Professional Documents

Culture Documents

Paraweb BBA 09-R146

Uploaded by

marius1979Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Paraweb BBA 09-R146

Uploaded by

marius1979Copyright:

Available Formats

Linear Composites Ltd

Vale Mills

Oakworth

Keighley

West Yorkshire BD22 0EB

Tel: 01535 643363 Fax: 01535 643605

e-mail: mail@linearcomposites.com

website: www.linearcomposites.com

Roads and Bridges

Agrment Certificate

No 09/R146

Product Sheet 1

PARAWEB STRAPS FOR REINFORCED SOIL RETAINING WALLS AND BRIDGE ABUTMENTS

This Certificate relates to Paraweb Straps for Reinforced

Soil Retaining Walls and Bridge Abutments.

AGRMENT CERTIFICATION INCLUDES:

factors relating to compliance with Highways Agency

requirements where applicable

factors relating to compliance with Regulations where

applicable

independently verified technical specification

assessment criteria and technical investigations

design considerations

installation guidance

regular surveillance of production

formal three-yearly review.

British Board of Agrment tel: 01923 665300

Bucknalls Lane fax: 01923 665301

Garston, Watford e-mail: mail@bba.star.co.uk

Herts WD25 9BA website: www.bbacerts.co.uk 2009

PRODUCT SCOPE AND SUMMARY OF CERTIFICATE

KEY FACTORS ASSESSED

Mechanical properties the following key areas have been evaluated:

short-term tensile strength and elongation and long-term tensile strength and elongation properties of Paraweb straps

(see sections 6.1 to 6.8)

safety factors for consistency of manufacture, assessment and extrapolation of available test data, short-term and

long-term effects of installation damage and environmental degradation (see sections 6.9 to 6.15)

Paraweb/fill interaction (see section 6.26).

Durability Paraweb straps have good resistance to hydrolysis, chemical corrosion, microbial attack, UV exposure

and temperature used in fills normally encountered in civil engineering practice (see section 7.1).

The BBA is a UKAS accredited certification body Number 113. The schedule of the current scope of accreditation for product certification is

available in pdf format via the UKAS link on the BBA website at www.bbacerts.co.uk

Readers are advised to check the validity and latest issue number of this Agrment Certificate by either referring to the BBA website or contacting the BBA direct.

Page 1 of 12

The Highways Agency requirements to which this Certificate is subject are detailed on page 2

TECHNICAL APPROVALS FOR CONSTRUCTION

APPROVAL

INSPECTION

TESTING

CERTIFICATION

The BBA has awarded this Agrment Certificate to the company named above for the products described

herein. These products have been assessed by the BBA as being fit for their intended use provided they are

installed, used and maintained as set out in this Certificate.

On behalf of the British Board of Agrment

Date of First issue: 22 January 2009 Brian Chamberlain Greg Cooper

Head of Approvals Engineering Chief Executive

Page 2 of 12

Highways Agency Requirements

All proposals for adopting the systems shall comply with current HA design and certification procedures and relevant

design data shall be submitted in accordance with the requirements of section 5 of this Certificate.

The design, materials specification and construction methods adopted shall be in accordance with HA Technical

Standard BD 70/03 (DMRB 2.1.5) and Manual of Contract Documents for Highway Works (MCHW)

(1)

, Volumes 1

and 2, August 1998 (as amended).

(1) The MCHW is operated by the Overseeing Organisations: The Highways Agency (HA), Transport Scotland, the Welsh Assembly Government and

The Department for Regional Development (Northern Ireland).

Regulations

Construction (Design and Management) Regulations 2007

Construction (Design and Management) Regulations (Northern Ireland) 2007

Information in this Certificate may assist the client, CDM co-ordinator, designer and contractors to address their

obligations under these Regulations.

See sections: 2 Delivery and site handling (2.1 to 2.3) and 8 Procedure (8.1).

General

This Certificate relates to Paraweb Straps for Reinforced Soil Retaining Walls and Bridge Abutments.

The structures are based on the use of Paraweb straps consisting of polyethylene-coated polyester multicoils acting as

frictional reinforcement connected to precast concrete facing units.

The design and construction of the reinforced soil structure shall be in accordance with the requirements of the

Highways Agency (HA); acting on behalf of the Department for Transport, the Scottish Executive, the Welsh Assembly

Government, and the Department for Regional Development, Northern Ireland, and the conditions set out in the

Design Considerations and Installation parts of this Certificate.

Paraweb straps are manufactured by the Certificate holder.

Technical Specification

1 Description

1.1 Paraweb straps are used in conjunction with precast concrete facing units, attachment loops and toggles,

temporary anchorage bars and clamps and fill materials to construct reinforced soil retaining walls and bridge

abutments.

Paraweb straps

1.2 The Paraweb straps comprise polyester tendons encased in a polyethylene sheath, and are manufactured in many

grades of differing thicknesses (see Table 1). The composite is passed through rollers, to give a knurled finish on the

sheath, cooled, cut to length and coiled.

1.3 The tendon is made from high-tenacity polyester fibre, concentrated into separate bundles and coated with

polyethylene using a vacuum die-coating process.

1.4 Factory production control is undertaken throughout all stages of manufacture. Checks include:

incoming materials yarn feeds manufacturing temperatures.

Specification for precast concrete facing units

1.5 The precast concrete facing units used in conjunction with Paraweb straps must be designed to HA requirements

BD 24/92 (DMRB 1.3.1) and BD 57/01 (DMRB 1.3.7). The reinforced concrete shall comply with series 1700 of

MCHW, Volume 1, and has to meet the requirements of exposure class XF2 in accordance with BS 8500-1 : 2006.

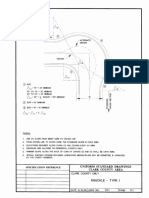

Specification for connections

1.6 The precast concrete facing units must be designed to incorporate suitable provision for the attachment of

Paraweb straps. A typical detail (see Figure 1) utilises galvanized steel attachment loops cast into the concrete and

galvanized steel toggle bars (minimum diameter 25 mm) to span between attachment loops. The Paraweb strap is

wrapped around the toggle bars during installation. All metallic components must be designed to BS 8006 : 1995,

section 6.8, as amended by BD 70/03 (DMRB 2.1.5) and must have a minimum zinc coating of 1000 gm

2

.

