Professional Documents

Culture Documents

ERD Tin Product Brochure

Uploaded by

Laura Elgarrista0 ratings0% found this document useful (0 votes)

58 views10 pagesERDEMIR tinplate is produced in two main types; Single Reduced (SR) and Double Reduced (DR) steel strip is reduced to desired thickness in one step by cold rolling in the cold mill and subsequently annealed, tempered then coated (depending on the steel quality and annealing type). DR tinplate is mainly used in, 2 and 3 - pieces can bodies and bases, beverage cans, easy-open lids and crown caps, aerosol bodies, bases and tops

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentERDEMIR tinplate is produced in two main types; Single Reduced (SR) and Double Reduced (DR) steel strip is reduced to desired thickness in one step by cold rolling in the cold mill and subsequently annealed, tempered then coated (depending on the steel quality and annealing type). DR tinplate is mainly used in, 2 and 3 - pieces can bodies and bases, beverage cans, easy-open lids and crown caps, aerosol bodies, bases and tops

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

58 views10 pagesERD Tin Product Brochure

Uploaded by

Laura ElgarristaERDEMIR tinplate is produced in two main types; Single Reduced (SR) and Double Reduced (DR) steel strip is reduced to desired thickness in one step by cold rolling in the cold mill and subsequently annealed, tempered then coated (depending on the steel quality and annealing type). DR tinplate is mainly used in, 2 and 3 - pieces can bodies and bases, beverage cans, easy-open lids and crown caps, aerosol bodies, bases and tops

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 10

Producing high quality tin

for you since 1965.

WE ARE SHAPING THE FUTURE

erdemir.export@erdemir.com.tr / www.erdemir.com.tr

WE ARE SHAPING THE FUTURE

We are always by your side whenever you need us. For 45 years.

CONTENTS

1) Tinplate & TFS Production ..................................................................................................

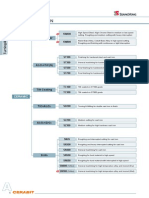

2) Production Flow Chart .........................................................................................................

3) ETL/TFS Line ......................................................................................................................

4) Technical Facts of ETL/TFS Line ........................................................................................

5) ERDEMIR Qualities .............................................................................................................

6) Properties of Tinplate/TFS Products ...................................................................................

7) Comparison of Tinplate & TFS Products .............................................................................

8) Packaging of Tinplate/TFS Products ...................................................................................

9) Tinplate in Packaging Sector ...............................................................................................

Beneath this lid you will find the real quality of ERDEMIR tinplate.

1) Tinplate & TFS Production

in ERDEMIR:

Cold rolled low carbon mild steel can be electrolytically

coated either by tin in various coating weights or

chromium. Products can be supplied in coil or sheet in the

thickness of 0.10-0.60 mm.

Production methods of Tinplate and TFS in ERDEMIR:

Electrolytically tin or chrome coated low carbon steel

Batch or continuous annealed

Single or double reduced

Coil or cut into length as a sheet

ERDEMIR tinplate is produced in two main types;

Single Reduced (SR) and Double Reduced (DR).

ERDEMR tin free steel is mainly single reduced.

Single Reduced (SR): Steel strip is reduced to desired

thickness in one step by cold rolling in the cold mill and

subsequently annealed, tempered then coated (depending

on the steel quality & annealing type). SR Tinplate is

mainly used in, 2 and 3 - pieces can bodies and bases,

industrial can bodies and bases, beverage cans, easy-

open lids and crown caps, aerosol bodies, bases and tops.

Double Reduced (DR): Steel strip received a further cold

rolling in which the steel is reduced by 10 to 30 percent

after annealing. Thus the steel reaches its final thickness

in two separate cold rollings (depending on the steel

quality & annealing type). DR Tinplate is mainly used in

2 - and - 3 pieces can bodies and bases, industrial can

ends, easy-open lids, twist-off caps and aerosol bodies.

Tinplate/TFS Applications

TH230-T1 484 Body 2 pieces, cans, nozzles and other applications involving deep drawing.

TH245-T2 524

Moderate drawing applications which requires extreme hardness. Small square and oval

cans and valves.

