Professional Documents

Culture Documents

Evaluation of Different Hybrid Energy Potential in AL-Arish

Uploaded by

Ahmed Kamal Othman0 ratings0% found this document useful (0 votes)

47 views5 pagesThis paper presents the potential impact of various energy generation utilizing wind turbines, photovoltaic cell, fuel cell and diesel generation for AL-Arish, Sinai, Egypt. In addition to investigating the feasibility for each combination where they are simulated using Hybrid Optimization Modeling for Energy Renewable (HOMER) software to find the optimum size for each unit and its corresponding economics.

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis paper presents the potential impact of various energy generation utilizing wind turbines, photovoltaic cell, fuel cell and diesel generation for AL-Arish, Sinai, Egypt. In addition to investigating the feasibility for each combination where they are simulated using Hybrid Optimization Modeling for Energy Renewable (HOMER) software to find the optimum size for each unit and its corresponding economics.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

47 views5 pagesEvaluation of Different Hybrid Energy Potential in AL-Arish

Uploaded by

Ahmed Kamal OthmanThis paper presents the potential impact of various energy generation utilizing wind turbines, photovoltaic cell, fuel cell and diesel generation for AL-Arish, Sinai, Egypt. In addition to investigating the feasibility for each combination where they are simulated using Hybrid Optimization Modeling for Energy Renewable (HOMER) software to find the optimum size for each unit and its corresponding economics.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 5

International Journal of Computer Applications (0975 8887)

Volume 88 No.17, February 2014

13

Evaluation of Different Hybrid Energy Potential

in AL-Arish

Ahmed M. Attala

Department of Electrical Power

and Machines.

Faculty of Engineering-Ain

Shams University.

Cairo, Egypt

A. T. M. Taha

Department of Electrical Power

and Machines.

Faculty of Engineering-Ain

Shams University.

Cairo, Egypt

Ahmed.K.Ryad

Department of Electrical Power

and Machines.

Faculty of Engineering-Ain

Shams University.

Cairo, Egypt

ABSTRACT

This paper presents the potential impact of various energy

generation utilizing wind turbines, photovoltaic cell, fuel cell

and diesel generation for AL-Arish, Sinai, Egypt. In addition

to investigating the feasibility for each combination where

they are simulated using Hybrid Optimization Modeling for

Energy Renewable (HOMER) software to find the optimum

size for each unit and its corresponding economics.

Keywords

HOMER Software, Wind Turbine, PV, Battery, Diesel

Generator, Fuel Cell.

1. INTRODUCTION

Using fossil fuels like petroleum and coal as energy resources

produce a bad effect on the environment in emission of

harmful gases specially carbon dioxide as well as their high

prices and these resources started depleting in the oil-

producing countries [1 3].

Renewable resources as wind and solar energy are clean,

freely-available and permanent, although they are un-

predictable. The combination of renewable resources is

widely used as an alternative for fossil fuel resources,

especially in remote sites where it's becoming more

promising. Usually the hybrid combination consists of two or

more resources, controller, converters and a storage system

[4].

2. HYBRID SYSTEM COMPONENTS

The hybrid system after the prefeasibility study consists of the

following components:

1) BWC Excel-R wind turbine.

2) CHSM 6610P-250 photovoltaic panel.

3) Trojan L16P Battery.

4) Converter.

5) Fuel Cell.

6) Diesel generator.

7) AL-Arish Load.

2.1.Wind Turbine:

In this simulation, Bergey Wind Powers BWC Excel-R

model is considered. It has a rated capacity of 7.5 kW and

provides 48 V DC as an output. Its initial cost is $28500 and

its replacement at$24500 [5]. Annual operation and

maintenance cost is $200. Its lifetime is estimated at 20 years,

a number from 1 unit to 10 is considered.

2.2.Photovoltaic module:

CHSM 6610P-250 photovoltaic panel is considered in the

scheme, with initial and replacement cost $ 265 with rated

power 250 watt and rated voltage 30 V [6] sizes to be

considered are (0.25 0.5 1 1.5 2 2.5 3 3.5 4 4.50 5 5.5 6 6.5 10

20 30 40 50 60 100) watts.

