Professional Documents

Culture Documents

691 Paper

Uploaded by

flytorahul0 ratings0% found this document useful (0 votes)

39 views24 pagesFood Paper

Original Title

691_Paper

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentFood Paper

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

39 views24 pages691 Paper

Uploaded by

flytorahulFood Paper

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 24

Title of Manuscript: Feasibility Analysis of Dairy Ventures in India

Author 1 Author 2 Author 3

Full Name Meka Dhananjay

Apparao

Nicola M Shadbolt Daniel Conforte

Affiliation Institution of Food

Nutrition and Human

Health, Massey

University, New

Zealand

Institution of Food

Nutrition and Human

Health, Massey

University, New

Zealand

Institution of Food

Nutrition and Human

Health, Massey

University, New

Zealand

Mailing

Address

29A Union Street,

Hokowhitu,

Palmerston North

4410, New Zealand

Email Address dhananjay.apparao@g

mail.com

Phone +64210581486

Fax

Contact Author: Nicola M Shadbolt (Author 2)

Title: Feasibility Analysis of Dairy Ventures in India

Abstract

India is the largest producer and consumer of milk and milk products in the world. With

rapid economic growth, the demand for milk is expected to increase at a faster pace than

supply and the resulting supply-demand gap could reach 40 million tonnes by 2022. This

situation presents an opportunity for alternative milk supply options to be introduced,

possibly by multinational dairy companies. As imports of dairy products into India are strictly

regulated by means of tariffs and non-tariff barriers these multinational dairy companies

would therefore have to meet their milk supply from domestic sources. But starting and

operating a successful dairy business in India is not an easy task. It is challenging because the

complicated business environment, subsistence type of farming system, lack of quality feeds,

large un-organised sector, fragmented structure of the industry, poor rural infrastructure, huge

socio-cultural diversity and drastic climatic variations, make the process of milk production

and procurement extremely complex. It is therefore important for a multinational dairy

company to thoroughly investigate and understand all the different models it can pursue and

perform a thorough feasibility analysis, before starting a dairy venture in India.

To date there has been limited research on possible larger scale milk supply models for

India. Nor has a comprehensive framework of feasibility analysis specifically for dairy

ventures in India been developed. In order to address these concerns, this study has identified

four possible milk supply models that a multinational dairy company could adopt. It has then

developed a comprehensive framework of feasibility analysis for dairy ventures in India. The

framework was tested on two possible milk supply models, which demonstrated that by

means of this framework it is possible to achieve a robust, disciplined and scientific method

of evaluating the feasibility of large scale dairy ventures in India.

Key words: Feasibility studies, Dairy, India

Introduction

India is the largest milk producer in the world with an annual production in excess of 110

million tonnes in 2009 (International Dairy Federation (IDF) 2009). India is also the worlds

largest consumer of dairy products, consuming nearly 100% of its production. Yet, per-capita

milk consumption (91 kg/year) in India is lower than the world average (103 kg/year). Being a

traditional dairy products consuming nation, with rapid economic development and increasing

house-hold incomes, it is expected that per capita milk consumption will increase considerably in

India. Its estimated that Indias demand for dairy products will increase to around 200 million

tonnes by 2021-22 (National Dairy Development Board (NDDB) 2011). Since dairy imports into

India are strongly regulated using tariffs and tariff rate quotas, much of Indias demand would

need to be met by the domestic dairy industry. However, based on past trends it is projected that

Indias domestic industry will only be able to supply 160 million tonnes resulting in a shortfall

of close to 40 million tonnes (NDDB 2011). This growing demand for dairy products and likely

supply-demand gap presents an opportunity for multinational dairy companies to venture into the

Indian dairy market with alternative milk supply models.

Starting and operating a successful large scale dairy business in India is not an easy task,

especially for a multinational company with little or no experience in India. The complicated

business environment, subsistence type of farming system, lack of quality feeds, large un-

organised sector, fragmented structure of the industry, poor rural infrastructure, huge socio-

cultural diversity and drastic climatic variations make the process of milk production,

procurement, processing and marketing extremely complex. These inherent issues and supply

chain complexities make it vital for a new entrant (multinational dairy company) to thoroughly

investigate and understand all the different models it can pursue and perform a thorough

feasibility analysis, before starting a dairy venture in India.

Although several types and methods of conducting feasibility studies have been described,

none of the research studies have looked at analysing and identifying approaches for conducting

feasibility studies for dairy ventures in India. Moreover, the standard and depth of pre-

investment feasibility studies in India in general and dairy ventures in specific are often not of a

sufficiently high level to ensure well informed decision making at successive stages of the pre-

investment process.

This paper addresses these concerns by developing a comprehensive framework of feasibility

analysis that can be applied to assess the feasibility of large dairy ventures in India. Additionally,

no study has looked at identifying and evaluating possible India specific milk supply models that

multinational dairy companies can adopt. We addressed this issue by identifying suitable milk

supply models for India. Furthermore we also tested the framework of feasibility analysis by

applying it to assess the feasibility of two milk supply models identified. On the whole, based on

the rationale of our study, there were three distinct objectives:

1. Identify/develop models that could be used by multinational dairy companies to meet milk

supply needs in India.

2. Review existing approaches for feasibility analysis and develop a framework feasibility

analysis that can be applied to large scale dairy ventures in India.

3. Test the framework of feasibility analysis by applying it to two of the milk supply models

identified.

Materials & Methods

Research Method and Design

To achieve our objectives, a qualitative research approach has been selected. Qualitative

research usually starts with a loosely defined research problem (Leedy and Ormrod 2001). But as

the study progresses the researcher gains a better understanding of the problem being researched,

and is able to ask specific questions (Leedy and Ormrod 2001). The qualitative research process

is thus evolutionary in nature and assumes structure/shape over the course of the study. This has

been the case in our research study as well.

