Professional Documents

Culture Documents

T 07 Vol II

Uploaded by

amitkap00r0 ratings0% found this document useful (0 votes)

46 views5 pagesd

Original Title

T_07_Vol_II

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentd

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

46 views5 pagesT 07 Vol II

Uploaded by

amitkap00rd

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 5

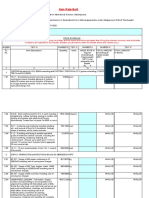

M P P G C L

TENDER NO. RITES/ GM/ NGP/ 07-2013, DATED 14/02/2013

Name of work: Fixing of Rails on top of Track Hopper and Loco shed in

connection with Construction of Railway Siding at Shree Singhaji

Thermal Power Project Khandwa, M.P.

VOLUME-II

(PRICE BID)

Consultants

RITES LTD

1, RITES BHAVAN, KADBI CHOWK,

NAGPUR-440 004

Tender Document issued to:

(Name of Tenderer)

(Address of Tenderer)

Signature of Officer issuing the document with Designation & Date of Issue.

1

2

PART - 2

FINANCIAL BID

SCHEDULE (BILL OF QUANTITIES)

NAME OF WORK:- Fixing of Rails on top of Track Hopper and Loco shed

in connection with Construction of Railway Siding at Shree Singhaji

Thermal Power Project Khandwa, M.P.

PART 2

SCHEDULE (BILL) OF QUANTITIES

(ITEM RATE TENDER)

Fixing of Rails on top of Track Hopper and Loco shed in connection with Construction of

Railway Siding at Shree Singhaji Thermal Power Project Khandwa, M.P.

ABSTRACT OF COST

SCHEDULE DESCRIPTION TOTAL QUOTED AMOUNT IN FIGURES

( Rs,)

1 Total Work

UNCONDITIONAL REBATE

TOTAL AFTER APPLYING REBATE (RUPEES)

(i) In figures

(ii) In words.

h) SIGNATURE OF AUTHORIZED

SIGNATORY OF TENDERER

ii) NAME OF SIGNATORY

iii) NAME AND SEAL OF TENDERER

iv) DATE

i) PLACE

Amount

In Figures (Rs.) In Words (Rs.) In Figures (Rs.)

1

Grouting oI SGCI Inserts in the existing hole on beam oI Track Hopper with

ARALDITE GY-257, HARDENER HY-840, HARDENER HY-960 and

QUARTZ SAND in the proportion oI 100:50:2:400 by weight upto the required

depth Ior laying oI track with 52 Kg rail over 10 mm thick continuous rubber

pads as per RITES Drg. The rate is also inclusive oI chipping oI existing pockets,

iI necessary to grout the Inserts at proper level.

Each Hole 1936

2

Making new pockets oI 65mm x 45 mm x 120mm depth as required Ior grouting

additional inserts over the existing concrete surIace oI beam oI Track Hopper. Each Hole 100

3

Making new epoxy leveling layer oI 13.6mm Ior a width oI 400mm with Araldite

Gy-257, hardner Hy-840 and Hardner Hy-960 and Quartz sand oI Mix 10 in the

proportion oI 100:50:2:800 by weight to be applied over a priming coat oI

Aradldite Gy-257 and Hardner Hy-840 in the proportion oI 100:50 and one top

coat over the leveling layer with Araldite Gy-257, Hardner Hy-840 and Hardner

Hy-960 in the proportion oI 100:50:2( as per RITES Drg.) The top coat over

levelling layer are to be applied only over the top oI Iinal levelling layer. The rate

is also inclusive oI chipping the undulated concrete surIace over the beam and

removal oI laitance by wire brushing and blowing oI pneumatic air to attain the

minimum levelling layer oI 13.6mm.

Sqm 250

Unit Rate

Schedu|e of uant|t|es for f|x|ng of ra||way 1rack on top of 1rack nopper] Loco shed |n connect|on w|th construct|on of ka||way S|d|ng at Shree S|ngha[| 1herma|

ower ro[ect khandwa M.

Quantity Unit Description of works

Sl .

No.

