Professional Documents

Culture Documents

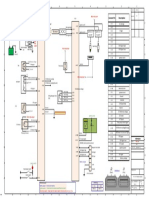

22 G3512 C555

Uploaded by

texwan_Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

22 G3512 C555

Uploaded by

texwan_Copyright:

Available Formats

CATERPILLAR

ENGINE SPECIFICATIONS

Type . . . . . . . . . . . Static regulator, brushless excited

Construction. . . . . . . . Single bearing, close coupled

Three phase . . . . . . . . . . . . . . . . . . . . . Wye connected

Insulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Class F

Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . Drip proof

Alignment. . . . . . . . . . . . . . . . . . Caterpillar pilot shaft

Overspeed capability . . . . . . . . . . . . . . . . . . . . . . 130%

Waveform. . . . . . . . . . . . . . . . Less than 5% deviation

Voltage regulator . . . . . . . . . . . 3-phase sensing with

Volts-per-Hertz

Voltage regulation. . . . . . . . . . . . . . . . Less than 1%

Voltage gain. . . . . . . . Adjustable to compensate for

engine speed droop and line loss

TIF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Less than 50

THF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Less than 3%

Gas Engine

Generator

Set

V-12, 4-Stroke-Cycle Spark-Ignited

Bore in (mm) . . . . . . . . . . . . . . . . . . . . . . . . 6.7 (170)

Stroke in (mm). . . . . . . . . . . . . . . . . . . . . . . 7.5 (190)

Displacement L (cu in) . . . . . . . . . . . . . . 3158 (51.8)

Aspiration . . . . . . . . . . . . Turbocharged-Aftercooled

Compression ratio . . . . . . . . . . . . . . . . . . . . . . 11:1, 9:1

FEATURES

G3512

1200 rpm

60 Hz

365-600 kW

Continuous Power

I CATERPILLAR

FACTORY PACKAGE

Factory designed, assembled, and tested.

Supported by Caterpillar parts and labor

warranty through your local Caterpillar

dealer.

I DIESEL STRENGTH BUILT IN

Blocks, crankshafts, liners, and connecting

rods are common with higher loaded Cat

diesel engines. Robust design provides

prolonged life at lower gas engine loads.

I ELECTRONIC IGNITION SYSTEM WITH

DETONATION SENSITIVE TIMING

The Caterpillar Electronic Ignition System

(EIS) provides optimized spark timing for all

operating conditions. Timing is automatically

controlled to maintain continuous detonation

protection.

I LOWEXHAUST EMISSIONS

2.0 gram/bhp-hr NOx. Lower emissions are

achievable for selected applications; consult

your Caterpillar dealer.

I FUEL FLEXIBILITY

Capability to burn a wide range of gaseous

fuels, including landfill gas, digester gas, coal

seam gas, and propane.

I GALLERY COOLED PISTONS

Oil passageways provide cooler piston

temperatures which prevent carbon build-up

and increase detonation margin.

I COOLING WATER TEMPERATURE

Choice of cooling water temperature between

99 C and 127 C to match heat recovery

requirements.

CATERPILLAR

SR4 GENERATOR

Shown with

Optional Equipment

OPTIONAL EQUIPMENT

Air cleaners with

service indicator

Breather, crankcase

Cooler, lubricating oil

Filters, lubricating oil, RH

Flywheel housing,

SAE No. 00

Governor (Woodward),

magneto engine: 2301

EIS engine: 2301A

Ignition system

Altronic III or

Caterpillar EIS

Instrument panel,

RH or LH

exhaust temp.

intake manifold

pressure

intake manifold

temp.

oil pressure

oil pressure

differential

service meter

water temp.