Data Collection & Analysis

Given the unique nature of the research problem being addressed, most of the data used was

obtained from secondary sources. To identify milk supply models in India, a comprehensive

review of literature as well as informal discussions with relevant stakeholders from the Indian

dairy industry was performed.

An extensive literature review was performed to understand the purpose, mechanics and

methods used for conducting feasibility studies. Based on comprehensiveness, ease of use,

flexibility and specific issues related to this research study, four approaches that could be used

for developing a framework for feasibility analysis of large scale dairy ventures in India were

identified. Elements of these four different approaches were then integrated and a single holistic

framework of analysis with two levels of analysis was developed.

When the framework was applied to a specific milk supply model, once again data from

secondary sources was used. For example, for the analysis of the world dairy sector, information

was primarily collected from reports published by the International Dairy Federation,

International Farm Comparison Network, and Food and Agricultural Organisation. For the

analysis of the Indian dairy sector a wide range of secondary sources such as news and magazine

articles, journal publications, industry/government reports and internet sources were used. For

the analysis of the Indian business environment, secondary sources used included reports

published by Business Monitor International, Economic Intelligence Unit, World Bank and

Political Risk Services.

For each of the model/project specific parameters that needed to be assessed in our

framework, data were collected from mainly secondary sources. These sources included internet

resources, magazine and news articles, journal publications and government reports. Data were

also collected from primary sources that included practicing field veterinarians, professionals in

dairy companies, engineers and agricultural officers

As a part of the data analysis process, all relevant data were initially screened to identify key

factors and conceptual themes that were outlined as critical in our framework. Following which a

filter was applied and only essential data that reflected a vital concept or phenomenon that was

relevant to the parameter being assessed were recorded. This data were then condensed and

categorised in a logical manner to meet the specific requirements and reinforce each theme

within the parameter that they represented.

Results & Discussion

Identifying Milk Supply Models

Based on the suitability (fit with) to the broad (general) vision, objectives and operations of

multinational dairy companies, we identified four possible models a multinational dairy

company can use for meeting its milk supply needs in India. In the first model (Single Tier

Dairy Farming Model) we suggest establishing (multiple) large scale dairy farms (>3000

cows/farm) that are owned (either wholly or in partnership) and operated by the dairy company.

It is expected that this model will give significantly greater control over the supply and quality of

raw material. No dairy company has used this model in India as yet.

In the second model (Two Tier Dairy Farming Model) we suggested establishing a two

level farming model consisting of 1) nucleus farms and 2) satellite farms. The nucleus farms

could be the focus of this operation and will be owned and operated by the dairy company. It will

be significantly larger than existing commercial dairy farms about 500- 1000 animals. The

satellite farms will be smaller in size (25 150 animals) and in relatively close proximity (<100

km) to the nucleus farm. They will be almost wholly owned (the dairy company can have a

minority stake) by dairy entrepreneurs/progressive dairy farmers. The satellite farms will

function as distinct entrepreneurial units but will receive technical/ management oversight and

support services from the dairy company. The satellite farms will have a contractual obligation to

produce milk of a standard quality and supply 100% of their production to the dairy company.

The satellite farms will also be open to audit/inspection by the dairy company. The Chitale group,

a dairy company based in Maharashtra state of India, uses a similar model

In thethird model (Retail Procurement Model) we suggest sourcing milk from small and

large dairy farmers without establishing dairy farms. Most cooperatives and private dairy

companies in India use this approach to source milk. The cooperative usually establishes a milk

collection centre at each of its primary milk societies (at village level) - covering a few hundred

farmers and the farmers deliver milk (usually twice a day) to the collection centre. The milk from

each collection centre is then transported to a chilling station or processing plant by the

cooperative.

Unlike cooperatives, most private companies do not deal with producers directly but instead

work with milk procurement agents at the village level. The dairy company negotiates its terms

of trade with the agent and the agent in turn negotiates his terms of trade with the producer. The

dairy company supplies the agents with milk coolers (Bulk Milk Tanks/ Vat) and necessary

equipment for performing routine milk testing at a milk chilling centre. The costs of running the

milk chilling centre are usually borne by the agent. The agent has a contractual obligation to

supply milk of standard quality and pre-determined volume to the dairy company.

In the fourth model (Wholesale Procurement Model) we suggest using one or more third

parties to supply milk. The third party will ideally be an existing dairy processor (either privately

owned or a cooperative) with well-developed milk sourcing operations. The third party will have

a contractual obligation to supply milk of specified standard and volume on a regular basis to the

dairy company. Through this approach large volumes of milk can be sourced from one or few

suppliers, thus preventing the need to establish and develop the elaborate infrastructure required

for sourcing milk directly from producers. The third party could also perform the task of

processing milk or manufacturing products as per the specifications of the dairy company,

thereby eliminating the need to establish a processing plant. A few well known dairy/food

companies in India (Nestle, Unilever, and Danone) use this model to meet some of their supply

needs.

Developing the Framework of Feasibility Analysis

We have identified four approaches that can be applied to conduct a feasibility analysis of a

dairy venture in India. The first approach is the method developed by the United Nations

Industrial Development Organisation (UNIDO Approach) specifically for conducting industrial

feasibility studies (UNIDO 1978). This approach allows for a stage-by-stage analysis of the

various components of a feasibility study. It is comprehensive, flexible and covers all the vital

components of a general feasibility study.

The second approach (S & S Approach) is a simple yet useful method for conducting a

feasibility study. It is adapted from the book how to prepare a feasibility study written by

Stevens and Sherwood (1982). It is not as comprehensive or in-depth as the UNIDO approach;

hence it cannot be used as stand-alone method for feasibility assessment. However, there are

certain elements of this approach that can be used to compliment other approaches and add value

to the Framework.

