Professional Documents

Culture Documents

DRP Faq

Uploaded by

Rahul KulkarniOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DRP Faq

Uploaded by

Rahul KulkarniCopyright:

Available Formats

FAQ - Distribution Planning in R12 - DRP / DPP

(Doc ID 761820.1)

To

Bottom

Modified:13-

May-2013

Type:FAQ

In this Document

Purpose

Users Guide Used For

Reference

Resource List

Questions and Answers

When discussing

Distribution Planning,

why do some people

use the term DPP and

others DRP?

What are the main

features of Distribution

Planning?

Does Distribution

Planning look at

resource constraints?

What kind of

business/verticals

require Distribution

Planning solution?

How does typically

ASCP integrate with

Distribution Planning

solution?

Does Distribution

Planning looks into

multi level BOM?

What is inventory

rebalancing?

I want to do inventory

rebalancing only after

ensuring that my next 4

days demands are met.

Only excess over and

above that should be

used to transfer it to

other org. Is it possible?

What types of supplies

are considered available

for inventory

rebalancing?

What planning method I

should use to plan my

items in Distribution

Planning?

I am not able to plan

trips, Why?

How do I set up by

Shipment Method /

Transit mode

capacities?

What is the default

demand priority used by

Distribution Planning.

Is it mandatory for me

to define demand

priority?

When should I

define/use demand

priority rules?

Can we have telescopic

allocation buckets?

What is the use of

allocation buckets?

How do the rules for

demand priority,

allocation bucket and

supply allocation work

together?

Which calendar is used

to create allocation

bucket?

By default Sales Order

(SO) has higher priority

than Forecast, does it

mean if SO on Day10

and Forecast is on

Day3, we still allocate

the supply to SO first

and starve the Forecast?

Is it mandatory to

define supply allocation

rules?

Can we have allocation

from some sources

based on org priority

and from other sources

based on demand

prioritization rule?

I have demand at Org2

and Org1 is source,

which has supply.

When I run Distribution

Planning plan, I see two

types of shipment

orders. It generates

recommended

shipments and planned

shipments. What is the

difference between the

two types?

Which order modifiers

are considered by

Distribution Planning?

Does Distribution

Planning support

Planning Time Fence

(PTF)?

How does Infinite Time

Fence (ITF) Horizon

Days work? Is it

applicable to all the

orgs?

Are allocation buckets

end dates fixed or

dynamic?

I am not able to release

IR/ISO. Getting errors,

which look related to

OM in the log file

What are the

Distribution Planning

specific profiles, which

I need to be aware of?

Why Does DRP Plan

Show Zero Qty for PO

Or Req With Action -

Cancel?

When releasing an

internal Order from

Distribution Planning,

the In transit Lead time

is not reflected in the

Suggest dock date -

Why?

How To Use The New

User Defined Row For

The Horizontal Plan in

11.5.10, 12.0 and 12.1

Why do sometimes I

dont see my future firm

supplies netted with

current demand and I

see a new planned order

created by DRP?

With 11.5.10 source,

why am I not able to

release Inter Operating

Unit planned Inbound

shipments?

Sometimes I dont see

inventory rebalancing

happening even though

I have enough supplies

in the supplying org.

Why Target Inventory

level when maintaining

Safety Stock is enough

for me?

How can I define target

and maximum

inventory levels?

Why are All Planned

Order Supplies from

Supply Schedule

(ASCP Plan) Firm in

the DRP Plan output?

Can We Release These

Planned Orders from

the DRP Plan?

Can DRP see IR/ISO

that is created by

Inventory Min-Max

Planning?

References

APPLIES TO:

Oracle Advanced Supply

Chain Planning - Version

12.0.4 to 12.1 [Release 12 to

12.1]

Information in this

document applies to any

platform.

