Professional Documents

Culture Documents

Process Guidelines for Cement Production Optimization

Uploaded by

MKPashaPasha100%(4)100% found this document useful (4 votes)

2K views20 pagesProcess Guidlines

Original Title

Process Guidlines

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentProcess Guidlines

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

100%(4)100% found this document useful (4 votes)

2K views20 pagesProcess Guidelines for Cement Production Optimization

Uploaded by

MKPashaPashaProcess Guidlines

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 20

Direction des Performances Cimenti res

Process Group Leaders Network

Process Guidelines V3

October 2005

Click to access the page

- Read me - ReadMe

Raw milling Raw milling

Preheater Preheater

Kiln Kiln

Cooler Cooler

Kiln and Cooler Filter Kiln and Cooler Filter

Kiln by-pass system Kiln By-pass system

Gas analyser Gas analyser

Coal mill Coal mill

Cement grinding Cement Gr

Weighing-dosing Weighing-dosing

05 10 05

Process guidelines - Contents -

Back to table of contents

Process Guidelines V3 - October 2005

Best practice /

recommendation

To be written

Specifications These are the figures we give to suppliers in the tender ; this column should contain the same

figures as other documents.

Alternatives In this column we describe alternatives, which could be accepted for cost reason, but also are

necessary for process reasons. Example would be cement mill specification is vertical mill,

Alternative is ball mill and in case of a existing ball mill a roller press

Operating target Operating target is the range where we want to have an equipment operated; this is not to be

given to suppliers, but we will check offers accordingly. Important value for process evaluation of

existing equipment or to calculate operation cost.

Not advisable These are choices we dont accept. Important if suppliers send alternatives on their own

Comments

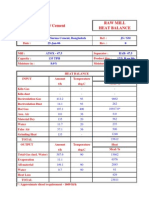

Raw milling

Best Practice /

Recommendation

Specifications Alternatives Operating target Not advisable Comments

Back to table of contents

CHOICE OF MILL SYSTEM

Vertical Mill with cyclone and

fan with VFD

Vertical Mill with cyclone and

fan with VFD

2 compartments closed circuit

tube mills with drying

chambers (if moisture < 7-8%)

or

Tube mills in combination with

heated hammer crushers.

High efficiency separator

or

Roller Press with Ball Mill

Tube mills without drying

chamber, or without external

drying.

Autogenous Mills (only in case

of specific applications).

Roll Press in circuit with V or

VSK separator and/or dynamic

separator.

Pregrinding circuit with two-

compartments ball mill.

Air Swept mill

Central discharge mill

Modification of existing

grinding shop

Closed circuit mill

High efficiency separator

Closed circuit mill

High efficiency separator

Roll Press in circuit with V or

VSK separator and/or dynamic

separator.

Pregrinding with two-

compartments ball mill circuit.

Modification of 1st generation

separator

Addition of external drying

drum

New Equipment Ball Mill with drying chamber

Mill Circuit Closed circuit Partial feed to the separator Open circuit

Ball mill speed 75% critical speed 75 % critical speed <73% or >78% critical speed

Ventilation ball mill

Air velocity above ball

charge=1,5 to 2,2 m/s

inside the trunion: 22-25 m/s

inside partition:8-14 m/s

0,6 - 0,8 Nm3/kg raw mix

hood < 5m/s

drop out box < 2m/s

VFD fan

Air velocity above ball

charge=1,5 to 2,2 m/s

VFD fan

Mill L/D ratio

1,5 < L/D < 3,2

First compartment length = 35 -

45% of mill total length

Process guidelines - Raw Milling - Page 1 / 3 06/10/2005 - 10:58

Raw milling

Best Practice /

Recommendation

Specifications Alternatives Operating target Not advisable Comments

Back to table of contents

Ball mill Liners

Moderate lifting liners for first

compartment, classifying liners

for second compartment

Classifying liners in second

compartment

Duo lift

Ripple liners

Without classifying liners keep

a maximum of 3 - 4 ball sizes

Intermediate Partition wall

Central opening adapted to

the filling degree. Slots placed

concentricly. - 8 to 12 mm slot

for central partition.

- open area > 50 % by central

opening

Diaphragms with material flow

control

Slots placed radially.

Outlet partition wall

Central opening adapted to

the filling degree. Slots placed

concentricly. Partition wall slot

size + 2mm (max slot = 0,5

min ball size)

Slots placed radially.

Ball charge

Volume Loading:

- for minimum kWh/t: 26-28%

in C1 and 28-30% in C2

- for max output: 32-34% in

C1 and 34-36% in C2

Separator Third Generation High

Efficiency

Dust load < 1kg/m3

Qf/Qa < 2.5

1st or 2nd generation

separators

Control

Fresh feed control to assure

constant feed to the separator.

Mill controled by LUCIE.

Weighing rejects (belt

weigher), measuring elevator

power, mill presure loss, mill

outlet temperature and

electronic ear.

Control mill fresh feed using

only one parameter (only

rejects flowrate or only

elevator power , for example)

Fresh feed control can be done

by different ways, using

different instruments or signals

(rejects flowrate, elevator

power, eletr. Ear, mill kW). It is

recommended to use them in

conjunction.

Feed

Feed size 95%< 50 mm

d80 feed < 20mm,

Precrushing, screening,

external drying

The finer, the better

Drying compartment Moisture inlet C1 < 1.5%

Specific drying capacity

<300kg/m3

Process guidelines - Raw Milling - Page 2 / 3 06/10/2005 - 10:58

Raw milling

Best Practice /

Recommendation

Specifications Alternatives Operating target Not advisable Comments

Back to table of contents

Equipment VRM

Vertical Roller Mill Recirculation of gas to the mill.