TH260-T2.5 554

In areas where T2 drawing and T3 hardness combinations are needed. Paint can cap

application, industrial & fancy soldered cans.

TH270-T3 574 Can caps and bodies, big caps, beverage cans and aerosol bodies.

TH415-T4 614

Used in areas in which greater hardness than T3 is required. 3 piece can bodies,

general line cans. Chrome corks.

TH430-T5 654

Used in areas where excellent buckling resistance is required like big can bodies and ends.

Aerosol bottoms.

TH520-DR7.5 694

Material for twist-off caps, non-retorted soldered food cans, non-eo food ends,

2 piece drawn cans.

TH550-DR8 704

TH580-DR8.5 714

TH620-DR9 734

Temper Grade Hardness Applications

Cleaning:

After cold rolling, the steel is covered with a thin film of

oil that is removed by an alkaline cleaning operation in

order to optimize the annealing process.

Annealing:

The steel is heated in a reducing atmosphere just

above the recrystallization point and then cooled.

There are two types of annealing: batch annealing

(BA) and continuous annealing (CA).

Tempering:

The strip is tempered to achieve the required level

of hardness, surface condition, shape, formability,

smoothness and the required mechanical properties. Also

a secondary rolling that is required for the production of

DR tinplate can be done in the suitable temper line.

Coating:

In this operation the blackplate is passed continuously

through the operations of cleaning, electrolytic pickling,

electrodeposition of tin or chromium, induction melting

for tinplate, passivation and oiling. The final product is

tinplate or tin free steel.

Temper Mill No. 2(DR)

Temper Mill No. 1

Tinplate Shear

Surface Coating

Electrolytic Tinning

&

TFS Line

Batch Annealing

Pickling:

The steel is pickled to eliminate the iron oxide

that forms on the strip during hot rolling process.

Tandem Rolling:

In this process the thickness of strip is reduced without

modifying the width.

Cleaning:

After cold rolling, the steel is covered with a thin film of

oil that is removed by an alkaline cleaning operation in

order to optimize the annealing process.

Annealing:

The steel is heated in a reducing atmosphere just

above the recrystallization point and then cooled.

There are two types of annealing: batch annealing

(BA) and continuous annealing (CA).

2) Production Flow Chart:

Ironmaking

Temper Mill No. 2(DR)

Tin-Cal Line

Cleaning & Annealing & Temper Rolling

Steelmaking

Hot Rolling

Pickling Lines Tandem Mill

Cold Rolling

Alkali Cleaning Line

Batch Annealing

6) Properties of Tinplate/TFS Products in ERDEMIR:

Production ranges and types of Tinplate and TFS in ERDEMIR.

5) ERDEMIR Qualities:

Tinplate and TFS grades in ERDEMIR are given below.

CORRESPONDING INTERNATIONAL STANDARDS

ERDEMIR GRADE

Single Reduced TFS Double Reduced

JISG3303 1987 ASTM A623 1998 DIN EN 10202:2001 BA CA BA CA BA CA

T1 T50 TS230 2023 2223 2123 2323 - -

T2 T52 TS245 2004 2225 2104 2325 - -

T2.5 T55 TS260 2026 2226 2126 2326 - -

T3 T57 TS275 2005 2228 2105 2328 - -

T4 T61 TS415 2006 2242 2106 2342 - -

T5 T65 TH435 - 2244 - 2344 - -

DR520 DR 7.5(T72) TH520 - - - - 2052 2252

DR550 DR 8 (T73) TH550 - - - - 2055 2255

DR580 DR 8.5(T74) TH580 - - - - - 2258

DR620 DR 9 (T76) TH620 - - - - - 2262

STEEL GRADES

BA:Batch Annealed

CA:Continuously Annealed

GENERAL THICKNESS RANGE (mm)

Min. Max. Product Type

0,16 0,60 Single reduced electrolytic tinplate coil

0,16 0,60 Single reduced electrolytic tinplate sheet cut from coil

0,12 0,30 Double reduced electrolytic tinplate coil

0,12 0,30 Double reduced electrolytic tinplate sheet cut from coil

0,16 0,60 Single reduced electrolytic chromium coated steel coil

0,16 0,60 Single reduced chromium coated steel sheet cut from coil

4) Technical facts of ETL/TFS Line in ERDEMIR:

The annual production capacity of ETL/TFS line is 250.000 t/y. The capacity of the shearing line is 100.000 t/y.