PURPOSE

***Checked for relevance

on 19-NOV-2011***

Development and Product

Management for APS

(Advanced Planning and

Scheduling) Applications,

working with Support has

put together this list of

Frequently Asked Questions

to help Support and Users

have a better understanding

the Distribution Planning:

Users Guide Used For

Reference

Oracle Advanced Supply

Chain Planning

Implementation and User's

Guide

Release 12 (12.1.1) Part No.

E13358-02 - October 2008

(Download Link - 8.6 MB)

Resource List

Note 412702.1 Getting

Started with R12 -

Advanced Planning and

Scheduling Suite FAQ

Note 414332.1 Getting

Started With R12 -

Advanced Planning Support

Enhanced RCD

This includes links to

presentations and PDF of

Powerpoint presentations.

Note 397199.1 R12 Feature

Document - Distribution

Planning

For 12.1.1 - See Note

763631.1 R12.1 Advanced

Planning and Scheduling -

Support Enhanced RCD -

Release Change Document

QUESTIONS AND

ANSWERS

When discussing

Distribution Planning, why

do some people use the

term DPP and others DRP?

In 11i10, the term DRP was

phased out. When

Distribution Planning was

introduced in R12, the

abbreviation is DPP.

However, many R12 users

refer to Distribution

Planning as DRP.

This should not be confused

with old standard MRP style

Supply Chain Planning in

11.5.9 and below where

DRP was seen in the menu

and item attributes Planning

Method lookup.

What are the main features

of Distribution Planning?

Fair share allocation, Load

consolidation , inventory

rebalancing and ability to

define inventory policy at

multiple levels.

Added ability to release both

the Internal Requisition (IR)

and the Internal Sales Order

(ISO) from the plan. Ability

to reschedule both the

existing IR and the ISO

from plan

See Note 414332.1 Getting

Started With R12 -

Advanced Planning Support

Enhanced RCD for more

information and links to TOI

presentations

Does Distribution Planning

look at resource

constraints?

No.

No. Distribution Planning is

designed to create detailed

distribution plan given the

supply schedule.

Distribution Planning plan is

mainly constrained by

shipping load sizing (Truck

capacity); supplier capacity,

supplier lead-time and inter-

org trans lead-time.

Distribution Planning does

not consider resources and

routings

What kind of

business/verticals require

Distribution Planning

solution?

Any business with

distribution intensive

environment would need

Distribution Planning

solution to create optimal

distribution plan. This can

include mfg where a

company manages both mfg

and distribution.

Distribution Planning is

designed to integrate well

with mfg planning in ASCP.

How does typically ASCP

integrate with Distribution

Planning solution?

Distribution Planning can be

used to push down Store /

Regional Distribution

Centers(RDC) / Distribution

Centers(DC) level demands

to the Manufacturing plant

where ASCP is run. After

creating constraint supply

schedule in ASCP,

Distribution Planning can be

used to allocate and push

supplies to

DCs/RDCs/Warehouses.

Does Distribution Planning

looks into multi level BOM?

Distribution Planning

supports kitting, which is

typically required to create a

small kitting assembly or to

pack items together at

DC/RDCs/Warehouses.

Distribution Planning can

explode multi-level Bill Of

Material(BOMs). However,

typically distributors would

not require this feature.

For more details , see

Defining Bills of Material

for Kitting in User Guide

page 12-3.

What is inventory

rebalancing?

If a particular RDC1 has

excess inventory and the

other RDC2 needs supply

then instead of pushing

down the RDC2 demand to

primary source and

ultimately to plant, it makes

sense to utilize the inventory

present in the network.

Inventory rebalancing first

looks at the inv present in

the rebalancing org (RDC1

here) and create inventory

transfer orders from RDC1

to RDC2. Any unmet

demand at RDC2 is passed

on to primary source. It

balances the supplies across

the network and reduce

excess inv production.

For more details , see

Inventory Rebalancing in

User Guide page 12-21..

I want to do inventory

rebalancing only after

ensuring that my next 4

days demands are met.

