Professional Documents

Culture Documents

Eng-Lifting Lug 01

Uploaded by

AbderraoufAffesCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Eng-Lifting Lug 01

Uploaded by

AbderraoufAffesCopyright:

Available Formats

EKON Dj ebel Ressas 5800 TPD Cement Pl ant Pr oj ec t Doc no:

Hse/L-L1

CHECK LIST OF LIFTING LUG

Date of issue:

Rev: 00

Name and number of the lifting equipment: Weight of the equipment:

Type,properties and quantity of the assigned sling:

Properties and quantity of the assigned lifting lug:

DETAILS OF THE STANDARD WELDED LIFTING LUG

A:Hole diameter/ B: Outside diameter/ C: Height from bottom to center/

D:The bottom width/ E:Wall thickness/ X:Welding surface width

LIFTING SYSTEM

a-) Single lug,

straight lifting

b-)Two lugs,lifting

with travers

c-)Two lugs, lifting angle

sling

load

sling

travers

load

sling

angle of sling

(a)

load

Operating limits on the loss-load (Tone) Manufacturing dimensions for the welded lug ( mm )

straight

lifting

travers angle of

sling

angle of

sling

angle of

sling

angle of

sling

Lifting Lugs

Base level

(if necessary)

Welding

width

0 0 30 60 90 120

1 lug 2 lugs 2 lugs 2 lugs 2 lugs 2 lugs

A B C D E F G H R X

0,5 1 0,95 0,87 0,7 0,5 22 30 35 75 10 100 100 10 25 7

1 2 1,9 1,74 1,4 1 25 33 35 75 10 100 100 10 25 7

1,5 3 2,8 2,6 2,1 1,5 28 36 35 75 10 100 100 10 25 7

2 4 3,8 3,5 2,8 2 31 41 40 100 10 125 125 15 35 7

3 6 5,7 5,2 4,2 3 35 45 45 115 15 150 150 20 35 10

4 8 7,6 6,9 5,6 4 38 50 50 135 20 170 170 20 40 14

5 10 9,5 8,7 7 5 43 58 50 145 20 175 175 20 40 14

7,5 15 14,2 13 10,5 7,5 50 65 60 160 25 200 200 20 40 17,5

10 20 19 17,4 14 10 60 75 70 205 35 340 225 25 50 24,5

12 24 22,8 20,8 16,8 12 65 85 75 205 35

Shall be designed

by site engineer

24,5

15 30 28,5 26,1 21 15 70 90 80 250 40 28

20 40 38 34,8 28 20 75 105 90 290 45 31,5

25 50 47,5 43,5 35 25 82 115 100 320 50 35

30 60 57 52,2 42 30 90 125 105 345 50 35

40 80 76 69,6 56 40 100 140 140 380 70 49

Note: Details of the special manufacturing required lifting lugs will be added by the foreman or site engineer. (if necessary) **

Assigned lug

Capacity:

Quantity:

Manufacture by Checked by Recorded by

Foreman- Name/Surname Site Engineer Name/Surname HSE Department

WELDING CONTROL FOR LIFTING LUG YES NO

Hayr

1-) The welding groove (V) is opened from both sides?

2-) Burrs of the welding grooves are cleaned?

3-) Welding surface on the lug is cleaned? (Paint,rust etc.)

4-) Root cleaning at the welding bent on the other side is done?

5-) Is there any notch at the welding turns at the edge of the lug?

6-) Is it done by a certified welder?

7-) The welder ID and welding date is indicated on the lug?

8-) Penetrant test performed? ( with the decision of the QC inspectors)*

CHECKED BY APPROVED BY RECORDED BY

Foremen or site eng.Name/Surname QC Department HSE Department

*This form will fill out for bulky materials over 5 tons and for all materials over 10 tons, the lifting will be commenced with supervision of the site supervisor after

check and approval of the welding by QC inspector.

**Penetrant test will be applied of lifting lug weldings over 10 tons load.

***According to the weight and shape of the load position,last control and decide for quantity of lifting lug are in the charge of foreman or engineer.

