Professional Documents

Culture Documents

1 s2.0 S1385894713010796 Main

Uploaded by

Clinton ThomsonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1 s2.0 S1385894713010796 Main

Uploaded by

Clinton ThomsonCopyright:

Available Formats

Glycerol valorisation as biofuels: Selection of a suitable solvent for an

innovative process for the synthesis of GEA

Rui P.V. Faria, Carla S.M. Pereira

, Viviana M.T.M. Silva, Jos M. Loureiro, Alrio E. Rodrigues

Laboratory of Separation and Reaction Engineering, Department of Chemical Engineering, Faculty of Engineering of University of Porto, 4200-465 Porto, Portugal

h i g h l i g h t s

Solvent selection for reactive

adsorptive processes: Synthesis of

glycerol acetal.

Acetalization of glycerol over

Amberlyst-15 in the presence of

dimethyl sulfoxide.

Kinetic model considering a LHHW

mechanism and diffusion inside the

catalyst.

g r a p h i c a l a b s t r a c t

a r t i c l e i n f o

Article history:

Received 30 March 2013

Received in revised form 6 August 2013

Accepted 12 August 2013

Available online 21 August 2013

Keywords:

Glycerol acetal

Acetalization

Amberlyst-15

Solvent selection

SMBR

a b s t r a c t

The study of the production of glycerol ethyl acetal, through the acetalization of glycerol with acetalde-

hyde in a simulated moving bed reactor requires the selection of a suitable solvent/desorbent for the pro-

cess. The methodology described in this paper, based on reaction, adsorption and environmental

variables, lead to the identication of dimethyl sulfoxide as the solvent that best tted the specications

of such reactiveadsorptive processes. Furthermore, a detailed study of the acetalization of glycerol in the

presence of this solvent and using Amberlyst-15 as catalyst, allowed the determination of its reaction

activation energy, 77.7 kJ mol

1

. The reaction rate was described by a LangmuirHinshelwoodHou-

genWatson model, and was obtained from batch experiments with a complete model considering dif-

fusion inside the catalyst particles.

2013 The Authors. Published by Elsevier B.V. This is an open access article under the CC BY-NC-ND

license (http://creativecommons.org/licenses/by-nc-nd/3.0/).

1. Introduction

For the past few years, biodiesel has been suggested as a reliable

renewable alternative for fossil fuels, mainly due to its reduced

toxicity and exhaust emissions. However, the intensication of

the production of these fatty acid esters [1] lead to an excess of

glycerol in the market, since it is a byproduct obtained in approx-

imately 10%, wt/wt, motivating the research and development of

several glycerol-based products [24].

Glycerol-acetals have shown interesting results as green oxy-

genated fuel additives [3,5,6]. Within this family of compounds,

glycerol ethyl acetal (GEA), has evidenced the potential to reduce

exhaust gases particle emissions [7,8] and control of fuel uid

properties [913]. However, it must be mentioned that GEA might

not be a suitable gasoline additive, due to the existence of solubil-

ity problems [14]. On the other hand, this problem was not veried

for diesel or biofuels [15,16].

Researchers have reported the acetalization of glycerol with

acetaldehyde [1724] and the transacetalization of glycerol with

1,1-diethoxyethane (DEE) [8,2528] as the two main reaction

pathways for the synthesis of GEA. In both cases an isomeric mix-

ture containing cis-5-hydroxy-2-methyl-1,3-dioxane, trans-5-hy-

droxy-2-methyl-1,3-dioxane, cis-4-hydroxymethyl-2- methyl-1,3-

dioxolane, and trans-4-hydroxymethyl-2-methyl-1,3- dioxolane

is obtained. However, the direct condensation of glycerol with

http://dx.doi.org/10.1016/j.cej.2013.08.035

1385-8947/ 2013 The Authors. Published by Elsevier B.V.

This is an open access article under the CC BY-NC-ND license (http://creativecommons.org/licenses/by-nc-nd/3.0/).

Corresponding author. Tel.: +351 22 508 1686; fax: +351 22 508 1674.

E-mail address: cpereir@fe.up.pt (C.S.M. Pereira).

Chemical Engineering Journal 233 (2013) 159167

Contents lists available at ScienceDirect

Chemical Engineering Journal

j our nal homepage: www. el sevi er . com/ l ocat e/ cej

acetaldehyde not only requires a less complex production scheme

but it also has a higher mass efciency and only makes use of

reactants obtained from biomass, presenting itself as a more inter-

esting route for the synthesis of GEA. Nonetheless, this route still

presents some drawbacks. On one hand, this is a thermodynami-

cally limited reaction. On the other hand, as the product is in-

tended to be applied as a fuel additive, the water formed as a

secondary product during the synthesis step must only be present

in residual amounts in the nal product. Therefore, the assay re-

quired for GEA might imply signicant separation costs.