Figure 1 A typical schematic connection detail

sectional view plan view

reinforcing bars by panel designer to provide

adequate anchorage for attachment loops

reinforcing bars by panel designer to provide

adequate anchorage for attachment loops

attachment loop

toggle bar

Paraweb strap

Paraweb strap

attachment loops

toggle bar

Grade Coil Weight Nominal Nominal Characteristic

length (0.2) (kg) width (a) thickness (b) short-term

(m) (mm) (mm) tensile strength

(2)

(T

char

) (kN)

Sheath type

(1)

2E 2D 2S 2E 2D 2S 2E 2D 2S 2E/2D 2S

30 100 8.7 12.7 14.8 83 83 85 1.5 1.9 2.2 30.16 33.75

40 100 10.9 16.7 18.5 83 84 85 1.7 2.2 2.5 40.20 45.00

50 100 12.4 19.5 23.0 87 90 90 2.0 2.5 3.5 50.27 56.25

70 100 16.7 24.1 28.6 90 90 90 2.5 3.0 4.0 70.38 78.78

75 100 17.9 25.6 30.0 90 90 90 2.6 3.1 4.1 75.40 84.35

100 100 24.1 31.1 37.7 90 90 90 3.1 3.7 6.0 100.54 112.5

Sheath type

(1)

ME MD MS ME MD MS ME MD MS ME/MD MS

27 100 6.4 8.5 9.4 46 47 48 1.8 2.2 2.5 27.14 27.14

36 100 8.1 10.8 12.0 47 49 49 2.2 2.8 3.0 36.18 36.18

37.5 100 8.2 10.9 12.1 47 49 49 2.3 2.9 3.1 37.70 37.70

45 100 10.1 13.2 14.5 48 48 49 2.7 3.3 3.6 45.22 45.22

54 100 12.7 17.4 21.4 63 65 65 2.5 3.2 3.6 54.27 54.27

63 100 14.4 20.4 22.7 63 65 66 2.8 3.7 3.9 63.31 63.31

(1) Sheaths in increasing order of thickness are 2E, 2D and 2S (equivalent to sheaths indicated by ME, MD and MS).

(2) Short-term tensile strength of virgin material in accordance with BS EN ISO 10319 : 1996.

Page 3 of 12

Table 1 Dimensions and short-term tensile strength

b

a

polyester tendons polyethylene sheath

a

b

= nominal width

= nominal thickness

Temporary anchorage bars and clamps

1.7 Temporary clamps used for connection between the straps are manufactured from 8 mm diameter plain mild steel

bar (grade 250) to BS 4449 : 2005 (see Figure 2). Ends of bar to be filed smooth to avoid damage to the Paraweb

straps.

1.8 16 mm diameter horizontal steel anchorage bars and 20 mm diameter vertical steel pins are used for holding the

Paraweb straps flat and taut temporarily prior to further fill being placed (see Figure 3).

Fill

1.9 Fill materials shall meet the requirements included in section 3.1.2 of BS 8006 : 1995 as amended by

BD 70/03 (DMRB 2.1.5).

2 Delivery and site handling

Paraweb straps

2.1 The straps are delivered to site in batches of coils, each batch carrying a label bearing the grade, length,

nominal breaking load and manufacturers date code. Each strap is impressed on one side at intervals of

approximately 200 mm, with a mark denoting the grade.

2.2 To prevent damage, care should be taken in transit and handling. During storage the straps should be kept under

cover in clean, dry conditions and should be protected from damage and extreme temperatures.

Other components

2.3 Other components should be handled, and stored, generally in accordance with HA requirements.

Assessment and Technical Investigations

The following is a summary of the assessment and technical investigations carried out on Paraweb Straps for

Reinforced Soil Retaining Walls and Bridge Abutments.

Design Considerations

3 General

3.1 Paraweb straps are satisfactory for use in providing reinforced soil structures. Structural stability is achieved

through frictional interaction of the soil particles and the Paraweb straps.

3.2 The BBA has not assessed the structures for supporting parapet loading caused by vehicle collision at the top of

the facing units. When applicable, this aspect of a design would require separate consideration and approval by the

HA.

3.3 Where appropriate, the reinforced soil structure should be protected against horizontal impact loads caused by

possible vehicle collision with the lower facing units of the wall.

3.4 Prior to the commencement of the work, the designer shall satisfy the HA technical approval requirements.

Page 4 of 12

Figure 2 Steel S clamp

(1)

(1) Dimensions shown are to suit grade 100 Paraweb strap.

Temporary clamp,

manufactured from

8 mm diameter plain

mild steel bar

(grade 250) to

BS 4449 : 2005.

Ends of bar to be

filed smooth to avoid

damage to the Paraweb.

100 mm

120 mm

100 mm

Figure 3 Anchorage bars

16 mm diameter

reinforcement bar

1

.0

m

to

1

.5

m

a

p

p

ro

x

steel 'S' clamp

Paraweb

20 mm diameter steel pin (or smaller

depending on fill type)

(length to be less than vertical spacing

of Paraweb)

3.5 Where appropriate to specific projects, the designer should provide the main contractor with details of:

working drawings

calculations

specification for fill material

acceptable moisture content of fill material at time of placement

method of tensioning Paraweb straps prior to fill placing

sequence of placing fill material

estimated movements of facing units during filling and compaction operations

tolerance on the position of finished line of the wall.

4 Practicability of installation

4.1 Paraweb straps are installed easily by trained ground engineering contractors in accordance with the

specifications and construction drawings and are able to withstand the forces imposed by compaction plant, provided:

composition of the fill and the compaction methods are in accordance with HA requirements

straps are laid and anchored correctly.

4.2 The connection between the straps is made easily using the temporary mild steel S clamp (see Figures 2 and 3).

4.3 To prevent damage, the straps must be protected from the passage of site traffic between applications of the

layers of fill material. Fill should be placed to ensure that a minimum post-compaction depth of 150 mm will be

achieved after each pass of the compaction plant, except when compacted by the method described in section 8.6.

5 Design

5.1 Reinforced soil structures incorporating Paraweb straps must be designed in accordance with BD 70/03

(DMRB 2.1.5).

5.2 Values of the partial material factors to be used in design are given in sections 6.11 to 6.15.

5.3 Guidance on determining the design strength, T

D

, of the Paraweb straps for ultimate and serviceability limit states

is given in sections 6.23 to 6.25.

5.4 Guidance on soil/Paraweb interaction coefficients can be found in section 6.26.

5.5 Particular attention should be paid to changes in direction of walls where overlapping of the straps may occur.

5.6 Adequate consideration must be given to the provision of drainage to the wall in accordance with HA requirements.

5.7 The straps must be used in conjunction with precast concrete facing units designed to conform to HA requirements

of BD 24/92 (DMRB 1.3.1) and BD 57/01 (DMRB 1.3.7). The reinforced concrete shall comply with series 1700 of

MCHW, Volume 1, and has to meet the requirements of exposure class XF2 in accordance with BS 8500-1 : 2006.