Only excess over and

above that should be used

to transfer it to other org. Is

it possible?

Only excess over and above

that should be used to

transfer it to other org. Is it

possible?

Ans: Yes.There is a

parameter in the plan option

InvRebalancing surplus

days. Use this parameter.

It is important to set this

parameter in the plan

options. If this parameter is

set to 0 (ZERO), then you

can see excessive

rebalancing shipments

between locations occurring

almost daily.

For more details , see

Setting Distribution Plan

Options in User Guide

page 13-11.

What types of supplies are

considered available for

inventory rebalancing?

Only firm supplies are

considered for inventory

rebalancing (On Hand

supplies, and any supply

that shows the Firm Flag

checked in the Planner

Workbench).

What planning method I

should use to plan my

items in Distribution

Planning?

In Item Attributes -

MPS/MRP Planning Tab -

set the Distribution Planning

planned flag to yes. Notice

that this item attribute is

different from MRP

Planning Method.

For more details , see

Defining Items as

Distribution Planned in

User Guide pg 12-2.

I am not able to plan trips,

Why?

In the Item Attributes

Physical Attributes Tab,

check the setups for Weight

and Volume

How do I set up by

Shipment Method / Transit

mode capacities?

In the:Transit Times form,

set the maximum trip limits

in terms of weight and

volume.

For more details , see

Defining Trip Limits for

Ship Methods by Lane in

User Guide. pg 12-7

What is the default demand

priority used by

Distribution Planning. Is it

mandatory for me to define

demand priority?

If demand priority rules are

not defined then

Distribution Planning will

use following priority, Sales

Orders> Forecast >

Overconsumed Forecast>

Safety Stock > Target

Inventory > Excess.

When should I define/use

demand priority rules?

Typically when you want to

prioritize one customers

Sales Order (SO) over other

or one orgs SO over other

then set up demand classes

and use the demand class, to

can prioritize the orders and

forecasts. Ion the priority

rules, specify which demand

classes have a higher or

lower priority.

For more details , see

Setting Up Distribution

Planning in User Guide

Can we have telescopic

allocation buckets?

Yes. We can have daily

allocation buckets for some

duration and then we can

have weekly for the

remaining planning

duration. Or we can have

only period (monthly)

allocation bucket.

See the next two questions

for more information.

What is the use of

allocation buckets? How do

the rules for demand

priority, allocation bucket

and supply allocation work

together?

Supply allocation to demand

is done by each allocation

bucket, one bucket at a time.

First we look at the highest

priority demands and within

a bucket, all demands

having that priority are

allocated the supply first,

based on the supply

allocation rule. Note that

allocation bucket and the

plan buckets are two very

different concepts.

Which calendar is used to

create allocation bucket?

The calendar defined in

profile MSC: Calendar

Reference for Bucketing

Plan is used for bucketing.

If not defined, we have seen

plan failures in DRP and

ASCP planning.

Can be defined at the

Responsibility Level for

Distribution planning if a

different calendar is

required than the one used

for ASCP.

IF not defined AND the plan

completes without error,

THEN the calendar for Org

owning the plan would be

used for bucketing.

By default Sales Order (SO)

has higher priority than

Forecast, does it mean if

SO on Day10 and Forecast

is on Day3, we still allocate

the supply to SO first and

starve the Forecast?

We do supply allocation by

allocation-bucket. In this

example if the bucket is

daily then the Forecast is

first allocated. We look for

demand priority within the

bucket. If the allocation

bucket in the above example

is monthly then we will first

allocate to SO because now

both the demands fall in the

same bucket and SO gets

higher priority over

Forecast.

Is it mandatory to define

supply allocation rules?

No. You can define default

fair share allocation rule on

the plan options- Main Tab

Can we have allocation

from some sources based

on org priority and from

other sources based on

demand prioritization rule?

