Professional Documents

Culture Documents

4 Normal Procedures

Uploaded by

viorelu99Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4 Normal Procedures

Uploaded by

viorelu99Copyright:

Available Formats

FLIGHT MANUAL

P2002-JR

SECTI ON 4

Normal Procedures

1

st

Edition 10

th

January 2007 4-1

SECTION 4

NORMAL PROCEDURES

TABLE OF CONTENTS

INTRODUCTION....................................................................................................2

RIGGING AND DERIGGING ENGINE COWLING.............................................2

PRE-FLIGHT INSPECTIONS.................................................................................3

CHECKLISTS..........................................................................................................7

FLIGHT MANUAL

P2002-JR

SECTI ON 4

Normal Procedures

1

st

Edition 10

th

January 2007 4-2

INTRODUCTION

Section 4 contains checklists and the procedures for the conduct of normal

operation.

RIGGING AND DERIGGING ENGINE COWLING

UPPER COWLING:

I. Parking brake: ON

II. Fuel selector valve: OFF

III. Magnetos: OFF

IV. Generator & Master switches: OFF

V. Unlatch all four butterfly Cam-locks mounted on the cowling by rotating

them 90 counterclockwise while slightly pushing inwards.

VI. Remove engine cowling paying attention to propeller shaft passing

through nose.

VII. To assemble: rest cowling horizontal insuring proper fitting of nose base

reference pins.

VIII. Secure latches by applying light pressure, check for proper assembly and

fasten Cam-locks.

Butterfly Cam-locks are locked when tabs are horizontal and open

when tabs are vertical. Verify tab is below latch upon closing.

WARNING

FLIGHT MANUAL

P2002-JR

SECTI ON 4

Normal Procedures

1

st

Edition 10

th

January 2007 4-3

LOWER COWLING

I. After disassembling upper cowling, move the propeller to a horizontal

position.

II. Using a standard screwdriver, press and rotate 90 the two Cam-locks

positioned on lower cowling by the firewall.

III. Disconnect the ram-air duct from the NACA intake. Pull out the first

hinge pin positioned on the side of the firewall, then, while holding

cowling, pull out second hinge pin; remove cowling with downward

motion.

IV. For installation follow reverse procedure.

PRE-FLIGHT INSPECTIONS

Before each flight, it is necessary to carry out a complete inspection of the

aircraft starting with an external inspection followed by an internal inspection

as below detailed.

CABIN INSPECTION

I. Flight Manual: check that a copy is on board

II. Weight and balance: check if within limits

III. Safety belts: flight controls free from safety belts

IV. Magnetos: OFF

V. Master switch: ON and check the operation of the acoustic stall warning

VI. Master switch: OFF

VII. Baggage: check for a proper stowage and fastening with the retaining net

FLIGHT MANUAL

P2002-JR

SECTI ON 4

Normal Procedures

1

st

Edition 10

th

January 2007 4-4

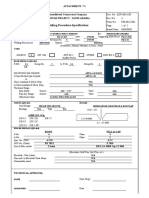

EXTERNAL INSPECTION

To carry out the external inspection it will be necessary to follow the checklist

below with the station order outlined in fig. 4-1.

Visual inspection is defined as follows: check for defects, cracks, detachments,

excessive play, unsafe or improper installation as well as for general condition.

For control surfaces, visual inspection also involves additional check for

freedom of movement and security.

A. Left fuel filler cap: check visually for desired fuel level. Drain the left fuel

tank by drainage valve using a cup to collect fuel. Check for water or other

contaminants.

FIG. 4-1

WARNING

FLIGHT MANUAL

P2002-JR

SECTI ON 4

Normal Procedures

1

st

Edition 10

th

January 2007 4-5

Fuel level indicated by the fuel quantity indicators (on the instrument panel) is

only indicative. For flight safety, pilot should verify actual fuel quantity embarked

before takeoff.

B. Remove protection cap and check the Pitot tube and the static ports mounted

on left wing are unobstructed, do not blow inside vents, place protection cap

inside the aircraft.

C. Left side leading edge and wing skin: visual inspection

D. Left tank vent: check for obstructions; Left aileron: visual inspection.

E. Left flap and hinges: visual inspection

F. Left main landing gear; check inflation 23 psi (1.6 bar), tire condition,

alignment, landing gear structure & fuselage skin condition.