2.3.Battery

Trojan L16P Battery models (6 V, 360Ah, 1.075 kWh), Cost

of one battery is $275 and maintenance cost $3 [7], a number

of units considered are (10 20 50 100 150 200 250 300).

2.4.Converter

For a 1 kW converter the installation and maintenance costs

are taken as $1000 and $10, number of units to be considered

(1 2 3 4 5 6 10 20 30 50 100 150 200) KW

2.5.Fuel Cell

A fuel cell is an energy conversion device, which converts the

chemical energy of a fuel and oxidant, often hydrogen and

oxygen, to electrical energy. Fuel cells are similar to batteries,

however, unlike battery a fuel cell must be continuously

provided with fuel, with initial and replacement cost $3000

and $2700 respectively, for 1KW size and operation and

annual maintenance cost $0.02 [8] sizes to be considered are

(1 2 3 4 5 6 7 10 15 20) KW.

2.6.Diesel generator.

The diesel generator sizes to be considered in simulation vary

from 3 to 7 kW. Their initial costs and replacement cost are

respectively (2990, 2400$), (3978, 3200$), (4984, 4000$),

(5981, 4800$) and (6978, 5600$). Their operation and

maintenance are of 0.05$/h [9]

International Journal of Computer Applications (0975 8887)

Volume 88 No.17, February 2014

14

2.7.AL-Arish Load:

The annual peak load is 11 KW with energy consumption of

85 kWh/day and the daily profile of the load is shown in Fig.

1.

Fig.1: AL-Arish Load Profile.

3. WIND AND SOLAR RESOURCES:

The annual average wind speed and the annual average

insolation level at AL-Arish is 5.29 m/s and 5.71

kWh/m

2

/day, respectively. The monthly wind speed variation,

the monthly clearness index and the daily radiation are shown

in Fig. (2, 3) [10].

Fig.2: AL-Arish Wind Speed

Fig.3: AL-Arish Solar Irradiance

4. SIMULATION OF HYBRID SYSTEMS

WITH HOMER SOFTWARE:

HOMER software simulates the operation of the proposed

system along the year by making an energy balance between

the generation and the load to determine the feasible system

architecture which meet the load demand under the site

condition beside specifying the cost-effective combination

based on the total net present cost [TNPC] which is the

summation of all the costs and revenue all over the project life

time which is assumed 25 years [11].

Where the cost of each element is given by:

Ci= Ni * [CCosti + RCosti * Ki + OMCosti]

i= PV, Wind Turbine, Diesel Generator, Fuel Cell, Battery

and Converter.

Where Ni is the number/size of the system component,

CCosti is the capital cost, RCosti is the replacement cost, Ki

is the number of replacement, and OMCosti is operation and

maintenance cost through the system operation.

Number of combinations are to be considered as follows:

1. Wind turbine, Batteries and Diesel generation.

2. PV panel, Batteries and Diesel generation.

3. Wind turbine, Batteries and PV panels.

4. Wind turbine, Batteries, PV panels and Diesel

generation.

5. Wind turbine and Fuel cell

6. PV panels and Fuel cell

7. Wind turbine, PV panels and Fuel cell.

Then simulated using HOMER software to determine the

most optimum combination for AL-Arish load.

4.1.Wind and Diesel generation

The Fig.4 shows Wind and Diesel System Design Using

HOMER.

Fig.4: Wind and Diesel System.

The simulation results present the optimum combination: 1

wind turbine, 4KW generator, 10 batteries and 4KW converter

as shown in Table. (1), with initial cost: 33,228$, operating

cost: 7,208$/year and cost of energy: 0.335$/kWh, Fig (5)

shows the energy yield of the optimum solution.

Table.1: Wind and Diesel Optimization Result.

Fig.5: Wind and Diesel Electric Production

International Journal of Computer Applications (0975 8887)

Volume 88 No.17, February 2014

15

4.2. PV and Diesel generation

The Fig.6 shows PV and Diesel System Design Using

HOMER.

