Professional Documents

Culture Documents

01.startup Preparation (1) A3

Uploaded by

Adib Zakariya0 ratings0% found this document useful (0 votes)

21 views1 page1

Original Title

01.Startup Preparation (1) a3

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

21 views1 page01.startup Preparation (1) A3

Uploaded by

Adib Zakariya1

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

1 Check all safety interlock 1 22

2 Check fuel firing equipment (oil and coal) 23

3

2 24

4 Check for any Isolated or Tag Out Equipment

3

5 Check for normalization of Drain valve, Vent valve etc

4 25

5 26

6 27

7 28

8 29

9 30

10 31

11 32

12

13 33

14 34

15

16 35

17

18

19

20

21

UNIT START UP PROCEDURE - PREPARATION

10kV UB A & B BUS Normal, Voltage > 9500V

DCC system is inservice

Steam Drum Level 0mm

Boiler filling complete

Dea. & FW tank Level > 50mm

LP Heaters, Deaerator and Feedwater Tank and HP Heaters filling complete

Hot-Well Level > -50mm

Instrument Air / Service Air Pressure > 7.6 barg

Compressed Air system is inservice

Closed Cysle Cooling Water system is inservice

Auxiliary Cooling Water system is inservice

Condensor Tube Cleaning system is inservice

Condenser Hot-Well filling complete

ESP Warming

- Fuel Oil System auto

- Fuel Oil Supply Flow SV Auto

CHECK

CEP A or B run

Condensate Water System is inservice

Electro Chlorination Plant is inservice

Circulating Water system and Intake Screen system are inservice

Make up water system and related tanks/basins and their water level, Make

up water tanks and EDG Day Tank normal level

CCCW chemical dosing system is in available

Service Water Pump Outlet Pressure > 8.0 barg

Service Water Pump is inservice

Make up water system for Condensate and Closed Cycle cooling water are

inservice

Plant water supply system include Desal plant and Demin plant inservice

Waste water treatment plant inservice

Fire Detection, alarm and fighting systems are ready

HVAC System inservice Check the Operation Mode of Equipment in Auto or Manual

operation

Fuel Oil System is available

STARTUP PREPARATION

HP TBN Bypass Control valve Oil supply unit is inservice and auto

Main TBN Turning Gear is inservice

Gen. Stator Cooling Water Inlet Pressure Normal : > 1.8 bar

Gen. Stator Cooling Water Discharge Pressure Normal

Generator Stator Cooling Water is inservice

- Main Oil Conditioner Filter Pump run

- Main Oil Tank Vapour Extractor A or B run

- EHC Oil Pump A or B run

- MOP A or B run

Power Receiving ready, and Electrical system are available

- Gen. Hydrogen Pressure Normal : 4.2bar ~ 4.6 bar

- Gen. Coll. End Gas Purity Normal : > 85%

- Gen. TBN End Gas Purity Normal : > 85%

Generator Hydrogen filling complete and Hydrogen pressure normal

Gen. Seal Oil Strainer DP (TBN END) > 0.3bar

Generator Seal Oil system is inservice

DCS System inservice DC power for Emergency Oil pumps and Emergency Seal Oil pump is inservice

Turbine Lube Oil and EHC Oil systems are inservice

FGD Warm up

Aux. steam system is inservice and check the condition of steam source and

Aux. steam Header

BFPT A and B Turning Gear is inservice

- BFPT A & B Oil Conditioner Filter Pump run

- BFPT A & B Main Oil Tank Vapour Extractor run

- BFPT A & B MOP run

BFPT A and B Lube Oil system is inservice

LP TBN Bypass Control is in Auto

01

You might also like

- 31.cooling Data (Forced and Natural) (78 79) A4 To A3Document4 pages31.cooling Data (Forced and Natural) (78 79) A4 To A3Adib ZakariyaNo ratings yet

- Problem Ac No. Area Qty. Name Problem RemarkDocument2 pagesProblem Ac No. Area Qty. Name Problem RemarkAdib ZakariyaNo ratings yet

- Cover Log Book Boiler 4Document2 pagesCover Log Book Boiler 4Adib ZakariyaNo ratings yet

- List of Equipment Need Small Maintenance When Outag1Document1 pageList of Equipment Need Small Maintenance When Outag1Adib ZakariyaNo ratings yet

- List Air Conditioner No. Area Qty. Name Problem RemarkDocument2 pagesList Air Conditioner No. Area Qty. Name Problem RemarkAdib ZakariyaNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Choke Flow CV PDFDocument5 pagesChoke Flow CV PDFMarcos IzquierdoNo ratings yet

- Vorticity and Turbulence EffectsDocument305 pagesVorticity and Turbulence EffectsMohammed Amine MoussaouiNo ratings yet