Metal detector and extractor in

the feeding line (after reject's

return)

Gas flow measurement after

cyclone or filter

Water injection system

Central mill feed.

HE Separator

Material External Recirculation

System >30% Fresh Feed

Capacity Fan

with VFD

Bed depth sensor

Metal detector and extractor in

the feeding line (after reject's

return)

Bed depth sensor

Water injection max 25 kg/t

Material External Recirculation

System >30% Fresh Feed

Capacity

Fan with VFD

Water injection facilities in the

mill housing

Gas speeds:

Nozzle ring >30 m/s

Mill Body: 5 - 7 m/s

Separator: 3 - 5 m/s

Dust Load: 600 g/m3 at mill

outlet

Feed device with triple flap

gate or rotary air lock valve,

heated if wet or sticky raw

materials.

Fan max speed typical 700 rpm

and >80% efficiency

Control Constant mill exit T

Constant mill gas flow

Mill feed a to mill deltaP

Process guidelines - Raw Milling - Page 3 / 3 06/10/2005 - 10:58

Preheater

Best practice /

Recommendation

Specifications Alternatives Operating target Not advisable Comments

Back to table of contents

Equipment

Cyclones

5 Stage Preheater - low

moisture < 5% raw materials

Low pressure drop

Bottom of cyclone

> 50 height

No horizonatal inlet ; no

horizontal surface

4 Stage Preheater - high

moisture >5% raw materials

For a 5 stage PH, 4.5 to 5.5

kPa (including kiln)

See priority study Preheater

Dip Tube Length relative to

cyclone inlet height

Top (stage 1): 100%

Stage 2/3: 75%min

Stage 4/5 : 50%min

Top (stage 1): 100%

Hurrivanes - depending on

geometry

Number in % of inlet height

Splash box

Lafarge design

cleaning devices. At least 55

to 80 between meal pipe and

splash box

2 m from flap, pipe without

elbow

60 for kiln feed to splash box.

>60

o

below C3 Splash plates See priority study Preheater

Pendulum flap External knife bearing

Precalciner

Vessel + Hot core preferred

Residence time > 6 sec

for petcoke, Low-Nox

Residence time > 6 sec Riser Duct plus hot core

Very specific to fuel and plant

conditions

Tertiary air duct

Downward split design

for in-line calciner

Damper control

Duct velocity 20 to 30 m/s

Process

Gas duct velocity at meal

entrance

Mini 12 m/s top stage

with 17 m/s bottom

(intermediate proportional)

Can install restriction

as alternative

Riser velocity 16 m/s minimum

Process guidelines - Preheater - Page 1 / 2 06/10/2005 - 10:58

Preheater

Best practice /

Recommendation

Specifications Alternatives Operating target Not advisable Comments

Back to table of contents

Cyclones Top cyclone efficiency > 95% Top cyclone efficiency > 95%

Meal curtain

Considered if high volatile

cycles expected

Most common on N-1 stage

on kiln side

Lateral

Consider a splitter

Kiln inlet box

No dead zone

Smooth design (entrance in the

middle)

No turbulances

45- 50 slope of inlet

Downcomer

Cooling by water sprays

Minimum evaporation: 4 sec

(for target at 185C)

No bleed air is recommended,

except for start up

Water design target able to

provide 185 C. Take care

about moisture in gas to coal

mill take off above water

injection

ID fan preheater

VFD drive

Fresh air intake before

the fan (fan protection)

Fan Typical Max speed 990

rpm and efficiency >80%.

Design margin 5% volume and

1 kPa pressure

number of fans

3

ID fan, raw mill fan &

baghouse fan

Only 2 fans

Secondary Fuel

usage

Burner preferred for Calciner

Process guidelines - Preheater - Page 2 / 2 06/10/2005 - 10:58

Kiln

Best Practice /

Recommendation

Specifications Alternatives Operating target Not advisable Comments

Back to table of contents

Equipment

Burner type and position Lafarge Burner

MAS burner in case of regular

solid fuel and alternative fuel ;

Position in center line of kiln

and aligned on kiln axis (only

if kiln is stable and burner

having sufficient impulse)

See Lafarge Burner Design

Spreadsheet

Fuel speed

Solid Fuel: 25 - 35 m/s in

burner ; >25m/s in conveying

line

Solid Fuel: 25 - 35 m/s in

burner ; >25m/s in conveying

line

Alternative Fuel: 25 - 40 m/s

in burner ; >25m/s in

conveying line

Total primary air <12% with coal / petcoke

< 15% primary air (as low as

possible when firing

alternative fuels)

Liquid (main fuel) > 25 cSt

Swirl Design: 0,15

Impulse Design: >2,2

Final design criteria to be

worked out.

Retaining rings

0,6 to 1 m from nosering as

single ring, triangulkar shape

Double flat bar

Maggoteaux system

Kiln slope 3 - 3,5 % 4%

L/D

>10,5 for preca (> 15 is

required when designing for

alternaitve fuels)

> 15 for preheater

Tertiary air

From kiln hood

Take off velocity 5-6 m/s

throat and tertiary air and 25

m/s in the duct

From kiln hood

Take off velocity 5-6 m/s

throat and tertiary air and 25

m/s in the duct

Settling chamber Heat shield IKN not proven

Shell cooling fans 12 to 18 m/s at shell Supplied

Fan should be below kiln so

that air flow comes up on

both sides.

Process guidelines - Kiln - Page 1 / 2 06/10/2005 - 10:58

Kiln

Best Practice /

Recommendation

Specifications Alternatives Operating target Not advisable Comments

Back to table of contents

Process

Thermal load

< 5 MW/m (kiln cross

section)

< 5 MW/m < 6.5 MW/m

Limit for refractory.

