Professional Documents

Culture Documents

Nephrol. Dial. Transplant. 1999 Vorbeck Meister 666 75

Uploaded by

Paola CerattoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nephrol. Dial. Transplant. 1999 Vorbeck Meister 666 75

Uploaded by

Paola CerattoCopyright:

Available Formats

Nephrol Dial Transplant (1999) 14: 666675

Nephrology

Dialysis

Transplantation

Original Article

Quality of water used for haemodialysis: bacteriological and chemical

parameters

Irene Vorbeck-Meister1, Regina Sommer1, Friedrich Vorbeck2 and Walter H. Ho rl3

1Hygiene Institute, University of Vienna, 2Department of Radiology 6F and 3Department of Nephrology and Dialysis,

General Hospital, University of Vienna, Vienna, Austria

Abstract suitability of materials in contact with the water and

of the chemicals used, for example regenerants or Background. The bacterial and chemical contamina-

tion of dialysate uids are important problems in corrosion inhibitors. From the microbiological point

of view, a safety UV disinfection step in the water- haemodialysis therapy and may be caused by the water

used for dialysate preparation. treatment system is favourable. To avoid bacterial

recontamination periodic cleaning and disinfecting of Methods. We performed a survey of the microbio-

logical and chemical quality of the water used in seven the water-treatment and distribution systems, as well

as the dialysis machine are essential. There is the need dialysis wards. Special attention was paid to the eects

of each water treatment step, for example ion exchange, for complete guidelines regarding dialysis water that

include all relevant chemical and microbiological para- reverse osmosis and UV disinfection, on the number

of bacteria (measured as colony forming units, CFU), meters. Based on this standard, periodic examination

of the water after each treatment step has to be the amount of endotoxin (endotoxin units, EU) and

various chemical parameters, the main focus being on performed.

calcium, magnesium, sulphate, aluminium and heavy

Key words: bacteria; chemical parameters; endotoxin;

metals.

heavy metals; haemodialysis; water treatment

Results. CFU values exceeding the European

Pharmacopeia value, determined at an incubation tem-

perature of 22C, were found in the samples of raw

water (20.0%, n=25), after ion exchange (66.7%, n=

Introduction

12), after reverse osmosis (33.3%, n=18) and also in

samples of the dialysis water taken at the inlets (12.5%,

In 1943 the Dutch internal specialist W. J. Kol

n=40) and outlets (50.0%, n=18) of the machines.

successfully used the rst dialysis machine (rotating

Whereas all raw water samples from the wards showed

drum) in a clinical application in an uraemic patient

high mean values for endotoxin (0.569.10 EU/ml )

[1,2]. Since that time the number of dialysis patients

and the endotoxin levels were often enhanced after ion

and their survival time have increased continuously.

exchange (0.13>9.49 EU/ml ), treatment by reverse

The uid used in dialysis therapy is the dialysate,

osmosis led to a satisfactory decrease in endotoxin in

which consists of dialysate concentrate and mainly of

all samples (<0.03 EU/ml ). Sucient reductions in

water (one part concentrate and 34 parts of water).

calcium, magnesium and sulphate could only be

Whereas the concentrate is produced commercially at

achieved by the combined application of ion exchange

a consistent composition and with strictly controlled

and reverse osmosis. Mercury contamination was

quality, the water used may vary widely in its composi-

observed in the samples after ion exchange at three

tion and quality. Basically, the source of dialysis water

treatment plants, this was possibly caused by polluted

is drinking (tap) water, which is used after purication

regenerants. Increased amounts of aluminium, copper

by dierent types of treatment, or in rare cases even

and zinc were found in water samples from dierent

directly. The composition of the water depends on its

sites in the treatment systems and were caused by

source (ground water, surface water), its geographical

materials in contact with the water.

origin, seasonal variations and the water-treatment

Conclusions. A sucient chemical water purication

processes used. During dialysis each patient is exposed

treatment system should consist of ion exchange and

indirectly to 15 00030 000 l of water per year.

reverse osmosis. Attention has to be paid to the

Therefore, the chemical and microbiological quality of

the water used for dialysis is essential if an additional

Correspondence and oprint requests to: Dr I. Vorbeck-Meister,

health risk to haemodialysis patients is to be avoided.

Hygiene Institute, University of Vienna, Kinderspitalgasse 15,

A-1095 Vienna, Austria. Beside cardiovascular diseases, infections are the most

1999 European Renal AssociationEuropean Dialysis and Transplant Association

Quality of water used for haemodialysis 667

frequent cause of death in dialysis patients, as there investigate selected quality parameters of fully treated

dialysis water or dialysate [ 6,7,1012]. The experi- are shunt-infections as well as infections related to the

dialysate and the water used for dialysate preparation mental design of these investigations varied in both

the test parameters chosen and the samples taken. [3]. In addition, endotoxin derived from Gram-

negative bacteria may penetrate the dialyser membrane None of the studies performed so far have considered

water samples taken after each single treatment step, and is responsible for pyrogenic reactions in haemodia-

lysis patients [4]. Furthermore, the chemical composi- although each single treatment step aects the water

composition. These eects comprise microbial and tion of the water may cause acute and chronic

complications during dialysis. High magnesium and chemical purication on the one hand, and contamina-

tion, on the other hand. Therefore, the aim of our calcium contents, for instance, lead to headache

or hypertension. Heavy metals may accumulate in study was to investigate the quality of water used for

the preparation of the dialysate in seven dialysis wards the body and produce various toxic side-eects.