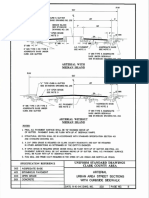

A typical sectional and plan view of a structure is shown in Figures 4 and 5. Adequate provision must be made in

accordance with BD 70/03 for the forward and other movements of the facing which will take place both during and

after construction.

Figure 4 Typical diagrammatic sectional view

concrete

upstand to

foundation

(optional)

concrete strip foundation

attachment loop

and toggle

precast concrete

facing units

compacted

fill

retained soil Paraweb

straps

Page 5 of 12

5.8 Attachment loops and toggles must be designed as described in section 1.6 of this Certificate. The anchorage of

the attachment loops into the concrete facing panels must be designed in such a way that adequate resistance to the

pull-out force will be provided.

5.9 The designer should specify the relevant properties of the fill material for the reinforced soil structure deemed

acceptable for the purpose of the design. Acceptable materials shall meet the requirements included in BS 8006 :

1995, section 3.1.2, amended by BD 70/03 (DMRB 2.1.5).

6 Mechanical properties

Tensile strength short term

6.1 Paraweb straps have the characteristic short-term strengths given in Table 1. A typical short-term stress/strain curve

is shown in Figure 6.

6.2 The actual strain at nominal breaking load 12% 2%.

Tensile strength long term

6.3 The method used by the BBA to assess the long-term strength of Paraweb straps is based on a traditional stress

rupture line for the load-carrying polyester as shown in Figure 7. From this graph, for the ultimate limit state, the value of

the tensile creep rupture strength (T

CR

) can be determined for the appropriate design life and design temperature.

6.4 For a 120-year design life, the value of (T

CR

) is a percentage of T

char

at various design temperatures as shown in

Table 2.

Figure 6 Typical load/extension curve

100

80

60

40

20

0

0 2 4 6 8 10 12 14

extension (%)

l

o

a

d

(

%

o

f

u

l

t

i

m

a

t

e

t

e

n

s

i

l

e

l

o

a

d

)

Table 2 Percentages of T

char

to determine T

CR

at

various temperatures

Design temperature (C) Percentage of T

char

20 72

25 71

30 69

40 67

Figure 5 Typical diagrammatic plan view

precast concrete

facing unit

Paraweb

clamp

alternative position

of clamp

attachment loop

attachment

toggle

2 m

1 m

1 m

26 mm min

26 mm min

Paraweb strap clamped

together (total overlap 2.0 m).

Overlapping of straps must

occur in the rear half of the

reinforced length and after

passing around the rear anchor

bar as shown in Figure 3

anchorage bar/pin

(see Figure 3)

L/2 L/2

C

Page 6 of 12

6.5 An alternative approach to determining the long-term strength of Paraweb straps is one of residual strength (see

Figure 7), particularly in respect of the strength available during seismic events. Such an approach is outside the scope

of this Certificate and would require separate evaluation and justification of the partial material factor (f

m

) components.

Creep performance

6.6 For the serviceability limit state, the prescribed allowable post-construction strains are:

bridge abutments 0.5% (2 months to 120 years) retaining walls 1.0% (1 month to 120 years).

6.7 The definitions of prescribed post-construction strain limit and T

cs

,the sensile load that would create the prescribed

post-construction strain, are explained in Figure 8..

6.8 Values of T

CS

derived from long-term creep tests are given in Table 3.

Figure 7 Regression line for life expectancy at constant stress defined by percentage of characteristic short-term

strength at 20C

t

e

n

s

i

l

e

s

t

r

e

n

g

t

h

(

%

)

0.01 0.1 1 10 100

50

55

60

65

70

75

80

85

90

95

100

extrapolated

residual strength approach

stress rupture approach

time (years)

1000

Figure 8 Definition of T

CS

prescribed post-construction

strain limit

(0.5% or 1.0%)

strain (%)

isochrone for end

of construction

(1 month or 2 months)

isochrone for

end of design

life (120 years)

l

o

a

d

(

k

N

)

T

CS

Page 7 of 12

Page 8 of 12

6.9 To determine the reinforcement design strength (T

D

), values are required for the partial material factor (f

m

) for both

the ultimate (ULS) and serviceability (SLS) limit states. In the opinion of the BBA, the values given below for the various

components of f

m

are conservative, assuming a traditional stress rupture approach (see Figure 7) when calculating T

CR

.

Conditions of use outside the scope for which partial material factor components are defined are not covered by this

Certificate.

6.10 In line with BD 70/03, the partial factor (f

m

) may be expressed as:

f

m

= f

m11

f

m121

f

m122

f

m21

f

m22

Consistency of manufacture (f

m11

)

6.11 For Paraweb straps the following values may be used:

f

m11

= 1.0 (ULS)

f

m11

= 1.0 (SLS)

Assessment of available test data (f

m121

)

6.12 For Paraweb straps the following values may be used, based on the assumption of 120-year design life:

f

m121

= 1.0 (ULS)

f

m121

= 1.0 (SLS)

Extrapolation to 120-year design life (f

m122

)

6.13 For Paraweb-2S straps the following values may be used:

f

m122

= 1.0 (ULS)

f

m122

= 1.0 (SLS)

Immediate and long-term effects of installation damage (f

m21

)

6.14 To allow for loss of strength due to mechanical damage sustained during installation, the appropriate value for

f

m21

for ultimate limit state (ULS) may be selected from Table 5. The partial factors given for site damage assume that

well-graded material is used (coefficient of uniformity >5) with a minimum compacted depth of 150 mm. For soils not

covered by Table 4, appropriate values of f

m21

may be determined from site-specific trials. For the serviceability limit

state (SLS), the value of f

m21

may be taken as 1.0.

Environmental degradation (f

m22

)

6.15 To account for environmental conditions the appropriate value at various temperatures for f

m22

should be taken

from Table 5 for a design life of 120 years.

Hydrolysis

6.16 Within most soil environments (pH between 4 and 9) and where temperatures are typical of those normally

found in reinforced soil structures in the United Kingdom, the strength of the straps is not adversely affected by

hydrolysis. The sheathing on Paraweb provides protection irrespective of temperature.

Chemical resistance

6.17 The straps and other components have a high resistance to degradation from the types of chemicals typically

found in soils.