No. Once we select Use

Organization Priority

Overrides" on the Main Tab

in Distribution Planning

Plan Option, it overrides all

other demand priority.

I have demand at Org2 and

Org1 is source, which has

supply. When I run

Distribution Planning plan,

I see two types of shipment

orders. It generates

recommended shipments

and planned shipments.

What is the difference

between the two types?

Recommended orders are

unconstrained orders used to

push down the demand to its

source. Whereas planned

shipment orders are actual

orders, which we can

release, and its based on

constrained supplies.

For more details , see

Managing Distribution

Plans in User Guide.

Which order modifiers are

considered by Distribution

Planning?

Distribution Planning

considers Fixed Lot

Multiplier (FLM). It can be

defined at item attributes

level for the destination org.

FLM can also be defined as

a source-destination pair for

the destination org, in the

supply allocation rule. The

FLM defined in supply

allocation rule is considered

first before item attribute

FLM.

In VCP 12.1.3.8, DRP now

supports two more order

modifiers: maximum order

quantity and minimum order

quantity. This is in addition

to the currently supported

fixed lot multiplier and

round order modifiers. Users

can specify maximum and

minimum order quantity as

an item attribute. Users can

also choose to specify each

newly supported order

modifier on the supply

allocation rule. Order

modifiers specified on a

supply allocation rule are

applied to transfers between

organizations. Ref the

release notes - Note

1462299.1

Ref Note 746824.1 for more

information on our

cumulative patches for

12.1.3.

Does Distribution Planning

support Planning Time

Fence (PTF)?

Yes. Within the PTF,

Distribution Planning

doesnt create any new

planned orders or any new

planned shipment

(inbound/outbound).

How does Infinite Time

Fence (ITF) Horizon Days

work? Is it applicable to all

the orgs?

ITF is applied to only those

orgs, which have a supply

schedule. Supplies outside

the ITF are considered

unconstrained (unlimited).

Trip consolidation and fair

share allocation is not done

outside the ITF

For more details , see

Defining Distribution

Plans in User Guide.

Are allocation buckets end

dates fixed or dynamic?

Allocation buckets end dates

are fixed, its based on the

planning calendar. Note that

if only weekly allocation

buckets are selected in the

plan option, then the number

of days in the first week

allocation bucket is

dynamic, depending on

which day of the week the

plan is run on. Similarly, if a

combination of daily and

weekly allocation buckets

are selected, then the

number of daily allocation

buckets is dynamic so that

the last daily allocation is

always the last day of the

first week in the plan.

I am not able to release

IR/ISO. Getting errors,

which look related to OM in

the log file

Go to OM / Set up /

Transaction types / Define.

Check if for the transaction

type Internal SO, all the

set up is correctly defined

be sure to check the

Effective Dates end date.

Also see:

Note.757599.1 - In

Distribution Planning When

Canceling, The Checkbox

'For Release' is Not

Unchecked After Release

Note.746762.1 - Release of

Shipments For DRP Plan

Errors When Trying To

Create Internal Req and

Internal Sales Order

What are the Distribution

Planning specific profiles,

which I need to be aware

of?

MSC: Distribution Planning

Ship Date

MSC: Cancel Outstanding

Sales order quantities

MSO: Maximum Inventory

level % of Safety Stock

MSO: Target Inventory

Level % of Safety Stock

MSC:Inventory Rebalancing

Surplus Inventory basis

MSC: DPP discrete job

cutoff window (Days)

For more details , see

Profile Options in User

Guide.

Why Does DRP Plan Show

Zero Qty for PO Or Req

With Action - Cancel?

Please see Note

760428.1 for the explanation

When releasing an internal

Order from Distribution

Planning, the In transit

Lead time is not reflected in

the Suggest dock date -

Why?