Lifting eyes

Manifold, exhaust,

watercooled

Paint,

Caterpillar yellow

Protection devices

Pumps

gear driven

aftercooler water

lubricating oil

jacket water

Rails, mounting, 10 inch

Regulator,

gas pressure

SAE standard rotation

Thermostats

and housing

Torsional vibration

damper

Cooling systems,

high temperature

Custom generator

voltages

Exhaust fittings

Generator mounted

control panel

Load share governor

Low BTU arrangements

Low pressure gas fuel

system (2 psi)

Muffler

Power takeoffs

Prelube pump

Starting systems

Tachometer

G3512 GAS ENGINE GENERATOR SET

STANDARD EQUIPMENT

G3512 GAS ENGINE GENERATOR SET

G3512 Gas Engine Generator Set1200 rpm 90 LE 90 TA NA

Electrical Output @ 0.8 PF without Fan kW 600 570 365

Voltage 480 480 480

Compression Ratio 11:1 9:1 9:1

Minimum Gas Pressure Required psi 30 30 2

Shipping Weight lb 20 190 20 190 17 930

Gen Set Length in 168.0 168.0 162.1

Gen Set Height in 73.4 73.4 75.2

NOx g/bhp-hr 2.0 22.1 12.2

CO g/bhp-hr 1.7 0.9 14.1

HC (total) g/bhp-hr 5.5 1.8 3.6

HC (non-methane) g/bhp-hr 0.8 0.3 0.5

Fuel Consumption (100% load) Btu/hp-hr 7089 7464 7859

Fuel Consumption (75% load) Btu/hp-hr 7209 7789 8913

Air Inlet Flow Rate scfm 1757 1185 739

Exhaust Gas Flow Rate @ Stack F cfm 4210 3277 2440

Heat Rejection to Jacket Water (total) Btu/min 28 150 38 614 25 420

Heat Rejection to Exhaust (to 350 F) Btu/min 12 796 12 511 11 772

Heat Rejection to Aftercooler Btu/min 6256 2673

Heat Rejection to Atmosphere from Engine Btu/min 9327 6824 5118

Exhaust Gas Stack Temperature Deg. F 709 855 1100

TECHNICAL DATA

LE refers to low emission engine configuration.

TA refers to standard engine configuration.

90 refers to aftercooler water inlet temperature in F.

130 refers to aftercooler water inlet temperature in F.

All data is based on standard conditions.

These ratings do not allow for overload capability.

G3512 GAS ENGINE GENERATOR SET

Materials and specifications are subject to change without notice. The International System of Units (SI) is used in this publication.

LEHX6783 1996 Caterpillar Inc. Printed in U.S.A.

Supersedes LEHX0472 All rights reserved.

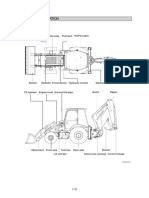

TOP VIEW

See general dimension drawing 119-9594 for additional

Electronic Ignition System (EIS) engine detail and NA

information.

For magneto ignition system engines see general

dimension drawing 7C-4609.

Note: General configuration not to be used for

installation.

RD

0

3

2

2

0

0

.

3

(

8

6

.

6

3

)

306

103

104

201

401

402

401

521

2

9

6

.

0

(

1

1

.

6

5

)

424.2 (16.70)

446.7 (17.59)

700.0 (27.56)

1

7

8

3

.

0

(

7

0

.

2

0

)

1

1

5

6

.

4

(

4

5

.

5

3

)

1170.0 (46.06)

851.5 (33.52)

304.8 (12.00)

523.2 (77.46)

02

0

3

02

Centerline of Engine

Rear Face of Cylinder Block

Water Inlet

Water Outlet

Fuel Inlet

Oil Filter

Air Inlet

Exhaust

Conduit Entrance

Removal Distance

02

03

103

104

201

308

401

402

521

RD

Ratings are based on SAE J1349 standard

conditions of 29.61 in Hg (100 kPa) and 77 F

(25 C). These ratings also apply at ISO3046/1,

DIN6271, and BS5514 standard conditions of

29.61 in Hg (100 kPa) and 81 F (27 C); and

API 7B-11C standard conditions of 29.38 in Hg

(99 kPa) and 85 F (29 C) also apply.

Ratings are based on dry natural gas having a low

heat value of 905 btu/ft

3

(35.22 MJ/m

3

). Variations

in altitude, temperature and gas composition

from standard conditions may require a reduction

in engine horsepower.

Turbocharged-aftercooled ratings apply to

5000 ft (1525 m) and 77 F (25 C). Naturally

aspirated engines apply to 500 ft (150 m) and

85 F (29 C). For applications which exceed these

limits consult your Caterpillar dealer.

Continuous Output available without varying

load for an unlimited time. Continuous power in

accordance with ISO8528, ISO3046/1, AS2789,

DIN6271, and BS5514.

