Professional Documents

Culture Documents

Comparative Study of The Packing Design

Uploaded by

Johnathan Ortega MenesesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Comparative Study of The Packing Design

Uploaded by

Johnathan Ortega MenesesCopyright:

Available Formats

COMPARATIVE STUDY OF

THE PACKING DESIGN FOR A

COOLING TOWER

JOHNATHAN ORTEGA M.

DANIELA JURADO B.

JUAN CAMILO HENAO D.

MILLER A. PUENTES L.

INTRODUCTION

Currently the mass transfer operations are of great importance and use in the chemical engineering

field. One of the biggest operations based on the heat and mass transfer are humidification operations.

These operations consist in put in contact a gas flow with a pure liquid in which is completely

immiscible, in order to achieve the liquid evaporation into the gas and thus increase the concentration

of steam in this gas stream. One of the largest applications of this operation is the cooling of water with

air through cooling towers

The next presentation pretends to show the results and analysis obtained through the experimental

procedure performed in a packed cooling tower.

For this, have been evaluated two packing types: one of them corresponds to the original tower packing

and the other one to a properly designed packing. In order to compare and evaluate the performance

and effectiveness of these, have been determined the global mass transfer coefficients for each one.

In addition to this, have been determined the minimum amount of air required to carry out the cooling

process in order to find the oversizing factor

EXPERIMENTAL METHOD

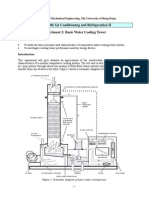

For this experiment was used a cooling tower PA Hilton brand, of forced draft and crosscurrent.

For this experience the working conditions were:

o A power of 0.5 KW

o 0% in the fan opening

The water that enters to the tower is pumped from a reservoir where it is heated. Water flow is also dosed by a

distribution system, and it falls by gravity from the top. The water flow temperature is measured at the inlet and

outlet of the tower with a thermocouple. The water flow is measured by a rotameter.

The air is provided by a fan located at the lower section of the tower and it can be adjusted by a rotatory door. Air

flows through the packing in the opposite direction of the water stream and while it rises, its moisture content

increases. The dry and wet bulb temperature at the air inlet and outlet is measured also by a thermocouple. The

airflow estimation is done by the air speed measurement, which is made using a anemometer.

During the experiment have been used two different kinds of packing, the original and a properly designed

packing. The original consists of several rows of shingles overlapping each other. The designed packing

consists of plastic and Styrofoam spheres which are randomly added into the tower with a total height

equivalent to the original packing height.

SCHEMATIC DIAGRAM OF THE COOLING TOWER

THEORETICAL METHOD

Mass Transfer Coefficient

:

1. Suppose the water that gets out of the tower

has his temperature 5C more than the wet

bulb temperature at the inlet of the gas.

2. Obtain the Psychometric chart of the air at the

Medellin atmospheric pressure.

3. Graph the air saturation enthalpy (axis y)

respect to the water flow temperature range

(axis x).

4. Plot the operation line. It consists in a straight

line between the water temperature at the inlet

and outlet of the tower (axis x) vs. the enthalpy

of the gas in the same points (axis y).

5. Plot the minimum operation line. In order to do

this, it must be taken the outlet conditions

point (lower point of the operation line) and

then trace a tangent line to the saturation

curve.

Definition:

=

1

2

(1)

Where:

: air saturation enthalpy .

: air operation line enthalpy.

1

and

2

correspond to the operation line extreme values.

6. Solve equation (1). This is done by tabulate the values of

1

, and then using a numerical

method.

H Saturation (Kj/Kgas) H Operation (Kj/Kgas) 1/(H'-H)

77,1 54,99 0,04523495

81,49 58,95 0,044362817

86,17 62,90 0,042981174

91,16 66,86 0,041151247

96,1 70,81 0,039548827

101,98 74,77 0,036751465

107,52 78,73 0,034728975

From equation (1):

=

(2)

Where:

: gas flow mass per square meter unit.

(3)

Z: packing height.