Quoted

1 of 2

3

Making new epoxy leveling layer oI 13.6mm Ior a width oI 400mm with Araldite

Gy-257, hardner Hy-840 and Hardner Hy-960 and Quartz sand oI Mix 10 in the

proportion oI 100:50:2:800 by weight to be applied over a priming coat oI

Aradldite Gy-257 and Hardner Hy-840 in the proportion oI 100:50 and one top

coat over the leveling layer with Araldite Gy-257, Hardner Hy-840 and Hardner

Hy-960 in the proportion oI 100:50:2( as per RITES Drg.) The top coat over

levelling layer are to be applied only over the top oI Iinal levelling layer. The rate

is also inclusive oI chipping the undulated concrete surIace over the beam and

removal oI laitance by wire brushing and blowing oI pneumatic air to attain the

minimum levelling layer oI 13.6mm.

Sqm 250

4

Making epoxy levelling layer as required over 13.6mm Ior a width oI 400 mm to

match with proposed rail level with Araldite Gy-257, Hardener Hy-840, Hardener

Hy-960 and quartz sand mix-10 in the proportion oI 100:50:2:800 by weight

(Approx. Addl. Thickness25mm)

per mm thick

per sqm

250 x 25

(Avg

Thickness

25mm)

3

Providing additional quantities oI grouting compound inside the pockets with

Araldite Gy-257, Hardener Hy-840, Hardener Hy-960 and quartz sand in the

proportion oI 100:50:2:400 by weight Ior bigger size oI pockets beyond the

actual pocket size oI 65mm x 45mm x 120mm.

100 Cucm 1001880

1 of 2

Amount

In Figures (Rs.) In Words (Rs.) In Figures (Rs.)

Unit Rate Quantity Unit Description of works

Sl .

No.

Quoted

6

Laying oI 52kg rail (Single rail/ 3 rail panneled rail as available at site over

concrete 'Track Hopper' with standard Iittings ensuring correct spacing oI SGCI

Inserts, Iixing & tightening oI Fish bolt & nuts and maintaining proper gauge,

alignment, level (both cross & longitudinal), expansion gap at rail joints. The rate

should be inclusive oI dekinnking oI rails as required, cutting oI rails as required

on straight Ior squaring oI joints, drilling holes on web oI rail square to rail

surIace by using proper template Ior Iish plated joints, greasing and oiling oI Iish

plates & Iish bolts and nuts at Iishing zone oI the rail ends including supply oI

grease oil etc. complete in all respect. The rate should also be inclusive oI

carrying rails, Iittings & Iastenings with all lead, liIt, ascent, descent, crossing

road/Rly lines, etc iI necessary Irom RITES/SSTPP/MPPGCL, Store Depot to

site oI work within distance oI 5 km.

Meter 620

7

Any other unIorseen items which will not cover under items oI work (sl.no 1 to 6

above) will operated as per schedule oI W.C.Rly 2007. Basic cost Rs. 30000

LS

2 of 2

7

Any other unIorseen items which will not cover under items oI work (sl.no 1 to 6

above) will operated as per schedule oI W.C.Rly 2007. Basic cost Rs. 30000

LS

Supply of material:

8

SGCI Inserts Ior 52 kg rails as per RDSO DRG. No. T-381 with upto date ALT

conIorming to IRS SpeciIication.

Each 1936

9

10mm thick and 130 mm wide Grooved Rubber Sole Plate Ior 52 kg Rails as per

RDSO Drg. No.T-1270 with upto date ALT conIorming to IRS SpeciIication Ior

rubber p|ad oI ballast track.

Meter 620

10

Elastic Rail Clip 'J-Clip' as per RDSO Drg. No. T-4158 with upto date ALT

conIorming to IRS-31-1989 Each 72

11

GFN Liners as per RDSO DRG. NO. T-3702 with upto date ALT conIorming to

IRS SpeciIication.

Each 1936

12

Fish Plate 52 Kg as per RDSO Drg. No. T-090 (M) with upto date ALT

conIorming to TRST

Pair 18

13

Bolts & Nuts (25mm X 140mm) as per RDSO Drg. No. T-1899, IRS T-23 and

steel round upto 63 mm conIorming to IRS-1857

Each 72

14

Elastic rail clip as per RDSO Drg. No,. T-3701 with upto date ALT conIorming

to IRS-1875

Each 1864

13 Single Coil Spring Washer to RDSO Drg. No. T-10773 Each 72

1C1AL

2 of 2

You might also like

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Asme B36.10M-2018Document36 pagesAsme B36.10M-2018امينNo ratings yet

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Estimate For Pitching & ApronDocument63 pagesEstimate For Pitching & ApronBilal Ahmed Barbhuiya67% (3)

- Generation of Electrical Energy - B. R. GuptaDocument171 pagesGeneration of Electrical Energy - B. R. GuptaIbrahim Ahmed43% (23)