G. Horizontal tail and tab: visual inspection.

H. Vertical tail and rudder: visual inspection; Battery case: closed.

I. Right main landing gear; check inflation 23 psi (1.6 bar), tire condition,

alignment, landing gear structure & fuselage skin condition.

I

1

Check the emergency LG extension system pressure (Working pressure: 20

2 bar)

L. Right flap and hinges: visual inspection.

M. Right aileron: visual inspection; Right side tank vent: check for obstructions

N. Right leading edge and wing skin: visual inspection.

O. Right the side fuel filler cap for desired fuel level and secure. Drain the right

fuel tank by the drainage valve using a cup to collect fuel. Check for water

or other contaminants.

P. Set the fuel selector valve OFF. Drain circuit using a cup to collect fuel by

opening the specific drainage valve (part of the gascolator). Check for water

or other contaminants (drainage operation must be carried out with the

aircraft parked on a level surface).

WARNING

FLIGHT MANUAL

P2002-JR

SECTI ON 4

Normal Procedures

1

st

Edition 10

th

January 2007 4-6

Q. Nose wheel strut and tire: check inflation 15 psi (1.0 bar), tire condition,

condition of shock absorber and retraction compass condition

R. Propeller and spinner condition: check for nicks, blades play in the hub.

S. Open engine cowling/s and perform the following checklist:

I. Check that no foreign objects are present.

II. Check the cooling circuit for leaks, check coolant level into the

expansion tank, insure radiator honeycomb is unobstructed.

III. Check lubrication circuit for leaks, check oil reservoir level, and insure

radiator honeycomb is unobstructed.

IV. Inspect fuel circuit for leaks.

V. Check integrity of engine silent-block suspensions.

VI. Check connection and integrity of air intake system, visually inspect

that ram air intake is unobstructed.

VII. Check that all parts are secured.

VIII. Check the integrity of muffler fixing springs

T. Close engine cowling.

U. Visual inspection of the Landing Light.

V. Remove tow bar and chocks.

NOTE

Avoid blowing inside Pitot-tube and inside airspeed indicator system's static vents

as this may damage instruments.

FLIGHT MANUAL

P2002-JR

SECTI ON 4

Normal Procedures

1

st

Edition 10

th

January 2007 4-7

CHECKLISTS

BEFORE STARTING ENGINE (after preflight inspection)

I. Flight controls: operate until their stop checking for movement

smoothness

II. Parking brake: engage

III. Throttle: free movement; set idle; adjust friction

IV. Propeller Pitch: minimum

V. Generator switch: ON, generator light ON, check the ammeter.

VI. Electric fuel pump: ON, (check for audible pump noise and fuel pressure)

VII. Check landing gear lights, verify functionality

VIII. Electric fuel pump: OFF

IX. Avionic Master switch: ON, instruments check, then set OFF position

X. Flap control: move flap between extreme positions

XI. Trim control: operate from both left and right controls the trim between

its extreme positions checking the trim position indicator

XII. Nav. light & Strobe light: ON, check

XIII. Landing light: ON, check

XIV. Landing light: OFF

XV. Fuel quantity: compare the fuel levels read by the fuel quantity indicators

with the quantity present into the tanks

XVI. Flight planning, fuel consumption, refuelling.

XVII. Seat position and safety belts adjustment

FLIGHT MANUAL

P2002-JR

SECTI ON 4

Normal Procedures

1

st

Edition 10

th

January 2007 4-8

In the absence of the passenger: fasten unused seat belts around the free seat

preventing interference with the operation of the aeroplane and with rapid

egress in an emergency.

XVIII. Canopy: Closed and locked

CAUTION

Master Avionic switch must be set OFF during the engines start-

up to prevent avionic equipments damages.

STARTING ENGINE

I. Circuit Breakers: check, all IN

II. Generator & Master switches: ON

III. Fuel selector valve: LEFT or RIGHT

IV. Electric fuel pump: ON (check for audible pump noise and fuel pressure)

V. Engine throttle: idle

VI. Propeller Pitch: minimum

VII. Choke: as needed

VIII. Propeller area: CLEAR

IX. Strobe light: ON

WARNING

Check to insure no person or object is present in the area close to

propeller.

