Professional Documents

Culture Documents

Aisi 200 Series

Uploaded by

sgupta_192494Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aisi 200 Series

Uploaded by

sgupta_192494Copyright:

Available Formats

AISI Type 202

Category Steel

Class Stainless steel

Type Austenitic standard

Common Names Chromium-Manganese-Nickel steel

Designations United States: ASTM A276 , ASTM A314 , ASTM A412 , ASTM A429 , ASTM A473 ,

ASTM A666 , FED QQ-S-763 , FED QQ-S-766 , FED STD-66 , SAE 30202 , SAE J405 (30202) , UNS

S20200

Composition

Element Weight %

C 0.15

Mn 7.5-10.0

Si 1.00

Cr 17.0-19.0

Ni 4.0-6.0

P 0.06

S 0.03

N 0.25

Mechanical Properties

Properties Conditions

Density (1000 kg/m3) 7.8 25

Poisson's Ratio 0.27-0.30 25

Elastic Modulus (GPa) 190-210 25

Tensile Strength (Mpa) 515 25 annealed (sheet, strip

Yield Strength (Mpa) 275

Elongation (%) 40

Reduction in Area (%)

Thermal Properties

Properties Conditions

Thermal Expansion (10-6/C) 17.5 0-100 more

Thermal Conductivity (W/m-K) 16.2 100 more

Specific Heat (J/kg-K) 500 0-100

Electric Properties

Properties Conditions

Electric Resistivity (10-9W-m) 690 25

200 Series stainless steels

Features:

~ Lower nickel than 300 series with it being replaced by Manganese

~ Thus lower cost than 300 series

~ Similar mechanical & physical properties to 300 series

~ Similar fabrication performance to 300 series, including deep-drawing

~ Corrosion resistance similar to 430 (i.e. not nearly as good as 300 series)

~ High carbon may cause stress corrosion cracking, especially after welding thicker material

~ Non Magnetic

Performance Comparison:

~ Formability: Similar to 304, better than 430

~ Strength: Stronger than 304 (and 430)

~ Corrosion Resistance @20 C: Similar to 304, better than 430 but susceptible to stress

corrosion cracking / intergranular corrosion especially after welding

Chemical Composition

Chemical Element % Present

Carbon (C) 0.0 max

Chromium (Cr) 16.00 - 18.00

Manganese (Mn) 6.80 - 8.50

Silicon (Si) 0.0 max

Phosphorous (P) 0.0 max

Sulphur (S) 0.0 max

Nickel (Ni) 2.00 - 5.00

Nitrogen (N) 0.0 - 0.25

Iron (Fe) Balance

See attached page for full chemical analysis and mechanical properties

Properties

Physical Property Value

Density 7.80 g/cm

Thermal Expansion 17 x10^-6 /K

Modulus of Elasticity 200 GPa

Thermal Conductivity 15 W/m.K

Mechanical Property Value

Proof Stress 310 Min MPa

Tensile Strength 655 Min MPa

Elongation A50 mm 40 min %

See attached page for full mechanical properties. Note that there are some differences in the

requirements of AISI 200 series types and the EN standards - The above is taken from AISI. EN

1.4372, the EN equivalent to AISI 201 has a minimum proof of 350 and a tensile range of 750 to

950 whilst minimum elongation is 45%

Alloy Designations

AISI 201 stainless steel corresponds to the following specifications:

UNS20100 / EN1.4372 / JIS SUS 201

AISI 201L stainless steel corresponds to the following specifications:

UNS20103 / EN1.4371

AISI 202 stainless steel corresponds to the following specifications:

UNS20200 / EN1.4373

AISI 204C stainless steel corresponds to the following specifications:

UNS20400 / EN1.4597

Supplied Forms

Sheet

Plate

Applications

200 series austenitics are typically used to replace types 304 and 301 as well as Carbon

(Chrome-Manganese) Steels mainly for indoor use for low corrosion applications at room

temperature

Furniture

Bins

Cookware & Serving Bowls

Window Channel Spacers

Safety Shoes (mid-sole protector)

Deep drawn kitchen equipment e.g. Cookware & Sinks

Hose Clamps

Trailer Frames

Industrial Strapping

Railway Rolling Stock

There is also grade 201LN for welded constructions, structural uses and low temperature

applications - Examples include sides & roofs of trains, liquified gas storage vessels, structural

members/chassis of railway rolling stock, trucks & trailers, coal handling equipment

Performance Comparison

The 200 series grades perform at a similar level to grades 304 and 301 in low corrosion, mainly

indoor applcations at room temperature.