The third approach (R-W-W approach) is not a feasibility study by itself, but instead is a

tool that can be used for screening and evaluating projects. The tool comprises of - 1) Risk

Matrix, and 2) Real-Worth -Win (R-W-W) screen and is considered to be a disciplined and

systematic process to identify and fix problems that constrain a project, to contain risk, and

expose problems that cannot be fixed (Day 2007). The origin of this method lies in the area of

innovation and product development and is therefore designed to specifically assess the viability

of new products /technologies /services /innovations. The underlying concepts and principles of

this method can be applied to assess the feasibility of a wide range of projects.

The fourth approach (AgSystems Approach) looks at feasibility studies from a (agro-

industrial) systems perspective. This approach has been adapted from the work of J ames Austin

Agroindustrial Project Analysis (Austin 1992) and focuses on the distinctive nature of

agroindustrial projects and the design factors critical to its success. The approach is based on the

rationale that agroindustrial projects are a part of an integrated system with vital inter-linkages

and focuses on four systemic linkages -1) Production chain linkages, 2) Macro-micro policy

linkages, 3) Institutional linkages, and 4) International linkages (Austin 1992). The feasibility

analysis therefore requires a comprehensive understanding of how these four linkages interact

and affect the viability of the agro-industrial project. To add additional depth to this analysis, the

inter linkages are viewed in conjunction with the three core operations of agroindustries 1)

procurement, 2) processing and 3) marketing. Since this approach introduces an agroindustrial

angle to project analysis, we believe it can generate vital insights that may not be revealed by the

other approaches.

Each of the four approaches identified has distinct strengths and weaknesses (Table 1).

Table 1: A Comparison of the relative Strengths and Weaknesses of the Four Approaches

Chosen

S. No Parameters/ Factors

Considered

Approach

I

(UNIDO)

Approach

II

(S & S)

Approach

III

(R-W-W)

Approach

IV

(AgSystems)

1. Contextual Factors

2. Project Rational &

Context

3. Demand & Market

4. Production, Technical &

Engineering

5. Material Input/Supply

6. Location & Site

7. Labour & Management

8. Project Economics

9. Financial Analysis

10. Risk Issues

11. Implementation and

Scheduling

12. Political & Legal Issues

13. Socio-Economic Impacts

14. Environmental Impacts

15. Sustainability*

16. Degree of being

HOLISTIC

17. Ease of Application

18. Flexibility of Assessing

other parameters (Ex.

Goodwill, Follow on

opportunities, etc)

Note: This is a relative assessment

-Indicates the approach that is BEST suited of the five for assessing a given

parameter/ factor

-Indicates the approach that is LEAST Suitable of the five for assessing a given

parameter/ factor

* For the assessment of Sustainability, a modification of the method recommended by

IFCN (2010) was used.

On the whole, to use as a stand-alone approach, the S& S approach is the weakest while the

UNIDO and RWW approaches are much more robust (Table 1). Although each of these

approaches appears to be different, their end objectives are similar to identify if a particular

project is worth pursuing. However, to increase the accuracy of a feasibility study, as well as to

make it multi-dimensional, it would be essential to follow a more holistic approach.

Assessing Feasibility of Dairy Ventures in India in Using the Framework

In order to have a more holistic approach, the feasibility study framework we developed

integrates elements from all four approaches, and had two levels of analysis. Guidelines and

principles recommended by all four approaches were used for assessment of the parameters

identified. But importance given to each approach, depended on the relative strength of that

approach with regards to the parameter being assessed. For example, in the assessment of Project

Rationale & Context, the exact order of importance of approaches used was Approach I>

Approach IV >Approach III >Approach II. This is in line with the relative strength of

Approaches for that particular parameter (Table 1).

The first level of analysis focuses on describing the underlying contextual factors that shape

and influence the outcomes of large scale dairy ventures in India. The outcomes of the level 1

analysis are put into context in the level 2 stage of the feasibility analysis process. The second

level of analysis is specific to the milk supply model being assessed. The main focus is on

identifying the project/model specific feasibility parameters to be assessed, and subsequently

capture necessary data for each of these parameters. Additionally outputs from level 1 were

rigorously screened/evaluated and put it into context for the specific milk supply model being

evaluated.

Level 1 Analysis

This analysis is based on rationale that agro-industries in general and the dairy sector in

specific do not exist either in a vacuum or in isolation. But instead they exist in a largely

interconnected global web of governments, markets, institutions and industries (Austin 1992).

The dairy sector in particular is an integral part of the global food market and the key to

understanding the global food industry lies with understanding changing consumer

demands/preferences and the food industrys efforts to meet these demands (Gehlhar 2006).

However, the global Food Market in itself is extremely dynamic and the process of transporting

food from the farm to the table has become more complex, and involves diverse local, national,

and global agents and networks (Regmi, 2003). These evolving Food Markets are driven not only

by changes in consumer preferences, but also by technology, linkages between members of the

food supply chains, and prevailing policies and business environments (Regmi, 2003).

Based on this rationale and principles recommended primarily by approach IV and

secondarily by approach I of our framework, we identified three critical contextual factors that

need in-depth analysis and understanding. These were The World dairy sector, the Indian dairy

sector and the India business environment. We believe this analysis will identify any significant

barriers to entry as well as critical factors that influence the success or failure of a dairy venture

in India. The concepts and themes covered in this analysis (Level 1) are not bound to a specific

milk supply model, but instead have a significant bearing/influence on any/all of the milk supply

models identified. Although an in-depth assessment of world dairy sector, Indian dairy sector

and India business environment was performed, only a brief summary is presented here.