Additional ratings may be available for specific

customer requirements. Consult your Caterpillar

representative for details.

CONDITIONS AND DEFINITIONS

You might also like

- Holden and Ford Key Code and BCM Linking InstructionsDocument59 pagesHolden and Ford Key Code and BCM Linking InstructionsDidier Van Der Lee86% (7)

- Corvette c5 - Driveshaft 2002 DRIVELINE/AXLE Propeller Shaft - Corvette Service ManualsDocument223 pagesCorvette c5 - Driveshaft 2002 DRIVELINE/AXLE Propeller Shaft - Corvette Service Manualsken cevaNo ratings yet

- Mercedes Emergency Response GuideDocument93 pagesMercedes Emergency Response GuideCori Si Luci Lovin100% (1)

- Bbuilders 09Document254 pagesBbuilders 09aaron100% (2)

- Operation and Maintenace Manual (5-10T)Document102 pagesOperation and Maintenace Manual (5-10T)pablo romeroNo ratings yet

- Subsea Pumping BrochureDocument8 pagesSubsea Pumping Brochurenaren_013No ratings yet

- SAGD Where Valves Are UsedDocument4 pagesSAGD Where Valves Are UsedAnonymous ntK705RtNo ratings yet

- Triplex Pump Design PDFDocument56 pagesTriplex Pump Design PDFManatchai BattōsaiNo ratings yet

- Ethane c2h6 Safety Data Sheet Sds p4592Document9 pagesEthane c2h6 Safety Data Sheet Sds p4592Lucious LightNo ratings yet

- The Fight Over Using Natural Gas for Transportation: AntagonistsFrom EverandThe Fight Over Using Natural Gas for Transportation: AntagonistsRating: 5 out of 5 stars5/5 (1)

- 2001 FORD WINDSTAR Service Repair Manual PDFDocument40 pages2001 FORD WINDSTAR Service Repair Manual PDFjkfmmsmef100% (1)

- Extraction of Ethane From Natural Gas at PDFDocument6 pagesExtraction of Ethane From Natural Gas at PDFanon_936836736No ratings yet

- SPE 185275 Design, Operation, Diagnosis, Failure Analysis and Optimization of ESP SystemsDocument19 pagesSPE 185275 Design, Operation, Diagnosis, Failure Analysis and Optimization of ESP SystemsEdgar GonzalezNo ratings yet

- MPFM-050 PresentationDocument19 pagesMPFM-050 Presentationrocket-vtNo ratings yet

- Previews HI 9 6 1 2012 PreDocument12 pagesPreviews HI 9 6 1 2012 Pretexwan_100% (2)

- 01 Gas GradesDocument20 pages01 Gas GradesRadu CerneaNo ratings yet

- Turbo Tutorial API 619 5thDocument33 pagesTurbo Tutorial API 619 5thmishraengg100% (2)

- The Basics of Cathodic ProtectionDocument2 pagesThe Basics of Cathodic ProtectionlsatchithananthanNo ratings yet

- TWD1643 Service PartsDocument104 pagesTWD1643 Service PartsDaniel Muratalla100% (1)

- 3 Framo Engineering - Rudisham MarjohanDocument25 pages3 Framo Engineering - Rudisham MarjohanantonNo ratings yet

- Pumping Station Design For EngineersDocument171 pagesPumping Station Design For EngineersMuhammad Irfan AwanNo ratings yet

- Carbon Dioxide SequestrationDocument10 pagesCarbon Dioxide SequestrationKevin Mandira LimantaNo ratings yet

- ESP SystemsDocument22 pagesESP SystemsNabila GhaisaniNo ratings yet

- Efficiency Improvement and Trouble-Shooting: Separation SystemsDocument8 pagesEfficiency Improvement and Trouble-Shooting: Separation SystemsAlberto darianNo ratings yet

- Leser PSV SizingDocument83 pagesLeser PSV SizingjrfmlNo ratings yet

- Leser PSV SizingDocument83 pagesLeser PSV SizingjrfmlNo ratings yet

- Service: 2.0, 1.6, 1.2 - Litre Diesel EnginesDocument44 pagesService: 2.0, 1.6, 1.2 - Litre Diesel EnginesGeorgiu Claudiu100% (1)