Corrosion Resistance

The 200 series grades perform at a similar level to grades 304 and 301 in low corrosion, mainly

indoor applcations at room temperature.

Not recommended for use in Chloride environments.

Heat Resistance

Oxidation resistance is similar to grade 1.4310 (301) up to 840 Centigrade.

Weldability

Reasonable, although sensitive to intergranular corrosion in the heat affected zone where

thickness exceeds 6mm.

Post-weld cleaning and passivation is crucial.

Mechanical properties of grade AISI 202

Technological properties of grade AISI 202

Hardness and heat treatment specification of grade AISI 202

Annealing hardness

HBS Cold pull hardness

HBS Preheating temperature

Quenching temperature

Holding time

min Hardening medium Temper temperature

After tempering hardness

HRC

salt-bath furnace controlled atmosphere furnace

235 262 788 1191 1204 515 air cooling 522 60

Steel plate/Sheet

thickness / mm b

MPa s

/MPa

Samples from the standard for 50 mm (2 in)

180 of cold bending test

longitudinal horizontal

Hot-rolled/Cold rolling:5 - 150 520 415 1618 2a 3.5a

Note:

(1) listed in the table apex diameter (d), to steel thickness (a) multiples said.

(2) in the ASTM A6 standard specified scope can meet any additional conditions.

(3) from the standard for 50 mm (2 in).

Mechanical properties

Mechanische Eigenschaften

Caracteristiques mecaniques

ReH Minimum yield strength / Mindestwert der oberen Streckgrenze / Limite delasticite

minimale

Rm Tensile strength / Zugfestigkeit / Resistance a la traction

A Minimum elongation / Mindestwert der Bruchdehnung / Allongement minimal

J Notch impact test / Kerbschlagbiegeversuch / Essai de flexion par choc

AISI 202 steel description:

Step Shaft: steel plate/sheet,coil,round bar,flat bar,tube/pipe,Profiled forgings

AISI 202 steel Specifications or Size:

Round bar:

Diameter : 1mm-2000mm

Square bar:

Size: 50mm * 50mm-600mm *600mm

Plate steel/flat bar:

Size: Thickness: 0.1mm-800mm Width: 10mm to 1500mm

Tube/pipe:

Size: OD: 6-219mm WT: 1-35 mm.

Cold-rolled sheet: Thickness: 2-5mm Width:1000mm Length: 2000mm

Hot-rolled sheet: Thickness:6-80mm Width: 210-610mm

Length: We can supply any length based on the customer's requirement.

Forging/hot rolling/ extrusion of steel.

Forging: Shafts with flanks/pipes/tubes/slugs/donuts/cubes/other shapes

Finished goods condition: hot forging/hot rolling + annealing/normalizing +

tempering/quenching + tempering/any conditions based on the customer's requirement

Surface conditions: scaled (hot working finish)/ground/rough machining/fine machining/based

on the customer's requirement

Furnaces for metallurgical processing: electrode arc + LF/VD/VOD/ESR/Vacuum consumable

electrode.

Ultrasonic inspection: 100% ultrasonic inspection for any inperfections or based on the

customer's requirement.

UTS according to SEP 1921 C/c,D/d,E/e;A388 or GB/T 6402

Excellent service for all kinds of industries, with advantages of technologies, equipment and

price.

We serve you with our honesty, integrity, and professionality.

AISI Type 202

Category Steel

Class Stainless steel

Type Austenitic standard

Common Names Chromium-Manganese-Nickel steel

Designations United States: ASTM A276 , ASTM A314 , ASTM A412 , ASTM A429 , ASTM A473 ,

ASTM A666 , FED QQ-S-763 , FED QQ-S-766 , FED STD-66 , SAE 30202 , SAE J405 (30202) , UNS

S20200

Composition

Element Weight %

C 0.15

Mn 7.5-10.0

Si 1.00

Cr 17.0-19.0

Ni 4.0-6.0

P 0.06

S 0.03

N 0.25

Mechanical Properties

Properties Conditions

T (C) Treatment

Density (1000 kg/m3) 7.8 25

Poisson's Ratio 0.27-0.30 25

Elastic Modulus (GPa) 190-210 25

Tensile Strength (Mpa) 515 25 annealed (sheet, strip) more

Yield Strength (Mpa) 275

Elongation (%) 40

Reduction in Area (%)

Thermal Properties

Properties Conditions

T (C) Treatment

Thermal Expansion (10-6/C) 17.5 0-100 more

Thermal Conductivity (W/m-K) 16.2 100 more

Specific Heat (J/kg-K) 500 0-100

Electric Properties

Properties Conditions

T (C) Treatment

Electric Resistivity (10-9W-m)