Fig.6: PV and Diesel System.

The simulation results present the optimum combination:

20KW PV, 2KW generator, 50 battery unit and 6KW

converter as shown in Table. (2) and Fig. (7) shows the

energy yield of the optimum solution.

Table.2: Wind and PV Optimization Result

Fig.7: Wind and PV Electric Production

4.3. Wind and PV.

The Fig.8 shows Wind and PV System Design Using

HOMER.

Fig.8: Wind and PV System

The simulation results present the optimum combination:

20KW, 1 wind turbine, 50 battery unit and 10 KW converter

as shown in Table. (3), and Fig. (9) shows the energy yield of

the optimum solution.

Table.3: Wind and PV Optimization Result

Fig.9: Wind and PV Electric Production.

4.4.Wind, PV and Diesel

The Fig.10 shows Wind , PV and System Design Using

HOMER.

Fig.10: Wind, PV and Diesel System

The simulation results present the optimum combination: 11

KW PV, 1 wind turbine, 2KW generator, 30 battery unit and 6

KW converter as shown in Table. (4) and Fig. (11) shows the

energy yield of the optimum solution.

Table.4: Wind, PV and Diesel Optimization Result

Fig.11: Wind, PV and Diesel Electric Production

International Journal of Computer Applications (0975 8887)

Volume 88 No.17, February 2014

16

4.5. Wind Turbine and Fuel Cell.

The Fig.12 shows Wind and Fuel System Design Using

HOMER.

Fig.12: Wind and Fuel Cell System

The simulation results present the optimum combination: 6

BWC wind turbine, 6 KW Fuel Cell, 10 KW converter, 10

KW Electrolyzer and 20 kg hydrogen tank as shown in table

(5) and Fig. (13) shows the energy yield of the optimum

solution.

Table.5: Wind and Fuel Cell Optimization Result

Fig.13: Wind and Fuel Cell Electric Production

4.6. PV panels and Fuel cell.

The Fig.14 shows PV and Fuel System Design Using HOMER.

Fig.14: PV and Fuel Cell System

There is no optimum solution found

4.7. Wind turbine, PV panels and Fuel cell.

The Fig.15 shows Wind, PV and Fuel System Design Using

HOMER.

Fig.15: Wind, PV and Fuel Cell System

The simulation results present the optimum combination: 40

KW PV, 2 BWC wind turbine, 6 KW Fuel cell, 10 KW

Converter (Inverter & Rectifier), 10 KW Electrolyzer and 10

Kg hydrogen tank as shown in table (6) and Fig. (16) Shows

the energy yield of the optimum solution.

Table.6: Wind, PV and Fuel Cell System Optimization

Result

Fig.16: Wind, PV and Fuel Cell Electric Production

5. LOAD SHEDDING

Load Shedding is a preferred method of saving energy for the

grid. During certain times of the day, or during emergencies,

large consumers of electricity will reduce their electricity

usage, thus reducing the load on the grid.

This can save the cost of having extra generators and reduce

the cost of electricity for consumers.

For AL-Arish load a percentage of 20% of the peak load is

reduced for the peak months (April, August) on the peak hour

(18:00 19:00)

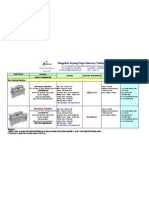

6. CONCLUSIONS

The previous cases are summarized in table (7) showing the

system architecture and economic value.

The results show that the combination including diesel

generators (as: wind &diesel, PV & diesel and wind & PV&

diesel) gives less net present cost than its corresponding

combination with fuel cell (as: wind &fuel cell, PV & fuel cell

and wind & PV & fuel cell)

PV and Fuel cell doesnt present any optimal solution.