X. Magnetos: BOTH

XI. Magnetos: START

NOTE

FLIGHT MANUAL

P2002-JR

SECTI ON 4

Normal Procedures

1

st

Edition 10

th

January 2007 4-9

XII. Check oil pressure rise within 10 sec. (maximum value: 7 bar)

XIII. Check engine instruments

XIV. Choke: OFF

XV. Propeller rpm: 1000-1100 rpm

XVI. Electric fuel pump: OFF

XVII. Check fuel pressure

XVIII. Electric fuel pump: ON

BEFORE TAXIING

I. Let the engine warms up to a min. oil temp. of 50C at 1100-1500 rpm.

II. Radio and Avionics: ON

III. Altimeter: set

IV. Direction indicator: set in accordance with the magnetic compass

V. Parking brake: OFF and taxi

TAXIING

I. Brakes: check

II. Flight instruments: check

PRIOR TO TAKE-OFF

I. Parking brake: ON

II. Check engine instruments:

Oil temperature: 50-110

Cylinder heads temperature: max 120

Oil pressure: 25 bar (above 1400 rpm); 0.8 bar (below 1400 rpm)

Fuel pressure: 2.2 5.8 psi (0.15 0.40 bar)

FLIGHT MANUAL

P2002-JR

SECTI ON 4

Normal Procedures

1

st

Edition 10

th

January 2007 4-10

III. Generator light: OFF (check)

IV. Throttle: 1700 rpm

V. MAP: increase, check

VI. Propeller speed check: pull completely 3 times (rpm drop 100200 rpm,

check the MAP increase and the oil pressure decrement)

VII. Magneto check: set L / R / BOTH (speed drop with only one ignition

circuit must not exceed 130 props rpm; maximum difference of speed by

use of either circuits LEFT or RIGHT is 50 rpm).

VIII. Check fuel quantity indicators.

IX. Flaps: T/O (15)

X. Stick free and trim set at zero

XI. Seat belts fastened and canopy closed and locked

TAKEOFF AND CLIMB

I. Call TWR to takeoff

II. Check for clear final and wind on runway

III. Parking brake: OFF

IV. Carburettors heat: OFF

V. Taxi to line-up

VI. Check magnetic compass and direction indicator

VII. Full throttle (approx. 2400 100 rpm)

VIII. Propeller pitch: minimum

IX. Engine instruments: check

X. Rotation speed Vr =35 KIAS

XI. Rotation and takeoff: check green lights and pump light turned off

XII. Apply brakes to stop wheel spinning

XIII. Flaps: retraction (at 300ft AGL)

XIV. Landing gear: up

FLIGHT MANUAL

P2002-JR

SECTI ON 4

Normal Procedures

1

st

Edition 10

th

January 2007 4-11

XV. Establish climb rate (Vy 66 KIAS)

XVI. Trim adjustment

XVII. Propeller speed: set 2400 rpm (after reaching safe height)

XVIII. Electric fuel pump: OFF

CRUISE

I. Reach cruising altitude

II. Throttle: as required

III. Propeller speed: 1900 2400 rpm

IV. Trim: as required

V. Check engine instruments

Oil temperature: 90110 C.

Temperature cylinder heads: 90 110 C

Oil pressure: 2 5 bar.

Fuel pressure: 2.2 5.8 psi (0.15 0.40 bar)

VI. Carburettor heat as needed, see paragraph on carb. heat in Section 3.

NOTE

Compensate unpredicted asymmetrical fuel consumption between left

and right fuel tanks operating the fuel selector valve. Switch on the

electric fuel pump prior to swap the fuel feeding from one tank to

another

BEFORE LANDING

I. Electric fuel pump: ON

II. Throttle: as required

III. Propeller Pitch: minimum

FLIGHT MANUAL

P2002-JR

SECTI ON 4

Normal Procedures

1

st

Edition 10

th

January 2007 4-12

IV. On downwind leg: speed 65 KIAS; Flaps: T/O (15)

V. On final leg: speed 56 KIAS; Flaps: Land (40)

VI. Landing gear: down,, verify the green lights turning on

VII. Establish descent

VIII. Optimal touchdown speed: 50 KIAS

BALKED LANDING

I. Full throttle

II. Propeller Pitch: minimum

III. Speed: 60 KIAS

IV. Carburettor heating: OFF (check)

V. Electric fuel pump: ON (check)

VI. Flaps position: T/O

VII. Landing gear: up

AFTER LANDING

I. Taxiing at an appropriate speed

II. Flaps: UP

III. Complete stop at parking

IV. Parking brake: engage

ENGINE SHUT DOWN

I. Keep engine running at 1200 rpm for about one minute in order to

reduce latent heat.