7. Solve equation (2)

Oversizing factor :

1. Obtain the minimum operation line slope:

=

(

2

1

)

(

2

1

)

(4)

Definition:

=

(5)

Where:

L': water mass flow

: Specific heat of liquid

2. Obtain

value from equations (4) and (5)

3. Find oversizing factor:

=

(6)

RESULTS AND ANALYSIS

Each figure contains the equilibrium curve for the saturated air and also the operating

line and the minimum operating line

and

results for each packing :

As can be seen, the designed packing has a value

of

less than the corresponding to the original

packing, which indicates that the original packing

presents a higher degree of mass-transfer from

the liquid phase to the gas phase, generating a

greater cooling of water. This implies that the

original packing of the tower has a higher contact

area between the gas phase and the liquid phase.

The designed packing has a higher Number of

Enthalpy Transfer Units and therefor a lower

difficulty for transfer this enthalpy. Also has a

greater Enthalpy Transfer Unit Height, which

represents a better packing efficiency.

Original Packing Designed Packing

(/

3

. ) 3,3492 2,2758

0,9682 0,7802

() 0,4462 0,5537

Oversizing results:

It can be seen that for both packing the relation

between

and

,

obtains values greater

than 1, which means that in both cases the tower is

oversized in a value greater than twice.

Therefore, it is possible to conclude that both towers

have an oversizing greater than 200%, which

indicates that the air flow used during the tower

operation greatly exceeds the minimum air flow

through which it would be possible to obtain the

same inlet and outlet conditions.

In this case, the oversizing is a bit high, which is of

very important care because it implies an

unnecessary increase in the equipment operation

cost and air flow wastage.

This situation can lead to two possible solutions:

reduce fan power or increase the packing height in

order to take advantage of this air excess and

increase the cooling effect.

G's

(Kg/m^2*s

)

G's min

(Kg/m^2*s

)

Oversizing

Original Packing 1,4944 0,0159 2,1288

Designed Packing 1,2601 0,0153 2,1297

Is important see that the results presented could be influenced by errors in measurements and by

incorrectly operating mechanisms. Some of these negative factors could be the distribution of the liquid

at the inlet to the tower which wasn't uniformly, the contact of the liquid with the walls of the tower

could possibly generate wet wall cooling, as may also exist inaccuracies in the measurement method for

the wet bulb temperature. All of this would influence the results for the overall coefficient of mass

transfer and for the oversizing

CONCLUSIONS

Molecular mass transport is mainly due to a concentration gradient, but sometimes may be due to a

temperature gradient which additionally generates an energy transfer. Therefore the mass transfer operations

are usually accompanied by a heat transfer.

The use of packing in cooling towers is of vital importance in these processes, due to they facilitate and provide

the necessary conditions for the mass and heat transfer phenomena generation.

Shape, size and others packing characteristics have a huge influence in the packing effectiveness. Therefore, the

proper selection and design of the packing can significantly increase or decrease the cooling process and tower

efficiency.

The consideration and analysis of concepts as

and

in cooling towers designing are of great importance

due to they bring a measure of the packing behavior and effectiveness.

The over sizing factor is a also a very important and useful parameter in designing and improving of cooling

towers due to it ensures that the process is carried out at the necessary conditions to obtain the required

results. However, it must be taken into account not reach very high values of this parameter due to it could lead

to some resource wastage and unnecessary costs

You might also like

- Cooling TowerDocument32 pagesCooling TowerPrasoon ChaturvediNo ratings yet

- Cooling TowersDocument11 pagesCooling TowersSlim Kat Nkosi0% (2)

- Heuristics for Engineering Problem SolvingDocument42 pagesHeuristics for Engineering Problem SolvingDEV RAJNo ratings yet

- Cooling Tower: Bangladesh University of Engineering and TechnologyDocument15 pagesCooling Tower: Bangladesh University of Engineering and TechnologyMarsya MaysitaNo ratings yet

- Cooling Tower LabDocument33 pagesCooling Tower Labkeckstand100% (2)

- Guidelines For Ethylene Quench Tower Rev IntroDocument12 pagesGuidelines For Ethylene Quench Tower Rev IntroGuntoro AliNo ratings yet

- Guidelines For Ethylene Quench Tower Rev IntroDocument13 pagesGuidelines For Ethylene Quench Tower Rev IntroMubarik AliNo ratings yet

- 3, Cooling Tower, 021170037Document14 pages3, Cooling Tower, 021170037balluzessaNo ratings yet