- Variable Geometry Turbine Technology For Marine Gas Turbines-Springer (2022)Document227 pagesVariable Geometry Turbine Technology For Marine Gas Turbines-Springer (2022)miladNo ratings yet

- Thickness Cal. Fo DM Water Storage Tank-API 650Document15 pagesThickness Cal. Fo DM Water Storage Tank-API 650Jose Rodriguez50% (2)

- Oil Analysis - Ruller and MPC TestDocument81 pagesOil Analysis - Ruller and MPC Testmaidul.islamNo ratings yet

- Civil Engineering Objective Type QuestionsDocument15 pagesCivil Engineering Objective Type QuestionsJean Simon100% (7)

- Propeller DesignDocument74 pagesPropeller DesignBambang Teguh Setiawan75% (4)

- Emerald BOQ Abstract RoadsDocument8 pagesEmerald BOQ Abstract RoadsyogeshNo ratings yet

- Estimate of Duct For OFCDocument12 pagesEstimate of Duct For OFCrajinder kutaalNo ratings yet

- Final BUA BOQ Tender - OB Plot and Podium - 03.09.21Document11 pagesFinal BUA BOQ Tender - OB Plot and Podium - 03.09.21Jaysukh N SapraNo ratings yet

- Item Rate Boq: Validate Print HelpDocument5 pagesItem Rate Boq: Validate Print HelpSOMNATH JANANo ratings yet

- UI Sample ResumeDocument6 pagesUI Sample ResumenazeerNo ratings yet

- DHA PHASE VIII ROAD WORKS BOQDocument4 pagesDHA PHASE VIII ROAD WORKS BOQdaddy003No ratings yet

- Techinical Specifications Welcome To NescoDocument54 pagesTechinical Specifications Welcome To NescotejzabNo ratings yet

- 1999 System Wiring Diagrams. Chevrolet - SuburbanDocument1 page1999 System Wiring Diagrams. Chevrolet - SuburbanJimmy Perera BurgosNo ratings yet

- Lta Sor 2020Document114 pagesLta Sor 2020kokuei50% (2)

- Sector 7 Infrastructure Cost AnalysisDocument129 pagesSector 7 Infrastructure Cost AnalysisSunil Kumar GeraNo ratings yet

- Sub Section 7.1 Bill of Quantities (Road Works) : 00-034sabarmati River Front Development Corporation Ltd. 00-034page:7Document6 pagesSub Section 7.1 Bill of Quantities (Road Works) : 00-034sabarmati River Front Development Corporation Ltd. 00-034page:7alfaza3No ratings yet

- Cyber Security Research Proposal - SandboxingDocument23 pagesCyber Security Research Proposal - SandboxingAnonymous Sa6jc83D100% (4)

- Filter DesignDocument4 pagesFilter Designhassan11783No ratings yet

- Eastern RlyDocument24 pagesEastern Rlyshivam.jhawar95No ratings yet

- Pipe Line 12Document33 pagesPipe Line 12Rajesh RaiNo ratings yet

- Eastern RlyDocument25 pagesEastern Rlyshivam.jhawar95No ratings yet

- Final Draft - Specification - ISEJ65 - 22 - 02 - 2021Document2 pagesFinal Draft - Specification - ISEJ65 - 22 - 02 - 2021Uday KumarNo ratings yet

- Boq 1Document12 pagesBoq 1Vivek kumar sinhaNo ratings yet

- Corrigendum No.1 (Reply To Quieries) For C.A.NO.01-HETAWANEDocument4 pagesCorrigendum No.1 (Reply To Quieries) For C.A.NO.01-HETAWANEpratima jadhavNo ratings yet

- Schedule of Rates For ROAD WORKS With New ItemsDocument161 pagesSchedule of Rates For ROAD WORKS With New ItemsShabbir1989No ratings yet

- Government of Telangana Roads & Buildings DepartmentDocument43 pagesGovernment of Telangana Roads & Buildings Departmentsaikumar yellankiNo ratings yet

- External Watersupply DatasDocument21 pagesExternal Watersupply DatasRK PROJECT CONSULTANTSNo ratings yet

- Item Rate Boq: Validate Print HelpDocument9 pagesItem Rate Boq: Validate Print HelpPriyank PatelNo ratings yet

- Bagimane BridgeDocument31 pagesBagimane BridgeGayathri Manjunath ShepurNo ratings yet