The most optimum combination is wind, PV and diesel with

lowest net present cost and energy cost so load shedding was

International Journal of Computer Applications (0975 8887)

Volume 88 No.17, February 2014

17

applied at the peak load to reduce twenty percent, which

results in reducing the net present cost from $112014 to

$107880 and reduce the energy cost from $/KW 0.284 to

$/KW 0.275, the system architecture changed from: 11 KW

PV, I wind turbine, 2 KW diesel generator and 30 battery unit

to 12 KW PV, 1 wind turbine, 3 KW diesel generator and 28

battery unit.

Table.7: Comparison between Different Hybrid Combinations

7. REFERENCES

[1] Mohamed El Badawe, Tariq Iqbal & George K. Mann,

(2012) OPTIMIZATION AND A COMPARISON

BETWEEN RENEWABLE AND NONRENEWABLE

ENERGY SYSTEMS FOR A

TELECOMMUNICATION SITE, 25th IEEE Canadian

Conference on Electrical and Computer Engineering

(CCECE).

[2] El Badawe & M. Iqal T George M, (2011) Optimal

sizing and modeling of a hybrid energy system for a

remote telecommunication facility presented at IEEE

21 NECEC conference St ohns NF.

[3] Ross M, Hidalgo R & Abbey C, Joos G, (2010)

Analysis of Energy Storage sizing and technologies

Electric Power and Energy Conference (EPEC), vol., no.,

pp.1-6, 2527Aug.2010.

[4] P. Nema et al, (2009)A current and future state of art

development of hybrid energy system using wind and

PV-solar: A review. Renewable and Sustainable Energy

Reviews 13, 20962103.

[5] Wind turbine manufacturer [Online]. Available at

http://msmelectric.com/montage/catalog/.

[6] Photovoltaic panels manufacturer [Online]. Available at

http://www.wholesalesolar.com/products.

[7] Manufacture and worldwide distributor of long-lasting

deep-cycle batteries [Online]. Available at

www.trojanbattery.com.

[8] BolfazlShiroudi & Seyed Reza HosseiniTaklimi, (2011)

Demonstration project of the solar hydrogen energy

system loc Taleghan-Iran: Technical-economic

assessments World Renewable Energy Congress -

Sweden.

[9] Souissi Ahmed & Hasnaoui Othman &

SallamiAni,(2010) Optimal Sizing of a Hybrid System

of Renewable Energy for a Reliable Load Supply without

Interruption European Journal of Scientific

ResearchISSN 1450-216X Vol.45 No.4,pp.620-629

[10] NASA Surface Meteorology and Solar Energy [Online].

Available at http://www.nasa.gov

[11] Sureshkumar, Manoharan, P.S. ; Ramalakshmi,(2012)

Economic cost analysis of hybrid renewable energy

system using HOMER IEEE- International Conference

On Advances In Engineering, Science And Management

(ICAESM -2012) March 30, 31, 2012

System Architecture Net Present Cost($) Cost of energy ($/kwh)

Wind and Diesel 1BWC WT

4KW generator

11L16P battery

4 KW converter

131371 0.335

PV and Diesel 01KW PV

0KW generator

01 L16P battery

6 KW converter

117664 0.299

PV and Wind 01KW PV

1BWC WT

01L16P battery

10 KW converter

115701 0.297

PV, Wind and Diesel 11KW PV

1BWC WT

2KW generator

30 L16P battery

112014 0.284

Wind and Fuel Cell 6 BWC WT

6 KW FC

10 KW Converter

10 KW Electrolyzer

20 Kg Hydrogen Tank

245000 0.915

PV and Fuel Cell No Optimal Solution No Optimal Solution No Optimal Solution

Wind, PV and Fuel Cell 2 BWC WT

40 KW PV

6 KW FC

10 KW Converter

10 KW Electrolyzer

10 Kg Hydrogen Tank

160400 0.626

IJCA

TM

: www.ijcaonline.org

You might also like

- Super CatalogueDocument8 pagesSuper CatalogueITL200_UNo ratings yet

- Solucionario Statistics For Business and Economics - David R. Anderson, Dennis J. Sweeney - 8edDocument8 pagesSolucionario Statistics For Business and Economics - David R. Anderson, Dennis J. Sweeney - 8edTukumaneriko Filiponditoniko0% (1)