World Dairy Sector

Over the last three decades the livestock sector in general and dairy sector in particular has

witnessed rapid global expansion in both production and consumption. The main driver of this

livestock revolution has been population and income growth, coupled with increased

urbanization and change in consumer preferences to livestock products. Dairy has been an

integral part of this revolution and world milk production has increased considerably over the

last there decades. In 2009, world milk production stood at 699 million tonnes (MT) with the

largest producers being EU-27 (150 MT), India (110 MT), and USA (86 MT) (International

Dairy Federation 2009).

But, dairy is a very sensitive industry in many countries (both developed and developing) and

is therefore protected by various trade policies. Milk is also a bulky and perishable commodity.

As result only 7% of world milk production is traded internationally. In recent years the demand

for dairy products has remained stagnant in developed nations. Consequently, dairy companies

operating in the big and mature markets such as Europe and USA face limited market growth

opportunities in terms of volumes per capita and growth can only occur by increasing market

shares or switching to higher value-added products. In contrast the demand for dairy products

has been quite robust in the developing countries and multi-national dairy companies are

increasingly looking towards these markets for ensuring growth in sales and revenue. However,

entry into these markets could be quite difficult. One such emerging market which presents both

an interesting challenge and opportunity for dairy companies is India.

Indian Dairy Sector

India is the largest milk producer in the world with an annual production in excess of 110

million tonnes in 2009 (International Dairy Federation 2009). The Indian dairy markets value

was estimated to be about 42.5 Billion US$ in 2007 (Dairy India 2007). The dairy industry in

India is integrally linked to the overall economic well being of the country because it serves as a

vital source of employment and provides livelihood opportunities to millions of small farmers in

rural India.

The average herd size of a dairy farmer in India is about 3 animals and farming systems are

essentially of a low input/subsistence type. As a result the productivity of these dairy animals

(1000kg ECM /year) is extremely low and quality of milk is poor. For most of these farmers,

dairying is a secondary occupation- with off farm employment or crop farming being the main

source of income. Moreover, the primary purpose of rearing dairy animals for these farmers is to

produce milk for self-consumption and satisfy a nutritional need; and selling milk (marketable

surplus) for profit is a secondary objective.

Apart from low productivity, another significant drawback is that the dairy industry is

underdeveloped and fragmented. Its estimated that only 25 percent of the marketable surplus is

delivered to the organized dairy sector which comprises of cooperatives and privately owned

milk processing companies. The remaining 75 percent of milk is marketed through the un-

organized or informal sector which comprises primarily of milk vendors. The milk vendors

generally source milk directly from farmers (in rural/peri urban areas) and sell fresh

(unprocessed) milk directly to their customers/consumers (in urban areas). The quality of raw

milk in India is also a major issue. A recent survey on Milk Quality across India by the Food

Safety and Standards Authority of India (FSAI) reported that 69 per cent of milk samples

collected failed to meet the basic quality standards (FSSAI 2011).

Although India is the worlds largest consumer of dairy products, consuming nearly 100% of

its production, per-capita milk consumption (91 kg/year) in India is lower than the world average

(103 kg/year) (IFCN 2010). With rapid economic development and increases in family incomes,

it is expected that per capita milk consumption will increase considerably in India. Its estimated

that Indias demand for dairy products will reach around 200 million tonnes by 2022 (NDDB

2011). Since dairy imports into India are strongly regulated using tariffs, tariff rate quotas, and

non-tariff barriers much of Indias demand has to be met by the domestic dairy industry.

However, based on past trends, Indias domestic industry will only be able to supply 160 million

tonnes resulting in a shortfall of 40 million tonnes (NDDB 2011). This growing demand for

dairy products and likely supply-demand gap presents an excellent opportunity for multinational

dairy companies to venture into the Indian dairy market.

Indian Business Environment

The overall business climate in India is characterised by excessive red tape, lack of

transparency, high levels of corruption, an archaic legal system, weak labour conditions and a

volatile security outlook. Foreign businesses have to manoeuvre through a maze of rules and

certifications to obtain approvals needed for setting up businesses in India (unless they are

operating within a special economic zone). Moreover, opposition from strong labour unions and

political constituencies has slowed reform in such areas as FDI, exit policy, bankruptcy, and

labour law. Additionally a significant challenge affecting the business environment in India

centre on its poor infrastructure. Due to these issues, India ranks a relatively lowly 134 (out of

183 countries) on the overall ease of doing business according to the World Bank's 2010 Doing

Business survey.

Level 2 Analysis

In this analysis, each of the 15 parameters identified in our framework are assessed

individually using the guidelines prescribed by two or more approaches (Table 2). Using the

mechanics of the RWW (approach III) as an example, the process of assessing each parameter in

our framework was simplified through the framing of well-defined questions and identifying

answers (Table 2). Based on a subjective analysis of data/information pertaining to each question,

a best answer is identified (Table 2). The flexibility of this method allows the researcher to

incorporate and analyse any specific issues/concerns that might arise within the context of the

larger parameter being assessed.

To add further structure to the analysis, answers to the questions were classified into one of

three categories Yes, Maybe and No. Additionally, to make interpretation easier a scoring

system was also introduced. Based on the analysis of the data, a Yes answer could receive a

score from 1 to 3, Maybe answer a score from 4 to 6 and No answer receives a score between 7

and 9. Depending on the relative importance of each theme a particular question represents,

weights can be assigned by a researcher if required. Following which an average feasibility score

(Ranging from 1 to 9) for the parameter can be calculated.

Once feasibility scores for all 15 parameters have been derived, the overall feasibility score

(Ranging from 1 to 9) and also feasibility profile for the project can be arrived at. Once again

weights can be included if required by an investor/researcher to stress the relatively greater

importance of certain parameters to the company/model.