The concept behind multifunctional reactors, which integrate

reaction and separation processes within a single unit, relies on

the equilibrium displacement promoted by the continuous re-

moval of the products from the reaction media, favouring products

formation and, therefore, increasing conversion. These hybrid tech-

nologies are able to improve selectivity towards a product and also

have the potential to reduce capital investment and energy con-

sumption. In what concerns acetals production, very satisfactory

results have been obtained with the simulated moving bed reactor

(SMBR) [29]. The production of 1,1-dimethoxyethane [30], DEE

[3132] and 1,1-dibuthoxyethane [33] was achieved by the direct

acetalization of methanol, ethanol and butanol with acetaldehyde,

respectively, in a SMBR where the chromatographic columns

where packed with Amberlyst-15 that acted both as catalyst and

adsorbent. Thus, the SMBR might be a suitable technology for the

production of GEA from glycerol and acetaldehyde, once it will

be able to shift the reaction thermodynamic equilibrium and,

simultaneously, remove the undesired water from the nal prod-

uct stream as veried for the previous acetalizations in this multi-

functional reactor.

In most SMBR applications reported in the open literature, one

of the reactants was used as solvent; however, in the GEA synthesis

by direct condensation of glycerol with acetaldehyde, this method-

ology cannot be applied. Glycerol, due to its high viscosity would

signicantly increase the pressure drop in the operation unit as

well as add a mass transfer resistance to the system. Plus, its high

boiling point would represent an increase in the nal product

purication costs. Acetaldehyde, on the other hand, in the presence

of an acid catalyst will undergo oligomerization reactions [34],

thus in order to decrease the possibility of side-products forma-

tion, acetaldehyde amount must be kept as low as possible. There-

fore, another compound must be selected as solvent and particular

attention was given to the analysis of parameters related to its

reactivity and physical properties with focus on adsorption. As

far as our knowledge goes, although some systematic solvent

screening methodologies have been published, none was speci-

cally focused on SMBR. They are either for generic organic

synthesis processes [3537], for simpler chromatographic systems

[3840] or mainly oriented for the identication of "green"

solvents [4143].

Therefore, the work herein reported, presents a rst approach

for a simple but expeditious solvent screening methodology for

reactiveadsorptive processes, such as the SMBR. A compilation

of signicant physicalchemical properties of a large list of the

most common solvents for chemical processes was performed

and the list was sequentially reduced based on theoretical param-

eters related with reactiveadsorptive processes requirements.

Miscibility, adsorption and reaction experimental tests were per-

formed with the solvents that presented the best results of the the-

oretical screening, allowing the selection of a suitable solvent for

the production of GEA in a SMBR.

Finally, a kinetic model was proposed for the direct condensa-

tion of glycerol with acetaldehyde in the presence of the selected

solvent. A parametric study comprising a wide range of operating

conditions was performed in order to determine the kinetic param-

eters for this reaction. The results were compared with the solvent

free reaction for the synthesis of GEA.

2. Experimental

2.1. Chemicals and catalyst

The chemicals used in the experimental tests were

acetaldehyde (>99%), glycerol (>99%), acetonitrile (>99%) and

Nomenclature

C

b,i

molar concentration of compound i in the bulk

(mol dm

3

)

C

p,i

molar concentration of compound i in the intraparticle

uid (mol dm

3

)

D

eff,i

compound i effective diffusion coefcient (cm

2

s

1

)

E

a

reaction activation energy (kJ mol

1

)

DG

0

standard reaction Gibbs free energy (kJ mol

1

)

DH

S,W

water enthalpy of adsorption (kJ mol

1

)

DH

S,DMSO

dimethyl sulfoxide enthalpy of adsorption (kJ mol

1

)

K

eq

reaction equilibrium constant ()

k

c

reaction kinetic constant (dm

6

mol

1

g

1

cat

s

1

)

k

c

0

Arrhenius pre-exponential factor for the reaction kinetic

constant (dm

6

mol

1

g

1

cat

s

1

)

K

S,W

water adsorption equilibrium constant (dm

3

mol

1

)

K

S;W

0

Vant Hoff pre-exponential factor for water adsorption

equilibrium constant (dm

3

mol

1

)

K

S,DMSO

dimethyl sulfoxide adsorption equilibrium constant

(dm

3

mol

1

)