- Paper An Exergy Analysis On The Performance of A Counterflow Wet Cooling TowerDocument8 pagesPaper An Exergy Analysis On The Performance of A Counterflow Wet Cooling TowerghezelasheghiNo ratings yet

- Cooling Tower PDFDocument30 pagesCooling Tower PDFcynaidu100% (1)

- Models - Heat.shell and Tube Heat ExchangerDocument26 pagesModels - Heat.shell and Tube Heat ExchangerLuis Esteban Vela DonosoNo ratings yet

- 2021 ThermodynamicDocument7 pages2021 ThermodynamicChampika V SamarasighaNo ratings yet

- Models - Heat.evaporative CoolingDocument28 pagesModels - Heat.evaporative CoolingmassomieNo ratings yet

- Boiling and CondensationDocument11 pagesBoiling and CondensationahaaNo ratings yet

- 12.0 Cooling Towers and LightingDocument55 pages12.0 Cooling Towers and LightingNesarkiran BagadeNo ratings yet

- Report Cooling TowerDocument15 pagesReport Cooling TowerAnonymous HikwNM092% (13)

- Worksheet - 3 AimDocument16 pagesWorksheet - 3 AimAnonymous 7Y5GUYHrNo ratings yet

- Lab 04Document7 pagesLab 04Areeba NaqviNo ratings yet

- Models - Heat.evaporative CoolingDocument26 pagesModels - Heat.evaporative CoolingJorge Agüero LópezNo ratings yet

- Cooling TowerDocument28 pagesCooling TowerKangae Ilham100% (4)

- Cooling TowersDocument35 pagesCooling TowersSingaravelu MariappanNo ratings yet

- UOFE AssignmentDocument4 pagesUOFE AssignmentSahar Batool QaziNo ratings yet

- Climbing Film Evaporator: I. CHE 1014 II. SB92Document14 pagesClimbing Film Evaporator: I. CHE 1014 II. SB92Khalid M MohammedNo ratings yet

- Exp 1 Cooling TowerDocument7 pagesExp 1 Cooling TowerhahaNo ratings yet

- MECH3423 Building Services Engineering II Experiment 1: Basic Water Cooling TowerDocument6 pagesMECH3423 Building Services Engineering II Experiment 1: Basic Water Cooling TowerMahleh Thabe'khuluNo ratings yet

- Guidelines For Ethylene Quench Tower Rev 17Document17 pagesGuidelines For Ethylene Quench Tower Rev 17totongop0% (1)

- Effective Thermal Design of Cooling TowersDocument11 pagesEffective Thermal Design of Cooling Towershamid vahedil larijaniNo ratings yet

- Flare Sweep GasDocument5 pagesFlare Sweep GasChem.EnggNo ratings yet

- Cooling TowerDocument10 pagesCooling TowerKeshav Rao100% (1)

- Rotary Heat Exchangers: For Heat Recovery in Ventilation SystemsDocument28 pagesRotary Heat Exchangers: For Heat Recovery in Ventilation SystemsDusan GordicNo ratings yet

- Gorai-Sahoo2022 Chapter EnergeticAndExergeticAnalysisODocument13 pagesGorai-Sahoo2022 Chapter EnergeticAndExergeticAnalysisOLilou MGKNo ratings yet

- Cooling Tower Deign Guidelines and ProcedureDocument6 pagesCooling Tower Deign Guidelines and ProcedureVikas Dadhich100% (4)

- UM Thermal Lab Experiment on Film and Dropwise CondensationDocument23 pagesUM Thermal Lab Experiment on Film and Dropwise CondensationAdnan NandaNo ratings yet

- Coolingtower With Tabulation PDFDocument6 pagesCoolingtower With Tabulation PDFsankarsuper83No ratings yet

- Cooling Tower: Asst - Prof.Dr - Sirirat WacharawichanantDocument4 pagesCooling Tower: Asst - Prof.Dr - Sirirat WacharawichanantAnonymous PkeI8e84RsNo ratings yet

- Filmwise and Dropwise ExperimentDocument16 pagesFilmwise and Dropwise ExperimentGoodMarissa100% (5)

- Air Cooling PowerDocument20 pagesAir Cooling PowerSantanu kumar AichNo ratings yet