Please see Note

758493.1 for the explanation

How To Use The New User

Defined Row For The

Horizontal Plan in 11.5.10,

12.0 and 12.1

Please

see Note.743420.1 for the

explanation of this

functionality

Added 18-Sep-2009

Why do sometimes I dont

see my future firm supplies

netted with current demand

and I see a new planned

order created by DRP?

In DRP, we do netting of

supply and demand within

an allocation bucket.

So if allocation bucket is say

weekly then supplies of 2nd

week onwards wont be

used to meet the demand of

1st week.

This is current

functionality.

To make this functionality

more flexible, in R12 CU8

we have provided one

profile where based on the

business requirement, user

can select whether to net

supplies of next buckets to

meet demands of current

buckets. The profile name is

"MSC: Distribution

Planning Use Firm Supplies

and Minimize Excess

Supplies".

Note 421097.1 shows latest

CU (Cumulative) Patches

released for R12.0.4/12.0.6

With 11.5.10 source, why

am I not able to release

Inter Operating Unit

planned Inbound

shipments?

You need to set profile

MO:Operating Unit at the

Responsibility level as

Source Orgs operating unit ,

in which ISO gets created.

If you have a scenario where

some of the items are

sourced from one operating

unit and others sourced from

different operating unit then,

you need to create two

responsibilities and set the

profile MO:Operating Unit

at the responsibility level for

each. Use the correct

responsibility while

releasing planned inbound

shipment

CAUTION: In a distributed

installation, where you have

EBS Source and APS

Destination on separate

instances, then the

responsibility must be

defined on BOTH the EBS

Source and APS

Destination and all fields

must match exactly. Then

assign the responsibility to

the user in both instances

Sometimes I dont see

inventory rebalancing

happening even though I

have enough supplies in

the supplying org.

Inventory rebalancing tries

to meet demand on time. So

if we have demand in Org A

on day 3 and supply in org

B on Day 1 and transfer lead

time from B to A is 5 days

then DRP doesnt do

inventory rebalancing since

the demand in Org A cant

be met on time. In such

scenario , DRP creates

planned Inbound from the

primary source org even if

the demand is met late from

this source org.

Why Target Inventory level

when maintaining Safety

Stock is enough for me?

Target Inventory level

allows flexibility while

planning trip due dates. This

helps in planning effective

truckloads and thus utilizing

transport constraints

effectively. We can decide

whether we want to plan for

new supplies to meet Target

Inventory levels.

Moreover and most

importantly, target inventory

is used to push excess

supplies from plants into the

distribution system.

How can I define target and

maximum inventory levels?

Following hierarchy is used

to define and derive target

and maximum inventory

levels:

A) Time phased target and

max inventory levels can be

defined directly in DRP.

B) If not defined then

planning uses item attribute

level target and max

inventory definition.

C) If its not defined then

plan will use profiles, MSO:

Maximum Inventory level

% of Safety Stock and

MSO: Target Inventory

Level % of Safety Stock to

calculate inventory levels.

Why are All Planned Order

Supplies from Supply

Schedule (ASCP Plan) Firm

in the DRP Plan output?

Can We Release These

Planned Orders from the

DRP Plan?

Supply Schedule

Orders are always firm

in the plan output. This

is per design.

You cannot release

supplies that are

coming from ASCP

manufacturing plan

from a DRP distribution

plan.

The source of truth for

the supplies planning in

ASCP manufacturing

plans are those same

manufacturing plans.

Supplies need to

released from ASCP

manufacturing plans

only.

Can DRP see IR/ISO that is

created by Inventory Min-

Max Planning?

While we realize the right

way to do Min-Max

planning with DRP is to use

the Safety Stock / Target /

Maximum inventory levels

for DRP inventory

rebalancing .. But we are

currently using this solution

and cannot switch all

items/users at one time.

Yes, DRP will see these

IR/ISO's that have been

created IF the item is also

checked for DRP Planning

in the item setups.

Notes:

1. In order to

see all the

supplies and

demands,

both orgs

must be

included in

the plan

options and

sales orders

parameter

should be

checked.