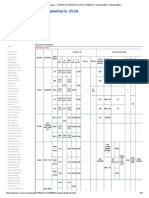

Chemical composition for AISI Standard stainless steel

Type Chemical Composition

Grade No. C Mn P S Si Cr Ni Mo Others

AISI 201 <=0.15 5.507.50 <=0.06 <=0.03 <=0.75 16.018.0 3.55.5 -

N<=0.25

AISI 202 <=0.15 7.5010.0 <=0.06 <=0.03 <=0.75 17.019.0 4.06.0 -

N<=0.25

AISI 205 0.120.25 14.015.5 <=0.06 <=0.03 <=0.75 16.518.0 1.01.75

- N 0.320.40

AISI 301 <=0.15 <=2.0 <=0.045 <=0.03 <=0.75 16.018.0 6.08.0 -

N0.10

AISI 302 <=0.15 <=2.0 <=0.045 <=0.03 <=0.75 17.019.0 8.010.5 -

N0.10

AISI 302B <=0.15 <=2.0 <=0.045 <=0.03 2.03.0 17.019.0 8.010.5

- N0.10

AISI 303 <=0.15 <=2.0 <=0.2 >=0.15 <=1.0 17.019.0 8.010.5 - N

0.10

AISI 303Se <=0.15 <=2.0 <=0.2 <=0.06 <=1.0 17.019.0 8.010.0 - -

AISI 304 <=0.08 <=2.0 <=0.045 <=0.03 <=0.75 18.020.0 8.010.5 -

Se>=0.15

AISI 304L <=0.03 <=2.0 <=0.045 <=0.03 <=0.75 18.020.0 8.012.0 -

N0.10

AISI 304N <=0.08 <=2.0 <=0.045 <=0.03 <=0.75 18.020.0 8.010.5 -

N0.10

AISI 304LN <=0.03 <=2.0 <=0.045 <=0.03 <=0.75 18.020.0 10.512.0 -

N 0.100.16

AISI 305 <=0.12 <=2.0 <=0.045 <=0.03 <=0.75 17.019.0 10.513.0 -

N 0.100.16

AISI 308 <=0.08 <=2.0 <=0.045 <=0.03 <=0.75 19.021.0 10.012.0 -

-

AISI 309 <=0.2 <=2.0 <=0.045 <=0.03 <=0.75 22.024.0 12.015.0 -

-

AISI 309S <=0.08 <=2.0 <=0.045 <=0.03 <=0.75 22.024.0 12.015.0 -

-

AISI 310 <=0.25 <=2.0 <=0.045 <=0.03 <=1.50 24.026.0 19.022.0 -

-

AISI 310S <=0.08 <=2.0 <=0.045 <=0.03 <=1.50 24.026.0 19.022.0 -

-

AISI 314 <=0.25 <=2.0 <=0.045 <=0.03 1.53.0 23.026.0 19.022.0

- -

AISI 316 <=0.08 <=2.0 <=0.045 <=0.03 <=0.75 16.0~18.0 10.0~14.0

1.75~2.25 -

AISI 316F <=0.08 <=2.0 <=0.2 <=0.1 <=0.75 16.0~18.0 10.0~14.0 1.75~2.25

-

AISI 316L <=0.03 <=2.0 <=0.045 <=0.03 <=0.75 16.0~18.0 10.0~14.0

2.0~3.0 -

AISI 316Ti <=0.08 <=2.0 <=0.045 <=0.03 <=0.75 16.0~18.0 10.0~14.0

2.0~3.0 N0.10,Ti5x(C+N)0.7

AISI 316N <=0.08 <=2.0 <=0.045 <=0.03 <=0.75 16.0~18.0 10.0~14.0

2.0~3.0 N 0.10~0.16

AISI 317 <=0.08 <=2.0 <=0.045 <=0.03 <=0.75 18.0~20.0 11.0~15.0

3.0~4.0 -

AISI 317L <=0.03 <=2.0 <=0.045 <=0.03 <=0.75 18.0~20.0 11.0~15.0

3.0~4.0 -

AISI 321 <=0.08 <=2.0 <=0.045 <=0.03 <=0.75 17.0~19.0 9.0~12.0 -

N0.10,Ti5x(C+N)0.7

AISI 329 <=0.10 <=2.0 <=0.040 <=0.03 <=0.75 23.0~28.0 2.5~5.0

1.0~2.0 -

AISI 347 <=0.08 <=2.0 <=0.045 <=0.03 <=0.75 17.0~19.0 9.0~13.0 -

Nb+Ta:10xC%~1.00

AISI 348 <=0.08 <=2.0 <=0.045 <=0.03 <=0.75 17.0~19.0 9.013.0 -

Nb+Ta10xC%1.00 Ta0.10,Co0.20

AISI 403 <=0.15 <=1.0 <=0.040 <=0.03 <=0.50 11.5~13.0 - - -

AISI 405 <=0.08 <=1.0 <=0.040 <=0.03 <=1.00 11.5~14.5 - -

AI:0.10~0.30

AISI 409 <=0.08 <=1.0 <=0.045 <=0.045 <=1.00 10.5~11.75 - -

Ti:6xC%~0.75

AISI 410 <=0.15 <=1.0 <=0.040 <=0.03 <=1.00 11.5~13.5 <=0.75 - -

AISI 414 <=0.15 <=1.0 <=0.040 <=0.03 <=1.00 11.5~13.5 1.252.50 -

-