Aluminium overload may cause anaemia, encephalopa- with particular consideration being given to the dier-

ent water-processing systems and treatment steps. In thy and osteopathy. Although the role of the quality

of water used for haemodialysis has been emphasized respect to microbiological parameters (heterotrophic

plate count, faecal indicator bacteria, endotoxin) and by several authors [514], few standards have been

developed so far, as there are recommendations from chemical parameters (with the main focus on calcium,

magnesium, sulphate, aluminium and heavy metals) the Association for the Advancement of Medical

Instrumentation (AAMI ) [ 15,16] and European we tried to elucidate the weak points in the dierent

treatment systems. Pharmacopeia ( EPh) [17]. Since these standards do

not take into account all relevant parameters (e.g.

nitrite, iron, nickel, manganese), we additionally used

the Austrian drinking water guidelines (OLMB) as Subjects and methods

quality criteria for dialysis water in our study [18].

Relevant parameters for these standards compared

Water-treatment systems in dialysis centres

with normal ranges for ion concentrations found in

human blood are listed in Table 1.

In total, the water treatment systems (for the water used to

prepare dialysate) from seven dialysis centres were tested. Several studies have already been performed to

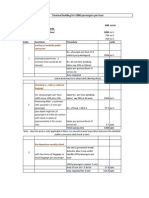

Table 1. Drinking water guideline OLMBa, the recommendations of AAMIb and EPhc for dialysis water in comparison to the normal

ranges of ion concentrations found in human blood

Parameter Amount in blood OLMB AAMI EPh

(plasma/serum)

Guideline Limit

value value

pH-value 7.357.45 6.58.5

KMnO

4

-demand (mg/l ) 8 20

ammonia (mg/l ) 0.200.80

ammonium (mg/l ) 0.05 0.5 0.2

nitrite (mg/l ) 0.1

nitrate (mg/l ) 25 50 8.9

calcium (mg/l ) 82110 400 2 2

magnesium (mg/l ) 1724.3 50 4 2

chloride (mg/l ) 34033900 100 50

sodium (mg/l ) 31283404 150 70 50

potassium (mg/l ) 140203 12 8 2

sulphate (mg/l ) 31 250 100 50

uoride (mg/l ) 1.5 0.2 0.2

lead (mg/l ) 50 5

cadmium (mg/l ) 5 1

mercury (mg/l ) 1 0.2 1

aluminium (mg/l ) 200 10 10

chromium (mg/l ) 50 14

copper (mg/l ) 7621525 100 100

nickel (mg/l ) 50

iron (mg/l ) 0.601.60 0.2

manganese (mg/l ) 0.05

zinc (mg/l ) 0.1 0.1 0.1

colony forming units 100 (22C)d 200 100

(CFU/ml ) 10 (37C)d

endotoxin ( EU/ml ) 0.25

aCodex Alimentarius Austriacus [18]. bAssociation for the Advancement of Medical Instrumentation [16]. cEuropean Pharmacopeia [ 17].

dIncubation temperature.

I. Vorbeck-Meister et al. 668

All systems received water from the public water supply. measured according to the Austrian national standards for

drinking water. Five of them (wards A, D, E, F and G) consisted of ion

exchangers followed by reverse osmosis. In two cases the The concentrations of lead, cadmium, mercury, aluminium,

chromium, copper and nickel were detected using ameless water was additionally disinfected by UV irradiation (wards

E and F). In one haemodialysis centre (ward C) single atomic absorption spectrophotometry (Zeeman 5000 with

HGA 500, PerkinElmer). To determine the levels of iron, reverse-osmosis plants, one for each dialysis machine, were

installed. We included two of these machines in our study. manganese and zinc ame-AAS-method (AAS 5000, Perkin

Elmer) was applied. Untreated tap water was used for dialysis in one centre

(ward B). All bacteriological and chemical tests were performed in

duplicate. The results were expressed as the mean.

Samples and sampling

The investigation included water samples before and after Results

each treatment step, and samples were taken from raw water

(RW), and after ion exchange (IE), reverse osmosis (RO)

and UV irradiation ( UV). All ion exchangers were cation

Microbiological parameters

exchangers. Samples of the nished dialysis water were taken

either directly at the inlet of the dialysis machine or at

dierent sites in the circulation systems at the ports con- The numbers of CFU in the samples taken from the

necting to the dialysis machines (in). In addition, water

seven dialysis water systems are shown in Figures 1

samples were taken, after routinely disinfecting and ushing

and 2. The counts diered considerably and were

the dialysis machine, at the outlets of the dialysis machines

independent of the distinct sampling site. The EPh

(out) during water ushing modus, immediately before the

[17] and AAMI [16] recommend colony counts of

preparation of the machine for the next patient. The disinfec-

100 CFU/ml and 200 CFU/ml, respectively, for water

tion procedures performed in the dialysis centres and the

used for dialysis. Values exceeding the EPh [ 17] value

intervals between disinfection varied widely. The chemicals

for CFU determined at an incubation temperature of

used for disinfection were citric acid, peracetic acid and

22C were found in the samples of raw water (20.0%, chlorine, respectively. Heat treatment for disinfection was