Details of the lines are given below.

ETL/TFS LINE

Total Production Capacity

Tinplate

Chromium Coated Steel

Width

Thickness

SHEAR LINE

Production Capacity

Width

Thickness

Length

250.000 t/y

200.000 t/y

50.000 t/y

508 - 1050 mm

0,10 - 0,60 mm

100.000 t/y

559 - 1016 mm

0,12 - 0,60 mm

450 - 1168 mm

3) ETL/TFS Line:

Production of tinplate and TFS is done in ETL/TFS line given below.

SURFACE TYPE

Single Reduced Bright BR Tinplate Available Ra 0,35

Single/Double

Reduced

Fine Stone FS

Tinplate Available

0,25 Ra 0,45

TFS Unavailable

Single/Double

Reduced

Stone ST

Tinplate Available

0,35 Ra 0,60

TFS Unavailable

Single Reduced Matt/Normal MM Tinplate Unavailable 0,60 Ra 1,90

Single Reduced Silver SG Tinplate Available Ra 0,90

Product Type Surface Type Code Tinplate/TFS Smelt

"Surface Roughness

(Ra, m)

COATING TYPES & WEIGHTS

Both Surfaces

Equal

(1,1 / 1,1) (0,050 / 0,050) 0,90 2,20 0,15

(2,8 / 2,8) (0,125 / 0,125) 2,45 5,60 0,39

(5,6 / 5,6) (0,250 / 0,250) 5,10 11,20 0,77

(8,4 / 8,4) (0,375 / 0,375) 7,75 16,80 1,16

(11,2 / 11,2) (0,500 / 0,500) 10,30 22,40 1,54

Both Surfaces

Different

(5,6 / 2,8) (0,250 / 0,125) 5,10 / 2,45 8,40 -

(8,4 / 2,8) (0,375 / 0,125) 7,75 / 2,45 11,20 -

(11,2 / 2,8) (0,500 / 0,125) 10,30 / 2,45 14,00 -

(11,2 / 5,6) (0,500 / 0,250) 10,30 / 5,10 16,80 -

Coating Type

Single Surface

Nominal Coating

Weight

(g/m

2

)

Single Surface

Nominal Coating

Weight

(LB/BB)

Single Surface

Min. Coating

Weight

(g/m

2

)

Both Surfaces

Coating Weight

(g/m

2

)

Coating

Thickness

(m)

S

i

n

g

l

e

R

e

d

u

c

e

d

T1 max. 53 max. 52 max. 51

D

o

u

b

l

e

R

e

d

u

c

e

d

DR7.5 714

T2 534 524 514 DR8 724

T2.5 564 554 544 DR8.5 734

T3 584 574 564 DR9 754

T4 624 614 604

T5 654 654 644

Temper Grade

Hardness Range

Temper Grade

Hardness

Range

t 0,21 0,21< t 0,28 0,28 < t

TEMPER GRADE

SURFACE TYPE

Single Reduced Bright BR Tinplate Available Ra 0,35

Single/Double

Reduced

Fine Stone FS

Tinplate Available

0,25 Ra 0,45

TFS Unavailable

Single/Double

Reduced

Stone ST

Tinplate Available

0,35 Ra 0,60

TFS Unavailable

Single Reduced Matt/Normal MM Tinplate Unavailable 0,60 Ra 1,90

Single Reduced Silver SG Tinplate Available Ra 0,90

Product Type Surface Type Code Tinplate/TFS Smelt

"Surface Roughness

(Ra, m)

COATING TYPES & WEIGHTS

Chromium coating: 80 mg/m for both sides.

The line also has the capability to coat different combinations between 1,1-11,2 g/m2.