**** Lifting for bulky or over 20 tons materials will be under the supervision of the mechanical chief and HSE chief.

Bottom layer

Lifting lug /details

of bottom layer

You might also like

- S.No SL - No Mogura Deuma Two Tee's One I Two Tee's Du. No Web TCK, MM Flange TCK, MM Width, MM Length, MMDocument12 pagesS.No SL - No Mogura Deuma Two Tee's One I Two Tee's Du. No Web TCK, MM Flange TCK, MM Width, MM Length, MMRajiv DamodarNo ratings yet

- Bolt Tightening Inspection Report Format FinalDocument2 pagesBolt Tightening Inspection Report Format FinalHugo FloresNo ratings yet

- Note in WRC 107 Lifting Lug Calculation (Horizontal Vessel) - Intergraph CADWorx & AnalysisDocument2 pagesNote in WRC 107 Lifting Lug Calculation (Horizontal Vessel) - Intergraph CADWorx & AnalysisDinesh VaghelaNo ratings yet

- Certified Inspector Checklist: New Tank ConstructionDocument11 pagesCertified Inspector Checklist: New Tank ConstructionamevaluacionesNo ratings yet

- Lift Study ChecklistDocument3 pagesLift Study ChecklistIkhsan Awan0% (1)

- Tabla HDPE-Pipe PDFDocument4 pagesTabla HDPE-Pipe PDFBerinssonScottHernandezSucsoNo ratings yet

- Demo Weld Cost Calc XLDocument10 pagesDemo Weld Cost Calc XLMarcelo Simão Do ValeNo ratings yet

- Welding Electrode Filter Metal CalculationDocument3 pagesWelding Electrode Filter Metal CalculationjsvrrajuNo ratings yet

- INS P 035, Circularity Check - Cyl.sectionsDocument10 pagesINS P 035, Circularity Check - Cyl.sectionsDeepakNo ratings yet

- NPT Thread Chart - NPT & NPS Fittings Dimensions & SizesDocument2 pagesNPT Thread Chart - NPT & NPS Fittings Dimensions & SizesMarc EdwardsNo ratings yet

- Fatigue Assessment of Existing Riveted Truss Bridges: Case StudyDocument9 pagesFatigue Assessment of Existing Riveted Truss Bridges: Case StudynaimulceNo ratings yet

- Welding Database CCT DiagramDocument1 pageWelding Database CCT DiagramcostycgNo ratings yet

- Closure Data PEDocument2 pagesClosure Data PEjowarNo ratings yet

- Structural Steel Sub-Grades JR, J0 and J2 PDFDocument1 pageStructural Steel Sub-Grades JR, J0 and J2 PDFJafarNo ratings yet

- Gantrail Welded Base Fixing: SpecificationsDocument2 pagesGantrail Welded Base Fixing: Specificationsaandueza_1No ratings yet

- Structural Estimate BasisDocument8 pagesStructural Estimate BasisKaloyNo ratings yet

- Disclosure To Promote The Right To InformationDocument96 pagesDisclosure To Promote The Right To InformationgovimanoNo ratings yet

- Delta Industrial Knife Gate ValvesDocument28 pagesDelta Industrial Knife Gate ValvesAlin AllinNo ratings yet

- Webbing Sling - SWLDocument4 pagesWebbing Sling - SWLChandrasekhar SonarNo ratings yet

- 07 Piping BOQDocument54 pages07 Piping BOQHRK65No ratings yet

- Master List of DrawingsDocument117 pagesMaster List of DrawingsBenudhar Sahoo100% (1)

- Febolt: Hexagon Covernut Type "Febolt"Document1 pageFebolt: Hexagon Covernut Type "Febolt"Tuntun TatNo ratings yet

- Line Pipe Is (Tolerance)Document4 pagesLine Pipe Is (Tolerance)Mani MaranNo ratings yet

- CJP WeldsDocument1 pageCJP WeldsbsagguNo ratings yet

- Filletweld 1Document4 pagesFilletweld 1Prakash RajNo ratings yet

- 1 Beam Fails Ub305x165x54Document4 pages1 Beam Fails Ub305x165x54Elencheliyan PandeeyanNo ratings yet

- Heat Input Calculation From WeldingDocument9 pagesHeat Input Calculation From Weldingemmanuilmoulos6339No ratings yet