used as single procedure or combined with chemical disinfect- n=25), after ion exchange (66.7%, n=12) and after

ants. The disinfection intervals were daily or weekly. None reverse osmosis (33.3%, n=18), as well as in the

of the dialysis machines tested was equipped with an ultral-

dialysis water taken at the inlets (12.5%, n=40) and

ter at the treated water inow. All water samples were

outlets (50.0%, n=18) of the machines. Data obtained

obtained after rinsing and disinfecting the sampling taps.

using an incubation temperature of 37C revealed

The number of the sample sites was 37 in total. At each

values exceeding the recommendations only in the

ward sampling was carried out at least three times at

water samples taken at the inlets (10.0%, n=40) and

approximately weekly intervals. The number of samples

outlets (66.7%, n=18) of the machines. However, it

taken at each site is shown in detail in the gures.

was noticeable, that in most cases the samples from

the outlets of the dialysis machines had high CFU

Bacteriological analysis

levels. It should be stressed that in the water samples

after UV disinfection a value of 0 CFU/ml was found.

Heterotrophic plate count was performed with 1.0 ml and

In the raw water and the samples taken directly after

0.1 ml samples by the pour-plate method using plate count

each treatment step no faecal indicator bacteria were

agar (CM 325, Oxoid), the incubation conditions were 72 h

found. In one case contamination with P. aeruginosa

at 22C and 48 h at 37C. The faecal indicator bacteria such

in 100 ml was detected in a sample taken at the inlet

as coliform bacteria, enterococci and Pseudomonas aeruginosa

of a dialysis machine (ward A, in3). In two samples were each tested in a 100-ml water sample. The tests for

coliform bacteria were performed using the most probable taken at the outlet of the dialysis machines one incid-

number (MPN) method in liquid medium, as well as the

ence of P. aeruginosa (ward F) and one of enterococci

membrane ltration technique according to the water exam-

(ward C1) per 100 ml water volume occurred during

ination standard of APHA [19]. Enterococci and P. aerugi-

the observation period.

nosa were analysed using the membrane ltration technique

A limit value of 0.25 EU/ml has been xed by the

[19].

EPh for the concentration of endotoxin in water used

To determine the concentration of endotoxin, a quantitat-

for dialysis [17]. Whereas all raw water samples showed

ive chromogenic limulus amoebocyte lysate assay (QCL-1000,

high mean values for endotoxin (0.569.10 EU/ml )

BioWhittaker) was employed in conformity with the FDA

and the endotoxin values were often enhanced after

guidelines [20] and using microtitre plates. Microtitre plates

ion exchange (0.13>9.49 EU/ml ), treatment by

were measured in an automatic reader (BioWhittaker). The

test system is calibrated in endotoxin units (EU) per ml, the reverse osmosis led to a sucient decrease in endotoxin

detection limit was 0.03 EU/ml. in all samples (<0.03 EU/ml ) as demonstrated in

Figure 3. Nevertheless, after the water had passed

through the tubing system of the dialysis machines an

Chemical analysis

increase in endotoxin was observed. Similar to the

results of the colony counts, large amounts of endo-

Chemical parameters (pH, conductivity, hardness, calcium,

toxin were found in 57.1% of the samples (n=21) magnesium, chloride, nitrate, nitrite, ammonium, sulphate

and oxidizability measured as permanganate demand) were taken at the outlet of the dialysis machines.

Quality of water used for haemodialysis 669

Fig. 1. Concentrations of colony forming units (CFU/ml ), at an incubation temperature of 22C, in the water samples taken at various

sampling sites. The columns indicate the mean of concentrations measured at each sampling site, standard deviations are shown by bars.

RW, raw water; IE, ion exchanger; RO, reverse osmosis; UV, UV disinfection; in, inlet of the dialysis machine; out, outlet of the dialysis

machine. AG, dialysis wards of seven hospitals. The guideline value for CFU in dialysis water is 100 CFU/ ml according to the European

Pharmacopeia [ 17].

Chemical parameters The concentrations of lead, cadmium, chromium,

iron, manganese and nickel in the samples of raw

The chemical parameters (pH, chloride, nitrate, nitrite,

water and treated water were within the levels suggested

ammonium and permanganate demand) in the raw

for drinking water guidelines as well as the limits

water samples, and in the treated dialysis water,

suggested by the EPh [ 16] and AAMI [17] standards.