Table 3 Maximum tensile load (T

CS

) inducing

prescribed post-construction strain limits

Paraweb Sheath T

CS

(kN)

grade type

Prescribed post-construction strain limits

0.5% 1.0%

30 2E/2D 15.1 19.6

2S 16.9 21.9

40 2E/2D 20.1 26.1

2S 22.5 29.3

50 2E/2D 25.1 32.7

2S 28.1 36.6

70 2E/2D 35.2 45.7

2S 39.4 51.2

75 2E/2D 37.7 49.0

2S 42.2 54.8

100 2E/2D 50.3 65.4

2S 56.3 73.1

27 ME/MD/MS 13.6 17.6

36 ME/MD/MS 18.1 23.5

37.5 ME/MD/MS 18.9 24.5

45 ME/MD/MS 22.6 29.4

54 ME/MD/MS 27.1 35.3

63 ME/MD/MS 31.7 41.2

Microbial attack

6.18 The straps and other components are highly resistant to microbial attack.

Effects of temperature

6.19 The long-term creep performance of the straps is not adversely affected by the range of soil temperatures typical

to the UK.

6.20 The long-term creep performance for a range of soil temperatures is shown in Table 2. Where the straps may be

exposed to temperatures higher than 40C or lower than 20C for significant periods, consideration should be given

to temperature levels, range of temperature, period of exposure and stress levels at the location in question.

6.21 The long-term environmental effects factor for a range of soil temperatures is shown in Table 5. Sustained

temperatures of greater than 40C increase the rate of hydrolysis of polyester and further reduction factors may be

required.

Resistance to UV light

6.22 The Paraweb has a high resistance to UV light. The product may be exposed to light for up to one month on

site. Exposure of up to four months may be acceptable depending upon the season and location.

Design strength (T

D

)

6.23 For the ultimate limit state:

Design strength, T

D

= T

CR

f

n

.f

m

(ULS)

where f

n

= partial factor for ramification of failure that shall be taken as 1.1 in accordance with BD 70/03.

Design load, T

j

, to be calculated using prescribed load factors, recommended by BD 70/03.

In all cases T

j

must be T

D

.

6.24 For the serviceability limit state:

Design strength, T

D

= T

CS

f

m

(SLS)

The average design load, T

avj

, to be calculated using prescribed load factors recommended by BD 70/03.

In all cases T

avj

must be T

D

.

6.25 For the SLS, the average load in the J

th

level, T

avj

, is related to the maximum load in the reinforcements, T

j

, by a

factor k

(1)

, where:

T

avj

= T

j

k

(1) A value of k may be derived by consideration of the actual shape of the load distribution diagram along the loaded length of reinforcement.

Table 5 Partial factor environmental effects (f

m22

)

Soil pH level Design temperature f

m22

(ULS) f

m22

(SLS)

(pH) (C)

4.0 9.0 20 1.08 1.00

4.0 9.0 25 1.12 1.00

4.0 9.0 30 1.21 1.00

4.0 9.0 40 1.64 1.00

Table 4 Effects of installation damage (f

m21

)

Paraweb grade Sheath type

(1)

fm

21

(ULS) fm

21

(SLS)

particle size d

50

(mm)

<0.1 <1.0 <15 >15

27 ME/MD/MS 1.10 1.10 1.10 1.10 1.00

30 2E/2D/2S 1.05 1.05 1.10 1.10 1.00

36 ME/MD/MS 1.05 1.05 1.10 1.10 1.00

37.5 ME/MD/MS 1.05 1.05 1.10 1.10 1.00

40 2E/2D/2S 1.05 1.05 1.10 1.10 1.00

45 ME/MD/MS 1.05 1.05 1.10 1.10 1.00

50 2E/2D/2S 1.05 1.05 1.05 1.05 1.00

54 ME/MD/MS 1.05 1.05 1.05 1.05 1.00

63 ME/MD/MS 1.05 1.05 1.05 1.05 1.00

70 2E/2D/2S 1.05 1.05 1.05 1.05 1.00

75 2E/2D/2S 1.05 1.05 1.05 1.05 1.00

100 2E/2D/2S 1.05 1.05 1.05 1.05 1.00

(1) Sheath type 2E/ME is not used where particle size (d

50

) is above 15 mm.

Page 9 of 12

6.26 For routine design purposes, the interaction coefficient, , in accordance with BS 8006 : 1995 relating soil

friction angle to soil/reinforcement bond (tan /tan ) can be taken conservatively as 0.70. Significantly enhanced

values of can be justified in design by carrying out soil and site-specific pull-out tests in accordance with

BS EN 13738 : 2004.

7 Durability

7.1 In the opinion of the BBA, when used and installed in accordance with this Certificate, the Paraweb straps and

other components can achieve a design life of 120 years as required by HA for permanent structures.

7.2 It is assumed that the exposure environment for the concrete is classified as XF2 to BS 8500-1 : 2006, where

concrete facing units are to be embedded in soils which could be potentially aggressive; the guidance in BRE Special

Digest 1 : 2005 Concrete in aggressive ground : Part C : Assessing the aggressive chemical environment should be

followed.

7.3 Fill materials classified as 6I, 6J, 7B, 7C and 7D should comply with the limits of Table 6/3 of the 600 series of

MCHW, Volume 1, regarding the content of maximum water soluble sulfates and maximum oxidizable sulfides.

Installation

8 Procedure

8.1 Installation shall be carried out in accordance with the Certificate holders Installation instructions, BS EN 14475 :

2006 and the requirements of the MCHW1.

8.2 Formation levels are prepared by levelling and compacting subgrade in accordance with the MCHW1. Fill

material is placed and compacted behind the facing to the level of the first layer of Paraweb straps (see Figure 4).

8.3 The straps are laid, attached to the facing units (see Figure 4), pulled and held flat and taut using a horizontal

anchor bar and vertical pins as shown in Figure 3, prior to further fill being placed. Further courses of facing units as

required are fixed and fill material is placed and compacted to specified heights. The sequence is repeated up to the

formation level for the parapet base or finished level as appropriate.

8.4 Fill is placed to a depth of not less than 150 mm. The fill material should be placed from the anchor pin to within

2 metres of the facing units, and compacted thoroughly. The remaining 2 metres of fill should be placed and

compacted using lighter compaction plant. However, the required compaction should be achieved.

8.5 Particular care should be taken to ensure the straps are adequately covered before compaction or trafficking. To

avoid excessive movement of the facing units, heavy compaction plant must not be used within two metres of the face

where the depth of fill before each pass may be less than 150 mm to suit the compaction plant used.