Finally, an overall feasibility score of less than 3 indicates that project/model is feasible, and

is worth pursuing provided most critical parameters are not in the not-feasible spectrum. A score

greater than 3 and less than 6 indicates that further study is required to try and identify if more

feasible options are possible. And a score greater than 6 indicates that the project/model is not

feasible, and hence not worth pursuing any further (at this point in time).

Applying the Framework of Feasibility Analysis to Milk Supply Models

In this section, the frame work of feasibility analysis was evaluated using a hypothetical

situation. We assumed that a large multinational dairy company (DC) planned to enter the Indian

dairy market and is examining possible milk supply options. In this initial/pilot venture, the DC

will process 27 million litres of milk each year or approximately 75,000 litres of milk each day.

This is similar to the processing capacity of an average dairy plant in India.

Due to serious concerns regarding the quality and safety of raw milk supply in India, the DC

has decided that it would have to take control of the milk production process at farm level. In

both Models 3 and 4 the DC has no control over milk production at farm level and are therefore

ruled out. However, in both models 1 and 2 the dairy company has control of milk production at

farm level. Hence both models 1 and 2 will be evaluated using the frame work of feasibility

analysis that was developed.

For the purpose of this study, quality milk is defined as - Milk produced from healthy

/disease free cows. The milk will be free of antibiotics, chemical substances, hazardous materials

and adulterants. The mean SCC will be <150,000/ml, and bacterial levels will be within

prescribed international standards. Since the principle researcher of this study comes from the

Krishna district of Andhra Pradesh state in India, it was selected as the region where the DC will

establish its operations. Krishna District is one of the most prosperous and developed regions of

India.

Model 1 Single tier dairy farming system

The dairy company will establish a single 3000 cow dairy farm to meet its entire milk supply

needs. The cows will be purebred Holstein Friesians and will be imported from North

America/Europe/New Zealand. Each cow is expected to produce 25 litres of milk/day on

average. The cows will be completely housed indoors in barns and will be milked in a state of

the art milking parlour. They will be fed a total mixed ration comprising of maize, leucerne, crop

residues and local agro-industrial by products. The significant benefit of this model is greater

control over quality and shorter time to achieve scale.

Model 2 Two tier dairy farming system

The dairy company will establish and own a nucleus farm of 600 cows, and have control and

ownership of dairy assets in 80 satellite farms. The rationale being, the nucleus farm will

produce around 20% of the milk (15,000 litres/day), while the satellite farms will produce the

rest (60,000 litres). Each of the satellite farms will be owned and managed by local farmers. It

will have 50 cows and produce 750 litres/day. The lower production is because this model will

be more adapted to local conditions, especially animal genetics & management systems. Once

the model is perfected it allows for a two directional expansion strategy by - increasing size and

numbers of 1) nucleus farms, and 2) satellite farms.

Analysis of Feasibility of Model 1 & Model 2

The parameters assessed, specific questions asked and scores obtained by Model 1 and

Model 2 are shown in Table 2. Model 1 had a greater number of answers in the No (Not feasible)

spectrum than Model 2 (Table 2). Also, the number of parameters with an average score greater

than 6 was more for model 1 (n =4), than model 2 (n =1) (Figure 1).

The overall weighted feasibility score of model 1 was 5.5, while that of model 2 was 4.5.

This indicates that both models fall in the Maybe spectrum and further investigation/study is

required before a final decision can be taken (Figure 1). Importantly, Material Input/Supply,

Location & Site, Risk and Socio-Economic/Cultural issues appear to be significant constraints

for Model 1 (Figure 1). While Implementation & Scheduling issues appear to be the most

critical constraint for model 2 (Figure 1).

0.00

1.00

2.00

3.00

4.00

5.00

6.00

7.00

8.00

Project

Rationale/Context

Demand & Market

Production &

Engineering

Material

Input/Supply

Location & Site

Labour &

Management

Project Economics &

Financial Analysis

Risk Issues Sustainability

Implementation&

Scheduling

Political &

Legal/Regulatory

Socio-

Economic/Cultural

Environmental

Impacts

Good-will & Follow

on opportunities

Other

Figure 1. Feasibility Profile of Model 1 and Model 2

Model 1 Model 2

Score 1 to 3 = Yes (Feasible)

Score > 3 to 6 = Maybe (Further Study Required)

Score > 6 to 9 = No (Not Feasible)

Although this analysis is based on in-depth data collection and analysis, it must be

remembered that the situation being studied is hypothetical, and the purpose of this exercise is to

test the framework and demonstrate its applicability.

Table 2. Assessing Feasibility of Model 1 and Model 2 using Framework of Analysis

S. No

Parameters

(Weightage %)

Questions framed

Score

Model 1 Model 2

1. Project

Rationale/

Context

Is model rationale sound? 3.00 4.00

(6) Does model fit into the larger context? 8.00 5.00

Does company have prior experience

in executing similar model?

4.00 7.00

Does company have superior

resources?

3.00 4.00

Is it in line with the vision & strategy

of the company?

4.00 4.00

Average Score 4.40 4.80

2. Demand &

Market

Is there a demand for the product? 3.00 3.00

(8) Are factors driving demand

known/clear?

3.00 3.00

Can customers buy it? 3.00 3.00

Is size of potential market large

enough?

4.00 4.00

Can an adequate market share be

achieved

5.00 5.00

Will customers buy it? 4.00 4.00

Can company understand and respond

to market?

6.00 6.00

Average Score 4.00 4.00

3. Production &

Engineering

Are the technical specifications

known?

5.00 6.00

(10) Can project/model be executed with

locally available technology &

materials?