Some wet and big kilns can

overpass the limit

Kiln hood velocity < 6 m/s

Kiln load <4,5 t/d/m

Production 24 m/s hearth velocity pc kiln <28 m/s

Clinker bypass

With > 0,025% of Cl input

(related to clinker) consider a

bypass

Clinker storage

For off specification clinker, 8

hour separate storage

considered

Process guidelines - Kiln - Page 2 / 2 06/10/2005 - 10:58

Cooler

Best practice /

Recommendation

Specifications Alternatives Operating target Not advisable Comments

Back to table of contents

Equipment

Equipment Selection Cross Bar or Walking Floor

Design

Cross Bar or Walking Floor

Design

Grate load < 45 t/m d < 45 t/m d

Variable speed fans All on 1st grate Variable speed on all on 1st

grate fans. 2nd grate fans can

be with variable inlet vanes

dampers

Fan dampers (inlet radial) Flap max speed typical 1500 rpm,

Efficiency > 80%. Normally 20-

30% pressure reserve.

Fix inlet rows 5 to 8 (1.5 - 2.5 m)

Max 15 degree angle

Refractory Horseshoe

Air Cannons

Crusher Roller crusher intermediate

or at the end

Hammer

Crusher

Hammer crusher can be the

first choice if no need for very

effective cooling

Grate slope 0 3 maximum

Evacuation hoppers Simple gate and sensor level Double gate mechanically

activated

Process

Air flow design Not < 2,1 Nm3/kg > 2.1 Nm/kg ck

> 1.7 Nm/m/s on first fans, 2

Nm/m/s for KIDS

First fans pressure > 10 kPa (100 mbar) for KIDS

Optimal bed depth Lowest stroke permitted with

20% reserve on fans

(6-8 st/min for properly

designed cooler)

Air velocity above clinker 5 to 7 m/s

Clinker transport design Min. 1,5 x nominal capacity

steel conveyor

Min. 1,5 x nominal capacity

steel conveyor

Process guidelines - Cooler - Page 1 / 1 06/10/2005 - 10:59

Kiln filter

Best practice /

Recommendation

Specifications Alternatives Operating target Not advisable Comments

Back to table of contents

Equipment

Equipment Selection

Low Pressure Pulse Jet Bag

Filter ( 2,5 bars)

Low Pressure Pulse Jet (LPPJ)

Bag Filter ( 2,5 bars)

High Pressure Pulse Jet (HPPJ)

Bag Filter (6bar/100psi),

Electrostatic precipitator

Max dP< allowed by fan

capacity at end of bag life.

Limit cleaning cycles to obtain

target bag life.

Off line cleaning is not

acceptable due to the

potential damage to the bags.

BH sizing must maintain

operating pressure drop within

the limits of the ID fan and the

pulse jet filter ability to clean

bag on line.

Equipment Sizing

Gross Air to clothe ratio:

1m/min average

1.3 m/min max (upset cond)

Gross Air to clothe ratio:

1m/min average

1.3 m/min max (upset cond)

Bag quality

Fabric with PTFE membrane

and fiberglass structure.

Known suppliers: Gore, BHA,

Tetratec working

at 180C- 230C max

Design temperature 230C

Peak temperature 260C

P84 bags of suitable

construction.

Adequate temperature control

to prevent teflon and SGT

evaporation and bag damage.

working at 180C- 230C max

Other bag materials that are

not proven.

If using P84 verify the risk of

hydrolysis.

Bag quality and workmanship

are critical. Bag to cage fit is

critical.

Airflow Distribution

Scale model to ensure good

airflow distribution and correct

fan sizing before purchase

Compressed Air Supply

Air coolers can be acceptable

for LPPJ.

Use air dryers (dessicant) for

HPPJ (-30deg C due point).

Prevent moisture condensation

in the bag during the

compressed air pulse.

No oil in cleaning air.

Exhaust Fan VFD VFD

Fan Typical Max speed 990

rpm and efficiency >80%.

Design margin 15% volume

False Air

Direct < 30% Preheater Gases

Compound < 50% Preheater

Gases

Process guidelines - Kiln and Cooler Filter - Page 1 / 2 06/10/2005 - 12:08

Kiln filter

Best practice /

Recommendation

Specifications Alternatives Operating target Not advisable Comments

Back to table of contents

COOLER FILTER

Equipment Selection

Air to air heat exchanger to

get 130C at exit

Air to air heat exchanger to

get 130C at exit

Common baghouse for

RM/kiln and cooler

ESP when all cooler gas used

for raw materials drying

Exhaust system capacity to

handle normal operation and

to provide sufficient capacity

for push conditions for the full

length of the bag life.

Gas flow in BH hopper must

not cause abrasion of filter

bags due ro high velocities.

Exhaust gas flow from the

cooler straight entry and

oriented downwards through

heat exchanger

Gas velocity at heat

exchanger's inlet in normal

conditions: <10 m/s

Water injection in the exhaust

pipe

Cooling fan are VFD speed

Exhaust Fan VFD VFD

Fan Typical Max speed 990

rpm and efficiency >80%.

