: TroubleshootingDocument8 pagesCat Data Link - Test: Troubleshootingmiguel oswaldo gonzalez benitezNo ratings yet

- 3406B (PEEC) Electronic TroubleshootingDocument15 pages3406B (PEEC) Electronic TroubleshootingRichard ChuaNo ratings yet

- CAT ET Basic Engine Rating Change ProceduresDocument11 pagesCAT ET Basic Engine Rating Change Proceduresbjm2060% (1)

- Improved Nozzles and Lines For New Scroll Fuel Systems (NSFS)Document11 pagesImproved Nozzles and Lines For New Scroll Fuel Systems (NSFS)betoven8437No ratings yet

- Acceleration Is Poor or Throttle Response Is PoorDocument6 pagesAcceleration Is Poor or Throttle Response Is Poorfalah100% (2)

- Jake BrackDocument6 pagesJake BrackDaniel DiazNo ratings yet

- 3126Document5 pages3126Ebied Yousif AlyNo ratings yet

- Injection Actuation Pressure - TestDocument18 pagesInjection Actuation Pressure - TestDanielly GersonNo ratings yet

- Engine Cranks But Will Not StartDocument52 pagesEngine Cranks But Will Not Startphuong lamhoang100% (8)

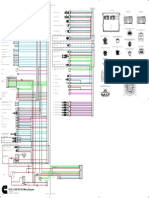

- C-15 Schematic - SENR9575 - 01Document2 pagesC-15 Schematic - SENR9575 - 01mohammad hazbehzadNo ratings yet

- FLS/FTS avg gains analysisDocument1 pageFLS/FTS avg gains analysisVicente Ortiz DelgadoNo ratings yet

- Speed Control Test Cat C15Document8 pagesSpeed Control Test Cat C15Mantenimiento La Punta100% (1)

- Engine Speed - Test SMCS-1907-038 - I02637941Document9 pagesEngine Speed - Test SMCS-1907-038 - I02637941EstoqueNo ratings yet

- Customer Cat ET OverviewDocument36 pagesCustomer Cat ET Overviewlisahun100% (5)

- CAT 3500b Application GuideDocument9 pagesCAT 3500b Application GuideKhaled Kamel100% (3)

- 2009-11!24!135132 ISX Troubleshooting TreeDocument34 pages2009-11!24!135132 ISX Troubleshooting TreeHarold PolkaNo ratings yet

- Cat C7 .Document4 pagesCat C7 .dionymackNo ratings yet

- AdemDocument35 pagesAdemKushagra Asopa100% (2)

- EMC Design Guide For PCBDocument78 pagesEMC Design Guide For PCBFaruq AhmedNo ratings yet

- Speed Sensor - Replace: Pruebas y AjustesDocument2 pagesSpeed Sensor - Replace: Pruebas y AjustesyeisonNo ratings yet

- My ECM GuideDocument2 pagesMy ECM GuideAdel Fawzi100% (1)

- 3126B Engine Harness Wiring DiagramDocument18 pages3126B Engine Harness Wiring DiagramMario Manson100% (1)

- Calculating Cylinder Liner Projection For G3500Document7 pagesCalculating Cylinder Liner Projection For G3500NimNo ratings yet

- Iso 16399-2014-05Document52 pagesIso 16399-2014-05nadim100% (1)

- C13, C15, and C18 Engines ARD Fuel Pressure Is LowDocument11 pagesC13, C15, and C18 Engines ARD Fuel Pressure Is LowRaphael Thorner80% (5)

- Cat C15-C18 Brake SystemDocument8 pagesCat C15-C18 Brake Systemhenry lavieraNo ratings yet

- ECM Clearing Reference GuideDocument2 pagesECM Clearing Reference Guidevictor.cipriani100% (1)

- 962g Trans Clutch CalibrateDocument8 pages962g Trans Clutch Calibrateluis eduardo corzo enriquez100% (1)

- Method Statement Pressure TestingDocument15 pagesMethod Statement Pressure TestingAkmaldeen AhamedNo ratings yet

- Enhanced Instructional Management by Parents, Community and Teachers (e-IMPACT)Document27 pagesEnhanced Instructional Management by Parents, Community and Teachers (e-IMPACT)Ryan Q. Blanco100% (1)

- Pathophysiology of Cardiogenic Pulmonary EdemaDocument8 pagesPathophysiology of Cardiogenic Pulmonary EdemaLili Fiorela CRNo ratings yet

- Singular and Plural NounsDocument3 pagesSingular and Plural NounsJosé BulquesNo ratings yet

- TheSun 2008-11-04 Page16 Asian Stocks Rally Continues On Policy HopesDocument1 pageTheSun 2008-11-04 Page16 Asian Stocks Rally Continues On Policy HopesImpulsive collectorNo ratings yet

- XDM-300 IMM ETSI B00 8.2.1-8.2.2 enDocument386 pagesXDM-300 IMM ETSI B00 8.2.1-8.2.2 enHipolitomvn100% (1)

- 1989 Volvo 740 Instruments and ControlsDocument107 pages1989 Volvo 740 Instruments and Controlsskyliner538No ratings yet

- C13, C15, and C18 Engines Acceleration Is Poor or Throttle ResDocument4 pagesC13, C15, and C18 Engines Acceleration Is Poor or Throttle ResRaphael ThornerNo ratings yet

- SSS ADEM3 WebContentDocument8 pagesSSS ADEM3 WebContentVikram Jit100% (1)

- CAT ELECTRONIC TECHNICIAN REPORTDocument17 pagesCAT ELECTRONIC TECHNICIAN REPORTJalel SaidiNo ratings yet