8.6 Joints in the strap are made adjacent to the steel pin bar and horizontal steel anchor bars or as shown in

Figure 5. Lengths of strap are overlapped by a distance of two metres and clamped together as shown in Figure 3.

Joints are made adjacent to the anchor bar. The clamp is a construction aid and is redundant once the fill has been

placed and compacted.

8.7 The ends of the strap are treated with a bitumastic-based sealant to reduce ingress of moisture.

Technical Investigations

9 Investigations

9.1 The manufacturing process of the product components was examined, including the methods adopted for quality

control, and details were obtained of the quality and composition of the materials used.

9.2 An examination was made of data relating to:

coefficient of friction between Paraweb straps and the fill evaluation of long- and short-term tensile properties

resistance to damage caused during installation evaluation of long- and short-term load/strain

characteristics

effects of temperature resistance to ultraviolet light

assessment of partial material factors resistance to hydrolysis

assessment of fill/Paraweb interaction resistance to microbial attack.

Additional Information

The management systems of Linear Composites Ltd have been assessed and registered as meeting the requirements of

BS EN ISO 9001 : 2000 by Lloyds Register Quality Assurance, Certificate No 902157.

Page 10 of 12

Bibliography

BS 4449 : 2005 Specification for carbon steel bars for the reinforcement of concrete

BS 5400-4 : 1990 Steel, concrete and composite bridges Code of practice for design of concrete bridges

BS 8500-1 : 2006 Concrete Complementary British Standard to BS EN 206-1 Method of specifying and

guidance for the specifier

BS 8006 : 1995 Code of practice for strengthened/reinforced soils and other fills

BS EN 10025-2 : 2004 Hot rolled products of structural steels Technical delivery conditions for non-alloy structural

steels

BS EN 13738 : 2004 Geotextiles and geotextile-related products Determination of pullout resistance in soil

BS EN 14475 : 2006 Execution of special geotechnical works Reinforced fill

BS EN ISO 9001 : 2000 Quality systems Model for quality assurance in production, installation and servicing

BS EN ISO 10319 : 1996 Geotextiles Wide-width tensile test

BD 57/01 Design for Durability

BD 24/92 The design of concrete highway bridges and structures use of BS 5400-4 : 1990

BD 70/03 Strengthened/Reinforced Soils and other Fills for Retaining Walls and Bridge Abutments

Manual of Contract Documents for Highway Works, Volume 1 Specification for Highway Works, August 1998 (as

amended)

Manual of Contract Documents for Highway Works, Volume 2 Notes for Guidance on the Specification for Highway

Works, August 1998 (as amended)

Page 11 of 12

Conditions of Certification

10 Conditions

10.1 This Certificate:

relates only to the product/system that is named and described on the front page

is granted only to the company, firm or person named on the front page no other company, firm or person may

hold or claim any entitlement to this Certificate

is valid only within the UK

has to be read, considered and used as a whole document it may be misleading and will be incomplete to be

selective

is copyright of the BBA

is subject to English law.

10.2 References in this Certificate to any Act of Parliament, Statutory Instrument, Directive or Regulation of the

European Union, British, European or International Standard, Code of Practice, manufacturers instructions or similar

publication, are references to such publication in the form in which it was current at the date of this Certificate.

10.3 This Certificate will remain valid for an unlimited period provided that the product/system and the manufacture

and/or fabrication including all related and relevant processes thereof:

are maintained at or above the levels which have been assessed and found to be satisfactory by the BBA

continue to be checked as and when deemed appropriate by the BBA under arrangements that it will determine

are reviewed by the BBA as and when it considers appropriate

remain in accordance with the requirements of the Highways Agency.

10.4 In granting this Certificate, the BBA is not responsible for:

the presence or absence of any patent, intellectual property or similar rights subsisting in the product/system or any

other product/system

the right of the Certificate holder to manufacture, supply, install, maintain or market the product/system

individual installations of the product/system, including the nature, design, methods and workmanship of or related

to the installation

the actual works in which the product/system is installed, used and maintained, including the nature, design,

methods and workmanship of such works.

10.5 Any information relating to the manufacture, supply, installation, use and maintenance of this product/system

which is contained or referred to in this Certificate is the minimum required to be met when the product/system is

manufactured, supplied, installed, used and maintained. It does not purport in any way to restate the requirements of

the Health & Safety at Work etc Act 1974, or of any other statutory, common law or other duty which may exist at the

date of this Certificate; nor is conformity with such information to be taken as satisfying the requirements of the 1974

Act or of any statutory, common law or other duty of care. In granting this Certificate, the BBA does not accept

responsibility to any person or body for any loss or damage, including personal injury, arising as a direct or indirect

result of the manufacture, supply, installation, use and maintenance of this product/system.

Page 12 of 12

British Board of Agrment tel: 01923 665300

Bucknalls Lane fax: 01923 665301

Garston, Watford e-mail: mail@bba.star.co.uk

Herts WD25 9BA website: www.bbacerts.co.uk 2009

You might also like

- BBA Cert 12-H182 For RECo Geostrap Reinforcement For Reinforced Soil Retaining WallsDocument12 pagesBBA Cert 12-H182 For RECo Geostrap Reinforcement For Reinforced Soil Retaining WallssandycastleNo ratings yet

- BBA Cert For ReCo High Adherence Strip and Panel Lug System For Ret Walls & Bridge Abuts (2003)Document8 pagesBBA Cert For ReCo High Adherence Strip and Panel Lug System For Ret Walls & Bridge Abuts (2003)sandycastleNo ratings yet

- Macdrain Installation DetailsDocument1 pageMacdrain Installation DetailsadrianNo ratings yet

- Technical Data Sheet TECHSTRAP 2020Document1 pageTechnical Data Sheet TECHSTRAP 2020BalrajNo ratings yet

- Standard For Mechanical Expansion JointsDocument29 pagesStandard For Mechanical Expansion JointsSARVANANo ratings yet

- The Joint - Take Away Menu (Full)Document1 pageThe Joint - Take Away Menu (Full)Bevan SmithNo ratings yet

- BBA Certificate 08-4609 ACEGrid Geogrids For Basal Reinforcement (BBA, Third Issue, Nov 2013)Document13 pagesBBA Certificate 08-4609 ACEGrid Geogrids For Basal Reinforcement (BBA, Third Issue, Nov 2013)sandycastleNo ratings yet

- What Is Lean ConcreteDocument2 pagesWhat Is Lean Concreteadam dam jhegsNo ratings yet

- Geosynthetics - ConstrofacilitatorDocument20 pagesGeosynthetics - ConstrofacilitatorConstro FacilitatorNo ratings yet