revealed inconspicuous results with respect to the

Surprisingly, after ion exchange, we noticed in the

drinking water guidelines [ 18] and the limit values of

water samples of three systems (E, F and G) mercury

the EPh [17] ( Table 1). The nitrate concentration of

in remarkably higher concentrations (mean values:

the raw water used for ward G exceeded the maximum

2.63.5 mg/l ) than had been found in the untreated

level suggested by the AAMI [16], but the treatment

waters (mean values: 0.120.19 mg/l ). In general after

process resulted in a sucient nitrate reduction. All

reverse osmosis only low amounts of mercury were

raw water samples had concentrations for calcium

found in the water samples, although the reverse

(4086 mg/l, n=21) and magnesium (823 mg/l, n=

osmosis system of ward C1 did not reduce mercury

21), that exceeded the guideline values of the AAMI

levels suciently (mean value: 0.58 mg/l ). A number

[16] and EPh [17]. A too high level of sulphate ( EPh)

(n=33, 18.2%) of the samples of the nished dialysis

was only observed in the raw water of plant G

waters revealed mercury concentrations which were

(80 mg/l ). Treatment of raw water by ion exchange

too high (mean values: 0.240.71 mg/l ) compared with

combined with reverse osmosis resulted in the complete

the AAMI guidelines [16].

elimination of calcium, whereas reverse osmosis alone

With the exception of wards A and G, the amount

(ward C) revealed Ca concentrations that were slightly

of aluminium measured in the raw water samples (n= too high (3 mg/l ). As expected, there was only an

21) exceeded the limits suggested by the EPh [17] and insignicant reduction in the amount of sulphate after

AAMI [16] (Figure 4). In the treated water samples cation exchange. The decrease in magnesium was

from wards E and F after ion exchange, extremely sucient using either ion exchange or reverse osmosis

(01.2 mg/l ). high concentrations were found. After reverse osmosis

I. Vorbeck-Meister et al. 670

Fig. 2. Concentrations of colony forming units (CFU/ml ), at an incubation temperature of 37C, in the water samples taken at various

sampling sites. The columns indicate the mean of concentrations measured at each sampling site, standard deviations are shown by bars.

RW, raw water; IE, ion exchanger; RO, reverse osmosis; UV, UV disinfection; in, inlet of the dialysis machine; out, outlet of the dialysis

machine. AG: dialysis wards of seven hospitals. The guideline value for CFU in dialysis water is 100 CFU/ml according to the European

Pharmacopeia [ 17].

aluminium was suciently eliminated, but we found a each single treatment step. Because of the diering

water quality and the specic water composition, which renewed increase in aluminium in some samples taken

at the inlet of the dialysis machines (wards D and F). depends for example on the origin of the water, water

ingredients may cause infectious diseases or intoxica- Measuring the concentration of copper showed

noticeable data for the raw water samples of wards C tion. Therefore the treatment of water used for haemo-

and D (mean values: 76 mg/l ) as shown in Figure 5. dialysis is obligatory. One of the dialysis centres

After reverse osmosis the samples revealed distinctly investigated in our study possessed some dialysis

reduced values for copper, although at one sampling machines which were supplied directly with untreated

site after dialysis a conspicuously high level appeared tap water. These machines were in use periodically,

(mean value: 106 mg/l ). according to the need for additional dialysis capacity.

As shown in Figure 6, the zinc concentrations in the Thus, we took the opportunity to also include

water samples varied from one sample site to the other, untreated dialysis water in our study to compare it

but were below the limits recommended by the AAMI with waters processed in dierent ways.

[16], EPh [17] and OLMB [18]. It is remarkable that The results of our study showed that, on the one

in some of the treated water samples we observed hand, as expected, the microbiological and chemical

levels of zinc that were even higher than in the raw quality of tap water is not sucient for the preparation

water samples. of dialysate, but on the other hand, during dierent

treatment steps severe chemical and microbial contam-

ination may occur.

Discussion

Some CFU values in the investigated tap water

exceeded the limit of 100 CFU/ml, but there was also

a problem of bacteriological contamination during Tap water represents the main component of the

water-treatment processes. In studies performed so far, dialysate and huge amounts of water are in indirect

only nished, treated, dialysis water has been investi- contact with the dialysis patient, yet insucient atten-

tion is paid to its quality, in particular with regard to gated. Therefore, for the purpose of comparison with

Quality of water used for haemodialysis 671

Fig. 3. Concentrations of endotoxin ( EU/ml ) in the water samples taken at various sampling sites. The columns indicate the mean of

concentrations measured at each sampling site, standard deviations are shown by bars. RW, raw water; IE, ion exchanger; RO, reverse

osmosis; UV, UV disinfection; in, inlet of the dialysis machine; out, outlet of the dialysis machine. AG: dialysis wards of seven hospitals.

The guideline value for endotoxin in dialysis water is 0.25 EU/ml according to the European Pharmacopeia [ 17].

previous ndings we use results from the in samples. and also because the water is heated to 37C within

the dialysis machine, bacteria preferring these temper- We found values exceeding the guideline value of the

EPh for CFU at incubation temperatures of 22C and atures, for example P. aeruginosa, can grow perfectly

well and endanger the patient. Nevertheless, the same 37C by 12.5% and 10.0%, respectively. Similar results

were found by Bambauer et al. [6,7] who reported that attention has to be paid to the estimation of CFU

incubated at a temperature of 22C to measure the 17.8% of fully treated dialysis water samples did not

comply with the AAMI guidelines. Investigations by number of cultivable indigenous water-specic bac-

teria. Thus, it is essential to control regularly the CFU Klein et al. [11] and Laurence and Lapierre [12]

showed higher numbers of non-compliant samples at both incubation temperatures of 22C and 37C.