Both Surfaces

Equal

(1,1 / 1,1) (0,050 / 0,050) 0,90 2,20 0,15

(2,8 / 2,8) (0,125 / 0,125) 2,45 5,60 0,39

(5,6 / 5,6) (0,250 / 0,250) 5,10 11,20 0,77

(8,4 / 8,4) (0,375 / 0,375) 7,75 16,80 1,16

(11,2 / 11,2) (0,500 / 0,500) 10,30 22,40 1,54

Both Surfaces

Different

(5,6 / 2,8) (0,250 / 0,125) 5,10 / 2,45 8,40 -

(8,4 / 2,8) (0,375 / 0,125) 7,75 / 2,45 11,20 -

(11,2 / 2,8) (0,500 / 0,125) 10,30 / 2,45 14,00 -

(11,2 / 5,6) (0,500 / 0,250) 10,30 / 5,10 16,80 -

Coating Type

Single Surface

Nominal Coating

Weight

(g/m

2

)

Single Surface

Nominal Coating

Weight

(LB/BB)

Single Surface

Min. Coating

Weight

(g/m

2

)

Both Surfaces

Coating Weight

(g/m

2

)

Coating

Thickness

(m)

S

i

n

g

l

e

R

e

d

u

c

e

d

T1 max. 53 max. 52 max. 51

D

o

u

b

l

e

R

e

d

u

c

e

d

DR7.5 714

T2 534 524 514 DR8 724

T2.5 564 554 544 DR8.5 734

T3 584 574 564 DR9 754

T4 624 614 604

T5 654 654 644

Temper Grade

Hardness Range

Temper Grade

Hardness

Range

t 0,21 0,21< t 0,28 0,28 < t

TEMPER GRADE

Precautions for Tinplate

Since tin coating is relatively soft in order to avoid scratches, necessary measures should be taken during transportation

and handling.

Paintability, solderability, paint adhesion and mechanical properties detoriorate as time passes.

Although tinplate has an excellent corrosion resistance, it becomes rusty in moist atmospheres. It should be processed

as soon as protective packaging is removed.

Tin is soluble in powerful alkali solutions so tinplate must be painted or lacquered when it is used for alkali solutions.

Tinplate becomes darker in case of contact with sulphur contents. So it should be painted or lacquered in these kind of

applications.

Precautions for TFS

TFS is not compatible for soldering, welding and DWI drawing operations.

Metallic coating layer of TFS has high electrical resistance, before welding, this layer should be removed.

TFS has a tendency to rust in humid atmospheres. It should be processed as soon as protective packaging is removed.

If it is to be used in connection with food and beverage, its surface should be painted and lacquered.

Scratches which may appear on surface due to incorrect transportation and handling should be avoided.

Comparison of Tinplate & TFS Products

Properties Tinplate TFS

Paintability O

Lacquering O

Shape Availability O O

Solderability O X

Weldability O X

Corrosion Resistance O O

Yellow Stain O

Heat Resistance O

7) Comparison of Tinplate & TFS Products:

Precautions for Tinplate

Since tin coating is relatively soft in order to avoid scratches, necessary measures should be taken during transportation

and handling.

Paintability, solderability, paint adhesion and mechanical properties detoriorate as time passes.

Although tinplate has an excellent corrosion resistance, it becomes rusty in moist atmospheres. It should be processed

as soon as protective packaging is removed.

Tin is soluble in powerful alkali solutions so tinplate must be painted or lacquered when it is used for alkali solutions.

Tinplate becomes darker in case of contact with sulphur contents. So it should be painted or lacquered in these kind of

applications.

Precautions for TFS

TFS is not compatible for soldering, welding and DWI drawing operations.

Metallic coating layer of TFS has high electrical resistance, before welding, this layer should be removed.

TFS has a tendency to rust in humid atmospheres. It should be processed as soon as protective packaging is removed.

If it is to be used in connection with food and beverage, its surface should be painted and lacquered.

Scratches which may appear on surface due to incorrect transportation and handling should be avoided.

Excellent O Good Fair X Poor

Comparison of Tinplate & TFS Products

Properties Tinplate TFS

Paintability O

Lacquering O

Shape Availability O O

Solderability O X

Weldability O X

Corrosion Resistance O O

Yellow Stain O

Heat Resistance O

7) Comparison of Tinplate & TFS Products:

Tinplate Layers:

TFS Layers:

8) Packaging of Tinplate/TFS Products:

Coil Packaging

Coil Packaging - Overseas Shipment

Sheet Packaging - Overseas Shipment

Non-toxic for human health

Lightness

Easy drawability

Weldability

Corrosion resistance

Brilliant surface

Paint adhesion

Cycling, healthy for environment

Sheet Packaging

Sheet Packaging - Overseas Shipment

9) Tinplate in Packaging Sector:

Tinplate and TFS are mainly used in packaging industry due to properties given below.