- Final Aac PDFDocument7 pagesFinal Aac PDFindrajit sodhaNo ratings yet

- Geogrids: Product DataDocument11 pagesGeogrids: Product Datamohan100% (1)

- 1 TRE300S Chapter 1 To 4 FINALDocument54 pages1 TRE300S Chapter 1 To 4 FINALSamkelo Mduna100% (1)

- Surface DressingDocument2 pagesSurface DressingdandyauroraNo ratings yet

- Geostrap 2022Document26 pagesGeostrap 2022Sumit GuptaNo ratings yet

- PDFDocument16 pagesPDFBibhuti B. BhardwajNo ratings yet

- Biaxial GeogridsDocument20 pagesBiaxial GeogridsLiliana RibeiroNo ratings yet

- Comparison of Marshall and Superpave Asp PDFDocument7 pagesComparison of Marshall and Superpave Asp PDFwillypraviantoNo ratings yet

- ArticulatedConcreteBlockSystem DesignmanualDocument71 pagesArticulatedConcreteBlockSystem DesignmanualbjlozadaNo ratings yet

- Asphtlatoseal NewDocument41 pagesAsphtlatoseal Newnagaraj_qce3499100% (1)

- Dense Bituminous MacadamDocument22 pagesDense Bituminous MacadamahmadsulNo ratings yet

- 1.0 Technical Specification Structure180215Document179 pages1.0 Technical Specification Structure180215Shantanu SinghNo ratings yet

- 11 22 Emperical and Mechanistic Pavement Design 2Document55 pages11 22 Emperical and Mechanistic Pavement Design 2Shams KhattakNo ratings yet

- Macres System - Paraweb 2E: Technical Data SheetDocument1 pageMacres System - Paraweb 2E: Technical Data SheetfaisaltmNo ratings yet

- ASPHALT CONCRETE Lecture NoteDocument11 pagesASPHALT CONCRETE Lecture Notekalana mihirangaNo ratings yet

- Nhi 10025Document404 pagesNhi 10025Carlos Alberto Gómez RamírezNo ratings yet

- Pavement DistressesDocument45 pagesPavement DistresseswedjefdbenmcveNo ratings yet

- High Slump Concrete Mix Design 2 PDFDocument68 pagesHigh Slump Concrete Mix Design 2 PDFBernie QuepNo ratings yet

- Asphalt NotesDocument15 pagesAsphalt NotesSaeed AhmedNo ratings yet

- Cert Road StudsDocument2 pagesCert Road StudswjfrancisNo ratings yet

- Part 1 - History and Basic Knowledge of GeosyntheticDocument36 pagesPart 1 - History and Basic Knowledge of Geosyntheticsazwan2No ratings yet

- BBA Certificate 14-H218 Securegrid HS Geogrid For Basal Reinforcement (BBA, First Issue, Oct 2018)Document14 pagesBBA Certificate 14-H218 Securegrid HS Geogrid For Basal Reinforcement (BBA, First Issue, Oct 2018)sandycastleNo ratings yet

- Concrete Block Paving - Technical Note For Steep SlopesDocument6 pagesConcrete Block Paving - Technical Note For Steep SlopesTrương KhảiNo ratings yet

- CRRI Presentation On GeosyntheticsDocument51 pagesCRRI Presentation On GeosyntheticsGautam RaiNo ratings yet

- L-1 Bituminous Mix DesignDocument86 pagesL-1 Bituminous Mix DesignrajibchattarajNo ratings yet

- HAWKEYE 2000 - ACD System PDFDocument61 pagesHAWKEYE 2000 - ACD System PDFNovita SariNo ratings yet

- Morth 3200Document9 pagesMorth 3200RameshNo ratings yet

- Panel Wall - Retaining Wall - Confinement Wall - Geogrid Reinforced Soil WallDocument4 pagesPanel Wall - Retaining Wall - Confinement Wall - Geogrid Reinforced Soil WalljeanfatNo ratings yet

- Design of Flexible PavementsDocument165 pagesDesign of Flexible Pavementskyugu67% (3)

- Final Flexible Pavement Design Guideline 2020 - 12th AprilDocument84 pagesFinal Flexible Pavement Design Guideline 2020 - 12th AprilSang RawalNo ratings yet

- Cement Grout Mix Design With Fosroc Cebex 100 Admixture and OPC 43 CementDocument4 pagesCement Grout Mix Design With Fosroc Cebex 100 Admixture and OPC 43 CementChalamaiah VM100% (1)

- Test of Sand QualityDocument4 pagesTest of Sand QualityJamaludin100% (1)

- BBA Certificate Maccaferri Gabions Mats No - DetailsDocument6 pagesBBA Certificate Maccaferri Gabions Mats No - DetailsSílvio GonçalvesNo ratings yet

- GEO-Instruments Vibrating Wire Piezometer: Installation MethodsDocument2 pagesGEO-Instruments Vibrating Wire Piezometer: Installation MethodsnembamoteNo ratings yet

- GEOGRIDS Final ReportDocument58 pagesGEOGRIDS Final ReportJovan BucolNo ratings yet

- Geogrid-Techgrid Technical LiteratureDocument13 pagesGeogrid-Techgrid Technical Literaturesachindagrawal90440% (1)

- Concrete Mix Design of M-15 (PCC)Document141 pagesConcrete Mix Design of M-15 (PCC)Abhishek SinghNo ratings yet

- Maufacturing of Dry Lean ConcreteDocument1 pageMaufacturing of Dry Lean ConcreteairpavsetNo ratings yet

- Potholes:: Technical Guide To Their Causes, Identification and RepairDocument52 pagesPotholes:: Technical Guide To Their Causes, Identification and RepairTerrenceNo ratings yet

- Acknowledgements: Design of Asphalt Mix (SP 12.5) For Upgrading Mpemba-Isongole RoadDocument25 pagesAcknowledgements: Design of Asphalt Mix (SP 12.5) For Upgrading Mpemba-Isongole RoadAmiry Halifa HidaNo ratings yet

- Durability of GeosyntheticsDocument295 pagesDurability of GeosyntheticsFilip StefanovicNo ratings yet

- 42 DBM GradationDocument2 pages42 DBM GradationPrasanna S Kulkarni100% (1)

- GRZ Pavement Design Guide & STDs PDFDocument43 pagesGRZ Pavement Design Guide & STDs PDFyouou HaaNo ratings yet

- Application of GeosyntheticsDocument30 pagesApplication of GeosyntheticsKiprono VincentNo ratings yet