8.00 5.00

Can technology & operational

standards be met easily?

7.00 5.00

Are local supply/support services

NOT critical/ essential?

7.00 5.00

Are local support services available/

dependable?

7.00 5.00

Does a value chain for the product

exist?

5.00 4.00

Can logistical challenges be easily

addressed?

6.00 6.00

Average Score 6.43 5.14

4. Material Input/

Supply

Can critical raw materials be

produced/ sourced?

8.00 5.00

(8) Is it of sufficient quantity? 8.00 4.00

Is it of acceptable quality? 7.00 5.00

Average Score 7.67 4.67

5. Location & Site Are climate and environment

conditions favourable?

9.00 6.00

(8) Can a project site be easily acquired? 8.00 5.00

Is it at reasonably close proximity to

markets?

6.00 5.00

Is it at close proximity to raw

materials?

6.00 4.00

Is local infrastructure adequate? 7.00 5.00

Can it function without support of

political establishments and

bureaucracy?

6.00 4.00

Average Score 7.00 4.83

6. Labour &

Management

Are sufficient un-skilled and semi-

skilled workers available locally?

4.00 3.00

(4) Do they (local skilled and semi-skilled

workers) have adequate/appropriate

experience/background?

7.00 4.00

Are sufficient supervisory &

managerial personnel available

locally?

6.00 5.00

Do they (local supervisory &

managerial personnel) have

adequate/appropriate

experience/background?

6.00 5.00

Can project be implemented without

Ex-pat managerial presence?

6.00 7.00

Is threat & impact of industrial strife

low?

5.00 3.00

Average Score 5.67 4.50

7. Project

Economics &

Financial

Analysis

Can costs be accurately determined? 4.00 5.00

(8) Will forecasted returns be greater than

costs?

4.00 4.00

Is forecasts riskiness low? 5.00 6.00

Is time to breakeven acceptable 4.00 5.00

Is ROI adequate (greater than 15%)? 4.00 4.00

Is NPV/IRR adequate? 4.00 4.00

Average Score 4.20 4.80

8. Risk Issues Is there a market risk* 6.00 6.00

(10) Is there a product risk* 7.00 5.00

Is there a significant input price risk? 7.00 5.00

Is there a significant output price? 5.00 6.00

Is there a food safety/human health

risk?

2.00 3.00

Is there an animal health/biosecurity

risk?

7.00 5.00

Is there a security risk? 5.00 5.00

Are there any potential causes for

project failure that cannot be

mitigated?

Are overall risks acceptable? 8.00 5.00

Average Score 5.88 5.00

9. Sustainability Can model be profitable without

government subsidies?

2.00 2.00

(6) Is cost of production less than US$

30/100 kg milk?

6.00 4.00

Is operating profit margin greater than

16%?

5.00 4.00

Is milk yield per cow greater than

7000 kg/year?

2.00 6.00

Is feed efficiency (kg milk/kg DM)

greater than 1.2

5.00 6.00

Is milk price greater than US$ 40/100

kg milk

4.00 4.00

Is labour price less than US$ 6/hour 3.00 2.00

Is quality of milk good? (SCC less

than 2000,000/ml & Bacterial count

less than 150,000 cells/ml)

2.00 4.00

Average Score 3.63 4.00

10. Implementation

and Scheduling?

Can a definite project timeline be

defined /designed?

4.00 6.00

(4) Can the targets in the timeline be met? 6.00 7.00

Are significant project overruns NOT

expected?

6.00 7.00

Average Score 5.33 6.67

11. Political &

Legal/

Regulatory

Issues

Is model NOT a politically sensitive

issue?

7.00 4.00

(6) Is general political environment stable

and favourable

5.00 5.00

Do political threats exist? 5.00 4.00

Are impacts of political threats small/

insignificant?

5.00 5.00

Can political system be prevented

from giving competitors unfair

advantages?

5.00 5.00

Is legal environment stable and

favourable?

6.00 7.00

Are rules, regulations and policies

affecting the model clearly defined/

transparent?

6.00 7.00

Can legal/regulatory system be

prevented from giving competitors

unfair advantages?

6.00 6.00

Average Score 5.63 5.38

12. Socio-Economic

&

Cultural

Impacts

Does it fit with the local culture &

norms

7.00 4.00

(6) Does it include participation of local

stakeholders

7.00 4.00

Does it deliver significant benefits to

local communities

7.00 4.00

Does it contribute towards

development of local dairy industry

6.00 3.00

Will it NOT cause displacement of

local farmers

6.00 3.00

Average Score 6.60 3.60

13. Environmental

Impacts

Does model pose a threat to

environment?

6.00 4.00

(6) Can environmental damage be

mitigated/contained /limited?

4.00 4.00

Is environmental damage (if any)

significantly less than existing

practices/systems?

4.00 4.00

Average Score 4.67 4.00

14. Good-will &

Follow on

opportunities

Will project generate good-will

locally?

7.00 3.00

(4) Will it enhance companies brand

equity?

5.00 3.00

Does it provide for follow-on

opportunities & new market access?

5.00 2.00

Average Score 5.67 2.67

15. Other Does model have a competitive

advantage?

4.00 3.00

(6) Can the advantage be sustained? 7.00 5.00

Is it known how competitors will

respond?

6.00 6.00

Can company be competitive? 4.00 4.00

Average Score 5.25 4.50

* For the assessment of Market Risk & Product Risk the guidelines (Risk Matrix)

suggested by Day (2007) were followed.