You might also like

- Plates PDFDocument10 pagesPlates PDFkarthiksaadhanaNo ratings yet

- CR StandardsDocument6 pagesCR Standardsalpha_beta48No ratings yet

- Cold Rolled Steel StripDocument40 pagesCold Rolled Steel StripshelarsanjayNo ratings yet

- Basic Sheet and Coil Training Edit VersionDocument35 pagesBasic Sheet and Coil Training Edit VersioncuongdcNo ratings yet

- Lasercut WB 100 enDocument0 pagesLasercut WB 100 enfbp81No ratings yet

- Somta Tools User GuideDocument150 pagesSomta Tools User GuideBarrie Van Wyk100% (1)

- Cold Rolling MillDocument4 pagesCold Rolling MillArslan BohioNo ratings yet

- POSCO Korea - Galvanized SheetDocument27 pagesPOSCO Korea - Galvanized SheetFrancis BoeyNo ratings yet

- Special Steel Sheet: Cat - No.B1E-005-05Document16 pagesSpecial Steel Sheet: Cat - No.B1E-005-05wahyuNo ratings yet

- Special Steel Sheet: Cat - No.B1E-005-04Document16 pagesSpecial Steel Sheet: Cat - No.B1E-005-04Arnaldo Macchi MillanNo ratings yet

- Steel Supply Sub-Grades To EC3Document22 pagesSteel Supply Sub-Grades To EC3Anonymous iS33V5No ratings yet

- Grinding WheelsDocument26 pagesGrinding Wheelsznovak77No ratings yet

- PlanchasDiamantadas RuukkiDocument3 pagesPlanchasDiamantadas RuukkiFelipeNo ratings yet

- Cutting Tool Materials of Common Use: Irshad K TDocument49 pagesCutting Tool Materials of Common Use: Irshad K TAswinNo ratings yet

- Pas CTG Tur Cer-Cermet enDocument36 pagesPas CTG Tur Cer-Cermet enshumi27No ratings yet

- Term Paper Mec 208Document20 pagesTerm Paper Mec 208lksingh1987No ratings yet

- Pro Dec PlateDocument9 pagesPro Dec PlateAbe VoigNo ratings yet

- Design in BrassDocument16 pagesDesign in Brassjohn_progecoNo ratings yet

- S TR CIVIL STEEL (Rev.0 2009) 1648785854104Document11 pagesS TR CIVIL STEEL (Rev.0 2009) 1648785854104Vimala PonnusamyNo ratings yet

- Standards R M Salem - UserguideDocument49 pagesStandards R M Salem - Userguidearunas1081No ratings yet

- Catalogue of Plates NewDocument36 pagesCatalogue of Plates NewCarlo Ulises Conteras Siuentes0% (1)

- Cutting Edge BrochureDocument2 pagesCutting Edge BrochureKen SmithNo ratings yet

- Userguide For SSDocument26 pagesUserguide For SSehsan4uNo ratings yet

- Tool Steel Alloy Cr12MoVDocument5 pagesTool Steel Alloy Cr12MoVMujjo Sahb100% (1)

- Cutting ToolsDocument61 pagesCutting ToolsKalai SelvanNo ratings yet

- Otel de Scule - GBDocument37 pagesOtel de Scule - GBColta VictorNo ratings yet

- NPA205 Black Rush TaeguTecDocument6 pagesNPA205 Black Rush TaeguTecpchakkrapaniNo ratings yet

- Ttha 115Document17 pagesTtha 115san moedanoNo ratings yet

- Aluminium Sheet Grade 65032 SuppliersDocument17 pagesAluminium Sheet Grade 65032 Supplierssanghvi overseas incNo ratings yet

- Cast Iron Welding AlloysDocument4 pagesCast Iron Welding AlloysKhin Aung ShweNo ratings yet

- Steel UserguideDocument50 pagesSteel UserguideBhanu Pratap ChoudhuryNo ratings yet