K

S;DMSO

0

Vant Hoff pre-exponential factor for dimethyl sulfoxide

adsorption equilibrium constant (dm

3

mol

1

)

NP total number of measurements for a kinetic experiment

()

NE number of kinetic experiments performed ()

P pressure bar

r radial position (cm)

r

Acet/Gly

reactants initial molar ratio ()

q

ads

adsorbed molar amount (mol L

1

cat

)

R ideal gas constant (J mol

1

K

1

)

R

2

correlation coefcient ()

R

p

catalyst particle radius (lm)

R reaction rate based on the local intraparticle composi-

tion (mol g

1

cat

s

1

)

T temperature (K)

t time (min)

wt

cat

/wt catalyst weight percentage (%)

x

i

molar fraction of compound i ()

X

exp

ij

jth point for the conversion measured in experiment i (

)

X

mod

ij

jth point for the conversion in experiment predicted by

the model i ()

e

b

bulk porosity ()

e

p

catalyst particle porosity ()

m

i

compound i stoichiometric coefcient ()

q

p

catalyst particle solid density

Abbreviations

DEE 1,1-diethoxyethane

GEA glycerol ethyl acetal

SMBR simulated moving bed reactor

160 R.P.V. Faria et al. / Chemical Engineering Journal 233 (2013) 159167

n,n-dimethylformamide (>99%), purchased from SigmaAldrich,

and dimethyl sulfoxide (>99%) purchased from VWR International.

Rohm & Haas Amberlyst-15 ion exchange resin was used as cat-

alyst. As water adsorbs strongly on Amberlyst-15 and it can lead to

a decrease of the reaction rate, since it is a product of the reaction,

anhydrous resin must be used on adsorption and reaction tests.

Hence, the resin was washed several times with deionized water,

then washed with ethanol and dried at 363 K until the mass re-

mained constant, prior to its use.

2.2. Solvent selection methodology for reactiveadsorptive process

The solvent selection methodology developed comprises misci-

bility, reactivity, adsorption and kinetic tests with the solvents that

were selected after a rst theoretical screening.

2.2.1. Miscibility tests

Miscibility tests were performed by preparing several binary

mixtures containing the solvent and one of the reactants to which

water or GEA was added in low amounts until phase split or the

formation of a single phase system was observed (depending on

if the initial binary mixture presented one or two phases, respec-

tively). The tests were performed in 5 mL closed test-tubes kept

at 313 K by a water bath (LAUDA, LaudaKonigshofen, Germany).

The samples were initially stirred in a vortex mixer and then al-

lowed to stand to promote the phase separation.

2.2.2. Adsorption tests

Amberlyst-15 adsorption capacity towards water, GEA and the

solvents, was estimated through swelling experiments performed

in 10 mL graduated cylinders where a known amount of sorbent

(approximately 1.0 g) was put in contact with 5 mL of sorbate at

a constant temperature of 293 K (temperature was kept this low

in order to avoid evaporation) for a period of 48 h. The nal sorbent

volume was registered. The sorbent was ltered and weighted and

its adsorption capacity for a given compound was considered to be

an approximation of its mass difference between the beginning

and the end of the experiments. The procedure was performed at

least three times for each compound.

2.2.3. Reaction tests

Batch reactions were carried out in a 150 mL stainless steel ves-

sel, equipped with a sampling valve and temperature and pressure

sensors, operating at 313 K and 5 bar. A magnetic hotplate stirrer

with external temperature control was used to supply heat and

to stir the reaction mixtures composed by 25 mmol of acetalde-

hyde and glycerol diluted in 50% of solvent (molar basis). Amber-

lyst-15 (1.0 wt%) was used as catalyst. The experiments were

carried out for 5 h. Samples were collected at predened time

intervals and analysed in a gas chromatograph (Shimadzu, GC

2010 Plus) using a thermal conductivity detector. Helium N50

(38.5 mL min

1

) was used as the carrier gas for the separation of

the compounds in a CPWax57CB column (25 m 0.53 mm i.d.,

lmthickness of 2.0 lm). The proper column temperature program

was dened for each solvent.

2.3. Detailed kinetic study: set-up and experimental procedure

The determination of the kinetics of the acetalization of glycerol

with acetaldehyde in the presence of the selected solvent was car-

ried out in a closed glass-jacketed 1 L vessel (Buchi Laboratory

Equipment, Flawil, Switzerland), mechanically stirred and

equipped with a blow-off valve, pressure and temperature sensors.

The reactor was operated in batch mode and its temperature was

controlled through a water bath (LAUDA, LaudaKonigshofen,

Germany).