- Book 1Document10 pagesBook 1BaghelnkNo ratings yet

- Schedule of Rates - 2011-12Document170 pagesSchedule of Rates - 2011-12Raja SekharNo ratings yet

- Estimate for 5TR AC installation at Nabanna Press CornerDocument4 pagesEstimate for 5TR AC installation at Nabanna Press CornerJunior EngineerNo ratings yet

- Raipur Water Supply Project Cost SummaryDocument46 pagesRaipur Water Supply Project Cost SummarymohitNo ratings yet

- TS - Lohata-Bhadoi 39 KM DoublingDocument125 pagesTS - Lohata-Bhadoi 39 KM DoublinggotosudNo ratings yet

- Abd 1B Labour Price BidDocument10 pagesAbd 1B Labour Price BidReference RNo ratings yet

- WBSEB TUBULAR STEEL POLES TECHNICAL SPECIFICATIONDocument8 pagesWBSEB TUBULAR STEEL POLES TECHNICAL SPECIFICATIONVarun SharmaNo ratings yet

- Rate Analyses For ConcreteDocument9 pagesRate Analyses For ConcreteLOKESH PUNJNo ratings yet

- Percentage Boq: Validate Print HelpDocument18 pagesPercentage Boq: Validate Print HelpASRAR AHMED KHANNo ratings yet

- KERALA STATE ELECTRICITY BOARD LIMITED MODIFIES EARTHING SYSTEM AT 220kV SUBSTATIONDocument116 pagesKERALA STATE ELECTRICITY BOARD LIMITED MODIFIES EARTHING SYSTEM AT 220kV SUBSTATIONMidhun VargheseNo ratings yet

- Removel of Old Track and Laying of New B.G Track For Aluminum Unloading Portion of Smelter 0.155k.m LengthDocument6 pagesRemovel of Old Track and Laying of New B.G Track For Aluminum Unloading Portion of Smelter 0.155k.m LengthAtul Kumar MishraNo ratings yet

- CE (Navy) / VIZ / ARK/Token / 11 of 2018 - 2019 Serial Page No. 54Document56 pagesCE (Navy) / VIZ / ARK/Token / 11 of 2018 - 2019 Serial Page No. 54BSCPLCHDNo ratings yet

- Aoc & Dom Gravity MainsDocument5 pagesAoc & Dom Gravity MainsChief Engineer PMUNo ratings yet

- BOQ Sector-63 NoidaDocument3 pagesBOQ Sector-63 NoidaSahadev TyagiNo ratings yet

- PMD Road KM 25.0-26.4Document69 pagesPMD Road KM 25.0-26.4VannurSwamyNo ratings yet

- PWD Pithoragarh Item Rate BoQ for Protection/Treatment work of Chronic land slide ZoneDocument6 pagesPWD Pithoragarh Item Rate BoQ for Protection/Treatment work of Chronic land slide ZoneSOMNATH JANANo ratings yet

- PIPE ABSTRACTDocument2 pagesPIPE ABSTRACTBipin PatilNo ratings yet

- Tender For Carrying Out Construction of Compound W Tender Notice 22486835 HPCL UttaranchalDocument5 pagesTender For Carrying Out Construction of Compound W Tender Notice 22486835 HPCL UttaranchalVeena NageshNo ratings yet

- Tender For Carrying Out Construction of Compound W Tender Notice 22486835 HPCL UttaranchalDocument5 pagesTender For Carrying Out Construction of Compound W Tender Notice 22486835 HPCL UttaranchalVeena NageshNo ratings yet

- BOQ- REVISEDDocument2 pagesBOQ- REVISEDKishan KumbharNo ratings yet

- 110kV YardDocument55 pages110kV YardMidhun VargheseNo ratings yet

- Uttarakhand PWD Schedule of RateDocument20 pagesUttarakhand PWD Schedule of RateBIJAY KRISHNA DAS33% (3)

- Manual For Glued Insulated Rail Joints (1998) : Government of India Ministry of RailwaysDocument13 pagesManual For Glued Insulated Rail Joints (1998) : Government of India Ministry of RailwaysbinodNo ratings yet

- Construction of 80m Height RCC ChimneyDocument13 pagesConstruction of 80m Height RCC ChimneyTVRNo ratings yet

- 03 SCH - B Without Rate Panthoda mr.5-7-18Document5 pages03 SCH - B Without Rate Panthoda mr.5-7-18N.J. PatelNo ratings yet

- 20mm Bitumen Carpet Road ConstructionDocument167 pages20mm Bitumen Carpet Road ConstructionrkpragadeeshNo ratings yet