The colony counts clearly depend on the incubation (>200 CFU/ml ) at 30% and 35.3%, respectively. It

has to be pointed out that in each study dierent conditions, time and temperature, as well as culture

media, as shown by Klein et al. [11]. Therefore results methods were used for the bacteriological tests (incuba-

tion conditions, culture media), since to date no stand- for colony counts without these specications are not

meaningful and limit values in standards have to be ard methods have been dened. Therefore, these results

are hardly comparable. completed by detailed methods.

To reduce the number of reproductive bacteria a The main reason for the bacterial recontamination

of water in tubing systems is water stagnancy [8,21]. UV-disinfection step within the water-treatment pro-

cess is recommended. Irradiation of water with UV As long as the water ow is continuous, the risk of

bacterial regrowth is minimized. However, some parts light (wavelength: 253.7 nm) represents an eective

technique to inactivate bacteria and viruses and has of the treatment system, for example lters or ion

exchangers, generally promote bacterial growth. In our been established in practice as a reliable disinfection

method for drinking water [22,23]. Moreover, UV study most of the samples taken at the outlets of the

dialysis machines had high numbers of CFU at an irradiation has proved useful in reducing bacterial

regrowth and therefore diminishing indirectly the incubation temperature of 37C. Because of water

stagnacy in the treatment and supply systems at elev- amount of endotoxins [8,21]. The principle of this

physical technique is based on the specic damage ated temperatures (room temperature or even higher),

I. Vorbeck-Meister et al. 672

Fig. 4. Concentrations of aluminium (mg/l ) in the water samples taken at various sampling sites. The columns indicate the mean of

concentrations measured at each sampling site, standard deviations are shown by bars. RW, raw water; IE, ion exchanger; RO, reverse

osmosis; UV, UV disinfection; in, inlet of the dialysis machine; out, outlet of the dialysis machine. AG: dialysis wards of seven hospitals.

The guideline value for aluminium in dialysis water is 10 mg/l according to the European Pharmacopeia [17] and the recommendations of

the Association for the Advancement of Medical Instrumentation [ 16].

caused to microbial nucleic acids by the absorption of the concentrate is an excellent nutrient, very high

concentrations of bacteria may develop, particularly if UV rays. There is no addition of chemicals and,

therefore, no risk of contaminating the dialysate with the concentrate is stored for a long time and is handled

without care. harmful substances. Nevertheless, we have to mention

that the microbicidal eect of this method only takes The raw water samples, and some of the samples

after ion exchange, had concentrations of endotoxin, place at the actual place of irradiation and does not

disinfect the following tubing system. Moreover, UV which far exceeded the limit of 0.25 EU/ml stated by

the EPh [17]. This underlines that untreated tap water irradiation does not remove bacterial cells from the

water per se, which means that endotoxins remain in is not suitable for dialysis. Similar results were found

by Laurence and Lapierre [12], who performed a study the water. Although UV disinfection does not eliminate

endotoxin, it reduces the absolute number of repro- on dialysis water from dierent dialysis centres includ-

ing three wards which used tap water directly. None ductive microorganisms and therefore the increase in

levels of endotoxin in the water. Because regrowth of these tap-water samples complied with the limits

given in the national recommendations for chemical may occur even inside the tubing system of the dialysis

machine, as conrmed by our data, periodic mainten- parameters and endotoxin.

Our results showed that treatment by reverse osmosis ance, cleaning and disinfection of the dialysis machines,

including all parts of the tubing system, are essential. led to a sucient decrease in endotoxin levels, even

related to the strict limit value of the EPh (0.25 The subject of interest in this study was the water

used for the preparation of the dialysate and its EU/ml ). Our ndings are in agreement with those of

Klein et al. [11] showing that most of the dialysis contribution to the composition and quality of the

dialysate. For the sake of completeness it has to be water samples contained 0.25 EU/ml. Nevertheless,

Laurence and Lapierre and Bambauer et al. found pointed out that the type of the dialysis concentrate

(acetate, bicarbonate) also inuences the susceptibility endotoxin values in their studies which were 35% and

12.2% in excess of a guide value of 5 EU/ml [6,7,12]. to bacterial contamination. In this respect a bicarbon-

ate concentrate is an extremely sensitive medium. As These results clearly indicate that endotoxin is able to

Quality of water used for haemodialysis 673

Fig. 5. Concentrations of copper (mg/l ) in the water samples taken at various sampling sites. The columns indicate the mean of

concentrations measured at each sampling site, standard deviations are shown by bars. RW, raw water; IE, ion exchanger; RO, reverse

osmosis; UV, UV disinfection; in, inlet of the dialysis machine; out, outlet of the dialysis machine. AG: dialysis wards of seven hospitals.