II. Electric fuel pump: OFF

III. Turn off all electrical utilities (with the exception of the Strobe Light)

IV. Magnetos: OFF

FLIGHT MANUAL

P2002-JR

SECTI ON 4

Normal Procedures

1

st

Edition 10

th

January 2007 4-13

V. Strobe light: OFF

VI. Master & Generator switches: OFF

VII. Fuel selector valve: OFF

VIII. Parking brake: engaged (check)

POSTFLIGHT CHECK

I. Insert hood over pitot tube on left wing

II. Lock commands using safety belts.

III. Close canopy.

FLIGHT MANUAL

P2002-JR

SECTI ON 4

Normal Procedures

1

st

Edition 10

th

January 2007 4-14

INTENTIONALLY LEFT BLANK

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Technical Proposals For The Treatment of Wood Ammonia Batch ProcessDocument3 pagesTechnical Proposals For The Treatment of Wood Ammonia Batch Processviorelu99No ratings yet

- 3 Emergency ProceduresDocument12 pages3 Emergency Proceduresviorelu99No ratings yet

- Sound Proofing Light Aircraft (And Other Stuff Too!)Document13 pagesSound Proofing Light Aircraft (And Other Stuff Too!)viorelu99100% (1)

- Blades Manufacturing of Main Rotor PDFDocument29 pagesBlades Manufacturing of Main Rotor PDFviorelu990% (1)

- 1 GeneralDocument12 pages1 Generalviorelu99No ratings yet

- A Pocket Guide To EFT For AddictionsDocument16 pagesA Pocket Guide To EFT For AddictionsAntonio Iglésias Marques100% (6)

- Fusion of Eight Psychic Channels - Opening and Sealing Psychic Channels PDFDocument48 pagesFusion of Eight Psychic Channels - Opening and Sealing Psychic Channels PDFAlexandra Ioana Niculescu100% (2)

- Reducing Blood Pressure NaturallyDocument2 pagesReducing Blood Pressure Naturallyviorelu99No ratings yet

- Poly Works Beginners GuideDocument121 pagesPoly Works Beginners GuideMałgorzata Butkiewicz100% (1)

- Health and Criminal RecordDocument1 pageHealth and Criminal Recordviorelu99No ratings yet

- Understanding Aircraft StructuresDocument224 pagesUnderstanding Aircraft Structuresviorelu9950% (2)

- AT3 Manual 8Document6 pagesAT3 Manual 8viorelu99No ratings yet

- Herbs and Their Magickal PropertiesDocument15 pagesHerbs and Their Magickal Propertieshermo100% (20)

- Extraordinary Encounters PDFDocument307 pagesExtraordinary Encounters PDFDunkMe100% (2)

- The Procrastination MatrixDocument33 pagesThe Procrastination Matrixviorelu99No ratings yet

- 5 PerformancesDocument14 pages5 Performancesviorelu99No ratings yet

- AT3 Manual 4Document9 pagesAT3 Manual 4viorelu99No ratings yet

- AT3 Manual 7Document14 pagesAT3 Manual 7viorelu99No ratings yet

- AT3 Manual 5Document9 pagesAT3 Manual 5viorelu99No ratings yet

- AT3 Manual 3Document5 pagesAT3 Manual 3viorelu99No ratings yet

- 2 LimitationsDocument14 pages2 Limitationsviorelu99No ratings yet

- AT3 Manual 6Document6 pagesAT3 Manual 6viorelu99No ratings yet

- AT3 Manual 2Document8 pagesAT3 Manual 2viorelu99No ratings yet

- AT3 Manual 1Document9 pagesAT3 Manual 1viorelu99No ratings yet

- THE ALPHA-NETICS RAPID READING PROGRAM - Owen D (1) SkousenDocument114 pagesTHE ALPHA-NETICS RAPID READING PROGRAM - Owen D (1) Skousenfreeplump3100% (8)

- The Mysterious Life and Death of DR ReichDocument6 pagesThe Mysterious Life and Death of DR Reichviorelu99No ratings yet

- Photoreading Whole Mind System - Paul ScheeleDocument169 pagesPhotoreading Whole Mind System - Paul ScheeleMorgan Rook100% (3)

- 6 - Audits and Surveys - SoP - INSTR 75-03P-02Document12 pages6 - Audits and Surveys - SoP - INSTR 75-03P-02viorelu99No ratings yet