- Prepared By: Chirag B. PatelDocument11 pagesPrepared By: Chirag B. PatelPatel ChiragNo ratings yet

- WeldingDocument18 pagesWeldingIlhamHidayatNo ratings yet

- A 307Document1 pageA 307GHULAM NABINo ratings yet

- WHS PRO 004 Maintenance of Equipment ProcedureDocument10 pagesWHS PRO 004 Maintenance of Equipment ProcedureWekesa RobinsonNo ratings yet

- DistortionDocument18 pagesDistortionSteransko100% (1)

- FlangeDocument13 pagesFlangehuangjlNo ratings yet

- 50.0m GUYED Tower-TA-ZRI681 - A-040811-ADocument105 pages50.0m GUYED Tower-TA-ZRI681 - A-040811-Aredflex9001889No ratings yet

- Heavy Hex NutsDocument3 pagesHeavy Hex NutsAhmadreza AminianNo ratings yet

- Check List of Column VerticalityDocument11 pagesCheck List of Column VerticalityyuwantoniNo ratings yet

- Why Is Preheating NecessaryDocument3 pagesWhy Is Preheating NecessaryahmedNo ratings yet

- En 10029 Dimensional TolerancesDocument1 pageEn 10029 Dimensional ToleranceswhngomjNo ratings yet

- t15b03-0102 - 0painting Specification For Whb&Steam DrumDocument36 pagest15b03-0102 - 0painting Specification For Whb&Steam DrumMuhammedHafisNo ratings yet

- 127.study The Effect of Welding Parameters of Tig Welding of PlateDocument43 pages127.study The Effect of Welding Parameters of Tig Welding of PlatemoorthikumarNo ratings yet

- How To Calculate Filler MetalDocument3 pagesHow To Calculate Filler MetalEdgar Coavas PérezNo ratings yet

- PED 2014-68-EU Guidelines EN v4Document235 pagesPED 2014-68-EU Guidelines EN v4Nav TalukdarNo ratings yet

- BS en 15614 Welder Tests Template1Document14 pagesBS en 15614 Welder Tests Template1delta lab sangliNo ratings yet

- Calculation of Electrode ConsumptionDocument4 pagesCalculation of Electrode ConsumptionhgolestaniNo ratings yet

- ASTM A131 Steel, Grade DDocument1 pageASTM A131 Steel, Grade DjulianmorantesNo ratings yet

- Basics of Pressure Piping For Junior EngineersDocument36 pagesBasics of Pressure Piping For Junior Engineersتدریس زبان ESLNo ratings yet

- CON 311 V00 Method Statement For Structural Steel and Pipe Support Fabrication PDFDocument22 pagesCON 311 V00 Method Statement For Structural Steel and Pipe Support Fabrication PDFfurkanNo ratings yet

- BS 499-1 SupplementDocument37 pagesBS 499-1 Supplementvuthuy94No ratings yet

- Pad Eye Calculation AllDocument3 pagesPad Eye Calculation Alldsn_sarmaNo ratings yet

- PDS-POLYKEN-1027-V1-AUG17 - AARPS-0972 PrymerDocument2 pagesPDS-POLYKEN-1027-V1-AUG17 - AARPS-0972 PrymerJoel SaucedoNo ratings yet

- 4DMechanical VesselDocument26 pages4DMechanical VesselBowo Edhi WibowoNo ratings yet

- How To Weld T-1 SteelDocument21 pagesHow To Weld T-1 SteelMuthu Barathi ParamasivamNo ratings yet

- Single V WeldDocument4 pagesSingle V WeldkoyahassanNo ratings yet

- Ewf - Technical Sheet - Calculation of Preheat Temperature For Butt WeldsDocument1 pageEwf - Technical Sheet - Calculation of Preheat Temperature For Butt WeldsDries VandezandeNo ratings yet

- CHG 55B2Document1 pageCHG 55B2Nhien ManNo ratings yet

- Failure Behavior of 2D C SiC I Beam Under Bending Load 2015 Composite StructuresDocument10 pagesFailure Behavior of 2D C SiC I Beam Under Bending Load 2015 Composite StructuresGECJNo ratings yet