- KPTCL Schedule Rates 2019Document224 pagesKPTCL Schedule Rates 2019pvaman100% (1)

- Sabarmati River Front Development Project Construction CostsDocument7 pagesSabarmati River Front Development Project Construction CostsShahrol Faizal AbdullahNo ratings yet

- Schedule of Rates 2011-12Document149 pagesSchedule of Rates 2011-12Riazahemad B JagadalNo ratings yet

- Pariej Final Specification.Document121 pagesPariej Final Specification.Douglas RobinsonNo ratings yet

- UntitledDocument34 pagesUntitledRayudu VVSNo ratings yet

- Model Bridge Estimate 9 Vents 10 37 M Span SSR 2014 15Document55 pagesModel Bridge Estimate 9 Vents 10 37 M Span SSR 2014 15Maniteja Reddy TatipallyNo ratings yet

- T 69 01 EstimateDocument3 pagesT 69 01 EstimateSagar ManchandaNo ratings yet

- BSCPL Boq Manfo Civil r00Document8 pagesBSCPL Boq Manfo Civil r00Darshit VyasNo ratings yet

- Vellampatty West Paver Block 1.50Document27 pagesVellampatty West Paver Block 1.50rkpragadeesh100% (1)

- Question Bank of PWay Engineering For TMO TRACK MACHINEDocument28 pagesQuestion Bank of PWay Engineering For TMO TRACK MACHINEamitkap00rNo ratings yet

- Railway Syllabus of LDCE For Promotion To Group B in Civil Engineering Cadre 30% Quota LDCE - CM JHA AcademyDocument3 pagesRailway Syllabus of LDCE For Promotion To Group B in Civil Engineering Cadre 30% Quota LDCE - CM JHA Academyamitkap00rNo ratings yet

- Importance of Bond and Water-Cement Ratio in RCCDocument23 pagesImportance of Bond and Water-Cement Ratio in RCCamitkap00rNo ratings yet

- General KnowledgeDocument36 pagesGeneral Knowledgeamitkap00rNo ratings yet

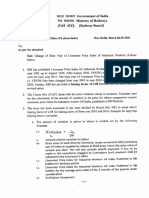

- 2021 - 09 - 06 RBCE - CE-I-CT Change of Base Year of Consumer Price Index of Industrial Workers (Labour Index)Document3 pages2021 - 09 - 06 RBCE - CE-I-CT Change of Base Year of Consumer Price Index of Industrial Workers (Labour Index)amitkap00rNo ratings yet

- Foundation & Construction EngineeringDocument20 pagesFoundation & Construction Engineeringamitkap00rNo ratings yet

- Question Paper For Junior Engineer Pway in S W RailwayDocument26 pagesQuestion Paper For Junior Engineer Pway in S W Railwayamitkap00rNo ratings yet

- 2021 - 09 - 06 RBCE - CE-I-CT Change of Base Year of Consumer Price Index of Industrial Workers (Labour Index)Document3 pages2021 - 09 - 06 RBCE - CE-I-CT Change of Base Year of Consumer Price Index of Industrial Workers (Labour Index)amitkap00rNo ratings yet

- Management of Engineering StoresDocument4 pagesManagement of Engineering Storesamitkap00rNo ratings yet

- SURVEYINGDocument29 pagesSURVEYINGamitkap00rNo ratings yet

- Strength of Materials, Structural Design & DrawingsDocument24 pagesStrength of Materials, Structural Design & Drawingsamitkap00rNo ratings yet

- Hydraulics & HydrologyDocument4 pagesHydraulics & Hydrologyamitkap00rNo ratings yet

- Construction MaterialDocument9 pagesConstruction Materialamitkap00rNo ratings yet

- Answer Key Jee 2 PDFDocument16 pagesAnswer Key Jee 2 PDFamitkap00rNo ratings yet

- JEE-MAIN-2019-Answer 3 PDFDocument40 pagesJEE-MAIN-2019-Answer 3 PDFamitkap00rNo ratings yet

- JEE-Main-January-12-Shift2 2 PDFDocument43 pagesJEE-Main-January-12-Shift2 2 PDFamitkap00rNo ratings yet

- IndexDocument1 pageIndexamitkap00rNo ratings yet

- Tax Information: Collecting CustomerDocument2 pagesTax Information: Collecting Customeramitkap00rNo ratings yet