Design Margin 15% volume

System Sizing

Design upset conditions 450 C

exhaust gas temp. Design

flow 1.7 nm3/kg clinker

Design upset conditions 450 C

exhaust gas temp. Design

flow 1.7 nm3/kg clinker

Process guidelines - Kiln and Cooler Filter - Page 2 / 2 06/10/2005 - 12:08

Kiln By-pass system

Best practice /

Recommendation

Specifications Alternatives Operating target Not advisable Comments

Back to table of contents

Equipment

Dedusting Bag filters (240C) ESP

Wet scrubber may be a

solution when cement Cl is a

limitation

Dust transport

As short as possible

Mechanical

Air transport if Cl < 10%

Storage

As small as possible,

with mechanical extraction

Direct dust addition to cooler

filter or heat exchanger

intermediate storage

Addition to cooler only if

clinker storage does not

promote segregation (quality -

dust separation in pile)

Process

Location take-off

On top of the smoke box, on

the kiln side

Distant from C3 discharge to

avoid dust mixing

Level of chlorine in dust

Dilution with kiln feed if >

10% Cl

Cl control using cyclone system

with bypass (Taiheyo)

Quenching

Air quenching as close as

possible to the take out, either

directly to 200C or at least to

400C

Air to air cooler as second

cooling step to minimize the

gas quantity

Exhaust air

To cooler fans to avoid

SO2/Dioxins

Raw mill or main stack if SO2 is

acceptable, dioxins still a

threat. Detached plume also a

potential issue if organics in

raw mix

Separate stack

Dust management

Cement (limiting factor forCl

as allowed by local standard)

Clinker (limiting factor for Cl)

Dust Washing with heavy

metal recovery, for low limit of

Cl in cement

Dust wasting

Target level of chlorine in kiln

back-end mat

1,00%

Higher concentration

acceptable if possible for build-

ups

Process guidelines - Kiln By-pass system - Page 1 / 1 06/10/2005 - 10:59

Gas analyser

Best practice /

Recommendation

Specifications Alternatives Operating target Not advisable Comments

Back to table of contents

Kiln inlet

Kiln inlet

Probe

Probe long enough to enter

the kiln, retractable,

motorised

Dry probe required

Water cooled jacket

Same probe for all gases

Back flush (clean, dry air)

Oil cooled

In-situ

CO

Mandatory

Type: IR

Scale: 0-20000 ppm

NOx

Mandatory

Type IR

No NO2 converter needed

Scale: 0-20000 ppm

O2

Mandatory

Type: Paramagnetic

0-10%

SO2

Required if Total SO3 input >

1.2% on clinker basis or

S/A ratio > 1.2

Type UV

Quartz cells

0-20000ppm

IR (on separated line)

Gas treatment

Heated line (>180C)

2 cooler dryer 1 for SO2 and 1

for other gases

For other gases H2O2 injection

Suspension preheater kiln - no PC

Exit of preheater tower Mandatory for O2 and CO

Exit of Precalciner

Precalciner

Probe

Probe at Bottom cyclone exit

retractable,

Dry probe required

Water cooled jacket

Same probe for all gases

Back flush (clean, dry air)

Process guidelines - Gas analyser - Page 1 / 2 06/10/2005 - 11:02

Gas analyser

Best practice /

Recommendation

Specifications Alternatives Operating target Not advisable Comments

Back to table of contents

CO

Mandatory

Type: IR

Scale: 0-20000 ppm

NOx

Mandatory

Type IR

No NO2 converter needed

Scale: 0-20000 ppm

O2

Mandatory

Type: Paramagnetic

0-10%

Gas treatment

Heated line (>180C)

2 cooler dryer 1 for SO2 and 1

for other gases

For other gases H2O2 injection

3 other in line O2 last

CEM (stack)

Location Follow local regulation

Dust Scattered light system

O2

In-situ system (Zircon)

0-10%

H2O

Optical in-situ system IR

0-10%

CO

Optical in-situ system IR

0-2000 mg/Nm3

Extractive with heated probe

and line (>180C) + FTIR

NOx

Optical in-situ system-UV

0-2000 mg/Nm3

Extractive with heated probe

and line (>180C) + FTIR

SO2

Optical in-situ system-UV

0-500 mg/Nm3

Extractive with heated probe

and line (>180C) + FTIR

HCl

Optical in-situ system-IR

0-100mg/Nm3

Extractive with heated probe

and line (>180C) + FTIR

COV

Extractive FID

0-200mg/Nm3

CO Protection with ESP

Precalciner Kiln

Use precalciner exit CO with

preheater exit CO as back up

Suspension preheater kiln

Use kiln exit CO with

preheater exit CO as back up

Process guidelines - Gas analyser - Page 2 / 2 06/10/2005 - 11:02

Coal Mill

Best practice /

Recommendation

Specifications Alternatives Operating target Not advisable Comments

Back to table of contents

Equipment

Equipment Selection Vertical mill Vertical mill

Ball mill ,

Ring roller mills

Pendulum mills

Central discharge mills

"deep bowl" mills

Ball mills are better suited for

very hard fuels and certain

cokes. Also need to consider

turndown ratios if AF is

significant - need VFD or

something appropriate.

Process Gas

Hot gas from pre heater with

de dusting

Hot gas from pre heater with

de dusting

Direct or semi direct firing

Sensors

CO analysers:

- Raw Coal Bin

- Mill Filter Exit

- Each Pulverised Fuel Bin

O2 analysers:

- Preheater Exit

- Before Mill

- Mill Filter Exit

Temperature sensors

- Raw coal hopper/silo

- Before mill

- After mill

- Hot gas duct

- Filter bottom

- Coal dust after filter

- PF silo bottom ( In banks of

four around cone)