- 2018 Energy Manager Quiz With AnswersDocument15 pages2018 Energy Manager Quiz With AnswersFalah DemeryNo ratings yet

- 2012-02-29 An Introduction To OptimizationDocument4 pages2012-02-29 An Introduction To OptimizationSam ShahNo ratings yet

- CCGT ExplainedDocument22 pagesCCGT ExplainedAli Bari100% (1)

- Power System Design ReportDocument81 pagesPower System Design ReportAnas RashidNo ratings yet

- Estimation and Costing by M Chakraborty PDFDocument4 pagesEstimation and Costing by M Chakraborty PDFAakash Kamthane0% (3)

- Cidtt The GuideDocument268 pagesCidtt The GuideAbdul Shameem100% (1)

- Bill of Materials SampleDocument31 pagesBill of Materials SampleOcsi YeahNo ratings yet

- Modeling, Analysis and Optimization of Process and Energy SystemsFrom EverandModeling, Analysis and Optimization of Process and Energy SystemsNo ratings yet

- Research DesignDocument6 pagesResearch DesignOsama Fayyaz100% (3)

- Research Proposal RubricsDocument1 pageResearch Proposal RubricsRonnie Dalgo0% (1)

- Description of HOMER Software - An Optimal Analysis ToolDocument17 pagesDescription of HOMER Software - An Optimal Analysis Toolanon_849607662No ratings yet

- Optimization of Hybrid Power Systems Using Homer: Mini Project ReportDocument18 pagesOptimization of Hybrid Power Systems Using Homer: Mini Project ReportMohan KumarNo ratings yet

- 073 FinalDocument6 pages073 FinalSherif M. DabourNo ratings yet

- Chapter 4Document8 pagesChapter 4U Aung Myint NaingNo ratings yet

- Optimization of Renewable Energy Efficiency Using Homer: Kenneth E. Okedu, Roland UhunmwanghoDocument7 pagesOptimization of Renewable Energy Efficiency Using Homer: Kenneth E. Okedu, Roland Uhunmwanghokaybecbe_indNo ratings yet

- 14.dynamic Modeling, Design and Simulation of A Windfuel Cellultracapacitor-Based Hybrid Power GeDocument16 pages14.dynamic Modeling, Design and Simulation of A Windfuel Cellultracapacitor-Based Hybrid Power GeYellaturi Siva Kishore ReddyNo ratings yet

- Techno-Economic Feasibility of A Hybrid Power Generation System For Developing EconomiesDocument4 pagesTechno-Economic Feasibility of A Hybrid Power Generation System For Developing EconomiesFahdNo ratings yet

- IJEE 05 v9n1 PDFDocument6 pagesIJEE 05 v9n1 PDFhamza mandlwiNo ratings yet

- Dynamic Modeling, Design and Simulation of A Wind/fuel Cell/ultra-Capacitor-Based Hybrid Power Generation SystemDocument16 pagesDynamic Modeling, Design and Simulation of A Wind/fuel Cell/ultra-Capacitor-Based Hybrid Power Generation SystemKamal SharmaNo ratings yet

- Hybrid Modeling of Fuel Cell in Power System: C.S.Hiwarkar, C.J.Sharma, S.K.Mude, S.R.GawandeDocument7 pagesHybrid Modeling of Fuel Cell in Power System: C.S.Hiwarkar, C.J.Sharma, S.K.Mude, S.R.GawandeInternational Journal of Engineering Inventions (IJEI)No ratings yet

- Amara Pub Amara2024 - 11Document8 pagesAmara Pub Amara2024 - 11mostronic69No ratings yet

- Diaf RevisedDocument37 pagesDiaf RevisedAkaruii BowoNo ratings yet

- MUSTAF 2002887+MAHBOOB 2003103 EE616 PV On-Grid System ProjectDocument18 pagesMUSTAF 2002887+MAHBOOB 2003103 EE616 PV On-Grid System ProjectHiyam HishamNo ratings yet