- Principles of Physical ChemistryDocument23 pagesPrinciples of Physical ChemistryShibu Kumard0% (1)

- ASR STN 8 CRDocument20 pagesASR STN 8 CRamitkap00rNo ratings yet

- Better Burger, Chicken Confidential & Mach2 discountsDocument10 pagesBetter Burger, Chicken Confidential & Mach2 discountsamitkap00rNo ratings yet

- Lowgradegypsum-Useinbuilding - ., - Industry-Codeofpractice 0 T ,' - VRM"RSDocument7 pagesLowgradegypsum-Useinbuilding - ., - Industry-Codeofpractice 0 T ,' - VRM"RSamitkap00rNo ratings yet

- CBIC GST: GST Goods and Services RatesDocument70 pagesCBIC GST: GST Goods and Services Ratesamitkap00rNo ratings yet

- 6508Document6 pages6508amitkap00rNo ratings yet

- Preparationandusbof Ltm-E-Pozzolana Mixtureconcrete Inbuildingsandroads-Code Ofpractice (Document11 pagesPreparationandusbof Ltm-E-Pozzolana Mixtureconcrete Inbuildingsandroads-Code Ofpractice (amitkap00rNo ratings yet

- Annexure Classification of ServicesDocument20 pagesAnnexure Classification of Servicesamitkap00rNo ratings yet

- Gu'Idelines For Manufacture OF $ Gypsum Plaster in 1L Iechanized ' Pan System w?hmw6 !Document7 pagesGu'Idelines For Manufacture OF $ Gypsum Plaster in 1L Iechanized ' Pan System w?hmw6 !amitkap00rNo ratings yet

- 4139Document7 pages4139amitkap00rNo ratings yet

- Reaffirmed 2002Document9 pagesReaffirmed 2002amitkap00rNo ratings yet

- DC DC DC DC Iiii 6 6 6 6: Spec Spec Spec SpecDocument12 pagesDC DC DC DC Iiii 6 6 6 6: Spec Spec Spec SpecarsolNo ratings yet

- Composite Repair PDFDocument13 pagesComposite Repair PDFNarendra PalandeNo ratings yet

- INTERCOMP Pt300 Users Manual Rev GDocument44 pagesINTERCOMP Pt300 Users Manual Rev GCTN2010No ratings yet

- Civil 3 8sem PDFDocument43 pagesCivil 3 8sem PDFG0utham100% (1)

- Partlist Smsport 110RDocument74 pagesPartlist Smsport 110RThai YunNo ratings yet

- Node diagnostics report for RBS6601WDocument9 pagesNode diagnostics report for RBS6601WWilson DiazNo ratings yet

- BPCL Kochi Refinery MS BLOCK PROJECT Piping Material SpecificationDocument1 pageBPCL Kochi Refinery MS BLOCK PROJECT Piping Material SpecificationDeepak DayalNo ratings yet

- SW-TS40T Sub-Miniature Toggle SwitchesDocument4 pagesSW-TS40T Sub-Miniature Toggle SwitchesVALTERNo ratings yet

- CV Enric Durany enDocument2 pagesCV Enric Durany enenricduranyNo ratings yet

- 1 s2.0 S0038080612000790 Main PDFDocument16 pages1 s2.0 S0038080612000790 Main PDFJuanSebastianGamezNo ratings yet

- XHLE Long Coupled Centrifugal Pump EnglishDocument8 pagesXHLE Long Coupled Centrifugal Pump Englishgagi1994brahimNo ratings yet

- V8fr-Ii V8r7-IiDocument1 pageV8fr-Ii V8r7-Iiaeroseb1No ratings yet

- ReleDocument3 pagesRelevitor4santos_6No ratings yet

- CUCM Intracluster Port Usage GuideDocument3 pagesCUCM Intracluster Port Usage GuideAbhinayMylavarapuNo ratings yet

- Hard Disk DriveDocument4 pagesHard Disk DriveAbhishek AbhiNo ratings yet

- How To Install GmtsarDocument24 pagesHow To Install GmtsardedetmixNo ratings yet

- Motion ReportDocument2 pagesMotion Reportmikeb-erau100% (2)

- Quotation 615-4078 BabulalDocument14 pagesQuotation 615-4078 Babulaldevrajan631No ratings yet

- The Tallest Buildings in The WorldDocument2 pagesThe Tallest Buildings in The WorldW4G8989No ratings yet

- Ceramic Terminal BlocksDocument1 pageCeramic Terminal BlockselijbbNo ratings yet