- Differential temperature

across filter

Differential temperature across

separator for ball mill

Load Cells

- Raw Coal Bin

- Pulverised Coal Bins

Pressure indication

- Before mill

- After mill

- Mill differential pressure

- Filter differential pressure

Dust monitor

- Coal bag filter main stack

Process guidelines - Coal mill - Page 1 / 2 06/10/2005 - 11:00

Coal Mill

Best practice /

Recommendation

Specifications Alternatives Operating target Not advisable Comments

Back to table of contents

Safety for mill and feeding

system

See Safety Equipment in Model

Plant

See Safety Equipment in Model

Plant

Study fuel - need to have

temperature limit at mill inlet

and mill outlet appropriate for

fuel. Favor high gas volume so

it can be run cooler. High

volatile O2<12%. Moderate

volatile 21% O2 is OK if

temperature < 70C

Pet coke grinding

Install a dynamic 3rd

generation separator

According to Combustion BP

the fineness should be less 0.1

% rejects on 200

Open circuit

See Combustion manual for

fineness vs. volatile

Fire suppression system Bulk system C0

2

2Kg/m

3

of volume of the

system coal mill, filter, silos and

ducts and enough for 2

complete discharges (X3 for

remote locations)

Bottle CO

2

systems can be

considered if local conditions

or regulations do not allow

bulk or if delivery time is

excessive.

Process guidelines - Coal mill - Page 2 / 2 06/10/2005 - 11:00

Cement Grinding

Best practice /

Recommendation

Specifications Alternatives Operating target Not advisable Comments

Back to table of contents

Equipment

Equipment Selection Vertical Mill Vertical Mill

Roller Press

Pregrinding circuit with two-

compartment ball mill

circuit.CKP with 2

compartment mill,

Ball mill

Ring roller mills,

central discharge mills

Ball Mill Circuit

Closed circuit mill with

separate filter for mill

ventilation and separator

Ball mill

Single compartment with

lifting and classifying liners*

2,8 < L / D <3,2

* 27% <Length first

Compartment< 35% mill

effective length.

1st comp: 8 - 10 kWh/t

Ball mill speed 75% of the critical speed 75% of the critical speed <73% Critical speed >78%

Separator

3rd generation high efficiency

separators,

de dusting by filters

Basket variable tip speed

10 to 30 m/s,

radial process air velocity 3 to

5 m/s,

Static separator for pregrinding

circuits,

fines to separator

1st generation separators, De

dusting by cyclones

By-pass 5 to 10 %

Imperfection < 0.30

Acuity <= 15 m

Rosin Rammler specification

value to be provided

Ventilation ball mill

Air velocity above ball

charge:1.4 - 2.2 m/s

Inside the trunion: < 22m/s

Inside partition:<12m/s

VFD fan

>1.5% moisture at mill

inlet(Pozzolanic materials

should be dried before

feeding)

Static separators for separation

of mill dust to final product for

open circuit mills and mills

with old dynamic separators

Process guidelines - Cement grinding - Page 1 / 2 06/10/2005 - 11:28

Cement Grinding

Best practice /

Recommendation

Specifications Alternatives Operating target Not advisable Comments

Back to table of contents

Ventilation separator

Separator Qf/Qa:1.8 kg/m,

VFD fan for HES,

The circulating load 200%

Separator Qf/Qa:1.8 kg/m,

VFD fan for HES,

The circulating load 200%

Separator Qf/Qa range: 1.8-

2.5 kg/m3(200% C.L), Cement

temp 90-110 deg ,

VFD for fan

Final product load<0,8 kg/m3

Ball mill internals

Reverse step liners for first

compartment, classifying liners

for second compartment

Reverse step liners in first

compartment with lifting ht

range: 70-75mm. Classifying

liners in second compartment

Duo lift

Ripple liners

Intermediate Partition wall

central opening adapted to the

filling degree

*Material transport capacity

500t/m2/h

* 6 to 8 mm slot

* Central screen open area 60

% minimum

*Provision of Flow control

gates to regulate material

flow

Single plate, slots

on reverse side of diaphragm

liners

Outlet partition wall

central opening adapted to the

filling degree

*Material transport capacity

500t/m2/h

Intermediate partition wall slot

size+2mm,

Ball charge

Nominal ball charge loading

28-30% for both

compartments,

(installed power on 32%

filling)

>32% ball charge

Higher filling causes higher

specific energy, problems for

cooling. Ball charge with

pregrinder needs to be

modified

Process

Control

Pre requisites for Lucie - Fresh

feed variation through

weighing of separator rejects,

feed accuracy with in +/- 1%,

electronic ear to detect filling

of first compartment.

Belt weigher for rejects

Elevator power

Feed

Feed size passing on

100% <30mm,

95% < 25mm

Precrushing, drying of wet

additives

Temperature control

Cement temp range:

90-110 deg C

Cement cooler

Water injection from partition

wall if required

Process guidelines - Cement grinding - Page 2 / 2 06/10/2005 - 11:28

Weighing Dosing

Best Practice /

Recommendation

Specifications Alternatives Operating target Not advisable Comments

Back to table of contents

Pulverised Coal

Equipment Selection

Small bins close to the burning

point <50 m

on cells for calibration

Schenck Coriolis,

Variation < 0,5 % (short term)

Small bins close to the burning

point <50 m

on cells for calibration

Schenck Coriolis,

Variation < 0,5 % (short term)

Pfister

New systems of Pfister and

Coriolis > 50 m

Old Pfister > 40 m. Actual limit

is back pressure. Long distance

means more backpressure but

can be compensated for by

proper design. Schenk Star

feeder with high pressure

transport line not

recommended (low tolerance).

Schenk Coriolis + Bremer

Screw + FK pump for long

distance is very good.

Velocity

Minimum number of elbows

velocity >= 25 m/s

Minimum number of elbows

velocity >= 25 m/s

Solid concentration 4-6 kg/nm3 4-6 kg/nm3 > 7 kg/nm3

Raw meal

Equipment Schenk Coriolis

Pfister

Weigh Feeder

Both still recommend level bin

ahead of scale to minimize silo

flushes. Using airlift pressure to

calculate flow can be

sufficiently accurate.