- Balancing Cost and Performance in A PV/Wind/Battery Hybrid Power SystemDocument5 pagesBalancing Cost and Performance in A PV/Wind/Battery Hybrid Power SystemKhubaib AhmedNo ratings yet

- Economic Analysis, Modeling and Simulation of Photovoltaic Fuel Cell Hybrid Renewable Electric System For Smart Grid Distributed Generation SystemDocument8 pagesEconomic Analysis, Modeling and Simulation of Photovoltaic Fuel Cell Hybrid Renewable Electric System For Smart Grid Distributed Generation SystemIAEME PublicationNo ratings yet

- A Comprehesnive Dynamic Modeling of Grid Connected Hybrid Renewable Power Generation and Storage SystemDocument4 pagesA Comprehesnive Dynamic Modeling of Grid Connected Hybrid Renewable Power Generation and Storage SystemChandar SinghNo ratings yet

- Saving Hydrogen Fuel Consumption and OpeDocument11 pagesSaving Hydrogen Fuel Consumption and OpeSab-Win DamadNo ratings yet

- Photovoltaic Cost Reduction, Reliability, Operational Performance, Prediction and SimulationDocument6 pagesPhotovoltaic Cost Reduction, Reliability, Operational Performance, Prediction and SimulationAnonymous VlKfgxLNo ratings yet

- Abt 935 Report 1Document61 pagesAbt 935 Report 1Shakil MaddilaNo ratings yet

- Power and Energy Analysis of Commercial Small Wind Turbine SystemsDocument6 pagesPower and Energy Analysis of Commercial Small Wind Turbine SystemsKamal DrawilNo ratings yet

- Energy Systems - Fuel CellDocument15 pagesEnergy Systems - Fuel Celleoghan mulliganNo ratings yet

- Power System Analysis: Economic DispatchDocument20 pagesPower System Analysis: Economic DispatchSalman ZafarNo ratings yet

- Stabilization of Wind Energy Conversion System With Hydrogen Generator by Using EDLC Energy Storage SystemDocument9 pagesStabilization of Wind Energy Conversion System With Hydrogen Generator by Using EDLC Energy Storage SystemPriyanka GuptaNo ratings yet

- White Paper - Do DC Generators Offer Fuel Economy Advantages - Lexe0339-01Document9 pagesWhite Paper - Do DC Generators Offer Fuel Economy Advantages - Lexe0339-01sdiamanNo ratings yet

- Economic Dispatch For A Microgrid Considering Renewable Energy Cost FunctionsDocument7 pagesEconomic Dispatch For A Microgrid Considering Renewable Energy Cost FunctionsibtihalislamNo ratings yet

- Ah 33186193Document8 pagesAh 33186193Shakeel RanaNo ratings yet

- Renewable Electrification in Remote Sites in Algeria by Wind-Diesel Hybrid SystemsDocument6 pagesRenewable Electrification in Remote Sites in Algeria by Wind-Diesel Hybrid SystemsTandjaoui Naceur Tandjaoui NaceurNo ratings yet

- Energy: Hassan FathabadiDocument9 pagesEnergy: Hassan FathabadiDinku Seyoum ZelekeNo ratings yet

- DMX9208 - CES - Final Exam PaperDocument5 pagesDMX9208 - CES - Final Exam PaperSampath WeeratungeNo ratings yet

- Optimal Design of A Hybrid Solar - Wind-Diesel Power System For Rural Electrification Using Imperialist Competitive AlgorithmDocument9 pagesOptimal Design of A Hybrid Solar - Wind-Diesel Power System For Rural Electrification Using Imperialist Competitive AlgorithmHafidz PratamaNo ratings yet

- Economic Dispatch Optimization of Microgrid inDocument5 pagesEconomic Dispatch Optimization of Microgrid inmsantos_186910100% (1)

- Analysis of Wind Diesel Hybrid System by Homer SoftwareDocument4 pagesAnalysis of Wind Diesel Hybrid System by Homer SoftwareEditor IJTSRDNo ratings yet