- An Overview of Methods To Mitigate Condensate Banking in Retrograde Gas ReservoirsDocument6 pagesAn Overview of Methods To Mitigate Condensate Banking in Retrograde Gas ReservoirsAdanenche Daniel EdohNo ratings yet

- Assignment 2 Sediment - FinalDocument12 pagesAssignment 2 Sediment - FinalzelalemniguseNo ratings yet

- Theory of Pressure Relief, 1Document6 pagesTheory of Pressure Relief, 1petrochemNo ratings yet

- Head Loss From Rapid Sand Filter To Clear Water TankDocument3 pagesHead Loss From Rapid Sand Filter To Clear Water TankNaungNo ratings yet

- CH 2 PDFDocument49 pagesCH 2 PDFswami061009No ratings yet

- Determination of Viscosity Through Brookfield Viscometer.Document6 pagesDetermination of Viscosity Through Brookfield Viscometer.ReginaldNo ratings yet

- Class - Xi - Physics - Properties of Bulk Matter - Worksheet - 7 PDFDocument4 pagesClass - Xi - Physics - Properties of Bulk Matter - Worksheet - 7 PDFLaksh GuptaNo ratings yet

- Hydraulic and Pneumatic EquipmentDocument194 pagesHydraulic and Pneumatic EquipmentHaery Uye100% (2)

- Instrument List: J300 011 405 REV-01Document5 pagesInstrument List: J300 011 405 REV-01hari reddyNo ratings yet

- How Pressure Regulators WorkDocument22 pagesHow Pressure Regulators WorkAdeel QaiserNo ratings yet

- Unit Ii Convection: Lower Temp Higher Temp 2 2 2Document26 pagesUnit Ii Convection: Lower Temp Higher Temp 2 2 2ASHISH K.K.No ratings yet

- Selecting Centrifugal Slurry Pump BasedDocument6 pagesSelecting Centrifugal Slurry Pump BasedRodrigo GarcíaNo ratings yet

- Curva Bomba 3K8X6-16 ARV M3ST Con 100Hp Imp. 13.0 inDocument5 pagesCurva Bomba 3K8X6-16 ARV M3ST Con 100Hp Imp. 13.0 ineduinNo ratings yet

- Project On Bottle Water IndustryDocument86 pagesProject On Bottle Water IndustryChristopher McknightNo ratings yet

- Wemco Isf: Hydraulically Induced Gas Flotation SystemDocument2 pagesWemco Isf: Hydraulically Induced Gas Flotation SystemMiguel PintoNo ratings yet

- Calculation For Jet MixerDocument3 pagesCalculation For Jet MixerrohitkushNo ratings yet

- Compressible Flow Bench: Yeditepe University Department of Mechanical EngineeringDocument5 pagesCompressible Flow Bench: Yeditepe University Department of Mechanical EngineeringAhmad AbukhashabehNo ratings yet

- ModelingDocument50 pagesModelingArasu SundaramNo ratings yet

- Spirax Sarco - Orifice Assembly Layout For Steam ServiceDocument1 pageSpirax Sarco - Orifice Assembly Layout For Steam ServicenasirmuzaffarNo ratings yet

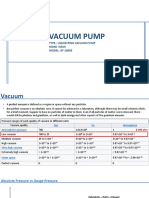

- Vacuum Pump: Type: Liquid Ring Vacuum Pump Make: Nash MODEL: AT-1006EDocument46 pagesVacuum Pump: Type: Liquid Ring Vacuum Pump Make: Nash MODEL: AT-1006EAmit Balot100% (2)

- 2 Irrigation Water Resources Engineering and Hydrology Questions and Answers - Preparation For EngineeringDocument18 pages2 Irrigation Water Resources Engineering and Hydrology Questions and Answers - Preparation For Engineeringahit1qNo ratings yet

- THE THE: Notes Meter Factor ForDocument19 pagesTHE THE: Notes Meter Factor Forjgarcia388No ratings yet

- Take Home Pack Gr. 9 TechnologyDocument8 pagesTake Home Pack Gr. 9 Technologythokoanebokang00No ratings yet

- Refresher Course MODULE 1 - HYDRAULICS: Room 206 JPD Building 1955 CM Recto Avenue, ManilaDocument1 pageRefresher Course MODULE 1 - HYDRAULICS: Room 206 JPD Building 1955 CM Recto Avenue, ManilaLenielle AmatosaNo ratings yet

- Learning About The of Nghi Son Refinery: Rude Istillation NitDocument17 pagesLearning About The of Nghi Son Refinery: Rude Istillation NitTrường Tùng LýNo ratings yet

- Hidrologi #2Document36 pagesHidrologi #2EVAFYNo ratings yet