Effective weighing Variation < 0,5 % (short term) Variation < 0,5 % (short term) Accuracy < 0,5 % (short term)

Transport Elevator Elevator Air-lift

Process guidelines - Weighing-dosing - Page 1 / 1 06/10/2005 - 11:05

You might also like

- Creating A BudgetDocument131 pagesCreating A BudgetMKPashaPashaNo ratings yet

- Tyron Butson (Order #37627400)Document74 pagesTyron Butson (Order #37627400)tyron100% (2)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Summerized Form of Budget - PO WISEDocument6 pagesSummerized Form of Budget - PO WISEMKPashaPashaNo ratings yet

- Geneva IntrotoBankDebt172Document66 pagesGeneva IntrotoBankDebt172satishlad1288No ratings yet

- CEMENT PROCESS ENGINEERING VADE-MECUM SECTION 7 - NOX, SOX, DUST, CO2 EMISSION GUIDEDocument14 pagesCEMENT PROCESS ENGINEERING VADE-MECUM SECTION 7 - NOX, SOX, DUST, CO2 EMISSION GUIDEMKPashaPashaNo ratings yet

- Blaine Vs ResiduesDocument3 pagesBlaine Vs ResiduesVisnu Sankar100% (2)

- Kiln Operator Emergency GuideDocument12 pagesKiln Operator Emergency GuideLe HoangNo ratings yet

- 04.04 Kiln Operations Guide Lines - ENGDocument23 pages04.04 Kiln Operations Guide Lines - ENGbrenbra50% (2)

- R A R F U: % Passing Size, M Feed Coarse FinesDocument3 pagesR A R F U: % Passing Size, M Feed Coarse FinesAli HüthütNo ratings yet

- (1.3) - Pyro Process Theory & Kiln System DesignDocument63 pages(1.3) - Pyro Process Theory & Kiln System DesignMuhammed Emami100% (1)

- Kiln Control and Operation - Infinity For Cement EquipmentDocument74 pagesKiln Control and Operation - Infinity For Cement EquipmentRizwanKhanNo ratings yet

- Chuong 2-Roller MillDocument24 pagesChuong 2-Roller MillAmit Sharma0% (1)

- Flow MeasurementsDocument19 pagesFlow MeasurementsHazem DiabNo ratings yet

- Pyro ProcessingDocument29 pagesPyro ProcessingMKPashaPasha100% (2)

- Vertical Roller Mill Process DetailsDocument49 pagesVertical Roller Mill Process Detailsrecai100% (3)

- Cement Ball-Mill-Heat-BalanceDocument3 pagesCement Ball-Mill-Heat-Balanceanurag soni100% (1)

- Report On Cement MillDocument9 pagesReport On Cement MillYounas Khan100% (1)

- A Raw Mill Nozzle Ring Area Velocity Calculation: 1/2 (A+B) C BDocument4 pagesA Raw Mill Nozzle Ring Area Velocity Calculation: 1/2 (A+B) C BYhaneNo ratings yet

- False Air - Measuerment OverviewDocument11 pagesFalse Air - Measuerment OverviewVijay BhanNo ratings yet

- Finish Grinding by Roller PressDocument3 pagesFinish Grinding by Roller PressManish Verma100% (3)

- Clinker Cooler SystemDocument69 pagesClinker Cooler SystemzementheadNo ratings yet

- VRM Heat and Mass BalanceDocument1 pageVRM Heat and Mass BalanceRajeshRockNo ratings yet

- Lucky Cement Raw Mill Budget vs Actual July-August 2012Document1 pageLucky Cement Raw Mill Budget vs Actual July-August 2012MKPashaPashaNo ratings yet

- Entrepreneurship WholeDocument20 pagesEntrepreneurship WholeKrizztian SiuaganNo ratings yet

- Pillard Burners and FlamesDocument21 pagesPillard Burners and FlamesIrshad HussainNo ratings yet

- Separator Efficiency CalculationsDocument13 pagesSeparator Efficiency Calculationstricky7770% (1)

- By-Pass Calculation Method - DocbDocument2 pagesBy-Pass Calculation Method - DocbElwathig BakhietNo ratings yet

- Roller Press Classifier Circulation FactorDocument9 pagesRoller Press Classifier Circulation Factorshahid2995100% (1)

- Brown ClinkerDocument21 pagesBrown ClinkerTamer Fathy0% (1)

- Flame For Cement Kilns KP Pradeep KumarDocument62 pagesFlame For Cement Kilns KP Pradeep KumarHuyentrang Nguyen100% (1)

- Cement Kilns-Chlorine Impact On ProcessDocument27 pagesCement Kilns-Chlorine Impact On Processmuhaisen2009100% (4)

- Filtration: Fiber FilterDocument20 pagesFiltration: Fiber FilterTamer Farouk KhalifaNo ratings yet

- 117 - DWP Difficult Solid Fuel Burning 191207 - RDB&YJBDocument10 pages117 - DWP Difficult Solid Fuel Burning 191207 - RDB&YJBMKPashaPashaNo ratings yet

- Snowman CompositionDocument7 pagesSnowman CompositionSunil MohanNo ratings yet

- Coolers SystemDocument69 pagesCoolers SystemM.IBRAHEEM100% (1)

- Complaint Handling Policy and ProceduresDocument2 pagesComplaint Handling Policy and Proceduresjyoti singhNo ratings yet

- Loesche Seminar VCM Study Dec03Document132 pagesLoesche Seminar VCM Study Dec03stelios nikoladosNo ratings yet