Summary & Conclusions

The biggest challenge Indias domestic dairy industry faces are increasing both production

and quality of milk to meet rising consumer demand and expectations. This challenge (expected

domestic Supply-Demand gap) presents multinational dairy companies with an opportunity to

enter the Indian dairy sector. However, the task of starting and successfully operating a large

dairy venture in India might be quite challenging - especially for a multinational company that

has little or no experience in India. It is therefore vital for a new entrant (multinational dairy

company) to identify and understand all the different models it can pursue, and perform a

thorough feasibility analysis before starting a dairy venture in India.

In our study, we identified four possible models a multinational dairy company can use for

venturing into the Indian dairy sector. We also developed a unique framework of feasibility

analysis for large scale dairy ventures in India. We then tested this framework by applying it to

two models (single-tier dairy farming model and two tier farming model) that a hypothetical

multinational dairy company might consider using.

By means of this framework we were able to achieve a robust, disciplined and scientific

method of evaluating the feasibility of large scale dairy ventures in India. As a part of our

framework of analysis a thorough study of the Global dairy sector, Indian dairy sector and the

Indian business environment was performed. The various global and local issues specific to the

Indian dairy market were highlighted through this process; all are critical to the success of any

dairy venture into India.

We suggest that future research should now focus on developing sub-models

(scenarios/options) within each identified model to identify milk supply options that are most

feasible as well as a best fit with a dairy companys vision, values and goals. The framework

of analysis can then be used to identify the most feasible option within each model.

The benefit of a rigorous feasibility analysis using this framework is presented as primarily

being the ability to forewarn of issues and so avoid the slower learning by experience that is a

common outcome when multinationals venture into new countries.

References

Austin J .E. 1992. Agroindustrial project analysis. EDI Series in Economic Development.

Washington, D.C.: The World Bank.

Day, A. 2007. Is It Real? Can We Win? Is It Worth Doing? Managing Risk and Reward in an

Innovation Portfolio, Harvard Business Review, December, pp. 110-120.

Food Safety and Standards Authority of India (FSSAI). 2011. Executive Summary on National

Survey on Milk Adulteration http://www.fssai.gov.in/Portals/0/Pdf/sample_analysed(02-01-

2012).pdf (accessed February 2, 2012)

Gehlhar, M, Regmi, A., Stefanou, S.E., and B. Zoumas. 2006. Managing Firm Competitiveness

in Global Markets, Working Papers 0714, University of Crete, Department of Economics.

International Dairy Federation (IDF). 2009. The World dairy Situation 2009. Bulletin of the

International Dairy Federation, 438/2009.

International Farm Comparison Network (IFCN). 2010. Dairy Report 2010 For a better

understanding of milk production world-wide.

Leedy, P.D. and J .E. Ormrod. 2001. Practical research: planning and designing (7

th

ed.). New

York. Macmillan Publishing Company.

National Dairy Development Board (NDDB). 2011. Annual Report 2010-2011.

http://www.nddb.org/English/AnnualReports/nddb-annual-report%202010-2011.pdf

(accessed February 2, 2012)

Regmi, A. 2003. A Richer World Wants a Richer Diet. AmberWaves (The Economics of Food,

Farming, Natural Resources, and Rural Ameatica).

http://www.ers.usda.gov/AmberWaves/November03/findings/richerworld.htm (accessed

April 5, 2011)

Stevens, R. E. and D. K. Sherwood 1982. How to Prepare a Feasibility Study. Englewood Cliffs,

NJ : Prentice-Hall.

United Nations Industrial Development Organisation (UNIDO). 1978. Manual for the

Preparation of Industrial Feasibility Studies. United Nations, New York.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A10VSO Repair ManualDocument29 pagesA10VSO Repair ManualAlexandru Ganziuc97% (29)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Building Social Business Muhammad YunusDocument186 pagesBuilding Social Business Muhammad YunusGisele Dottori Barreto100% (2)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Conversão de Correias CumminsDocument93 pagesConversão de Correias CumminsRafael Fernando67% (6)

- HSN Code DetailsDocument6 pagesHSN Code DetailsflytorahulNo ratings yet

- Budget Literacy PDFDocument233 pagesBudget Literacy PDFramNo ratings yet

- Mechemco - R-30102017 PDFDocument7 pagesMechemco - R-30102017 PDFflytorahulNo ratings yet

- Exe Summ RajatCement Eng PDFDocument12 pagesExe Summ RajatCement Eng PDFflytorahulNo ratings yet

- 4018 Signa (Mat447230) - 70-81Document12 pages4018 Signa (Mat447230) - 70-81flytorahulNo ratings yet

- List of Sanctioned Cases Under IIPP 98th SLC Held On 14/08/2013Document43 pagesList of Sanctioned Cases Under IIPP 98th SLC Held On 14/08/2013flytorahulNo ratings yet

- Airline Mobile Marine BrochureDocument16 pagesAirline Mobile Marine BrochureflytorahulNo ratings yet

- Alkyl Phenolic Resin - 1 (TDS) PDFDocument1 pageAlkyl Phenolic Resin - 1 (TDS) PDFflytorahulNo ratings yet

- Srma Steel News: Steel Re-Rolling Mills Association of IndiaDocument20 pagesSrma Steel News: Steel Re-Rolling Mills Association of Indiaflytorahul100% (1)

- Brochure EC250D EC300D T3 EN 30 20035491 CDocument28 pagesBrochure EC250D EC300D T3 EN 30 20035491 CLU YO100% (1)

- Tarrif Schedule 18-19Document29 pagesTarrif Schedule 18-19flytorahulNo ratings yet

- WipexDocument20 pagesWipexflytorahulNo ratings yet

- JSPL Hydra InquiryDocument5 pagesJSPL Hydra InquiryflytorahulNo ratings yet

- Swing Bearing - KTR PDFDocument2 pagesSwing Bearing - KTR PDFflytorahul100% (1)

- Goods Rates Booklet 03july2017Document176 pagesGoods Rates Booklet 03july2017Vaishnavi JayakumarNo ratings yet

