Professional Documents

Culture Documents

Matrix Bag in Bag Brochure 052114-LR

Uploaded by

ramasamy0 ratings0% found this document useful (0 votes)

43 views2 pagesMatrix bag in bag packing system brochure

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentMatrix bag in bag packing system brochure

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

43 views2 pagesMatrix Bag in Bag Brochure 052114-LR

Uploaded by

ramasamyMatrix bag in bag packing system brochure

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

The Bag in Bag machine

provides an innovative

solution to fll single serve

and multi-serve pillow bags

in an overwrap bag for:

Vertical Form/Fill/Seal

Bag in Bag

Matrix Packaging Machinery

650 Dekora Woods Blvd.

Saukville, WI 53080

Toll Free: 888-Matrix1

Main Offce: 262-268-8300

info@MatrixPM.com

www.MatrixPM.com

OVERVIEW

Pillow packages are produced in

the upper section of the Bag in Bag

machine and then drop down into an

overwrap package (pillow or optional

fat bottom or gusseted bags) produced

on the lower section of the machine.

FEATURES

& BENEFITS

Automatic flm tracking

American Made - Designed and

built in Milwaukee, WI

Stainless steel frame

Stainless steel NEMA 4X

electrical enclosure

Stainless steel adjustable

mounting feet

Registered flm sensors

Unwind flm spindle

14" maximum roller diameter

Allen Bradley MicroLogix PLC

10.5" color touch screen

Bodine gear motors for flm pull

with Danaher microstepping

motors for jaw motion control

Unique cost effective machine

for overwrap bags

Laminate or poly flm sealing

capability

Full compatibility with all types

of fllers

Convenience Craving

Cost

Save $ Save

Time

Taste

Great

Matrix

B

a

g

i

n

B

a

g

S

olu

t

i

o

n

S

a

t

i

s

f

e

s

y

o

u

r

C

u

s

t

om

e

r

s

N

e

e

d

s

Bakery Products

Candy and Nuts

Coffee and Tea

Fresh Cut Fruit &

Vegetables

Liquid Products

Pet Products

Powder Products

Snack Products

Upper Section Bag Type

Lower Section Bag Types

Pillow

Pillow Gusset Flat Bottom

Vertical Form/Fill/Seal

Matrix Packaging

650 Dekora Woods Blvd.

Saukville, WI 53080

Telephone:

(262) 268-8300

Fax:

(000) 000-0000

info@MatrixPM.com

www.MatrixPM.com

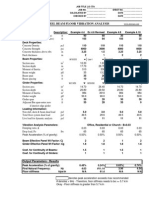

TYPICAL SYSTEM HEIGHTS

TECHNICAL SPECS

Rev 051412

Bag in Bag

Hole punch (mechanical or heated)

Flat bottom and gusset/tucker attachment

Printer, labeler, valve applicators

Gas fushing system for M.A.P. applications

Load shelf for heavier bags (several types)

UL electrical system

OPTIONS

Cycle Speed Up to 110 BPM

(depending on application)

Electrical 208 - 240 VAC 30 AMP

Air Pressure 6 - 20 CFM @ 80 PSI

(demand varies by application)

Bag Sizes Upper (Primary Bag) Lower (Overwrap Bag)

Width 3" - 9" 3" - 12"

Length 12" maximum 15" maximum

220"

to top of

Combination scale with

in-line metal detector

160"

to top of

Auger with typical tooling and top plate

165"

to top of

Cup fller product hopper

(infeed location)

Front View Side View Top View

You might also like

- Suzlon Annual Report 2015 16Document184 pagesSuzlon Annual Report 2015 16ramasamyNo ratings yet

- Cosmos Standard Labelling Guide v2!3!271116Document7 pagesCosmos Standard Labelling Guide v2!3!271116ramasamyNo ratings yet

- 49861bed 1Document28 pages49861bed 1ramasamyNo ratings yet

- Drones in AgricultureDocument28 pagesDrones in Agricultureramasamy100% (1)

- Blast Chilling and Freezing Equipment Price ListDocument32 pagesBlast Chilling and Freezing Equipment Price Listramasamy100% (2)

- Drones in AgricultureDocument28 pagesDrones in Agricultureramasamy100% (1)

- Starch To Plastics Lab March 26 2015Document10 pagesStarch To Plastics Lab March 26 2015Philip Jayson L. LestojasNo ratings yet

- BRC 6 Vs 5 - Overview of The Changes Issue 5 To 6Document8 pagesBRC 6 Vs 5 - Overview of The Changes Issue 5 To 6ramasamyNo ratings yet

- Dehydrated VegetablesDocument6 pagesDehydrated VegetablesTrans TradesNo ratings yet