- Agitated Vessel PDFDocument9 pagesAgitated Vessel PDFKr AyushNo ratings yet

- Theory and Experiment ProcedureDocument25 pagesTheory and Experiment ProcedureNazrul HafizNo ratings yet

- Cooling Power of Mine AirDocument16 pagesCooling Power of Mine AirVihari RahulNo ratings yet

- Thermal Analysis of A Commercial Plate Fin Heat Exchanger With Non-Uniform Inlet Flow ConditionsDocument47 pagesThermal Analysis of A Commercial Plate Fin Heat Exchanger With Non-Uniform Inlet Flow ConditionsdondiNo ratings yet

- Effective Thermal Design of Cooling TowersDocument13 pagesEffective Thermal Design of Cooling TowersKarthick VelayuthamNo ratings yet

- Cooling Tower PDFDocument3 pagesCooling Tower PDFmaimslapNo ratings yet

- Cooling TowerDocument8 pagesCooling TowerMohammed IhsanNo ratings yet

- Air Compressor: BMMM 2333 - Hydraulic and Pneumatic TechnologyDocument34 pagesAir Compressor: BMMM 2333 - Hydraulic and Pneumatic TechnologyFgj JhgNo ratings yet

- Cooling Tower PowerpointDocument17 pagesCooling Tower Powerpointdebu1985No ratings yet

- Heat Transfre Subsea PipelinesDocument34 pagesHeat Transfre Subsea Pipelinesatils100% (1)

- Mr. Dinesh Sharma Mr. Hansraj Prajapati Neetu Verma Tarachand Yadav Yogesh Kumar Vikram SinghDocument7 pagesMr. Dinesh Sharma Mr. Hansraj Prajapati Neetu Verma Tarachand Yadav Yogesh Kumar Vikram SinghAnkush KhokharNo ratings yet

- Cooling Towers: Training Session On Energy EquipmentDocument38 pagesCooling Towers: Training Session On Energy EquipmentVijay KumarNo ratings yet

- Uitm Pahang: Faculty of Civil EngineeringDocument9 pagesUitm Pahang: Faculty of Civil EngineeringAmelia SyarinaNo ratings yet

- Cooling TowersDocument9 pagesCooling TowersTapan KumarNo ratings yet

- Rotary Heat ExchangersDocument32 pagesRotary Heat Exchangerspal_stephenNo ratings yet

- Experimental Investigation of A Thermosyphon Based Heat Exchanger Used in Energy Efficient Air Handling UnitsDocument8 pagesExperimental Investigation of A Thermosyphon Based Heat Exchanger Used in Energy Efficient Air Handling Unitsmjs9170No ratings yet

- H A (T∞ - T) Dt = M Cpdt With M = Ρv And Change Of Variable Dt = D (T -T∞), We FindDocument9 pagesH A (T∞ - T) Dt = M Cpdt With M = Ρv And Change Of Variable Dt = D (T -T∞), We FinddxjsNo ratings yet

- Air Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&AFrom EverandAir Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&ANo ratings yet

- Flow, Mixing and Heat Transfer in Furnaces: The Science & Applications of Heat and Mass Transfer Reports, Reviews & Computer ProgramsFrom EverandFlow, Mixing and Heat Transfer in Furnaces: The Science & Applications of Heat and Mass Transfer Reports, Reviews & Computer ProgramsK. H. KhalilNo ratings yet

- Phase Equilibrium in Mixtures: International Series of Monographs in Chemical EngineeringFrom EverandPhase Equilibrium in Mixtures: International Series of Monographs in Chemical EngineeringNo ratings yet

- Fineness of Portland Cement by The Turbidimeter: Standard Test Method ForDocument8 pagesFineness of Portland Cement by The Turbidimeter: Standard Test Method ForJohnathan Ortega MenesesNo ratings yet

- Masonry Cement: Standard Specification ForDocument4 pagesMasonry Cement: Standard Specification ForJohnathan Ortega MenesesNo ratings yet

- Air Content of Hydraulic Cement Mortar: Standard Test Method ForDocument4 pagesAir Content of Hydraulic Cement Mortar: Standard Test Method ForJohnathan Ortega MenesesNo ratings yet

- Janosch-Panama Album PDFDocument74 pagesJanosch-Panama Album PDFJohnathan Ortega Meneses100% (2)