The kinetic study was performed evaluating the effect of param-

eters such as stirring speed (500 rpm and 700 rpm), temperature

(303 K, 323 K and 358 K), initial acetaldehyde to glycerol molar ra-

tio (0.5, 1.0 and 2.0), solvent molar fraction (0.25, 0.5 and 0.75) and

catalyst loading (0.15 and 0.3 wt% of the total reaction medium

mass), according to the experiments described in Table 1.

The pressure was set to 8.0 bar with helium for all the experi-

ments. Vapourliquid equilibrium calculations indicated that at

this pressure, even at the higher operating temperature, the molar

amount of the reaction medium species in the vapour phase would

not exceed 0.5% of the total molar amount introduced in the reac-

tor and, therefore, the vapour phase would be mainly constituted

by helium.

Each reaction kinetic experiment was performed only once in

order to keep the tests manageable and due to high reactants

consumption.

All the samples collected were analysed in the previously de-

scribed gas chromatograph by injecting 0.8 lL of sample (split ratio

of 15.0). Helium N50 was used as the carrier gas at a ow rate of

38.5 mL min

1

. The temperatures of the injector and thermal con-

ductivity detector were set to 573 K. The column was initially kept

at 373 K for 1 min and its temperature was then increased at a rate

of 120 K min

1

until it reached 493 K and held constant at that va-

lue for the following 6 min. After this period the column tempera-

ture was decreased to 463 K at a rate of 30 K min

1

. The total

analysis time was 60 min.

3. Results and discussion

3.1. Solvent selection for reactiveadsorptive processes

As previously stated, none of the reactants of the GEA synthesis

by means of glycerol acetalization can be used as solvent in the

SMBR technology. Therefore, a four stage methodology was devel-

oped and applied for the selection of the most suitable solvent for

the production of this acetal by reactiveadsorptive processes. For

that purpose, a typical set of operating conditions was dened and

an extensive bibliographic review was conducted in order to iden-

tify common solvents used in similar processes. The process tem-

perature was assumed to be 313 K, at a pressure of 5 bar and the

initial reaction medium composition was established as

0.25:0.25:0.50, in terms of molar fractions of acetaldehyde, glyc-

erol and solvent, respectively.

3.1.1. Theoretical based solvent screening

The list of approximately 100 solvents elaborated was reduced

considering three major process variables: solvent reactivity, sol-

vent physical state at the reaction conditions and hypothetical

phase split promoted by the use of the solvent. Solvents that have

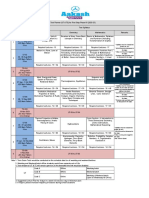

Table 1

Kinetic experiments operating conditions.

Exp.

No.

Stirring

speed

(rpm)

Temperature

(K)

Initial

reactants

molar ratio

Solvent

molar

fraction (n/

n)

Catalyst

loading

(wt%)

1 700 323 1.00 0.50 0.15%

2 500 303 1.00 0.50 0.15%

3 500 323 1.00 0.50 0.15%

4 500 323 1.00 0.50 0.30%

5 500 343 1.00 0.50 0.30%

6 500 323 0.50 0.50 0.15%

7 500 323 2.01 0.50 0.30%

8 500 323 1.00 0.25 0.15%

9 500 323 1.00 0.75 0.30%

R.P.V. Faria et al. / Chemical Engineering Journal 233 (2013) 159167 161

been reported as reactive with any of the reactants or products of

the selected synthesis route, such as alcohols, aldehydes, ketones

and carboxylic acids, were eliminated from the primary list.

Due to operational requirements of the SMBR unit, the solvent

to be used should, preferably, be at the liquid state. Making use

of published data in the open literature the melting point of each

solvent was compiled and its boiling point determined through

the Antoine equation [44], at the previously mentioned pressure

values. Applying a safety factor of 10 K to the phase change tem-

peratures considered, the solvents for which the melting point was

above 303 K and the boiling point was below 323 K were excluded

from the screening.

In the following solvent screening step, Aspen Plus

software

was used to estimate miscibility of the solvent with the initial reac-

tion medium at the dened operating conditions, considering the

UNIFAC model for computing the activity of each species. If the

area of the miscibility region of the ternary phase diagram for a

specic solvent was lower than 75% that solvent was excluded

from the solvents list. It must be noticed that due to lack of data

for 1,3-dioxolane, chloroform, dimethyl sulfoxide and n,n-dimeth-

ylformamide, these solvents could not be excluded.