- Line BalancingDocument18 pagesLine BalancingramasamyNo ratings yet

- l2 NetworkplanDocument48 pagesl2 NetworkplanramasamyNo ratings yet

- Fuels and CombustionDocument47 pagesFuels and CombustionMelai Pinlac-AdanteNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Mat3002 Applied-Linear-Algebra LT 1.0 1 Mat3002Document2 pagesMat3002 Applied-Linear-Algebra LT 1.0 1 Mat3002Tanmay BohraNo ratings yet

- MtdbooksDocument4 pagesMtdbooksabraham_imam_muttaqinNo ratings yet

- Deterministic Performance EstimationDocument36 pagesDeterministic Performance EstimationErwdukNo ratings yet

- Turbo GelDocument1 pageTurbo GelWilliam David LopezNo ratings yet

- Engineering Services LTD: CalculationDocument29 pagesEngineering Services LTD: CalculationtomNo ratings yet

- القطعDocument11 pagesالقطعcam spiderNo ratings yet

- 271 Introduction To Process Control Course PreviewDocument17 pages271 Introduction To Process Control Course PreviewAdrian Reyes0% (1)

- Laser Welding Steel Wheel RimsDocument5 pagesLaser Welding Steel Wheel RimsSamanthaPereraNo ratings yet

- 09 M1 Silver 4Document13 pages09 M1 Silver 4RoshNo ratings yet

- ExamplesCh18 AccessibleDocument34 pagesExamplesCh18 AccessibleSyed YousufuddinNo ratings yet

- The Determination of The Icl and Icc of Material To Be Stabilised. 1 ScopeDocument3 pagesThe Determination of The Icl and Icc of Material To Be Stabilised. 1 ScopeBruno Ramírez PonceNo ratings yet

- IEEE Xplore Download 135Document9 pagesIEEE Xplore Download 135Madalina MejdreaNo ratings yet

- Dry Sieve AnalysisDocument2 pagesDry Sieve AnalysisManish AryaNo ratings yet

- AQA As Unit 2 Sample PageDocument34 pagesAQA As Unit 2 Sample Pagenchauhan2120% (1)

- Civil Service Exam Reviewer For Analogy and LogicDocument9 pagesCivil Service Exam Reviewer For Analogy and LogicLaurie Mae Rivera100% (2)

- HW5 PDFDocument7 pagesHW5 PDFKamineni JagathNo ratings yet

- Experimental Study On Steel Shear Wall With SlitsDocument10 pagesExperimental Study On Steel Shear Wall With SlitsTY ZNo ratings yet

- SUPERCHANGER Plate and FrameDocument28 pagesSUPERCHANGER Plate and Framejack-bcNo ratings yet

- Physics Syllabus in 40 CharactersDocument3 pagesPhysics Syllabus in 40 CharactersAmit YadavNo ratings yet

- OPGW Map (2021!02!09) - PGCB Optical Fibre NetworkDocument1 pageOPGW Map (2021!02!09) - PGCB Optical Fibre NetworkMD SOHEL RANANo ratings yet

- Allison Transmision Om3753en, 3000-4000 SP Series Operators ManualDocument111 pagesAllison Transmision Om3753en, 3000-4000 SP Series Operators ManualHernan Reyes Carbonell100% (1)

- AISC DG11 ExamplesDocument7 pagesAISC DG11 ExamplesMarcel Toruño MendezNo ratings yet

- ACI Method of Proportioning Concrete MixesDocument6 pagesACI Method of Proportioning Concrete MixesEulogio JameroNo ratings yet

- Ultimate Bearing Capacity of Foundation On Clays Meyerhof PDFDocument3 pagesUltimate Bearing Capacity of Foundation On Clays Meyerhof PDFNadherNo ratings yet

- Dell 1815dn Service Manual PDFDocument150 pagesDell 1815dn Service Manual PDFHugo Manuel Sánchez MartínezNo ratings yet

- 952 - Comparative Statement - Electrical - Rev 00Document8 pages952 - Comparative Statement - Electrical - Rev 00clickanant4171No ratings yet

- Catalog 2011Document84 pagesCatalog 2011Marlou RabinaNo ratings yet

- 421 Lab Report 3Document4 pages421 Lab Report 3Christian SawayaNo ratings yet

- Design For Manufacturing and AssemblyDocument168 pagesDesign For Manufacturing and Assemblygnanasekar100% (2)

- The Kinetic Theory of Gases: Dr. Tariq Al-AbdullahDocument33 pagesThe Kinetic Theory of Gases: Dr. Tariq Al-AbdullahSlayer 45073No ratings yet