2. Also if the

demand for

these items is

not in the

plan, then we

can

recommend

that we

cancel the

requisitions

and the sales

orders. So in

this case,

using profile

MRP: Firm

Internal

Orders

transfered to

OE = Yes

should be

used.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- w9 - L2 - Review For Lecture Midterm 2Document14 pagesw9 - L2 - Review For Lecture Midterm 2Rashid AyubiNo ratings yet

- Hershey Case StudyDocument16 pagesHershey Case StudyNino50% (2)

- Purchase 50.000 MT of CoalDocument1 pagePurchase 50.000 MT of CoalFarlinton HutagaolNo ratings yet

- Req ImportDocument2 pagesReq ImportRahul KulkarniNo ratings yet

- Marketing Entry LevelDocument1 pageMarketing Entry LevelRahul KulkarniNo ratings yet

- Hyperion PlanningDocument5 pagesHyperion PlanningAnndyChiricaNo ratings yet

- SubstitutionkinikDocument23 pagesSubstitutionkinikRahul KulkarniNo ratings yet

- PO ApprovalDocument1 pagePO ApprovalRahul KulkarniNo ratings yet

- Ascp Process1234Document2 pagesAscp Process1234Rahul Kulkarni100% (1)

- Purchasing RoleDocument1 pagePurchasing RoleRahul KulkarniNo ratings yet

- Supply Chain ERDDocument1 pageSupply Chain ERDidealbloomsNo ratings yet

- ASCP Item Attribute Simulation SetsDocument10 pagesASCP Item Attribute Simulation SetsRahul KulkarniNo ratings yet

- PLSQL Syllabus CoveredDocument1 pagePLSQL Syllabus CoveredRahul KulkarniNo ratings yet

- Terms To ExploreDocument1 pageTerms To ExploreRahul KulkarniNo ratings yet

- PO ApprovalDocument1 pagePO ApprovalRahul KulkarniNo ratings yet

- R12.2 VCP UgDocument266 pagesR12.2 VCP UgRahul KulkarniNo ratings yet

- Item Class2Document1 pageItem Class2Rahul KulkarniNo ratings yet

- CaseDocument1 pageCaseRahul KulkarniNo ratings yet

- Execise 1Document2 pagesExecise 1Rahul KulkarniNo ratings yet

- Reduce MPSDocument1 pageReduce MPSRahul KulkarniNo ratings yet

- AnswersDocument24 pagesAnswersRahul KulkarniNo ratings yet

- Places To VisitDocument3 pagesPlaces To VisitRahul KulkarniNo ratings yet

- Mensuration PDFDocument89 pagesMensuration PDFRahul KulkarniNo ratings yet

- PO ApprovalDocument1 pagePO ApprovalRahul KulkarniNo ratings yet

- PO ApprovalDocument1 pagePO ApprovalRahul KulkarniNo ratings yet

- How To Resubmit Pending TxnsDocument6 pagesHow To Resubmit Pending TxnsRahul KulkarniNo ratings yet

- AnswersDocument24 pagesAnswersRahul KulkarniNo ratings yet

- PO ApprovalDocument1 pagePO ApprovalRahul KulkarniNo ratings yet

- PO ApprovalDocument1 pagePO ApprovalRahul KulkarniNo ratings yet

- ATP CaluclationsDocument7 pagesATP CaluclationsRahul KulkarniNo ratings yet

- Creating Resource in Oracle BOM: Bill of MaterialDocument2 pagesCreating Resource in Oracle BOM: Bill of MaterialRahul KulkarniNo ratings yet

- Understanding A Scaled Score: What Is A Scale?Document3 pagesUnderstanding A Scaled Score: What Is A Scale?Rahul KulkarniNo ratings yet