When designing an industrial process two main questions must

be considered: process performance and process impact. Regarding

the studied process, the acetalization reaction catalyzed by an ion

exchange resin in a SMBR unit, one can promptly conclude that

polarity will be a key performance parameter. On one hand, a

highly polar medium favours the acetalization reaction once its

rate determining step is the formation of a cation from the proton-

ated hemi-acetal [23], and polar media allow the stabilization of

the intermediate cations [45]. On the other hand, as an ion ex-

change resin will be used as catalyst/adsorbent, the sorption prop-

erties of the solvents can be roughly approximated by their

polarity. Water is a highly polar compound and will adsorb in large

amounts in Amberlyst-15; thus, the decrease of solvent consump-

tion (that acts as desorbent), will be favoured if a highly polar sol-

vent is chosen. In ideal terms, the polarity of the solvent should be

somewhere between the polarity of water and that of GEA. For that

reason, the solvents remaining in study from the previous pre-

selection steps were ranked (Table 2) considering a weight of

50% for process performance parameters (25% for dipole moment

and 25% for dielectric constant) and 50% for process impact param-

eters (25% for lethal dose, LD

50

, and NFPA health hazard classica-

tion; and 25% for octanolwater partition coefcient, log P

ow

, and

persistence time in evaluative environment). For each variable, a

score of 100% was attributed to the solvent that presented the

higher value for that variable and a score of 0% for the lower, if

the variable analysed is intended to be maximized. All the other

solvents were scored proportionally. The inverse scoring procedure

was applied to variables that were intended to be minimized.

In order to keep experimental tests practicable the list was

shortened, including only the solvents that had a score above

50%. However, as acrylonitrile has a severe health hazard (as can

be conrmed through its NFPA health classication maximum

hazard classication and through its Material Safety Data Sheet)

it was also excluded. Therefore, dimethyl sulfoxide, acetonitrile,

n,n-dimethylformamide were the solvents selected for further

experimental tests.

3.1.2. Experimental based solvent selection

3.1.2.1. Miscibility tests. In an attempt to assess the miscibility of

the solvents selected from the previous screening steps with the

compounds present in the reaction medium, ternary mixtures con-

taining one of the reactants, one of the products and one solvent

were prepared. Both dimethyl sulfoxide and n,n-dimethylformam-

ide have proven to be miscible with all of the reaction species. Ace-

tonitrile, however, presented some miscibility problems with

glycerol as can be observed in Fig. 1. This fact represents a handi-

cap of acetonitrile against the remaining solvents since it is ex-

pected to originate additional mass transfer resistances.

3.1.2.2. Adsorption tests. As previously mentioned, adsorption is

one of the key parameters to be analysed when dealing with SMBR

technology. It is known that the performance of these units, for in-

stance in terms of desorbent consumption, is improved if the sol-

vent presents an high adsorption capacity but preferably

between the values observed for the two products that have to

be separated. For this particular system, the adsorption capacity

of Amberlyst-15 towards the solvent should be higher than to-

wards GEA and lower than for water. The results for the swelling

tests performed are presented in Fig. 2.

As it can be concluded form Fig. 2, all the three tested solvents

present adsorption capacities between water and GEA. However,

dimethyl sulfoxide presents a slightly higher adsorption value than

the rest of the solvents. Therefore it is expected that dimethyl sulf-

oxide will lead to the minimum desorbent consumption in the

SMBR unit.

3.1.2.3. Reaction tests. The rst objective was to verify that none of

the solvents would react with any of the species of the reaction

media. Furthermore, for the assessment of the inuence of the

presence of the solvents in the kinetics of the reaction between

glycerol and acetaldehyde, experimental tests were carried out.

The results are presented in Fig. 3.

As Fig. 3 shows, dimethyl sulfoxide, n,n-dimethylformamide

and acetonitrile present similar kinetic performances, achieving

conversions of above 50% after 100 min. Moreover, no secondary

products were observed during the experiments. Although

equilibrium results are not represented in Fig. 3 (for a better

Table 2

Rank of solvents by process performance and process impact, based on their properties [44].