AISI 416 <=0.15 <=1.25 <=0.06 <=0.15 <=1.00 12.0~14.0 - - -

AISI 416Se <=0.15 <=1.25 <=0.06 <=0.06 <=1.00 12.0~14.0 - - Se>=0.15

AISI 420 >0.15 <=1.00 <=0.040 <=0.03 <=1.00 12.0~14.0 <=0.75 <=0.50 -

AISI 420F 0.300.40 <=1.25 <=0.06 <=0.15 <=1.00 12.0~14.0 <=0.50 -

Cu<=0.60

AISI 429 <=0.12 <=1.0 <=0.040 <=0.03 <=1.00 14.0~16.0 <=0.75 - -

AISI 430 <=0.12 <=1.0 <=0.040 <=0.03 <=1.00 16.0~18.0 <=0.75 - -

AISI 430F <=0.12 <=1.25 <=0.06 <=0.15 <=1.00 16.0~18.0 - - -

AISI 430FSe <=0.12 <=1.25 <=0.06 <=0.06 <=1.00 16.0~18.0 - - Se>=0.15

AISI 431 <=0.20 <=1.00 <=0.040 <=0.03 <=1.00 15.0~17.0 1.252.50 -

-

AISI 434 <=0.12 <=1.00 <=0.040 <=0.03 <=1.00 16.0~18.0 - - -

AISI 440A 0.600.75 <=1.00 <=0.040 <=0.03 <=1.00 16.0~18.0 - -

-

AISI 440B 0.750.95 <=1.00 <=0.040 <=0.03 <=1.00 16.0~18.0 - -

-

AISI 440C 0.951.20 <=1.00 <=0.040 <=0.03 <=1.00 16.0~18.0 - -

-

AISI 442 <=0.20 <=1.00 <=0.040 <=0.03 <=1.00 18.0~23.0 - - -

AISI 446 <=0.20 <=1.50 <=0.040 <=0.03 <=1.00 23.0~27.0 <=0.75 - N:

0.10~0.25

AISI 631 <=0.09 <=1.00 <=0.040 <=0.03 <=1.00 16.0~18.0 6.507.50 0.4

0.65 AI 0.751.00

Properties Conditions

T (C) Treatment

Density (1000 kg/m3) 7.8 25

Poisson's Ratio 0.27-0.30 25

Elastic Modulus (GPa) 190-210 25

Tensile Strength (Mpa) 515 25 annealed (sheet, strip) more

Yield Strength (Mpa) 275

Elongation (%) 40

Reduction in Area (%)

Propertise of S.S.200

Chemical Properties ::

The chemistry offered is derived form the parent AISI 200 series, with suitable technical

modification to achieve the final properties in a cost effective manner as compared to the

existing 304 Grade SS. Literature survey reveals that AISI 200 series were developed in 1950's in

the United States, that development was strictly by the nickel shortage which was prevalent at

that time. The composition of these Steels varied widely with carbon ranging from 0.08 to as

high as 0.25%, nickel from 0.3 to around 7 % , Nitrogen from 0.10 to 0.4% with a chromium

level of 14 to 18%. The technical theme behind development of these grades was mainly to

substitute the costly nickel with manganese and nitrogen to achieve the austenitic structure by

controlling the ratio of austenite forming elements and ferrite forming elements (Ferrite Factor)

The drawbacks with these steel were higher carbon (>0.1%) and higher nitrogen resulting into

poor formability characteristics. With these backgrounds a new chemistry was designed in

which the carbon is controlled to a maximum level of 0.09% and nitrogen up to 1700ppm to aid

in formability addition Copper is made so that the work hardening rate is controlled. Thus the

optimized chemistry offered by us is

Grade SI4 S 0.015

C 0.07-0.09 Ni 0.75-0.95

Mn 9.2-9.4 Cr 14.8-15.2

Si 0.4-0.6 Cu 1.7-.9

P 0.075 N2 1550-1750

Physical Properties ::