- Bisphenol A: Profile Last Published January 14, 2008Document1 pageBisphenol A: Profile Last Published January 14, 2008Johnathan Ortega MenesesNo ratings yet

- Heat of Hydration of Hydraulic Cement: Standard Test Method ForDocument7 pagesHeat of Hydration of Hydraulic Cement: Standard Test Method ForJohnathan Ortega MenesesNo ratings yet

- 4650 6723 1 PB PDFDocument13 pages4650 6723 1 PB PDFJohnathan Ortega MenesesNo ratings yet

- Cement Industry Profile - South AmericaDocument35 pagesCement Industry Profile - South AmericaJohnathan Ortega MenesesNo ratings yet

- 4650 6723 1 PB PDFDocument13 pages4650 6723 1 PB PDFJohnathan Ortega MenesesNo ratings yet

- The Cement Plant Operations Handbook - 5th EditionDocument218 pagesThe Cement Plant Operations Handbook - 5th EditionJohnathan Ortega Meneses75% (4)

- Presentación de Resultados 26.08.2014Document18 pagesPresentación de Resultados 26.08.2014Johnathan Ortega MenesesNo ratings yet

- R Mín. 0,74 R Ope. 1,6: Figura "Mass and Energy Balance"Document1 pageR Mín. 0,74 R Ope. 1,6: Figura "Mass and Energy Balance"Johnathan Ortega MenesesNo ratings yet

- The Flixborough Disaster - Report HSC PDFDocument108 pagesThe Flixborough Disaster - Report HSC PDFJohnathan Ortega MenesesNo ratings yet

- Design of Ionic Liquids Via ComputationalDocument5 pagesDesign of Ionic Liquids Via ComputationalJohnathan Ortega MenesesNo ratings yet

- Diseño de ExperimentosDocument480 pagesDiseño de ExperimentosJohnathan Ortega Meneses100% (1)

- Electrochemical Investigation of The Bunsen ReactionDocument11 pagesElectrochemical Investigation of The Bunsen ReactionJohnathan Ortega MenesesNo ratings yet

- Reporte Bisphenol A ICIS ForecastDocument28 pagesReporte Bisphenol A ICIS ForecastJohnathan Ortega MenesesNo ratings yet

- Computer Aided Methods & Tools For Separation & Purification of Fine Chemical & Pharmaceutical ProductsDocument6 pagesComputer Aided Methods & Tools For Separation & Purification of Fine Chemical & Pharmaceutical ProductsJohnathan Ortega MenesesNo ratings yet

- Falling DownDocument2 pagesFalling DownJohnathan Ortega MenesesNo ratings yet

- Emerson-Valve Sizing Calculations (Traditional Method)Document21 pagesEmerson-Valve Sizing Calculations (Traditional Method)iqtorresNo ratings yet

- BPA Bisphenol ManufactureDocument21 pagesBPA Bisphenol ManufactureJohnathan Ortega MenesesNo ratings yet

- Among The Trends For A Modern ChemicalDocument7 pagesAmong The Trends For A Modern ChemicalJohnathan Ortega MenesesNo ratings yet

- Comparative Study of The Packing Design (Comparative Study of The Packing Design)Document14 pagesComparative Study of The Packing Design (Comparative Study of The Packing Design)Johnathan Ortega MenesesNo ratings yet

- Security Assessment Bisphenol ADocument13 pagesSecurity Assessment Bisphenol AJohnathan Ortega MenesesNo ratings yet

- Comparative Study of The Packing Design (Comparative Study of The Packing Design)Document14 pagesComparative Study of The Packing Design (Comparative Study of The Packing Design)Johnathan Ortega MenesesNo ratings yet

- Worksheet Conspiracy TheoryDocument2 pagesWorksheet Conspiracy TheoryJohnathan Ortega MenesesNo ratings yet

- The Flixborough Disaster.Document7 pagesThe Flixborough Disaster.Johnathan Ortega MenesesNo ratings yet

- MethodsDocument2 pagesMethodsJohnathan Ortega MenesesNo ratings yet

- Mathematical Modelling On Thin Layer Microwave Drying of Apple Pomace With and Without Hot Air Pre-DryingDocument9 pagesMathematical Modelling On Thin Layer Microwave Drying of Apple Pomace With and Without Hot Air Pre-DryingJohnathan Ortega MenesesNo ratings yet