Solvent Dipole moment (D) Dielectric constant LD50 (mg/kg) Log P

ow

Persistence time (h) NFPA health Score (%)

Dimethyl sulfoxide 3.96 46.45 14500 1.350 573 1 82

Acetonitrile 3.92 37.50 2460 0.340 347 2 68

N,N-dimethylformamide 3.82 38.00 2800 1.010 438 2 67

Acrylonitrile 3.87 33.00 78 0.250 258 3 60

Dimethyl carbonate 0.91 3.09 13000 0.230 185 2 41

Ethyl acetate 1.78 6.02 5620 0.730 264 2 39

Methyl acetate 1.68 6.68 5000 0.180 277 2 38

1,3-Dioxolane 1.45 7.34 3000 0.370 310 2 37

Dichloromethane 1.60 9.10 1600 1.250 186 2 36

Tetrahydrofuran 1.63 7.58 1650 0.460 293 2 35

1,2-Dimethoxyethane 1.71 2.00 775 0.210 354 2 32

Chloroform 1.01 4.81 695 1.970 189 2 29

1,4-Dioxane 0.00 2.21 4200 0.270 350 2 24

Tetrachloromethane 0.00 2.20 2350 2.830 177 3 18

162 R.P.V. Faria et al. / Chemical Engineering Journal 233 (2013) 159167

understanding of the kinetic results), it was observed that n,n-

dimethylformamide has a lower equilibrium conversion (approxi-

mately 85%) than the other solvents, for which the conversion

achieved was similar (slightly above 90%), due to the effect of the

non-ideality of the mixtures.

In summary, one can say that the application of the methodol-

ogy herein developed to the production of GEA in a SMBR lead to

the identication of dimethyl sulfoxide as the most appropriate

solvent for this process, as shown by the theoretical as well as

the experimental part of the screening procedure implemented.

Besides its reduced environmental impact and health hazard, this

solvent is completely miscible with the reaction mixture in oppo-

sition to acetonitrile. On the other hand, it presents the higher

adsorption capacity, which will minimize its consumption in the

SMBR unit, without having any negative impact on the kinetics

of the reaction or the equilibrium compositions when compared

with the remaining solvents. However, a more detailed description

of the kinetics of the acetalization of glycerol in the presence of di-

methyl sulfoxide will be of signicant relevance for a correct eval-

uation of the SMBR process with this solvent. Therefore, the results

of the study of the kinetics of this reaction are presented in the

next section.

3.2. Kinetic study in the presence of the selected solvent

An experimental parametric study (summarized in Table 1) was

performed in an isothermal batch reactor in order to determine the

kinetic parameters for the acetalization of glycerol catalysed by

Amberlyst-15, in the presence of dimethyl sulfoxide.

For kinetic modelling purposes, an assessment of the mass

transfer limitations was required. Concerning mass transfer

limitations inside the catalyst, as previously reported in the open

literature [4650], a bidisperse pore size distribution, containing

micro- and macropores, was suggested for Amberlyst-15. In the

model adopted the reactants diffuse through the macropores,

adsorb in its walls and then diffuse through microspheres

(homogeneous gel particles) adsorbing in its active sites where

they react. Mass transport phenomena at the microspheres can

be considered innitely fast and, therefore, the internal mass

transfer resistance can be limited to the diffusion through the

macropores [46,48]. On the other hand, it was determined that

for the studied reaction system a stirring speed of 500 rpm could

signicantly reduce external mass transfer resistances to the point

that they became negligible.

The mathematical model implemented comprises the mass bal-

ance to the bulk and intraparticle uid given by Eqs. (1) and (2),

respectively.

dC

b;i

dt

3

R

p

1 e

b

e

b

D

eff ;i

@C

p;i

@r

rRp

1

e

p

@C

p;i

@t

1

r

2

@

@r

D

eff ;i

r

2

@C

p;i

@r

1 e

p

m

i

q

p

R 2

Species i (i = acetaldehyde, glycerol, water, GEA, dimethyl sulf-

oxide) molar concentrations in the bulk and intraparticle uid

are represented by, C

b,i

and C

p,i

, respectively; m

i

and D

eff,i

are its stoi-

chiometric and effective diffusion coefcients (computed as de-

scribed elsewhere [24]); R is the reaction rate based on the

composition along the catalyst radius, r; e

b

is the bulk porosity;

R

p

, e

p

and q

p

represent the catalyst particle radius (342.5 lm

[55]), porosity (0.36 [56]) and solid density (1016 kg m

3

[55]).

Eqs. (3)(6) dene the initial and boundary conditions consid-

ered for this model.

t 0 !C

b;i

C

b;i

0

3

t 0 !C

p;i

C

p;i

0

4

r 0 !

@C

p;i

@r

0 5

Fig. 1. Ternary phase diagram for glycerol:acetonitrile:water and glycerol:acetoni-

trile:GEA mixtures, in molar compositions at 313 K.

Fig. 2. Adsorption tests on Amberlyst-15.

Fig. 3. Comparison of the performance of the solvents on the kinetics of the

acetalization of glycerol (T = 313 K; P = 5 bar; r

acet/gly

= 1.0; x

solv

= 0.5; cat. loading of

2.0 wt% of the total reactants mass; 500 rpm).