Physical Properties of annealed AISI 200 Series

Destiny gr/cu.cm 7.74

ib/cu.in 0.28

Thermal 20-100C Cal/cm/sec/C/cm 0.039

Conductivity 68-212C Btu/ft2/hr/F/ft 9.4

Specific Heat 0-100C Cal/gm/C 0.122

32-212F Btu/ib/F 0.12

Coefficient of 20-100C cm/cm/C 16.6*10^-6

Thermal 68-212F in/in/F 9.2*10^-6

Expansion 20-316C cm/cm/C 18.0*10^-6

68-600Fin/in/F 10.0*10^-6

20-538Ccm/cm/C 19.6*10^-6

Mechanical Properties ::

200 Series 300Series

0.2% proof stress(kg/mm2) 35.5 26.7

Tensile Strength (ksi) 85-115 75-85

Elogation 45-55 40

Yield Stress (ksi) 50 35

GSN 8-9 7.8

Hv 208 157

Erchsen value 12.5 12.9

Limited Drawing Limit 2.0 2.3 to 2.5

Corrosion Properties ::

Considering that the components manufactured out of these sheets are used in normal

atmospheric condition chromium level 14.5% to 25.5% is quite to resist pitting corrosion.

Experiment carried out showed the following result

Kitchen utensils and cutleries retained their surface finish and luster similar to 304 Grade

Laboratories scaled experiments carried out under different media revealed the following data

Corrosion rates of the Stainless Steels Fully Immersed in 3% Sodium Chloride

B>Stainless

Steel Temperature Duration B>Corrosion

Rate B>Visual

Observation

K C (Hour) B>x 10^-

mmpy

J 3032 302 720 2.58 Localised

Attack

S 3032 302 720 3.29 Localised

Attack

J 3712 982 100 0.25 Material Remained

Same

Mixture (0.5% Citric Acid +0.5% Trataric Acid )

B>Stainless

Steel Temperature Duration Corrosion

Rate B>Visual

Observation

K C (Hour) B>x 10^-

mmpy

J 3032 302 720 0.44 Fungal growth

S 3032 302 720 0.38 Fungal growth

J 3712 982 100 0.34 Material Remained

Same

S 3712 982 100 0.17 Material Remained

Same

Dissolution Behavior of the three stainless steel in 3%NaCl on total Immersion

SS B>Temp

C B>Duration

(Hours) Elements estimated by AAS (ppm)

Fe Cr Cu Mn Ni Ti

J 302 720 0.177 0.011 0.003 0.508 - -

S 302 720 0.157 0.048 0.024 0.48 - -

J 982 100 0.057 0.007 0.015 0.829 - -

S 982 100 0.010 0.012 0.028 0.035 - -

Formability ::

The blanks cut from the annealed sheets respond favorable to the commonly fabrication

operation such as deep drawing, spinning, welding, bidding, rib formation, embossing, electro

deposition of metal like copper and necking of cylindrical parts. The quantified data on

formability is given bellow: Limited Drawing Ration - 2 Percentage Stretch in Spinning - 30%

Erichsen Value - 12.5

Note : Information in this document is only for the explanation of general characteristics and

properties of our product. For requirement of exact report you should contact our technical

department for same.

You might also like

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- The Essentials of Material Science and Technology for EngineersFrom EverandThe Essentials of Material Science and Technology for EngineersRating: 5 out of 5 stars5/5 (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Tabel Bunga Untuk Ekonomi TeknikDocument32 pagesTabel Bunga Untuk Ekonomi TeknikElvina Noviarni Chandra78% (9)

- Stainless AISI 3XXDocument3 pagesStainless AISI 3XXThitaphol HuyananNo ratings yet

- Engineering Material Standard Designation and ClassificationDocument57 pagesEngineering Material Standard Designation and ClassificationBoni PrakasaNo ratings yet

- Aalco Metals LTD - Stainless Steel - 201 201L 202 204 200 Series - 97Document3 pagesAalco Metals LTD - Stainless Steel - 201 201L 202 204 200 Series - 97sgupta_192494No ratings yet

- FsafsaDocument45 pagesFsafsapvmssonNo ratings yet

- Data SAF2205 04Document8 pagesData SAF2205 04il_yoo_1No ratings yet

- Standards R M Salem - UserguideDocument49 pagesStandards R M Salem - Userguidearunas1081No ratings yet