- 2 Grade InformationDocument17 pages2 Grade InformationAndres Alejandro RoblesNo ratings yet

- Material SpecificationDocument50 pagesMaterial SpecificationSangyt Karna0% (2)

- Tool Steel Grade and Standard DesignationDocument7 pagesTool Steel Grade and Standard DesignationMustafa SevimliNo ratings yet

- 0 Sa-263Document23 pages0 Sa-263avazcNo ratings yet

- 16MnCr5 SteelDocument3 pages16MnCr5 SteelaravindhNo ratings yet

- BSD SteelGuide2013Document122 pagesBSD SteelGuide2013ManikdnathNo ratings yet

- Material PropertiesDocument16 pagesMaterial PropertiesMadan Kulkarni100% (1)

- BSK 46 Materials - For - Automobiles11Document62 pagesBSK 46 Materials - For - Automobiles11shuklahouse100% (1)

- Iscar Grade ChartDocument1 pageIscar Grade ChartsmarjanNo ratings yet

- D2 Data SheetDocument9 pagesD2 Data SheetJim ToddNo ratings yet

- Consumables enDocument36 pagesConsumables enmuqtadirNo ratings yet

- Casting (Recovered)Document44 pagesCasting (Recovered)prabhu100% (1)

- Steel CoilDocument20 pagesSteel CoilParimala SubramaniamNo ratings yet

- CoroKey 2008engDocument208 pagesCoroKey 2008engStela LjevarNo ratings yet

- Tooling and Work Holding Devices: Unit VDocument57 pagesTooling and Work Holding Devices: Unit VGowtham SakthivelNo ratings yet

- Steel MaterialsDocument10 pagesSteel Materialsmanideep219No ratings yet

- Tubular Products From Special MetalsDocument26 pagesTubular Products From Special Metalskaveh-bahiraeeNo ratings yet

- Steel PlatesDocument36 pagesSteel PlatesAntónio Grade100% (1)

- PLDocument4 pagesPLselvamuthukumarNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonRating: 4 out of 5 stars4/5 (1)

- Forging Operations - Machine Forging, Forging Dies and Special Forging OperationsFrom EverandForging Operations - Machine Forging, Forging Dies and Special Forging OperationsNo ratings yet

- Sheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkFrom EverandSheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkNo ratings yet

- Oxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Blacksmithing on the Farm - With Information on the Materials, Tools and Methods of the BlacksmithFrom EverandBlacksmithing on the Farm - With Information on the Materials, Tools and Methods of the BlacksmithNo ratings yet

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopFrom EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopRating: 4.5 out of 5 stars4.5/5 (2)

- Engineering A Bamboo BicycleDocument110 pagesEngineering A Bamboo BicycleLaura ElgarristaNo ratings yet

- Catalogo de MoldurasDocument1 pageCatalogo de MoldurasLaura ElgarristaNo ratings yet

- Guia Ava EnglDocument101 pagesGuia Ava EnglPreso ULNo ratings yet

- ABC T: B D: S OF Oxicology Asic EfinitionsDocument4 pagesABC T: B D: S OF Oxicology Asic EfinitionsLaura ElgarristaNo ratings yet

- Reference 1 (Arch Dams)Document179 pagesReference 1 (Arch Dams)Kevin A PereiraNo ratings yet

- Transboundery Bassins MGIREB UK 2012-2-0Document122 pagesTransboundery Bassins MGIREB UK 2012-2-0Laura ElgarristaNo ratings yet

- TN277 PT8 Tutorial Two Way Slab-10Document30 pagesTN277 PT8 Tutorial Two Way Slab-10Laura ElgarristaNo ratings yet

- Post Tensioned SlabsDocument44 pagesPost Tensioned SlabsMaad Ahmed Al-Maroof100% (2)

- ADAPT TN11 DSGN Concrete Floors Ref PTDocument16 pagesADAPT TN11 DSGN Concrete Floors Ref PTLaura Elgarrista100% (1)

- PWHT Procedure For Petrol Steel - CoreDocument9 pagesPWHT Procedure For Petrol Steel - CoreSuleyman HaliciogluNo ratings yet