- Akpo LeafletDocument4 pagesAkpo LeafletMusa MohammedNo ratings yet

- TNT135 EFI System Electric Diagram PDFDocument1 pageTNT135 EFI System Electric Diagram PDFGabriel Zamora100% (1)

- Statoil Technology LNG PDFDocument15 pagesStatoil Technology LNG PDFmctimlimNo ratings yet

- Insulation ContraThermDocument16 pagesInsulation ContraThermmarcins85No ratings yet

- Subsea Chokes BrochureDocument12 pagesSubsea Chokes Brochureprihartono_diasNo ratings yet

- Market Strategies of ToyotaDocument39 pagesMarket Strategies of ToyotaSaqib Ashraf100% (1)

- Process Simulation of Dehydration Unit For The Comparative Analysis of Natural Gas Processing and Carbon Capture ApplicationDocument40 pagesProcess Simulation of Dehydration Unit For The Comparative Analysis of Natural Gas Processing and Carbon Capture ApplicationeduryuNo ratings yet

- CECO Peerless Produced Water TreatmentDocument10 pagesCECO Peerless Produced Water TreatmentIdris Siddiqui100% (1)

- 98july DasDocument8 pages98july DasManash MudoiNo ratings yet

- Flow Assurance SolutionsDocument1 pageFlow Assurance SolutionsRoo FaNo ratings yet

- Multiphase - Pumps - Axel CalgaryDocument45 pagesMultiphase - Pumps - Axel CalgaryAlberto Enrique De Santa Anna CampderáNo ratings yet

- The Official Ministry of Transportation (MTO) Driver's Handbook PDFDocument167 pagesThe Official Ministry of Transportation (MTO) Driver's Handbook PDFVivian XiaoNo ratings yet

- ROX000318781 - AF Functional Description For Roxar 2600 MPFMDocument34 pagesROX000318781 - AF Functional Description For Roxar 2600 MPFMOmar Al SousliNo ratings yet

- Steam TurbineDocument8 pagesSteam TurbineWalid FattahNo ratings yet

- HYDRO A320 - Equipment CatalogueDocument90 pagesHYDRO A320 - Equipment CatalogueDũng NguyễnNo ratings yet

- SPE MEG Workshop 18 June 2009 PDFDocument122 pagesSPE MEG Workshop 18 June 2009 PDFprabhuarunkumar850% (1)

- ASCOM General IntroductionDocument12 pagesASCOM General IntroductionperrychemNo ratings yet

- PipeLife Soluforce CatalogueDocument32 pagesPipeLife Soluforce CatalogueA_Valsamis100% (1)

- Wartsila Zero Flaring BakuDocument13 pagesWartsila Zero Flaring Bakui786zzyNo ratings yet

- Oil and Gas Offshore Pipeline Leak Detection System A Feasibility StudyDocument6 pagesOil and Gas Offshore Pipeline Leak Detection System A Feasibility StudyGuillerm Prudent BaldeonNo ratings yet

- Benefits of Standby Time in Adsorption Dehydration ProcessDocument10 pagesBenefits of Standby Time in Adsorption Dehydration ProcessantonkiryushinNo ratings yet

- 2012 Mar Natural Gas Facts FiguresDocument98 pages2012 Mar Natural Gas Facts FiguresChristopher Hampton100% (1)

- Carbon Capture & StorageDocument2 pagesCarbon Capture & Storagevelmurugan00000No ratings yet

- Polyflow ExPERT Ecuador PresentationDocument29 pagesPolyflow ExPERT Ecuador PresentationRené Luis Perez MagneNo ratings yet

- SeaStar Mini TLP PaperDocument8 pagesSeaStar Mini TLP PaperSean MiddletonNo ratings yet

- Merpro SPE March 2006Document42 pagesMerpro SPE March 2006dayrogNo ratings yet

- Spaans Screw Pumps BrochureDocument8 pagesSpaans Screw Pumps BrochureEdson França Rodrigues100% (1)

- Spe 21696 MSDocument9 pagesSpe 21696 MSAleks ProañoNo ratings yet

- SPE 150495 Worldwide Drill-Stem-Testing Experiences in Heavy and Viscous-Oil Offshore Environments That Improve Operational EfficiencyDocument9 pagesSPE 150495 Worldwide Drill-Stem-Testing Experiences in Heavy and Viscous-Oil Offshore Environments That Improve Operational Efficiencychris_glezzNo ratings yet