- Transport For NSW (TFNSW) Qa Specification R57 Design of Reinforced Soil WallsDocument69 pagesTransport For NSW (TFNSW) Qa Specification R57 Design of Reinforced Soil WallsGhassan Abood HabeebNo ratings yet

- Hapas: Bonar Geosynthetics A.SDocument11 pagesHapas: Bonar Geosynthetics A.SE Hammam El MissiryNo ratings yet

- AKENYA Standard SpecsDocument346 pagesAKENYA Standard SpecsAkin A. OkupeNo ratings yet

- BBA Cert 99-R113 - Tensar RE and RE500 Geogrids For Reinforced Soil Embankments (Third Isuue, Feb 2010)Document12 pagesBBA Cert 99-R113 - Tensar RE and RE500 Geogrids For Reinforced Soil Embankments (Third Isuue, Feb 2010)sandycastleNo ratings yet

- HAPAS Cert 13-H201 TensarTech TW1 Wall System For Reinforced Soil Retaining Walls and Bridge AbutmentsDocument11 pagesHAPAS Cert 13-H201 TensarTech TW1 Wall System For Reinforced Soil Retaining Walls and Bridge AbutmentssandycastleNo ratings yet

- SikaTack Panel System - Sheet 1 Cert 05 - 4218Document10 pagesSikaTack Panel System - Sheet 1 Cert 05 - 4218Peter DudasNo ratings yet

- USD211 1knuckleDocument1 pageUSD211 1knucklemarius1979No ratings yet

- v1 CI5806 LazicDocument13 pagesv1 CI5806 Lazicmarius1979No ratings yet

- Usd 202100 FT StreetDocument1 pageUsd 202100 FT Streetmarius1979No ratings yet

- Road Design With Autocad Civil 3d 0912 enDocument26 pagesRoad Design With Autocad Civil 3d 0912 enAMTRIS33% (3)

- Midwest U 2015 Corridor Modeling Tips Tricks and ToubleshootingDocument49 pagesMidwest U 2015 Corridor Modeling Tips Tricks and ToubleshootingRadu SandaNo ratings yet

- Usd 210 Private StreetDocument1 pageUsd 210 Private Streetmarius1979No ratings yet

- Map UgDocument1,466 pagesMap Ugmarius1979No ratings yet

- Test It: Download The Bridge PackageDocument3 pagesTest It: Download The Bridge Packagemarius1979No ratings yet

- CS - Hallandss - LTR-En-LR Tunnel in MicrostationDocument2 pagesCS - Hallandss - LTR-En-LR Tunnel in Microstationmarius1979No ratings yet

- FET TheEssentialFDODocument56 pagesFET TheEssentialFDOmarius1979No ratings yet

- 8ebc0ff5 3419 4f4f B6ad Acc1bcf8f1db - classPresentationCI125444HowtoConnectAutoCADCivil3DwithRevitDocument2 pages8ebc0ff5 3419 4f4f B6ad Acc1bcf8f1db - classPresentationCI125444HowtoConnectAutoCADCivil3DwithRevitmarius1979No ratings yet

- Class Handout CI124118 MEP Modeling Made Easy With Dynamo Cesare Caoduro 2Document29 pagesClass Handout CI124118 MEP Modeling Made Easy With Dynamo Cesare Caoduro 2marius1979No ratings yet

- 3 1BasicGradingDocument24 pages3 1BasicGradingjcazNo ratings yet

- FET TheEssentialFDODocument56 pagesFET TheEssentialFDOmarius1979No ratings yet

- Class Presentation CI124118 MEP Modeling Made Easy With Dynamo Cesare CaoduroDocument56 pagesClass Presentation CI124118 MEP Modeling Made Easy With Dynamo Cesare Caoduromarius1979No ratings yet

- Handout - 11198 - REVITalize Bridge Design PDFDocument37 pagesHandout - 11198 - REVITalize Bridge Design PDFsegun ajibola100% (1)

- Presentation - 11198 - REVITalize Bridge DesignDocument38 pagesPresentation - 11198 - REVITalize Bridge Designmarius1979No ratings yet

- BIMDocument36 pagesBIMmeici100% (1)

- Creating A 3D-BIM-compliant Road Design Based On IFC AlignmentDocument14 pagesCreating A 3D-BIM-compliant Road Design Based On IFC Alignmentmarius1979No ratings yet

- HTTP CGPR - Ce.Document5 pagesHTTP CGPR - Ce.marius1979No ratings yet

- Road Map For Digital Design and ConstructionDocument20 pagesRoad Map For Digital Design and ConstructionSyl Vain RissNo ratings yet

- CS - Hallandss - LTR-En-LR Tunnel in MicrostationDocument2 pagesCS - Hallandss - LTR-En-LR Tunnel in Microstationmarius1979No ratings yet

- Provi What'S New in Version 6.0: 1 GeneralDocument32 pagesProvi What'S New in Version 6.0: 1 Generalmarius1979No ratings yet

- Rasucirea Frunzelor La Tomate-RosiiDocument4 pagesRasucirea Frunzelor La Tomate-Rosiimarius1979No ratings yet

- Altoire Citrice in T InversatDocument1 pageAltoire Citrice in T Inversatmarius1979No ratings yet

- About Csi Etabs 2013 v13!1!2Document4 pagesAbout Csi Etabs 2013 v13!1!2marius1979No ratings yet

- Caracteristici Portaltoi MarDocument14 pagesCaracteristici Portaltoi Marmarius1979No ratings yet

- Rasucirea Frunzelor La Tomate-RosiiDocument4 pagesRasucirea Frunzelor La Tomate-Rosiimarius1979No ratings yet

- TP No. 02-Micrografting Citrus-EDocument9 pagesTP No. 02-Micrografting Citrus-Emarius1979No ratings yet

- A Study of Effective Soil Compaction Control of Granular SoilsDocument193 pagesA Study of Effective Soil Compaction Control of Granular Soilsvidyaranya_bNo ratings yet

- V-1 BOQ - Intake & SitewokDocument136 pagesV-1 BOQ - Intake & Sitewokkandeepan100% (1)

- 1982 Mechanics of Ballast Compaction Volume I - Technic PDFDocument311 pages1982 Mechanics of Ballast Compaction Volume I - Technic PDFNyakakussagaNo ratings yet

- WSDOT Errata To FOP For AASHTO T 310Document10 pagesWSDOT Errata To FOP For AASHTO T 310943589901No ratings yet

- TPF 4 Work Plan and Methodology 02-12-15 (Final) ANDREDocument30 pagesTPF 4 Work Plan and Methodology 02-12-15 (Final) ANDREAndrea BroccoliNo ratings yet