The guideline value for copper in dialysis water is 100 mg/l according to the recommendations of the Association for the Advancement of

Medical Instrumentation [16].

pass through reverse osmosis membranes or osmosis eral sources of chemical contamination occur during

transportation, storage and treatment, which may lead units. This may be because of microlesions, leakages

or active penetration in particular by Gram-negative to enhanced levels of metals in the dialysis water. In

this respect we found increased concentrations of alu- bacteria [ 21]. Therefore it is very important to prevent,

as far as possible, any increase in the levels of bacteria minium (wards E and F), zinc (wards C1 and D) and

copper (ward C1) caused by materials in contact with and endotoxin during the whole water-treatment pro-

cess in order to minimize the risk of pyrogenic reaction the water. This clearly demonstrates that heavy-metal

pollution of the water due to corrosion of the water in haemodialysis patients. Moreover, owing to bacterial

growth, the endotoxin concentration in the water may installation system also has to be considered in dialysis.

The rst but most expensive choice of an installation increase while in the water mains on the way to the

dialysis machine. Therefore, the latest technology material for dialysis water is stainless steel, followed

by high-quality synthetic materials. involves the application of an ultralter as a last safety

step installed either in the circulating system or at the The material making up the drinking-water systems

installed in buildings may also negatively aect the water inlet of the dialysis machine to produce, as far

as possible, sterile and endotoxin-free dialysis water. chemical quality of the water used as raw water in the

dialysis centre. This was shown by the suspiciously Such lters, consisting for instance of hollow-bre

membranes made of polyether sulphon, are already on high levels of copper in the raw water from wards C1,

C2 and D, which are situated in buildings with water the market. To date, few water-treatment systems or

dialysis machines are equipped with these lters. distribution systems made of copper.

While heavy-metal contamination is mostly the In our study we showed that, in principle, a satisfact-

ory chemical water quality can be obtained only by result of the corrosion of the metal tubing systems,

aluminium is often released from dierent synthetic the combined application of ion exchange and sub-

sequent reverse osmosis. Laurence and Lapierre [12] materials (for example polyethylene). In most cases

reverse osmosis devices were able to eliminate alumi- drew the same conclusion from their study monitoring

the water quality in haemodialysis centres and rening nium suciently, but, based on our results, we agree

with Mascher et al. [13] that aluminium ions may pass and optimizing the treatment processes. However, sev-

I. Vorbeck-Meister et al. 674

Fig. 6. Concentrations of zinc (mg/l ) in the water samples taken at various sampling sites. The columns indicate the mean of concentrations

measured at each sampling site, standard deviations are shown by bars. RW, raw water; IE, ion exchanger; RO, reverse osmosis; UV, UV

disinfection; in, inlet of the dialysis machine; out, outlet of the dialysis machine. AG: dialysis wards of seven hospitals. The guideline

value for zinc in dialysis water is 0.1 mg/l according to the European Pharmacopeia [17] and the recommendations of the Association for

the Advancement of Medical Instrumentation [ 16].

through reverse osmosis membranes. In this way alumi- ion exchangers as the source of the high mercury levels.

Possible causes could be leaching after resin exhaustion nium can be absorbed by the patient. Since aluminium

hydroxide is used as a phosphate binder in dialysis or contamination from the chemicals used for its

regeneration, for example caustic soda lye. therapy, an additional aluminium intake, including

input from the dialysis water, has to be taken into Pollution with other heavy metals has been described

previously for various chemicals used in water treat- account. High chronic aluminium concentrations may

result in encephalopathy and osteopathy by interfering ment [9,12,13]. This implies the need to use chemicals

in water treatment with an appropriate high-degree of with the calciumphosphate equilibrium [24].

Another point requiring attention, is the fact that purity to prevent heavy-metal pollution of the dia-

lysis water. chemicals used in water treatment, for example regen-

erants or corrosion inhibitors, may contain signicant

levels of heavy metals such as lead or mercury. This

Conclusions

was shown in the results of our investigation for wards

E, F and G, where we found remarkably higher

concentrations of mercury after ion exchange than in The quality of potable water varies from one location

to another and is generally not sucient for preparing the raw water. In 18.2% of the fully treated water

samples we found levels exceeding the AMMI guideline dialysis uids.

A reliable treatment system is essential, consisting value, whereas Laurence and Lapierre [12] reported

that 3.7% of samples contained excessive levels. The of an ion exchanger, reverse osmosis and a UV-

disinfection device. authors argue, beside other possible causes, that the

mercury contamination may stem from the feed water To avoid a health risk due to bacterial contamination

in the dialysis water, a low colony count in the raw and that purifying systems are not very ecient in

removing mercury. Our results, based on sampling water, a safety UV-disinfection step in the water treat-

ment and periodic cleaning and disinfection of the each single treatment step, did not show excess levels

in the dierent feed waters but clearly identied the dialysis machines, including all parts of the tubing

Quality of water used for haemodialysis 675

dialysate in haemodialysis. Nephrol Dial Transplant 1996; 11:

system, are fundamental. The nished treated water

946949

should be distributed using circulation systems. Storage

4. Lonnemann G. Dialysate bacteriological quality and the per-

tanks, unused branches and dead legs have to be

meability of dialyzer membranes to pyrogens. Kidney Int 1993;

avoided. An additional safety step for minimizing the 43 (Suppl 41): 195200

5. Arduino JM, Bland LA, Aguero SM, Carson L, Ridgeway M,

risk of contamination of the dialysis water by bacteria

Favero MS. Comparison of microbiologic assay methods for

and endotoxin is the use of ultralters either installed

hemodialysis uids. J Clin Microbiol 1991; 29: 592594

in the circulating system or at the water inlet of the

6. Bambauer R, Schauer M, Jung WK, Daum V, Vienken

dialysis machine.