- 07 VRM PregrinderDocument22 pages07 VRM PregrinderVishnu Vardhan . C100% (9)

- Cooler Design and Operation CriteriaDocument19 pagesCooler Design and Operation Criteriatricky777100% (1)

- 081 - TSP HUA400 20080305 Kiln Audit Dec07Document30 pages081 - TSP HUA400 20080305 Kiln Audit Dec07mkpq100% (2)

- Kiln AuditDocument13 pagesKiln AuditAdnan Nawaz100% (2)

- Raw Mill Heat BalanceDocument1 pageRaw Mill Heat BalanceElwathig Bakhiet100% (1)

- Course 3 - Clinker Production: 3.4 CalcinerDocument28 pagesCourse 3 - Clinker Production: 3.4 CalcinerAndreea Ștefura100% (1)

- Alk-SO3-Cl Balance - v2.1Document4 pagesAlk-SO3-Cl Balance - v2.1shani5573100% (4)

- What Is A Process ControlDocument17 pagesWhat Is A Process ControlpashaNo ratings yet

- Doc VRM Measurements BATDocument15 pagesDoc VRM Measurements BATsaji kumarNo ratings yet

- How To Line The Burner Pipe PDFDocument19 pagesHow To Line The Burner Pipe PDFMustafa Ramadan100% (2)

- Granulometry of ClinkerDocument18 pagesGranulometry of ClinkerNael100% (12)

- Manufacturing Workforce Training - Optimized Kiln Control GuideDocument26 pagesManufacturing Workforce Training - Optimized Kiln Control GuideOUSSAMA LAKHILI100% (1)

- Optimize Vertical Roller Mills OperationsDocument4 pagesOptimize Vertical Roller Mills OperationsSai Sricharan Reddy83% (6)

- How To Align The Kiln Burner v1-1 PDFDocument2 pagesHow To Align The Kiln Burner v1-1 PDFMustafa Ramadan100% (1)

- By Pass SystemDocument56 pagesBy Pass SystemIrshad Hussain100% (2)

- VRM Operation and OptimizationDocument39 pagesVRM Operation and OptimizationJitendra Jangid100% (5)

- Clinker FormationDocument120 pagesClinker FormationDragos PlaesuNo ratings yet

- CM 2 Filling DegreeDocument9 pagesCM 2 Filling DegreeElwathig BakhietNo ratings yet

- Cement Grinding Vertical Roller Mills Versus Ball Mills 1654248086Document17 pagesCement Grinding Vertical Roller Mills Versus Ball Mills 1654248086Salah Romdani100% (1)

- Vertical Roller Mill Operation and OptimizationDocument49 pagesVertical Roller Mill Operation and OptimizationMKPashaPasha100% (4)

- Rotaflam PillardDocument34 pagesRotaflam PillardRogério CorreiaNo ratings yet

- CM2 Process Media Mix Up 2014 2015Document31 pagesCM2 Process Media Mix Up 2014 2015Junaid MazharNo ratings yet

- Increasing cement grinding capacity with vertical roller mill technologyDocument7 pagesIncreasing cement grinding capacity with vertical roller mill technologymahreza189100% (2)

- Group 4 HR201 Last Case StudyDocument3 pagesGroup 4 HR201 Last Case StudyMatt Tejada100% (2)

- Alkali - Chlorine - Sulfur - Balance: Preheater / PC KilnDocument4 pagesAlkali - Chlorine - Sulfur - Balance: Preheater / PC KilnBùi Hắc Hải100% (1)

- Duoflex BurnerDocument6 pagesDuoflex Burnersinghite100% (1)

- Kiln Cooler Heat Mass BalanceDocument84 pagesKiln Cooler Heat Mass BalancePrabhakar Reddy PeramNo ratings yet

- S. Description Symbol Unit No.: F.L. Smidth's ATOX Vertical Roller MillDocument2 pagesS. Description Symbol Unit No.: F.L. Smidth's ATOX Vertical Roller Millvvijaybhan0% (1)

- Mechanism of Clinker Coating Formation & FlameDocument39 pagesMechanism of Clinker Coating Formation & FlameNael93% (14)

- PREHEATER BLOCKAGES Problem Diagnosis and Solution - INFINITY FOR CEMENT EQUIPMENTDocument19 pagesPREHEATER BLOCKAGES Problem Diagnosis and Solution - INFINITY FOR CEMENT EQUIPMENTali100% (2)

- How To Control The Hot MealDocument4 pagesHow To Control The Hot MealGiequat100% (2)

- Rotary Kilns: Transport Phenomena and Transport ProcessesFrom EverandRotary Kilns: Transport Phenomena and Transport ProcessesRating: 4.5 out of 5 stars4.5/5 (4)

- Nozzle Ring Area of Raw MillDocument6 pagesNozzle Ring Area of Raw MillThaigroup CementNo ratings yet

- Req 4 422108 0 enDocument2 pagesReq 4 422108 0 enMKPashaPashaNo ratings yet

- Mechanical Properties For Steel FastenersDocument7 pagesMechanical Properties For Steel FastenersepriyonoNo ratings yet

- AIS-Mechanical Maintenance ModuleDocument3 pagesAIS-Mechanical Maintenance ModuleMKPashaPashaNo ratings yet

- POwise Monthly Trend-812Document1 pagePOwise Monthly Trend-812MKPashaPashaNo ratings yet

- POwise Monthly Trend-153Document1 pagePOwise Monthly Trend-153MKPashaPashaNo ratings yet

- POwise Monthly Trend-812Document1 pagePOwise Monthly Trend-812MKPashaPashaNo ratings yet

- POwise Monthly Trend-405406407Document1 pagePOwise Monthly Trend-405406407MKPashaPashaNo ratings yet