R.P.V. Faria et al. / Chemical Engineering Journal 233 (2013) 159167 163

r R

p

!C

b;i

C

p;i

rRp

6

The reaction rate of acetaldehyde with glycerol [24], as well as

with several linear chain alcohols [5053], has been described by

several authors by a LangmuirHinshelwoodHougenWatson

model. This model assumes the adsorption of both reactants, fol-

lowed by a surface reaction that originates a hemi-acetal. Two sub-

sequent surface reactions will lead to the formation of adsorbed

water and acetal. The nal step is the desorption of both products.

The surface reaction leading to the formation of the adsorbed

hemi-acetal is considered as the rate determining step. Previous

authors have suggested that water adsorption is signicantly high-

er than that of the remaining reaction species and, consequently,

the adsorption of those species could be neglected. However, for

this system, as dimethyl sulfoxide is the major compound and it

is a very polar solvent (which indicates that it will adsorb strongly

on Amberlyst-15), its adsorption must also be considered. Eq. (7)

presents the simplied rate expression used to describe the exper-

imental data, taking into account the previous considerations.

R k

c

C

Ac

C

Gly

C

GEA

C

W

Keq

1 K

S;W

C

W

K

S;DMSO

C

DMSO

2

7

In this equation, K

eq

represents the reaction thermodynamic

equilibrium constant, k

c

, the reaction kinetic constant and K

S,W

and K

S,DMSO

the adsorption equilibrium constants for water and di-

methyl sulfoxide, respectively.

The kinetic constant depends on temperature according to

Arrhenius law (Eq. (8)),

k

c

k

c

0

exp

E

a

RT

8

where E

a

, represents the reaction activation energy and k

c

0

, is the

pre-exponential term.

The equilibrium constants depend on temperature according to

Vant Hoff law (Eqs. (9)(11)),

K

eq

exp

DG

0

RT

!

9

K

S;W

K

S;W

0

exp

DH

S;W

RT

10

K

S;DMSO

K

S;DMSO

0

exp

DH

S;DMSO

RT

11

where DG

0

, is the reaction free Gibbs energy, DH

S,W

and DH

S,DMSO

are the adsorption enthalpies for water and dimethyl sulfoxide

and K

S;W

0

and K

S;DMSO

0

, are the pre-exponential terms. From previous

work [24], computing the thermodynamic equilibrium constant in

terms of composition, a value of 12.95 kJ mol

1

was determined

for DG

0

.

The studied reaction system comprises a non-ideal mixture.

However, for modelling purposes, it was impossible to account to

this factor due to the absence in the open literature, as far as our

knowledge goes, of the necessary binary interaction parameters

between the species present in the reaction mixture. Although

the rst bibliographic references to the synthesis of GEA are dated

to 1865 [17], the study of the non-ideality of the species involved

in the different synthesis routes has been neglected by the scien-

tic community. As a consequence, no binary interaction parame-

ters involving GEA have been published so far. Without this data it

is impossible to determine the activity coefcients of each species

with the most common methods such as Wilson, NRTL or UNI-

QUAC. For the solvent free condensation of glycerol with acetalde-

hyde [24], the determination of the activity coefcients was

reported using the UNIFAC group contribution method. However,

when dimethylsulfoxide is used as solvent in this reaction, the

UNIFAC model cannot be applied since the binary interaction

parameter between the aldehyde group and dimethyl sulfoxide

does not exist in the open literature.

The model equations presented were solved with gPROMS

(General Process Modelling System, version 3.4.0) using one of its

integrated solvers, DASOLV, discretizing the radial dimension in

28 non uniform intervals and making use of a second order cen-

tered nite-difference method. The determination of the unknown

parameters, E

a

, k

c

0

, DH

S,W

, K

S;W

0

, DH

S,DMSO

and K

S;DMSO

0

, was carried

out using the Parameter Estimation tool and tting the experi-

mental data by the maximum-likelihood method, assuming a con-

stant variance model and setting the estimation tolerance to 10

5

.

For the determination of the errors associated to the parameters

estimated a Jackknife methodology [54] was applied, considering

8 groups of experiments where one experiment was removed from

the original set of experiments (experiment 1 was not taken into

account since no external mass transfer limitations were observed

and, therefore, the results are similar to those obtained in experi-

ment 3, and it was considered that the same weight should be gi-

ven to every experiment, representing a unique set of operating

conditions, on the parameter estimation procedure).