J. Contamination of dialysis water and dialysate. ASAIO J 1994;

40: 10121016 To reduce heavy metal contamination of the dialysis

7. Bambauer R, Schauer M, Schiel R, Jung WK, Daum V, Vienken

water, the material making up the water installations

J. Kontamination von Leitungswasser und Dialysieru ssigkeiten

and the purity of chemicals used in water treatment

in 30 Dialysezentren. Nieren Hochdruckkrankh 1997; 26: 4549

have to be selected carefully. The best material for that

8. Bommer J, Ritz E. Water quality a neglected problem in

hemodialysis. Nephron 1987; 46: 16 purpose would be stainless steel followed by a high-

9. Carlson S, Hasselbarth U. Wasseraufbereitung fur die

quality plastic material.

Hamodialyse. Bundesgesundheitsblatt 1971; 14: 256262

A suitable standard that includes all relevant chem-

10. Harding GB, Klein E, Pass T, Wright R, Million C. Endotoxin

ical and microbiological parameters has to be

and bacterial contamination of dialysis center water and dialys-

developed. The AAMI monograph [ 16] includes guide- ate; a cross sectional survey. Int J Artif Organs 1990; 13: 3943

11. Klein E, Pass T, Harding GB, Wright R, Million C. Microbial

line values for some important parameters, but other

and endotoxin contamination in water and dialysate in the

essential values are missing, for example iron, mangan-

central United States. Artif Organs 1990; 14: 8594

ese and nickel, metals involved in corrosion and nitrite

12. Laurence RA, Lapierre ST. Quality of hemodialysis water: a

as a toxic substance. Furthermore, the high limits for 7-year multicenter study. Am J Kidney Dis 1995; 25: 738750

13. Mascher F, Udermann H, Brantner H. Chemische und mikrobi-

disinfectant residuals (0.5 mg/l for chlorine and

ologische Untersuchungen wasserfu hrender Systeme in fu nf

0.1 mg/l for chloramine) suggested by the AAMI seem

Dialysestationen. Hyg Med 1988; 13: 260264

questionable and should be lowered as a maximum

14. Watzke H, Mayer G, Schwarz H et al. Bacterial contamination

value of only 0.3 mg/l chlorine is permitted even in

of dialysate in dialysis-associated endotoxaemia. J Hosp Infect

1990; 13: 109115 drinking water [18].

15. Association for the Advancement of Medical Instrumentation,

From a microbiological point of view, the culture

AAMI. American national standard for hemodialysis systems.

conditions used to estimate the CFU have to be

Arlington Press, Arlington, VA, 1981

optimized and standardized (incubation time, temper-

16. Association for the Advancement of Medical Instrumentation,

AAMI. Water quality for hemodialysis, 2nd edition. Arlington ature and culture medium). Moreover, water samples

Press, Arlington, VA, 1993

should be tested for the presence of dened indicator

17. Anonymus. EPh. Water for diluting concentrated haemodialysis

bacteria, such as pseudomonads, in volumes of at least

solutions. European Pharmacopeia 1992; VIII.91VIII.96

100 ml. A guideline value for the level endotoxin in

18. Anonymus. OLMB. Codex Alimentarius Austriacus, Chapter

dialysis water as given in the EPh has to be included. B1, Drinking water, 1993

19. American Public Health Association, APHA. Standard methods

To minimize a potential risk due to water used for

for the examination of water and waste water, 17th edition.

haemodialysis it is of enormous importance to control

American Public Health Association, Washington, DC, 1989

the water quality during the whole treatment procedure

20. Department of Health and Human Services, Public Health

indicating weak points in time. Therefore we recom- Service, Food and Drug Administration. Guideline on validation

of the Limulus amebocyte lysate test as an end-product endotoxin

mend at least monthly bacteriological and quarterly

test for human and animal parenteral drugs, biological products,

selected chemical examinations of the water including

and medical devices, 1987

samples of each treatment step.