- Banco Alu Radiator Price ListDocument8 pagesBanco Alu Radiator Price Listflytorahul0% (1)

- RaipurDocument9 pagesRaipurflytorahulNo ratings yet

- Replacement Spare Parts For ZF: Made in ItalyDocument29 pagesReplacement Spare Parts For ZF: Made in Italyflytorahul100% (2)

- Nit 1Document29 pagesNit 1flytorahulNo ratings yet

- SERIE 80M20 - 2C: Wing Style ComponentsDocument8 pagesSERIE 80M20 - 2C: Wing Style ComponentsflytorahulNo ratings yet

- Suman Singh VsDocument5 pagesSuman Singh VsflytorahulNo ratings yet

- Us Er Plugged in The Last MileDocument16 pagesUs Er Plugged in The Last MileflytorahulNo ratings yet

- Ac Spares OrderDocument2 pagesAc Spares OrderflytorahulNo ratings yet

- Alfacurrate AAA PMS Jul16Document39 pagesAlfacurrate AAA PMS Jul16flytorahulNo ratings yet

- Beml Vendor ListDocument30 pagesBeml Vendor ListPrashanth Kumar Nagraj Ganiga100% (1)

- Ag13034 Ag Cat Uk WebDocument172 pagesAg13034 Ag Cat Uk WebflytorahulNo ratings yet

- 00 ConversionsDocument28 pages00 ConversionsrandyooiscribdNo ratings yet

- Crisil Analysis 50 Leading SmesDocument64 pagesCrisil Analysis 50 Leading Smesflytorahul100% (1)

- Prepared by M Suresh Kumar, Chief Manager Faculty, SBILD HYDERABADDocument29 pagesPrepared by M Suresh Kumar, Chief Manager Faculty, SBILD HYDERABADBino JosephNo ratings yet

- Public Administration MainsDocument4 pagesPublic Administration MainsvaripsNo ratings yet

- Jeremy RothfieldDocument7 pagesJeremy RothfieldJeremy RothfieldNo ratings yet

- LIC New Endowment Plus 9 Inch X 8 Inch EngDocument20 pagesLIC New Endowment Plus 9 Inch X 8 Inch EngMexico EnglishNo ratings yet

- Final Answer KeyDocument13 pagesFinal Answer Keysiva prasadNo ratings yet

- Asset-Liability Management in BanksDocument42 pagesAsset-Liability Management in Banksnike_4008a100% (1)

- Indusind Bank Internship PresentationDocument19 pagesIndusind Bank Internship Presentationcharu kapoorNo ratings yet

- CFA Level 2 Fixed Income 2017Document52 pagesCFA Level 2 Fixed Income 2017EdmundSiauNo ratings yet

- Fund Acc - Ringkasan Chapter 1Document3 pagesFund Acc - Ringkasan Chapter 1Andini OleyNo ratings yet

- MGT8200 - Chapter 3Document9 pagesMGT8200 - Chapter 3Si WongNo ratings yet

- CIR v. Aichi Forging Company of Asia, IncDocument22 pagesCIR v. Aichi Forging Company of Asia, IncAronJamesNo ratings yet

- UntitledDocument25 pagesUntitledapi-167940199No ratings yet

- DIGEST - BPI Vs CIR 2005Document2 pagesDIGEST - BPI Vs CIR 2005Mocha BearNo ratings yet

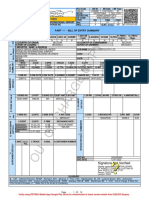

- 679089110072023INBLR4BE1120720231426Document12 pages679089110072023INBLR4BE1120720231426Abishek AbiNo ratings yet

- First National City Bank of New York Vs Tan - G.R. No. L-14234. February 28, 1962Document4 pagesFirst National City Bank of New York Vs Tan - G.R. No. L-14234. February 28, 1962RonStephaneMaylonNo ratings yet

- 0102 34 Si Eog 1Document79 pages0102 34 Si Eog 1Sanjiv KubalNo ratings yet

- AlgorithmDocument2 pagesAlgorithmPato MartinezNo ratings yet

- Hitungan Kuis 6 Bethesda Mining CompanyDocument6 pagesHitungan Kuis 6 Bethesda Mining Companyrica100% (1)

- Regine Mae Yaniza - 2 Year BsceDocument10 pagesRegine Mae Yaniza - 2 Year BsceRegine Mae Lustica Yaniza0% (1)

- Democracy and The Policy Preferences of Wealthy AmericansDocument53 pagesDemocracy and The Policy Preferences of Wealthy AmericansUmkc EconomistsNo ratings yet

- Central Bank of India Recruitment 2013, Vice President, Manager, Executive Officer - Sep 2013Document10 pagesCentral Bank of India Recruitment 2013, Vice President, Manager, Executive Officer - Sep 2013malaarunNo ratings yet

- SINAG Business PlanDocument23 pagesSINAG Business PlanErika FloresNo ratings yet

- Real Estate Finance and Investment - Lecture NotesDocument2 pagesReal Estate Finance and Investment - Lecture NotesCoursePin100% (1)

- 4AC0 01 Que 20150107Document20 pages4AC0 01 Que 20150107anupama dissanaykeNo ratings yet

- October 2022 BOLTDocument78 pagesOctober 2022 BOLTsauravNo ratings yet

- MKC006910 PDFDocument1 pageMKC006910 PDFShylesh RaveendranNo ratings yet

- Excel Budget ProjectDocument7 pagesExcel Budget Projectapi-341205347No ratings yet

- D 4 MZ DHG HUVMd IVDGDocument12 pagesD 4 MZ DHG HUVMd IVDGSagar VermaNo ratings yet