- NASA Clean Room ChecklistDocument6 pagesNASA Clean Room Checklistviorelu99No ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Postgrad Courses PDFDocument36 pagesPostgrad Courses PDFShah Wali UllahNo ratings yet

- Steel Structure Fabrication Work: Inspection and Test Plan (Itp)Document6 pagesSteel Structure Fabrication Work: Inspection and Test Plan (Itp)Togar Richard SihotangNo ratings yet

- Greaves Power 100 Kva Silent Diesel GeneratorDocument2 pagesGreaves Power 100 Kva Silent Diesel Generatorabhinav9274No ratings yet

- 032 Aeroplane Performance (JAA ATPL Theory)Document429 pages032 Aeroplane Performance (JAA ATPL Theory)dforceman0% (1)

- Product CatalogDocument106 pagesProduct CatalogAri AzadNo ratings yet

- Hyster j2 2 3 5xnDocument12 pagesHyster j2 2 3 5xnBraveBoy JalloNo ratings yet

- 6.7L Cummins Maintenance Schedule & Service InformationDocument3 pages6.7L Cummins Maintenance Schedule & Service InformationNick Brady100% (1)

- Cek Item SapDocument30 pagesCek Item Sapiduy emailsNo ratings yet

- Gears PresentationDocument33 pagesGears PresentationNaveen YadavNo ratings yet

- Curriculam Vitae: Mohamed Ibrahim.mDocument4 pagesCurriculam Vitae: Mohamed Ibrahim.mAzizul AnwarNo ratings yet

- Consolidated Contractors Welding Procedure SpecificationDocument3 pagesConsolidated Contractors Welding Procedure Specificationsiva8000100% (1)

- An Insight of Compacted Graphite Iron (Cgi) Characteristics and Its Production A ReviewDocument18 pagesAn Insight of Compacted Graphite Iron (Cgi) Characteristics and Its Production A ReviewMiguel BrionesNo ratings yet

- FVD SeminarDocument2 pagesFVD Seminaranand_316764947No ratings yet

- Escort Limited Champion F 11 Brand Name - FarmtracDocument12 pagesEscort Limited Champion F 11 Brand Name - Farmtrachugo fernandezNo ratings yet

- Taneks Deutz CatalogueDocument123 pagesTaneks Deutz CatalogueeCommerce SAJID AutoNo ratings yet

- Depressurisation - A Practical GuideDocument20 pagesDepressurisation - A Practical GuideAhmad Firman Masudi100% (2)

- Bending and Transverse TensionDocument23 pagesBending and Transverse TensionAsghar Hussain ShahNo ratings yet

- 236d ElectricalDocument4 pages236d ElectricalJavier CaceresNo ratings yet

- Characteristics Series CE, CP, C: 2 Way Slip-In Cartridge ValvesDocument17 pagesCharacteristics Series CE, CP, C: 2 Way Slip-In Cartridge Valvess_waqarNo ratings yet

- Overhauling Slipring Motors StandardDocument19 pagesOverhauling Slipring Motors StandardAhmed AshourNo ratings yet

- CV Rod Manuel TayaoDocument4 pagesCV Rod Manuel TayaojaymarNo ratings yet

- Downtime BD TyreDocument127 pagesDowntime BD TyreRidhani IqbalNo ratings yet

- Assemble Xootr Scooter in Under 20 MinutesDocument1 pageAssemble Xootr Scooter in Under 20 MinutesPulkit AggarwalNo ratings yet

- PFEIFER Tension Rod System: Data Sheet CollectionDocument16 pagesPFEIFER Tension Rod System: Data Sheet Collectioncerbu_bass_cdcNo ratings yet

- LHB Monograph PDFDocument60 pagesLHB Monograph PDFVijay Ranjan KumarNo ratings yet

- Shear & Diagonal Tension in BeamsDocument15 pagesShear & Diagonal Tension in BeamsS. M. ZAHIDUR RAHMAN 1301129No ratings yet

- Grindex Lista de PartesDocument28 pagesGrindex Lista de PartesMarco Antonio Cerna HaroNo ratings yet

- Img 20180122 0001 PDFDocument2 pagesImg 20180122 0001 PDFAnonymous vtZNXtACNo ratings yet

- Corner Cast in Place AnchorDocument7 pagesCorner Cast in Place Anchorwaweng22No ratings yet

- MMA welding electrode changes and weld defectsDocument14 pagesMMA welding electrode changes and weld defectsUmaibalanNo ratings yet