- Principal of DPTDocument5 pagesPrincipal of DPTAkshith SulliaNo ratings yet

- En 12451 1999Document24 pagesEn 12451 1999victoraghiNo ratings yet

- HY-8 Culvert Analysis Report: Project NotesDocument52 pagesHY-8 Culvert Analysis Report: Project NotesDiego López ArtigueNo ratings yet

- A E G H J M N O C D: Test Project For The 42Nd. Worldskills Competition in Leipzig, Germany 2013. All Rights ReservedDocument8 pagesA E G H J M N O C D: Test Project For The 42Nd. Worldskills Competition in Leipzig, Germany 2013. All Rights ReservedMiller Andres Ladino Fernandez100% (1)

- Astm A36 PDFDocument5 pagesAstm A36 PDFAnindya Aulia Pratiwi67% (3)

- Design of Lifting LugDocument7 pagesDesign of Lifting Luga_toups100% (1)

- Mathcad - Spreader Beam Design Calculations As Per DNV 5th VerDocument29 pagesMathcad - Spreader Beam Design Calculations As Per DNV 5th VerAbderraoufAffes100% (3)

- Asme b16 9 2003Document50 pagesAsme b16 9 2003alokbdas100% (1)

- ASME SpreaderBar CalcsDocument5 pagesASME SpreaderBar Calcsganesh100% (1)

- API Tank DesignDocument189 pagesAPI Tank DesignDD3NZ91% (11)

- Caddwell High-Capacity Adj. Spreader A - SB - 27Document1 pageCaddwell High-Capacity Adj. Spreader A - SB - 27AbderraoufAffesNo ratings yet

- Cadwell High Capacity Spreader Beam A - SB - 22-23Document2 pagesCadwell High Capacity Spreader Beam A - SB - 22-23AbderraoufAffesNo ratings yet

- Lifting Lug Design Calcs As 4100Document2 pagesLifting Lug Design Calcs As 4100JONHCENA13No ratings yet

- Caldwell Adjustable Spreader Beam A - SB - 26Document1 pageCaldwell Adjustable Spreader Beam A - SB - 26AbderraoufAffesNo ratings yet

- Caldwell Adjustable Spreader Beam A - SB - 26Document1 pageCaldwell Adjustable Spreader Beam A - SB - 26AbderraoufAffesNo ratings yet

- Primavera P6 Project Management Refrence ManualDocument700 pagesPrimavera P6 Project Management Refrence ManualDebabrata Trivedi100% (8)

- Mathcad - Spreader Beam Design Calculations As Per DNV 5th VerDocument29 pagesMathcad - Spreader Beam Design Calculations As Per DNV 5th VerAbderraoufAffes100% (3)

- Tandemloc EAD21000ADocument3 pagesTandemloc EAD21000AAbderraoufAffesNo ratings yet

- Primavera P6 Project Management Refrence ManualDocument700 pagesPrimavera P6 Project Management Refrence ManualDebabrata Trivedi100% (8)

- ASME SpreaderBar CalcsDocument5 pagesASME SpreaderBar Calcsganesh100% (1)

- ASME SpreaderBar CalcsDocument5 pagesASME SpreaderBar Calcsganesh100% (1)

- Design Calculation of Spillway GateDocument11 pagesDesign Calculation of Spillway GateAnonymous sfkedkymNo ratings yet

- Structural Standard Details: Construction NotesDocument4 pagesStructural Standard Details: Construction Notesjohn rey toledo100% (1)

- The History of Investment Foundry ProcessDocument11 pagesThe History of Investment Foundry ProcessVrinda NilotpalNo ratings yet

- BAR CHART - Pert - CPM SampleDocument2 pagesBAR CHART - Pert - CPM SampleLester Neil LomodNo ratings yet

- CHAPTER 1 Soil PropertiesDocument27 pagesCHAPTER 1 Soil PropertiesLyzette LeanderNo ratings yet

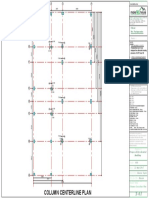

- 1 Column Centerline PlanDocument1 page1 Column Centerline PlanRhishikesh IngoleNo ratings yet