- 05 VruDocument17 pages05 VruSergio RodriguezNo ratings yet

- Ledeen Actuator Control SolutionsDocument28 pagesLedeen Actuator Control SolutionsAbgNakalLaNo ratings yet

- Sand Management UkDocument12 pagesSand Management UkffernandaaaNo ratings yet

- Spe 196248 MS PDFDocument31 pagesSpe 196248 MS PDFdwidwi novryNo ratings yet

- SoluForce Corporate Brochure 2014 06Document15 pagesSoluForce Corporate Brochure 2014 06René Luis Perez MagneNo ratings yet

- Gear Ratio Transmission MPH CalculatorDocument3 pagesGear Ratio Transmission MPH CalculatorGreg SuchomelNo ratings yet

- AMT Module 1 - PartB-1Document12 pagesAMT Module 1 - PartB-1PrathikNo ratings yet

- Leistritz PDFDocument8 pagesLeistritz PDFJose MarquezNo ratings yet

- Isentropic Calcs PD BlowersDocument18 pagesIsentropic Calcs PD BlowersMerge e-mail JAGNNo ratings yet

- Subsea Europe - Shtokman PresentationDocument24 pagesSubsea Europe - Shtokman PresentationEyoma EtimNo ratings yet

- Ethane (R-170) : Physical & Chemical PropertiesDocument3 pagesEthane (R-170) : Physical & Chemical Propertiesfaiq_pp10No ratings yet

- Case Study: Sand Removal From 3 Phase Production Separators and VesselsDocument5 pagesCase Study: Sand Removal From 3 Phase Production Separators and VesselssterlingNo ratings yet

- Acumulador 1Document30 pagesAcumulador 1Carolina GalavisNo ratings yet

- RBI CatalogDocument6 pagesRBI CatalogtictacalNo ratings yet

- RisersDocument3 pagesRisersSubsea_Team100% (1)

- Reciprocating Pumps - NDPDDocument2 pagesReciprocating Pumps - NDPDDhanny MiharjaNo ratings yet

- Baker Hughes Caisson ESP (2010)Document2 pagesBaker Hughes Caisson ESP (2010)hermit44535No ratings yet

- Uop-Twister-Supersonic-Gas-Separation-System1.pdf - Feed Pressure PDFDocument2 pagesUop-Twister-Supersonic-Gas-Separation-System1.pdf - Feed Pressure PDFmofiyinfoluNo ratings yet

- LNG Cold Energy Utilization UpdatedDocument13 pagesLNG Cold Energy Utilization UpdateddishankmpatelNo ratings yet

- WGM MPFMDocument16 pagesWGM MPFMahcenenNo ratings yet

- International Thermodynamic Tables of the Fluid State, Argon, 1971: Division of Physical Chemistry, Commission on Thermodynamics and Thermochemistry, Thermodynamic Tables ProjectFrom EverandInternational Thermodynamic Tables of the Fluid State, Argon, 1971: Division of Physical Chemistry, Commission on Thermodynamics and Thermochemistry, Thermodynamic Tables ProjectNo ratings yet

- Valves Brame HydrogenengineeriDocument3 pagesValves Brame Hydrogenengineeritexwan_No ratings yet

- Hrd-f02!02!0412 Bio Data DC (Rev 02)Document1 pageHrd-f02!02!0412 Bio Data DC (Rev 02)texwan_No ratings yet

- EHB en 11 Quality and Environmental ManagementDocument23 pagesEHB en 11 Quality and Environmental Managementtexwan_No ratings yet

- EHB en File 2.2-Loading-PrincipleDocument1 pageEHB en File 2.2-Loading-Principletexwan_No ratings yet

- Williams W Series Pump IomDocument25 pagesWilliams W Series Pump Iomtexwan_No ratings yet

- EHB en 0-IntroductionDocument0 pagesEHB en 0-IntroductionAquos78No ratings yet

- EHB en 10-ConnectionsDocument102 pagesEHB en 10-Connectionstexwan_No ratings yet

- EHB en 10-ConnectionsDocument102 pagesEHB en 10-Connectionstexwan_No ratings yet

- EHB en 6 Installation and Plant DesignDocument64 pagesEHB en 6 Installation and Plant Designtexwan_No ratings yet