- CAT C9 Oil Pan InstslationDocument4 pagesCAT C9 Oil Pan InstslationEwgenyNo ratings yet

- Troubleshooting Fuel Dilution of Engine Oil PDFDocument2 pagesTroubleshooting Fuel Dilution of Engine Oil PDFmanu luvungaNo ratings yet

- Ether Injection Control SolenoidDocument3 pagesEther Injection Control SolenoidBlowby HighNo ratings yet

- Injection Actuation Pressure - Test: TroubleshootingDocument19 pagesInjection Actuation Pressure - Test: TroubleshootingMbahdiro KolenxNo ratings yet

- Acceleration Is Poor or Throttle Response Is Poor: TroubleshootingDocument7 pagesAcceleration Is Poor or Throttle Response Is Poor: TroubleshootingEshop ManualNo ratings yet

- Isl8.9 CM2150 SN 4022165Document1 pageIsl8.9 CM2150 SN 4022165Raphael ThornerNo ratings yet

- Mf15 Hardstart Nostart Eged520Document12 pagesMf15 Hardstart Nostart Eged520Raphael ThornerNo ratings yet

- PDF VehicleDocument7 pagesPDF VehicleRaphael ThornerNo ratings yet

- PDF VehicleDocument7 pagesPDF VehicleRaphael ThornerNo ratings yet

- PDF VehicleDocument7 pagesPDF VehicleRaphael ThornerNo ratings yet

- Nuevo Documento de Microsoft Office WordDocument1 pageNuevo Documento de Microsoft Office WordRaphael ThornerNo ratings yet

- 10 Tips para Mantener Tu AcertDocument1 page10 Tips para Mantener Tu AcertRaphael ThornerNo ratings yet

- C13, C15, and C18 Engines Alternator Problem - Charging Problem Andor Noisy OperationDocument3 pagesC13, C15, and C18 Engines Alternator Problem - Charging Problem Andor Noisy OperationRaphael ThornerNo ratings yet

- Interviews: Personal Interview. Advantages and Disadvantages Business Is Largely A Social PhenomenonDocument8 pagesInterviews: Personal Interview. Advantages and Disadvantages Business Is Largely A Social PhenomenonSanjeev JayaratnaNo ratings yet

- Sheet Metal FormingDocument13 pagesSheet Metal FormingFranklin SilvaNo ratings yet

- Valhalla Repair ManualDocument8 pagesValhalla Repair ManualKirby AllenNo ratings yet

- TD EGGER Eurospan E1E05 TSCA Hydro P3 (Rec 224) enDocument2 pagesTD EGGER Eurospan E1E05 TSCA Hydro P3 (Rec 224) enClarencegiNo ratings yet

- FRP/HDPE septic tank specificationDocument2 pagesFRP/HDPE septic tank specificationpeakfortuneNo ratings yet

- Axis Bank Placement Paper Interview Questions 48072Document3 pagesAxis Bank Placement Paper Interview Questions 48072Ravi RanjanNo ratings yet

- Construction Internship ReportDocument8 pagesConstruction Internship ReportDreaminnNo ratings yet

- Vortex: Opencl Compatible Risc-V Gpgpu: Fares Elsabbagh Blaise Tine Priyadarshini Roshan Ethan Lyons Euna KimDocument7 pagesVortex: Opencl Compatible Risc-V Gpgpu: Fares Elsabbagh Blaise Tine Priyadarshini Roshan Ethan Lyons Euna KimhiraNo ratings yet

- Bond Strength of Normal-to-Lightweight Concrete InterfacesDocument9 pagesBond Strength of Normal-to-Lightweight Concrete InterfacesStefania RinaldiNo ratings yet

- CM - Scope of ServicesDocument3 pagesCM - Scope of ServicesMelvin MagbanuaNo ratings yet

- Or Medallist Results WorldSkills Scale and 100 ScaleDocument39 pagesOr Medallist Results WorldSkills Scale and 100 ScaleJoseNo ratings yet

- Import Sample 2Document63 pagesImport Sample 2akkyNo ratings yet

- List of Psychotropic Drugs Under International ControlDocument32 pagesList of Psychotropic Drugs Under International ControlRadhakrishana DuddellaNo ratings yet

- Product Data Sheet: Eas Configurator: Easy Online Configuration Ekv1+1 120 Vg4Gxhq (Vg4Gxhq)Document1 pageProduct Data Sheet: Eas Configurator: Easy Online Configuration Ekv1+1 120 Vg4Gxhq (Vg4Gxhq)Attila HorvathNo ratings yet

- Sles-55605 C071D4C1Document3 pagesSles-55605 C071D4C1rgyasuylmhwkhqckrzNo ratings yet

- Food Sub Inspector Question PaperDocument12 pagesFood Sub Inspector Question PaperGoutam shitNo ratings yet

- Liebert PEX+: High Efficiency. Modular-Type Precision Air Conditioning UnitDocument19 pagesLiebert PEX+: High Efficiency. Modular-Type Precision Air Conditioning Unitjuan guerreroNo ratings yet

- 2-STM Answers SokhaDocument6 pages2-STM Answers SokhamenghokcNo ratings yet

- Dxgbvi Abdor Rahim OsmanmrDocument1 pageDxgbvi Abdor Rahim OsmanmrSakhipur TravelsNo ratings yet

- Raj Priya Civil Court Clerk FinalDocument1 pageRaj Priya Civil Court Clerk FinalRaj KamalNo ratings yet

- Subtracting-Fractions-Unlike DenominatorsDocument2 pagesSubtracting-Fractions-Unlike Denominatorsapi-3953531900% (1)