- Copper and It's AlloysDocument5 pagesCopper and It's AlloysReza MortazaviNo ratings yet

- ATA Heet: L Escalloy 52100 VAC-ARC ARC 52100 VACDocument2 pagesATA Heet: L Escalloy 52100 VAC-ARC ARC 52100 VACAntonioNo ratings yet

- Proceedings of RMSW 2010 - Volume IDocument546 pagesProceedings of RMSW 2010 - Volume IRaheel_maqsoodNo ratings yet

- FinDocument3 pagesFinTVP_contechNo ratings yet

- Astm B148 - 14Document6 pagesAstm B148 - 14raulNo ratings yet

- Wear Resistance of High Chromium White Cast Iron For Coal Grinding RollsDocument9 pagesWear Resistance of High Chromium White Cast Iron For Coal Grinding RollsJoseph CureNo ratings yet

- Laboratory EnglishDocument76 pagesLaboratory Englishrafaesneider1No ratings yet

- Astm A 108 (2007)Document7 pagesAstm A 108 (2007)IMSQANo ratings yet

- Casting Material: Carbon Steel BS3100 Gr. A2Document6 pagesCasting Material: Carbon Steel BS3100 Gr. A2dexterisNo ratings yet

- PURPOSE: 1. To Decrease Internal Stresses Due To Cold Working, Welding Etc.Document6 pagesPURPOSE: 1. To Decrease Internal Stresses Due To Cold Working, Welding Etc.Sumit JainNo ratings yet

- Dictionary of Metal TerminologyDocument59 pagesDictionary of Metal TerminologyyogeshNo ratings yet

- Internship Report MAINDocument31 pagesInternship Report MAINprajwal bdvtNo ratings yet

- CH 11Document55 pagesCH 11Anuj shuklaNo ratings yet

- Sandvik Rock Drill Steels 259 Eng. March 2003Document12 pagesSandvik Rock Drill Steels 259 Eng. March 2003Alejandro Arrieta C100% (1)

- Structural Changes in 12-2.25% CR Weldments - An Experimental and Theoretical ApproachDocument8 pagesStructural Changes in 12-2.25% CR Weldments - An Experimental and Theoretical ApproachAli AhmadNo ratings yet

- Nitriding Steel: ApplicationsDocument1 pageNitriding Steel: Applicationsmadhu gawadeNo ratings yet

- Module 1 5Document48 pagesModule 1 5Richard MendozaNo ratings yet

- LNG Ship Construction - 1Document71 pagesLNG Ship Construction - 1Jayan Pillai90% (10)

- A4-80 Stainless Steel Grade Specification - Midland Bright SteelsDocument4 pagesA4-80 Stainless Steel Grade Specification - Midland Bright SteelsramonaghergheNo ratings yet

- Aircraft Materials and ProcessesDocument4 pagesAircraft Materials and ProcessesthandialNo ratings yet

- Roll Cage, Safety and Ergonomics Report: AbstractDocument32 pagesRoll Cage, Safety and Ergonomics Report: AbstractJuicYm mNo ratings yet

- Lumino - HTLSDocument11 pagesLumino - HTLSvishnu ojhaNo ratings yet

- Andritz Salem HaplDocument2 pagesAndritz Salem HaplRajkumar ASNo ratings yet

- Properties Srainless Steel 309LSDocument3 pagesProperties Srainless Steel 309LSGabriel BozzaNo ratings yet

- What Is Heat TreatmentDocument32 pagesWhat Is Heat TreatmentSoumyajit RoyNo ratings yet

- 1.4006 en PDFDocument2 pages1.4006 en PDFutkuNo ratings yet

- Heat Treatment of Steels (Power Point Presentation)Document14 pagesHeat Treatment of Steels (Power Point Presentation)Armando Lopez Bond75% (4)

- ND - Edu - Manufact - MPEM PDF - Files - Ch02Document33 pagesND - Edu - Manufact - MPEM PDF - Files - Ch02Enrique CalderónNo ratings yet

- Chief Engineer Officer, Small Vessel, III/2 Written Examination SyllabusDocument11 pagesChief Engineer Officer, Small Vessel, III/2 Written Examination SyllabusAdrianDanNo ratings yet