- Mould SteelsDocument32 pagesMould SteelsAnonymous B3I6zYNhqdNo ratings yet

- Selection of Engg Materials of Equipment and Piping SystemDocument17 pagesSelection of Engg Materials of Equipment and Piping SystemNiraj PandyaNo ratings yet

- Atlas 304 - 304L: Colour Code: Lilac/TurquoiseDocument3 pagesAtlas 304 - 304L: Colour Code: Lilac/TurquoiseOthoniel MunizNo ratings yet

- Stainless Steel Grade Composition ChartDocument8 pagesStainless Steel Grade Composition ChartZaveri SagarNo ratings yet

- AISI Type 302 Stainless Steel (UNS S30200) : Chemical CompositionDocument4 pagesAISI Type 302 Stainless Steel (UNS S30200) : Chemical CompositionnagboccaNo ratings yet

- Stainless SteelDocument6 pagesStainless SteelNiko NištićNo ratings yet

- Duplex Stainless SteelDocument24 pagesDuplex Stainless SteeljeffreymacaseroNo ratings yet

- Stainless Steel 304 Material Property Data SheetDocument2 pagesStainless Steel 304 Material Property Data SheetRahul SrivastavaNo ratings yet

- AISI 430 Ferritic Stainless Steel Grade for AppliancesDocument3 pagesAISI 430 Ferritic Stainless Steel Grade for AppliancesAgus MulyadiNo ratings yet

- Structural SteelsDocument1 pageStructural SteelsrjueiNo ratings yet

- Material Cross Reference TableDocument3 pagesMaterial Cross Reference TableLuis Pol SistiNo ratings yet

- Equivalent Standards - A - SA516-70, A - SA515-70, ST52-3, S355J2+N, SAILMA 350HI, SAILMA 450HIDocument10 pagesEquivalent Standards - A - SA516-70, A - SA515-70, ST52-3, S355J2+N, SAILMA 350HI, SAILMA 450HIPuneet BahriNo ratings yet

- AISI 1035 Steel, Cold Drawn, High Temperature, Stress Relieved, 16-22 MM (0.625-0.875 In) RoundDocument2 pagesAISI 1035 Steel, Cold Drawn, High Temperature, Stress Relieved, 16-22 MM (0.625-0.875 In) RoundJakJhonNo ratings yet

- Spring wire materials guideDocument6 pagesSpring wire materials guideKishore BhatNo ratings yet

- Steel Clasification and WeldabilityDocument32 pagesSteel Clasification and Weldabilitycentaury2013No ratings yet

- The Role Stainless Steel in Industrial Heat ExchangersDocument46 pagesThe Role Stainless Steel in Industrial Heat ExchangerswholenumberNo ratings yet

- AISI 4130: Incoloy Alloys, Fast QuoteDocument5 pagesAISI 4130: Incoloy Alloys, Fast QuoteSantanu SahaNo ratings yet

- P20 Steel Plate Tool SteelDocument4 pagesP20 Steel Plate Tool SteelSama UmateNo ratings yet

- Product Description Wire RodDocument3 pagesProduct Description Wire RodEngr Farrukh RehanNo ratings yet

- Sandvik SAF 2205: Duplex Stainless SteelDocument8 pagesSandvik SAF 2205: Duplex Stainless SteelIuliu HurducaciNo ratings yet

- Stainless steels - properties, classes, composition and applicationsDocument24 pagesStainless steels - properties, classes, composition and applicationsdennykvgNo ratings yet

- Manufactory Profile: Characteristics For Grade 12050Document3 pagesManufactory Profile: Characteristics For Grade 12050kifle abelNo ratings yet

- Properties of Stainless Steel AISI Type 420Document2 pagesProperties of Stainless Steel AISI Type 420Samir SalamaNo ratings yet

- EN 10152 Grade DC01Document3 pagesEN 10152 Grade DC01Vanesh KumarNo ratings yet

- SG Iron and Cast Iron Material SpecificationsDocument9 pagesSG Iron and Cast Iron Material Specificationsvtsusr fvNo ratings yet

- 304 Grade SteelDocument6 pages304 Grade SteelShashank SaxenaNo ratings yet

- Userguide For SSDocument26 pagesUserguide For SSehsan4uNo ratings yet

- AISI 1038 Steel Round BarDocument1 pageAISI 1038 Steel Round BaredraelmxNo ratings yet

- 42crmo4 - HardnessDocument8 pages42crmo4 - HardnessavijayakumarsamyNo ratings yet