- Ce2033 Ground Improvement Techniques L T P CDocument2 pagesCe2033 Ground Improvement Techniques L T P Camma832No ratings yet

- Garage Door Opener Abridor de Puerta de Cochera: Owner's Manual/Manual Del PropietarioDocument76 pagesGarage Door Opener Abridor de Puerta de Cochera: Owner's Manual/Manual Del PropietarioAbbas ShahidNo ratings yet

- Water Hammer in Gravity LinesDocument12 pagesWater Hammer in Gravity LinesMuhammad Ehtsham0% (1)

- Arriostre de VigasDocument20 pagesArriostre de VigasGonzalo Guerrero CáceresNo ratings yet

- Damp Prevention in BuildingsDocument43 pagesDamp Prevention in Buildingswaterproofing_best100% (3)

- Itp For STR Steel WorksDocument9 pagesItp For STR Steel WorksGauravSinghNo ratings yet

- Gemu DB FlareStar GBDocument32 pagesGemu DB FlareStar GBejrfjxhjtntauuwtfcNo ratings yet

- Item 200 - Aggregate Sub Base Course Sieve DesignationDocument20 pagesItem 200 - Aggregate Sub Base Course Sieve DesignationAeron Paul AntonioNo ratings yet

- Marshal Stability TestDocument1 pageMarshal Stability TestAenan BashirNo ratings yet

- Zhao - Lee - Post Weld Heat Treatment For High Strength Steel Welded ConnectionsDocument11 pagesZhao - Lee - Post Weld Heat Treatment For High Strength Steel Welded Connectionsbob8c5No ratings yet

- Housing Policies and Strategies in Libya - Brief An OverviewDocument5 pagesHousing Policies and Strategies in Libya - Brief An OverviewsatgasppksNo ratings yet

- 01-Contracts and The SurveyorDocument48 pages01-Contracts and The SurveyorJoanne TanNo ratings yet

- Balanced Concession For The Airport Industry PDFDocument80 pagesBalanced Concession For The Airport Industry PDFPricop CosminNo ratings yet

- Registration CRDocument5 pagesRegistration CRnandha gopalNo ratings yet

- Lintels Problems - STEEL STRUCTURESDocument8 pagesLintels Problems - STEEL STRUCTURESDarya Memon100% (1)

- Water Specs English-FinalDocument266 pagesWater Specs English-FinalMohammed HanafiNo ratings yet

- Saudi Construction Rates - 2021Document4 pagesSaudi Construction Rates - 2021BobNo ratings yet

- Ashrae Pubcatalog 2019winter PDFDocument16 pagesAshrae Pubcatalog 2019winter PDFkunkzNo ratings yet

- Design of Steel Structures: Mahmud Dwaikat Assistant Professor Civil Engineering Dept. An-Najah National UniversityDocument32 pagesDesign of Steel Structures: Mahmud Dwaikat Assistant Professor Civil Engineering Dept. An-Najah National Universityप्रभु नाथ सिंहNo ratings yet

- Your Dream Home Awaits!: Rera Web Site - WWW - Rera.wb - Gov.in Rera Registration No. - WBRERA/P/SOU/2023/000281Document30 pagesYour Dream Home Awaits!: Rera Web Site - WWW - Rera.wb - Gov.in Rera Registration No. - WBRERA/P/SOU/2023/000281discovernealNo ratings yet

- Piling: Information Provided Rules Definition Coverage Rules Supp MentDocument1 pagePiling: Information Provided Rules Definition Coverage Rules Supp MentVimalNo ratings yet

- SAES-A-206 - 2020 - Positive Material IdentificationDocument18 pagesSAES-A-206 - 2020 - Positive Material IdentificationMEHBOOB19786No ratings yet

- Fuel Tank Ring Beam Design CalculationDocument11 pagesFuel Tank Ring Beam Design CalculationDawson Preethi EA94% (16)

- National HVAC Design Report ENERGY STAR Certified Homes Rev10Document4 pagesNational HVAC Design Report ENERGY STAR Certified Homes Rev10thamerkayedNo ratings yet