21. Bommer J. Wasser- und Dialysataufbereitung. In: Franz HE,

ed. BlutreinigungsverfahrenTechnik und Klinik. Georg Thieme

Verlag, Stuttgart, 1997; 4355

22. Sommer R, Cabaj A. Evaluation of the eciency of UV plants

References for drinking water disinfection. Water Sci Technol 1993; 27:

357362

1. Bundschu D. Gechichte der Hamodialyse. In: Franz HE, ed. 23. Cabaj A, Sommer R, Schoenen D. Biodosimetry: Model calcula-

Dialyse fur Pegeberufe. Georg Thieme Verlag, Stuttgart, 1996; tions for UV water disinfection devices with regard to dose

2628 distributions. Water Res 1996; 30: 10031009

2. Wetzels E, Colombi A, Dittrich P et al. Hamodialyse, 24. Von Bonsdor M, Sipila R, Pitkanen E. Correction of haemodia-

Peritonealdialyse, Membranplasmapherese und verwandte lysis-associated anaemia by deferoxamine. Eects on serum

Verfahren. Springer-Verlag, Berlin, 1986; 39 aluminium and iron overload. Scand J Urol Nephrol 1990; 131

(Suppl ): 4954 3. Lonnemann G, Krautzig S, Koch KM. Quality of water and

Received for publication: 28.11.96

Accepted in revised form: 10.11.98

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Financial Management Full Notes at Mba FinanceDocument44 pagesFinancial Management Full Notes at Mba FinanceBabasab Patil (Karrisatte)86% (7)

- Bus Terminal Building AreasDocument3 pagesBus Terminal Building AreasRohit Kashyap100% (1)

- Roy II vs. Herbosa, G.R. No. 207946, November 22, 2016Document20 pagesRoy II vs. Herbosa, G.R. No. 207946, November 22, 2016Rina OlandoNo ratings yet

- Room Air Conditioner: Service ManualDocument68 pagesRoom Air Conditioner: Service Manualervin0% (1)

- Attachment 1 - Memorandum Order No. 21-1095 - Revised Guidelines For The Implementation of Shared Service Facilities (SSF) ProjectDocument28 pagesAttachment 1 - Memorandum Order No. 21-1095 - Revised Guidelines For The Implementation of Shared Service Facilities (SSF) ProjectMark Jurilla100% (1)

- Click To Enlarge (The Skeptic's Annotated Bible, Hosea)Document11 pagesClick To Enlarge (The Skeptic's Annotated Bible, Hosea)Philip WellsNo ratings yet

- Reflections: The Sol JournalDocument13 pagesReflections: The Sol Journalapi-268650070No ratings yet

- Answer Sheet RRLDocument2 pagesAnswer Sheet RRLDolores PanchoNo ratings yet

- Jaringan Noordin M. TopDocument38 pagesJaringan Noordin M. TopgiantoNo ratings yet

- DocuPrint C2255Document2 pagesDocuPrint C2255sydengNo ratings yet

- Technical ReportDocument39 pagesTechnical ReportTope-Akanni AyomideNo ratings yet

- Article ReviewDocument3 pagesArticle ReviewRAMADEVI A/P THANAGOPAL MoeNo ratings yet

- Painter Decorator Curriculum Eng l1 2 3 CC 404c.404dDocument100 pagesPainter Decorator Curriculum Eng l1 2 3 CC 404c.404dM.a. KhaderNo ratings yet

- APEX Forms Sergei MartensDocument17 pagesAPEX Forms Sergei MartensIPlayingGames 301No ratings yet

- Case Analysis OF Rajinder Singh V. State of PunjabDocument12 pagesCase Analysis OF Rajinder Singh V. State of PunjabP TejeswariNo ratings yet

- 1393Document7 pages1393Victor IkeNo ratings yet

- Untitled PresentationDocument23 pagesUntitled Presentationapi-543394268No ratings yet

- Natural Wonders of The World: I:GrammarDocument8 pagesNatural Wonders of The World: I:GrammarNhị NguyễnNo ratings yet

- A Catechism of Anarchy (Cover)Document2 pagesA Catechism of Anarchy (Cover)Charles W. JohnsonNo ratings yet

- AIPT 2021 GuidelineDocument4 pagesAIPT 2021 GuidelineThsavi WijayasingheNo ratings yet

- A Freudian Look Into Roger Waters' True Expressions in "The Wall."Document5 pagesA Freudian Look Into Roger Waters' True Expressions in "The Wall."Jacob Ritteman100% (1)

- Welcome To UnixDocument14 pagesWelcome To UnixSrinivas KankanampatiNo ratings yet

- Certificat: S Ent of Ivth M T R A Y S Fte O Ogy B NG Ore. H Und R On G N U Organ A Ion Durin The E A C 2 8Document71 pagesCertificat: S Ent of Ivth M T R A Y S Fte O Ogy B NG Ore. H Und R On G N U Organ A Ion Durin The E A C 2 8Chetana YadawadNo ratings yet

- Dolomite in Manila Bay A Big HitDocument3 pagesDolomite in Manila Bay A Big HitJoanaPauline FloresNo ratings yet

- USA V Meng Letter DPADocument3 pagesUSA V Meng Letter DPAFile 411No ratings yet

- Preparatory Surface Cleaning of Architectural Sandstone: Standard Practice ForDocument2 pagesPreparatory Surface Cleaning of Architectural Sandstone: Standard Practice Fors.swamyNo ratings yet

- Metsec Steel Framing SystemDocument46 pagesMetsec Steel Framing Systemleonil7No ratings yet

- Indian RailwaysDocument20 pagesIndian RailwaysNirmalNo ratings yet

- Grimshaw v. Ford Motor CoDocument35 pagesGrimshaw v. Ford Motor CozichenNo ratings yet

- 10 Ideas For ConversationDocument116 pages10 Ideas For ConversationGreenLake36100% (1)