- EHB en 9-MaterialsDocument0 pagesEHB en 9-MaterialsAquos78No ratings yet

- EHB en 2 Design FundamentalsDocument30 pagesEHB en 2 Design FundamentalstdecebalusNo ratings yet

- Propane PropertiesDocument4 pagesPropane Propertiestexwan_No ratings yet

- EHB en 3-TerminologyDocument32 pagesEHB en 3-Terminologytexwan_No ratings yet

- BAV BAVM 9510-070-EnDocument23 pagesBAV BAVM 9510-070-Entexwan_No ratings yet

- D 512Document1 pageD 512texwan_No ratings yet

- EHB en 1 History and Basic FunctionDocument0 pagesEHB en 1 History and Basic FunctionAquos78No ratings yet

- DeaDocument2 pagesDeatexwan_No ratings yet

- Bisnis SapiDocument5 pagesBisnis SapiIlham AdinusaNo ratings yet

- Pipe Flow Design 1: Results DataDocument7 pagesPipe Flow Design 1: Results Datatexwan_No ratings yet

- Pipe Flow Design 1: Results DataDocument7 pagesPipe Flow Design 1: Results Datatexwan_No ratings yet

- Pipe Flow Design 1: Results DataDocument7 pagesPipe Flow Design 1: Results Datatexwan_No ratings yet

- Ansi Atex LR CompleteDocument148 pagesAnsi Atex LR Completetexwan_No ratings yet

- CUMMINS X15 Engine: Jacobs Engine Brake - IntebrakeDocument2 pagesCUMMINS X15 Engine: Jacobs Engine Brake - IntebrakeTony RodríguezNo ratings yet

- Eaton SprzegłaDocument9 pagesEaton SprzegłaMichał WłodarkiewiczNo ratings yet

- Ravaglioli PresentationDocument42 pagesRavaglioli PresentationRavaglioli OnlineNo ratings yet

- 955i Torque SpecificationsDocument6 pages955i Torque SpecificationsRodney Alan Armarego100% (3)

- Preliminary Design ReportDocument28 pagesPreliminary Design ReportpankajNo ratings yet

- Mahle Air Filter (Primary) For Tata - HitachiDocument9 pagesMahle Air Filter (Primary) For Tata - HitachiSurajPandeyNo ratings yet

- Chapt1 - Classification & ParametersDocument94 pagesChapt1 - Classification & ParameterspeterNo ratings yet

- ANALYSIS-79-Light & Medium Duty State Wise Truck Market Analysis With Kerala Case Study - ACG PDFDocument29 pagesANALYSIS-79-Light & Medium Duty State Wise Truck Market Analysis With Kerala Case Study - ACG PDFVivek SinghalNo ratings yet

- XVRS 606 BrochureDocument2 pagesXVRS 606 Brochureitang100% (1)

- Hyundai Creta Accessories DetailsDocument4 pagesHyundai Creta Accessories DetailsSriNo ratings yet

- G1-2. Specification - Indd PDFDocument7 pagesG1-2. Specification - Indd PDFAlex MorsNo ratings yet

- 3.4 Hyundai - Mạch Điện 2020 Engine D6HA (Euro-5)Document11 pages3.4 Hyundai - Mạch Điện 2020 Engine D6HA (Euro-5)1360Nguyễn Hoàng NhậtNo ratings yet

- 2023 Nissan KicksDocument9 pages2023 Nissan KicksRiady SulindroNo ratings yet

- Price List All Models - ASHDocument1 pagePrice List All Models - ASHSia Siaw LangNo ratings yet

- Transport Regulations 20 May 2020Document8 pagesTransport Regulations 20 May 2020BusinessTech43% (14)

- Bell Uh-1 Iroquois & Ah-1 HueycobraDocument21 pagesBell Uh-1 Iroquois & Ah-1 HueycobraGiora MinorNo ratings yet

- 182-Point Inspection Checklist: Dealer NameDocument4 pages182-Point Inspection Checklist: Dealer NamequsayNo ratings yet

- Engine Timing Tools: Opel - Vauxhall 1.0 - 1.2 - 1.4Document8 pagesEngine Timing Tools: Opel - Vauxhall 1.0 - 1.2 - 1.4cip2009No ratings yet