- AISI 1020 Steel, Cold RolledDocument2 pagesAISI 1020 Steel, Cold RolledAnonymous ZMwWk2v50% (2)

- Wire Mesh Steel Reinforcement BarsDocument6 pagesWire Mesh Steel Reinforcement Barssattar12345No ratings yet

- Steel UserguideDocument50 pagesSteel UserguideBhanu Pratap ChoudhuryNo ratings yet

- Casting MaterialsDocument42 pagesCasting MaterialsTirta BudiawanNo ratings yet

- Propiedades Aceros InoxDocument2 pagesPropiedades Aceros Inoxjarv7910No ratings yet

- Material SpecificationDocument50 pagesMaterial SpecificationSangyt Karna0% (2)

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Machining of Stainless Steels and Super Alloys: Traditional and Nontraditional TechniquesFrom EverandMachining of Stainless Steels and Super Alloys: Traditional and Nontraditional TechniquesNo ratings yet

- Oxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Fundamentals of Industrial Heat Exchangers: Selection, Design, Construction, and OperationFrom EverandFundamentals of Industrial Heat Exchangers: Selection, Design, Construction, and OperationNo ratings yet

- The Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelFrom EverandThe Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelNo ratings yet

- Proceedings of the 8th International Symposium on Superalloy 718 and DerivativesFrom EverandProceedings of the 8th International Symposium on Superalloy 718 and DerivativesNo ratings yet

- CCS Pension Rules For Central GovtDocument4 pagesCCS Pension Rules For Central Govtsgupta_192494No ratings yet

- GATE Mechanical SyllabusDocument2 pagesGATE Mechanical Syllabussgupta_192494No ratings yet

- Empanelment of Ayurvedic, Yoga and Naturopathy Day Care Centers Under CGHSDocument3 pagesEmpanelment of Ayurvedic, Yoga and Naturopathy Day Care Centers Under CGHSsgupta_192494No ratings yet

- Empanelment of Ayush HospitalsDocument2 pagesEmpanelment of Ayush Hospitalssgupta_192494No ratings yet

- Jhwesdjhweslfbejhfblkjbvds V DSVKCJDBSVKJ DVKBDSKJV Dkjvas DVKJDV DSJVKJDV Dbfguio Rhge /rghreg Rhgpre Urhui9gpDocument1 pageJhwesdjhweslfbejhfblkjbvds V DSVKCJDBSVKJ DVKBDSKJV Dkjvas DVKJDV DSJVKJDV Dbfguio Rhge /rghreg Rhgpre Urhui9gpsgupta_192494No ratings yet

- Lec1 PDFDocument38 pagesLec1 PDFSaqib AkhtarNo ratings yet

- Job Application FormDocument2 pagesJob Application Formsgupta_192494No ratings yet

- KPSCDocument4 pagesKPSCsgupta_192494No ratings yet

- China's Growing Naval Power and India's ResponseDocument3 pagesChina's Growing Naval Power and India's Responsesgupta_192494No ratings yet

- Lec1 PDFDocument38 pagesLec1 PDFSaqib AkhtarNo ratings yet

- SopDocument1 pageSopsgupta_192494No ratings yet

- IdflisdfhbdsifDocument1 pageIdflisdfhbdsifsgupta_192494No ratings yet

- SopDocument1 pageSopsgupta_192494No ratings yet

- SopDocument1 pageSopsgupta_192494No ratings yet

- TEST 1 SolutionDocument25 pagesTEST 1 Solutionsgupta_192494No ratings yet

- Termsband Conditions FullDocument83 pagesTermsband Conditions Fullsgupta_192494No ratings yet

- Steam Jet RefrigerationDocument3 pagesSteam Jet RefrigerationmontymilkyNo ratings yet

- Dont OpenDocument1 pageDont Opensgupta_192494No ratings yet

- List of Summer Trainee 2014Document4 pagesList of Summer Trainee 2014sgupta_192494No ratings yet

- Result 3 SemDocument9 pagesResult 3 Semsgupta_192494No ratings yet

- 7 Sem SyllabusDocument4 pages7 Sem Syllabussgupta_192494No ratings yet

- Agriculture Profile of The StateDocument27 pagesAgriculture Profile of The StateDeepak KumarNo ratings yet

- DocumentDocument27 pagesDocumentsgupta_192494No ratings yet

- Electric MotorsDocument10 pagesElectric Motorssgupta_192494No ratings yet

- Pipe MaterialsDocument4 pagesPipe Materialssgupta_192494No ratings yet

- Computational-Fluid-Dynamics by Richard Pletcher John Tannehill Dale AndersonDocument803 pagesComputational-Fluid-Dynamics by Richard Pletcher John Tannehill Dale Andersonsgupta_192494No ratings yet