- New Approach in Size Optimization and Performance Prediction Photovoltaic Hybrid Power SystemsDocument4 pagesNew Approach in Size Optimization and Performance Prediction Photovoltaic Hybrid Power SystemsAkis ApostolidisNo ratings yet

- 7.8 Typical Cogeneration Performance ParametersDocument5 pages7.8 Typical Cogeneration Performance ParametersaizatmaricanNo ratings yet

- Performance Analysis of Hybrid Model of Wind Mill, Photovoltaic Cell and Fuel CellDocument4 pagesPerformance Analysis of Hybrid Model of Wind Mill, Photovoltaic Cell and Fuel CellShakeel RanaNo ratings yet

- Cost - Benefit Analysis of Biogas CHP (Combined Heat and Power) PlantDocument5 pagesCost - Benefit Analysis of Biogas CHP (Combined Heat and Power) Plantgiuseppe tropianoNo ratings yet

- Cjbas 13 01 01 03Document7 pagesCjbas 13 01 01 03CJBAS ManagerNo ratings yet

- Wind-to-Wheel Energy Assessment: Patrick Mazza and Roel HammerschlagDocument8 pagesWind-to-Wheel Energy Assessment: Patrick Mazza and Roel HammerschlagkramtonNo ratings yet

- Cost Co2 CaptureDocument6 pagesCost Co2 CaptureMostafa BazriNo ratings yet

- Assignment Questions - EamDocument4 pagesAssignment Questions - EamSiddharthaNo ratings yet

- Bess Sizing With DGsDocument10 pagesBess Sizing With DGseng7senNo ratings yet

- Exhaust Gas Heat Recovery Power GenerationDocument52 pagesExhaust Gas Heat Recovery Power GenerationabhinavkarthickNo ratings yet

- Energy Cost Analysis of A Solar-Hydrogen Hybrid Energy System For Stand-Alone ApplicationsDocument9 pagesEnergy Cost Analysis of A Solar-Hydrogen Hybrid Energy System For Stand-Alone ApplicationsTrần Tâm PhươngNo ratings yet

- MPC For Battery Fuel Cell Hybrid VehicleDocument30 pagesMPC For Battery Fuel Cell Hybrid VehicleSab-Win DamadNo ratings yet

- Fuzzy Based Ev Charging With Reduced Power Fluctuation Under Renewable Power Consumption ConstraintDocument16 pagesFuzzy Based Ev Charging With Reduced Power Fluctuation Under Renewable Power Consumption ConstraintkesavantNo ratings yet

- Dynamic Modeling and Control of A Wind-Fuel Cell Through Hybrid Energy SystemDocument5 pagesDynamic Modeling and Control of A Wind-Fuel Cell Through Hybrid Energy Systemsurendiran123No ratings yet

- Modeling and Design of Hybrid Power Plants: Ahmed KH A. E. AlkhezimDocument5 pagesModeling and Design of Hybrid Power Plants: Ahmed KH A. E. AlkhezimIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNo ratings yet

- Integrated Solar Combined Cycle Power Plants: Paving The Way For Thermal SolarDocument23 pagesIntegrated Solar Combined Cycle Power Plants: Paving The Way For Thermal SolarNisar AhmedNo ratings yet

- A Micro-Grid With PV, Fuel Cells, and Energy EfficiencyDocument6 pagesA Micro-Grid With PV, Fuel Cells, and Energy EfficiencySammie AuduNo ratings yet

- Performance Characteristics of A Diesel Engine Power Plant: Mehmet Kanog Lu, Su Leyman Kazım Isßık, Aysßegu L Abusßog LuDocument11 pagesPerformance Characteristics of A Diesel Engine Power Plant: Mehmet Kanog Lu, Su Leyman Kazım Isßık, Aysßegu L Abusßog LuralphholingsheadNo ratings yet