- POwise Monthly Trend-405406407Document1 pagePOwise Monthly Trend-405406407MKPashaPashaNo ratings yet

- POwise Monthly Trend-102Document1 pagePOwise Monthly Trend-102MKPashaPashaNo ratings yet

- POwise Monthly Trend-205206207Document1 pagePOwise Monthly Trend-205206207MKPashaPashaNo ratings yet

- XClass - BrochureDocument25 pagesXClass - BrochureMKPashaPashaNo ratings yet

- 01 - IP SOW Template v3.0Document26 pages01 - IP SOW Template v3.0MKPashaPashaNo ratings yet

- Testing and Repairing Festo and Numatics Valve StacksDocument13 pagesTesting and Repairing Festo and Numatics Valve StacksMKPashaPashaNo ratings yet

- PDDDocument77 pagesPDDMKPashaPashaNo ratings yet

- POwise Monthly Trend-102Document1 pagePOwise Monthly Trend-102MKPashaPashaNo ratings yet

- GCCL ManualDocument26 pagesGCCL ManualMKPashaPashaNo ratings yet

- GCCL ManualDocument26 pagesGCCL ManualMKPashaPashaNo ratings yet

- Design Manual WHADocument18 pagesDesign Manual WHAMKPashaPashaNo ratings yet

- Trainer Profile Detailed Course ContentsDocument12 pagesTrainer Profile Detailed Course ContentsMKPashaPashaNo ratings yet

- The Marketing Environment and Competitor Analysis: - SWOT Analysis - PEST Analysis - Five Forces AnalysisDocument10 pagesThe Marketing Environment and Competitor Analysis: - SWOT Analysis - PEST Analysis - Five Forces AnalysisMKPashaPashaNo ratings yet

- NAC Case Study AnalysisDocument25 pagesNAC Case Study AnalysisSushma chhetriNo ratings yet

- Journal Publication FormatDocument37 pagesJournal Publication FormatAbreo Dan Vincent AlmineNo ratings yet

- ABBBADocument151 pagesABBBAJeremy MaraveNo ratings yet

- An Overview of Tensorflow + Deep learning 沒一村Document31 pagesAn Overview of Tensorflow + Deep learning 沒一村Syed AdeelNo ratings yet

- Bank Statement AnalysisDocument26 pagesBank Statement AnalysisAishwarya ManoharNo ratings yet

- Lister LRM & SRM 1-2-3 Manual and Parts List - Lister - Canal WorldDocument4 pagesLister LRM & SRM 1-2-3 Manual and Parts List - Lister - Canal Worldcountry boyNo ratings yet

- Jurisdiction On Criminal Cases and PrinciplesDocument6 pagesJurisdiction On Criminal Cases and PrinciplesJeffrey Garcia IlaganNo ratings yet

- Improvements To Increase The Efficiency of The Alphazero Algorithm: A Case Study in The Game 'Connect 4'Document9 pagesImprovements To Increase The Efficiency of The Alphazero Algorithm: A Case Study in The Game 'Connect 4'Lam Mai NgocNo ratings yet

- Advanced Real-Time Systems ARTIST Project IST-2001-34820 BMW 2004Document372 pagesAdvanced Real-Time Systems ARTIST Project IST-2001-34820 BMW 2004كورسات هندسيةNo ratings yet

- Wind EnergyDocument6 pagesWind Energyshadan ameenNo ratings yet

- Backup and Recovery ScenariosDocument8 pagesBackup and Recovery ScenariosAmit JhaNo ratings yet

- 3 Course Contents IIIBDocument5 pages3 Course Contents IIIBshahabNo ratings yet

- ITS America's 2009 Annual Meeting & Exposition: Preliminary ProgramDocument36 pagesITS America's 2009 Annual Meeting & Exposition: Preliminary ProgramITS AmericaNo ratings yet

- Installing and Registering FSUIPCDocument7 pagesInstalling and Registering FSUIPCKAPTAN XNo ratings yet

- Tokyo Disneyland ItineraryDocument8 pagesTokyo Disneyland ItineraryTayla Allyson ThomasNo ratings yet

- Mini Ice Plant Design GuideDocument4 pagesMini Ice Plant Design GuideDidy RobotIncorporatedNo ratings yet

- Philippine Architecture, Film Industry EvolutionDocument4 pagesPhilippine Architecture, Film Industry EvolutionCharly Mint Atamosa IsraelNo ratings yet

- CompactLogix 5480 Controller Sales GuideDocument2 pagesCompactLogix 5480 Controller Sales GuideMora ArthaNo ratings yet

- Database Chapter 11 MCQs and True/FalseDocument2 pagesDatabase Chapter 11 MCQs and True/FalseGauravNo ratings yet

- Case Analysis - Compania de Telefonos de ChileDocument4 pagesCase Analysis - Compania de Telefonos de ChileSubrata BasakNo ratings yet

- Diagnostic Information For Database Replay IssuesDocument10 pagesDiagnostic Information For Database Replay IssuesjjuniorlopesNo ratings yet

- Code Description DSMCDocument35 pagesCode Description DSMCAnkit BansalNo ratings yet

- The Value of Repeat Biopsy in SLEDocument8 pagesThe Value of Repeat Biopsy in SLESergio CerpaNo ratings yet

- Circular 09/2014 (ISM) : SubjectDocument7 pagesCircular 09/2014 (ISM) : SubjectDenise AhrendNo ratings yet

- Bar Exam 2016 Suggested Answers in Political LawDocument15 pagesBar Exam 2016 Suggested Answers in Political LawYlnne Cahlion KiwalanNo ratings yet