- VTH Sem SyllabusDocument7 pagesVTH Sem Syllabussgupta_192494No ratings yet

- EasyLogic PM2000 Series - METSEPM2130Document4 pagesEasyLogic PM2000 Series - METSEPM2130ٍJordan SportNo ratings yet

- Amo Plan 2014Document4 pagesAmo Plan 2014kaps2385No ratings yet

- Ds 3805Document4 pagesDs 3805sparky2017No ratings yet

- John Williams - WikipediaDocument2 pagesJohn Williams - Wikipedia三木和代No ratings yet

- Divide Fractions by Fractions Lesson PlanDocument12 pagesDivide Fractions by Fractions Lesson PlanEunice TrinidadNo ratings yet

- C++ Programmierung (Benjamin Buch, Wikibooks - Org)Document257 pagesC++ Programmierung (Benjamin Buch, Wikibooks - Org)stefano rossiNo ratings yet

- Assessment (L4) : Case Analysis: Managerial EconomicsDocument4 pagesAssessment (L4) : Case Analysis: Managerial EconomicsRocel DomingoNo ratings yet

- Course Handbook MSC Marketing Sept2022Document58 pagesCourse Handbook MSC Marketing Sept2022Tauseef JamalNo ratings yet

- Yardi Commercial SuiteDocument52 pagesYardi Commercial SuiteSpicyNo ratings yet

- Solidwork Flow Simulation TutorialDocument298 pagesSolidwork Flow Simulation TutorialMilad Ah100% (8)

- Design Your Loyalty Program in 2 WeeksDocument53 pagesDesign Your Loyalty Program in 2 WeeksLorena TacuryNo ratings yet

- Module-1 STSDocument35 pagesModule-1 STSMARYLIZA SAEZNo ratings yet

- Working With Session ParametersDocument10 pagesWorking With Session ParametersyprajuNo ratings yet

- Siemens MS 42.0 Engine Control System GuideDocument56 pagesSiemens MS 42.0 Engine Control System GuideIbnu NugroNo ratings yet

- The Patient Self-Determination ActDocument2 pagesThe Patient Self-Determination Actmarlon marlon JuniorNo ratings yet

- Data Sheet FC SIDocument2 pagesData Sheet FC SIAndrea AtzeniNo ratings yet

- Batool2019 Article ANanocompositePreparedFromMagn PDFDocument10 pagesBatool2019 Article ANanocompositePreparedFromMagn PDFmazharNo ratings yet

- Mono - Probiotics - English MONOGRAFIA HEALTH CANADA - 0Document25 pagesMono - Probiotics - English MONOGRAFIA HEALTH CANADA - 0Farhan aliNo ratings yet

- Module 2 What It Means To Be AI FirstDocument85 pagesModule 2 What It Means To Be AI FirstSantiago Ariel Bustos YagueNo ratings yet

- Conservation of Kuttichira SettlementDocument145 pagesConservation of Kuttichira SettlementSumayya Kareem100% (1)

- Network Theory - BASICS - : By: Mr. Vinod SalunkheDocument17 pagesNetwork Theory - BASICS - : By: Mr. Vinod Salunkhevinod SALUNKHENo ratings yet

- Location: Connectivity To The MuseumDocument7 pagesLocation: Connectivity To The MuseumAbhishek AjayNo ratings yet

- Strategy GlossaryDocument15 pagesStrategy GlossaryMahmoud SaeedNo ratings yet

- Siegfried Kracauer - Photography (1927)Document17 pagesSiegfried Kracauer - Photography (1927)Paul NadeauNo ratings yet

- Benefits of Eating OkraDocument4 pagesBenefits of Eating Okraama931No ratings yet

- Chapter 2 Literature ReviewDocument10 pagesChapter 2 Literature ReviewSharan BvpNo ratings yet

- Publications FireSafetyDesign SDocument369 pagesPublications FireSafetyDesign SJayachandra Reddy AnnavaramNo ratings yet

- Theatre Arts I 9 - 12 Grade Beginning Theatre Students: TH THDocument18 pagesTheatre Arts I 9 - 12 Grade Beginning Theatre Students: TH THAppleSamsonNo ratings yet

- BE 510 Business Economics 1 Problem Set 5 SolutionsDocument5 pagesBE 510 Business Economics 1 Problem Set 5 SolutionsCreative Work21stNo ratings yet

- Eating and HealingDocument19 pagesEating and HealingMariana CoriaNo ratings yet