- Method of Test For Preparation of Marshall SpecimensDocument14 pagesMethod of Test For Preparation of Marshall SpecimensKiplagat ChelelgoNo ratings yet

- FHWA - Design and Construction of Stone Columns Vol IDocument210 pagesFHWA - Design and Construction of Stone Columns Vol IGeorge Christodoulidis100% (2)

- CBR and Bearing CapacityDocument8 pagesCBR and Bearing Capacityzagros100% (1)

- Compaction Seminar ReportDocument32 pagesCompaction Seminar ReportKhalid Bin Walid100% (1)

- General NotesDocument15 pagesGeneral NotesTufail KhanNo ratings yet

- Dynamic Compaction of SoilDocument6 pagesDynamic Compaction of SoilAhmed ibraheemNo ratings yet

- Watani Pipe Installation Instruction ManualDocument84 pagesWatani Pipe Installation Instruction ManualAbdou Bouziane100% (1)

- Critical Review of Innovative Soil Road Stabilization TechniquesDocument9 pagesCritical Review of Innovative Soil Road Stabilization TechniquesshivaniNo ratings yet

- Practices and Track TechnologyDocument149 pagesPractices and Track Technologyomar_aljNo ratings yet

- Msolwa Ujamaa Irrigation Scheme: Bill of QuantityDocument6 pagesMsolwa Ujamaa Irrigation Scheme: Bill of QuantitypaduuNo ratings yet

- Transportation Engineering: Course Code - CE-422Document61 pagesTransportation Engineering: Course Code - CE-422Anwaar SafdarNo ratings yet

- Super Cor EnglishDocument16 pagesSuper Cor EnglishutzercNo ratings yet

- AustralianGeomechanicsLLPLpaper38 2 5Document7 pagesAustralianGeomechanicsLLPLpaper38 2 5Apoorv MahajanNo ratings yet

- Draft BQDocument248 pagesDraft BQWanNo ratings yet

- Chapter: R-1 Road Material and Their Carriage Part-A Carriage of MaterialsDocument90 pagesChapter: R-1 Road Material and Their Carriage Part-A Carriage of MaterialsrakeshcbNo ratings yet

- Investigating Correlations Between Stiffness Indexes For Brazilian SoilsDocument9 pagesInvestigating Correlations Between Stiffness Indexes For Brazilian SoilsRodrigo Souza FreitasNo ratings yet

- New Microsoft Word DocumentDocument4 pagesNew Microsoft Word DocumentVinothan VasavanNo ratings yet

- Compaction PilesDocument11 pagesCompaction PilesJuhili SawantNo ratings yet

- Stabilization of Colombian Lateritic Soil With A Hydrophobic Compound (Organosilane)Document8 pagesStabilization of Colombian Lateritic Soil With A Hydrophobic Compound (Organosilane)Mohammad Asad FirdausNo ratings yet

- UNIT - II Partial Differentiation 12 Hrs PDFDocument350 pagesUNIT - II Partial Differentiation 12 Hrs PDFbarbara_ropeNo ratings yet

- Soil Mechanics Formula Notes 63Document71 pagesSoil Mechanics Formula Notes 63Bhanu prakash dwivediNo ratings yet

- Foundation Engineering Questions and AnswersDocument25 pagesFoundation Engineering Questions and AnswersGetachew AdmasuNo ratings yet

- Civil Engineering Practices Volume-01 - BY SH - JP Mishra 06.11.2019Document106 pagesCivil Engineering Practices Volume-01 - BY SH - JP Mishra 06.11.2019Ashok kumar100% (1)

- Civil Engineering McqsDocument51 pagesCivil Engineering McqsNaeem ImranNo ratings yet

- CH 5 Earthwork and QuantificationDocument43 pagesCH 5 Earthwork and QuantificationZeleke Taimu0% (1)

- Crossings: How Road Ecology Is Shaping the Future of Our PlanetFrom EverandCrossings: How Road Ecology Is Shaping the Future of Our PlanetRating: 4.5 out of 5 stars4.5/5 (10)

- To Engineer Is Human: The Role of Failure in Successful DesignFrom EverandTo Engineer Is Human: The Role of Failure in Successful DesignRating: 4 out of 5 stars4/5 (138)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansFrom EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansNo ratings yet

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsFrom EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsNo ratings yet

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansFrom EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansRating: 4.5 out of 5 stars4.5/5 (21)

- Geotechnical Engineering Calculations and Rules of ThumbFrom EverandGeotechnical Engineering Calculations and Rules of ThumbRating: 4 out of 5 stars4/5 (17)

- Troubleshooting and Repair of Diesel EnginesFrom EverandTroubleshooting and Repair of Diesel EnginesRating: 1.5 out of 5 stars1.5/5 (2)

- Structural Cross Sections: Analysis and DesignFrom EverandStructural Cross Sections: Analysis and DesignRating: 4.5 out of 5 stars4.5/5 (19)

- Rocks and Minerals of The World: Geology for Kids - Minerology and SedimentologyFrom EverandRocks and Minerals of The World: Geology for Kids - Minerology and SedimentologyRating: 4.5 out of 5 stars4.5/5 (5)

- The Great Bridge: The Epic Story of the Building of the Brooklyn BridgeFrom EverandThe Great Bridge: The Epic Story of the Building of the Brooklyn BridgeRating: 4.5 out of 5 stars4.5/5 (59)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Summary of Neil Postman's Amusing Ourselves to DeathFrom EverandSummary of Neil Postman's Amusing Ourselves to DeathRating: 4 out of 5 stars4/5 (2)

- The Finite Element Method: Linear Static and Dynamic Finite Element AnalysisFrom EverandThe Finite Element Method: Linear Static and Dynamic Finite Element AnalysisRating: 5 out of 5 stars5/5 (3)

- CAREC Road Safety Engineering Manual 3: Roadside Hazard ManagementFrom EverandCAREC Road Safety Engineering Manual 3: Roadside Hazard ManagementNo ratings yet

- Finite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesFrom EverandFinite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesNo ratings yet

- Cable Supported Bridges: Concept and DesignFrom EverandCable Supported Bridges: Concept and DesignRating: 5 out of 5 stars5/5 (1)

- Construction Innovation and Process ImprovementFrom EverandConstruction Innovation and Process ImprovementAkintola AkintoyeNo ratings yet

- Rock Fracture and Blasting: Theory and ApplicationsFrom EverandRock Fracture and Blasting: Theory and ApplicationsRating: 5 out of 5 stars5/5 (2)