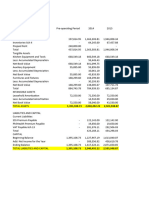

- Business Viability CalculatorDocument3 pagesBusiness Viability CalculatorKiyo AiNo ratings yet

- Aeon Corporate EthicsDocument0 pagesAeon Corporate EthicsTan SuzenNo ratings yet

- InvoiceDocument1 pageInvoicetanya.prasadNo ratings yet

- Importance of Project Management in ConstructionDocument10 pagesImportance of Project Management in ConstructionNicole SantillanNo ratings yet

- Mandy Craven: Career ObjectiveDocument2 pagesMandy Craven: Career ObjectiveMandy CravenNo ratings yet

- VP Director Sales Pharmaceuticals in Philadelphia PA Resume James BruniDocument3 pagesVP Director Sales Pharmaceuticals in Philadelphia PA Resume James BruniJamesBruni10% (1)

- The BEST PAPER CPM 26086235 A Palladium Group White PaperDocument24 pagesThe BEST PAPER CPM 26086235 A Palladium Group White PaperColiveira_brNo ratings yet

- Chapter 1Document4 pagesChapter 1Micaela BakerNo ratings yet

- CRM Course No. 10 - 2020 - Complaints and Claims ManagementDocument11 pagesCRM Course No. 10 - 2020 - Complaints and Claims ManagementMihaela ZăbavăNo ratings yet

- Tax Invoice/Bill of Supply/Cash Memo: (Original For Recipient)Document1 pageTax Invoice/Bill of Supply/Cash Memo: (Original For Recipient)Ganesh PrabuNo ratings yet

- Suse Ha Saphana WPDocument17 pagesSuse Ha Saphana WPaterchenNo ratings yet

- The Entrepreneurial ProcessDocument13 pagesThe Entrepreneurial ProcessNgoni Mukuku100% (1)

- Appendix V-Honda CSR 003Document11 pagesAppendix V-Honda CSR 003SowdayyaNo ratings yet

- Sample Format FSDocument2 pagesSample Format FStanglaolynetteNo ratings yet

- Test 1 MCQDocument3 pagesTest 1 MCQKarmen Thum50% (2)

- Mergers and AcquisitionDocument17 pagesMergers and AcquisitionKhushal Mittal33% (3)

- Marketing IndividualDocument2 pagesMarketing Individualsinyi0No ratings yet

- Indo Gold Mines PVT LTDDocument30 pagesIndo Gold Mines PVT LTDSiddharth Sourav PadheeNo ratings yet

- Male, 26 Years: Email: Mip@tapmi - Edu.in Mob: +91 7008878125 Roll No.: 18S723Document1 pageMale, 26 Years: Email: Mip@tapmi - Edu.in Mob: +91 7008878125 Roll No.: 18S723Kushal KanungoNo ratings yet

- Lesson 10 - Beverage Control Systems (Revised)Document17 pagesLesson 10 - Beverage Control Systems (Revised)Daniela FotaNo ratings yet

- Chapter 1 Global ServiceDocument23 pagesChapter 1 Global ServiceRandeep SinghNo ratings yet

- Ibs Bukit Pasir, BP 1 31/03/22Document5 pagesIbs Bukit Pasir, BP 1 31/03/22Design ZeroNo ratings yet

- HBX 6516DS VTMDocument2 pagesHBX 6516DS VTMRoma Zurita100% (1)

- Design and Implementation of Real Processing in Accounting Information SystemDocument66 pagesDesign and Implementation of Real Processing in Accounting Information Systemenbassey100% (2)

- Start A New Challenge - FXIFYDocument1 pageStart A New Challenge - FXIFYSähïl GäjëräNo ratings yet

- NAFTA Verification and Audit ManualDocument316 pagesNAFTA Verification and Audit Manualbiharris22No ratings yet

- Saji DDDD DDDDDocument37 pagesSaji DDDD DDDDTalha Iftekhar Khan SwatiNo ratings yet