- Ijetr022774 PDFDocument6 pagesIjetr022774 PDFerpublicationNo ratings yet

- Pso 1Document4 pagesPso 1OMKAR PATILNo ratings yet

- A Polygeneration Process Concept for Hybrid Solar and Biomass Power Plant: Simulation, Modelling, and OptimizationFrom EverandA Polygeneration Process Concept for Hybrid Solar and Biomass Power Plant: Simulation, Modelling, and OptimizationNo ratings yet

- Modeling of Photovoltaic Systems Using MATLAB: Simplified Green CodesFrom EverandModeling of Photovoltaic Systems Using MATLAB: Simplified Green CodesNo ratings yet

- Ric RG90 y RG60Document1 pageRic RG90 y RG60GabrielConsentidoNo ratings yet

- 7ML19981GC61 1Document59 pages7ML19981GC61 1Andres ColladoNo ratings yet

- A330 Tire Inspn PDFDocument21 pagesA330 Tire Inspn PDFRithesh Ram NambiarNo ratings yet

- Dr. Ambedkar Institute of Technology: Mandatory Non-Credit NSS Course (22NSN310) Bachelor of Engineering inDocument4 pagesDr. Ambedkar Institute of Technology: Mandatory Non-Credit NSS Course (22NSN310) Bachelor of Engineering inshamalac2004No ratings yet

- Company Name: Facility Name: Dust Collection Emissions - Particulate (PM 10)Document2 pagesCompany Name: Facility Name: Dust Collection Emissions - Particulate (PM 10)Kumaran GopalNo ratings yet

- A-VIP Compressor BrochureDocument6 pagesA-VIP Compressor BrochureHans Hans SadzNo ratings yet

- Gym Mega ForceDocument3 pagesGym Mega ForceAnonymous iKb87OINo ratings yet

- Mmro C 053 MD 0357 Interior PL DrawingsDocument82 pagesMmro C 053 MD 0357 Interior PL DrawingsAnonymous 4Ts8UBFwzNo ratings yet

- Performance Impact Analysis With KPP Using Application Response Measurement in E-Government SystemsDocument4 pagesPerformance Impact Analysis With KPP Using Application Response Measurement in E-Government SystemsFredrick IshengomaNo ratings yet

- Wireless Body Area Networks: A SurveyDocument29 pagesWireless Body Area Networks: A Surveyabdul hananNo ratings yet

- Different Types of Steering Systems + ExamplesDocument0 pagesDifferent Types of Steering Systems + ExamplesAbhilash NagavarapuNo ratings yet

- Microsoft ISA Server 2006 - Certificate Troubleshooting - Part IIDocument7 pagesMicrosoft ISA Server 2006 - Certificate Troubleshooting - Part IIKhodor AkoumNo ratings yet

- Infineon IKFW50N65DH5Document15 pagesInfineon IKFW50N65DH5nithinmundackal3623No ratings yet

- AAE 11.3.1 User Guide ClientDocument475 pagesAAE 11.3.1 User Guide Clientme4ias100% (2)

- InternshipDocument14 pagesInternshipMohammed Shaheeruddin0% (1)

- Topic 5 FB Stability PDFDocument26 pagesTopic 5 FB Stability PDFAbdulrahman NasserNo ratings yet

- Quotation For Blue Star Printek From Boway2010 (1) .09.04Document1 pageQuotation For Blue Star Printek From Boway2010 (1) .09.04Arvin Kumar GargNo ratings yet

- TCE BE EEE RulesandRegulationsDocument509 pagesTCE BE EEE RulesandRegulationsAplieNo ratings yet

- Blank Irf - 2023-03-22T001455.667Document2 pagesBlank Irf - 2023-03-22T001455.667mar asepmalNo ratings yet

- Mathematical Modelling of Gear Tooth Stiffness: Bachelor of Technology in Mechanical EngineeringDocument40 pagesMathematical Modelling of Gear Tooth Stiffness: Bachelor of Technology in Mechanical EngineeringVishal ShasiNo ratings yet

- d350 Taper Lock End Anchor Tech Data SheetDocument2 pagesd350 Taper Lock End Anchor Tech Data SheetEdsantadNo ratings yet