The estimation of the six parameter for the model previously

described led to large standard errors. For instance, the standard

errors for the pre-exponential factors from the Arrhenius and the

Vant Hoff laws achieved almost 100% of its absolute values. Thus,

the number of parameters to be estimated had to be reduced. Since

the range of operating temperatures can be considered narrow

(40 K), the effect of temperature on the adsorption equilibrium

was considered negligible and Eqs. (10) and (11) were removed

from the nal model. This assumption was based on the results

published for other acetalization reaction between acetaldehyde

and several alcohols [24,5153], described by a LHHW rate law,

in which it is possible to observe a more signicant temperature

dependence of the kinetic constant when compared to the adsorp-

tion constant. For instance, for the acetalization leading to the syn-

thesis of 1,1-dibutoxyethane [53], considering a temperature range

from 303 K to 343 K, the water adsorption constant is expected to

decrease to approximately one third of its value, while the increase

of the reaction kinetic constant reaches ten times its value from the

lower to the higher temperature. The parameters determined and

the corresponding errors are presented on Table 3.

The reaction rate is favoured by the increase of temperature. As

expected, Fig. 4 shows that both the experimental results, obtained

in the range of 303343 K, and the model present a higher reaction

rate for higher temperatures.

Moreover, the model has also shown to be in good agreement

with the experimental observations when changes on the initial

composition of the reaction medium were promoted. A higher

reaction rate was achieved when an excess of either of the reac-

tants was used, as presented in Fig. 5, where the rates for mixtures

with an initial acetaldehyde to glycerol molar ratio of 0.5, 1.0 and

2.0 are compared. However, the greater difculties in predicting

the effect of this parameter on the kinetic behaviour, when com-

pared with the effect of temperature, might be related with the

major impact that changes in the reaction medium composition

Table 3

Kinetic parameters estimated for the acetalization of glycerol in presence of dimethyl

sulfoxide.

Parameter (units) Estimated Value Standard Error

E

a

(kJ mol

1

) 77.7 0.8

kc

0

dm

6

mol

1

g

1

cat

s

1

5.97 10

8

1.06 10

8

K

S,W

(dm

3

mol

1

) 3.45 10

1

5.4 10

2

K

S,DMSO

(dm

3

mol

1

) 1.06 10

1

1.9 10

2

164 R.P.V. Faria et al. / Chemical Engineering Journal 233 (2013) 159167

have on the activity coefcients of the species present in the mix-

ture that could not be accounted for due to the previously men-

tioned reasons.

On the other hand, the reaction proceeded at lower rates when

the solvent amount was enlarged due to the dilution factor applied

to the reactive species (Fig. 6). Molar fractions of 0.25, 0.50 and

0.75 of dimethyl sulfoxide were studied.

The increase of the catalyst loading from 0.15 wt% to 0.30 wt%

lead to an increasing on the experimental reaction rate of approx-

imately 50% (Figs. 46), estimated by the initial reaction rate meth-

od. A similar increase was observed for the model prediction.

The parametric study performed showed that the model is able

to predict the effect of changes in the design variables. In order to

make a more objective assessment of the quality of the tting of

the experiments, considering the parameters estimated for the

mathematical model implemented, its correlation coefcient was

computed (Eq. (12)). The value determined was 0.980, indicating

that the model describes with high accuracy the kinetic behaviour

of this reaction over the wide range of experimental conditions

tested.

R

2

1

P

NE

i1

P

NP

j1

X

exp

i;j

X

mod

i;j

2

P

NE

i1

P

NP

j1

X

exp

i;j

X

exp

2

12

To conclude, the values obtained for the kinetic parameters of the

reaction for the synthesis of GEA in the presence of dimethyl

sulfoxide were compared with the values obtained in a previous

work for the solvent free reaction, for which the authors have deter-

mined an activation energy of 51.2 kJ mol

1

[24]. The difference to

the value reported hereby (approximately 35%) may rely on several

factors. First of all, the prior model (in the absence of solvent) has

been described in terms of activities [24], while the model for this

new system (in the presence of dimethyl sulfoxide) does not ac-

count for the non ideality of the liquid phase, due to lack of param-

eters for the computation of the activity coefcients (namely, the

binary interaction coefcient between dimethyl sulfoxide and the

aldehyde group of the UNIFAC method). Additionally, the inuence

of the temperature on the adsorption equilibrium was not consid-

ered for the reaction in the presence of the solvent as previously de-

scribed, since the number of parameters to be estimated would not

allow a reliable determination of their values. As a consequence, the

enthalpies of adsorption, and their impact on the adsorption con-

stants and in the reaction rate according to the LangmuirHinshel-

woodHougenWatson model, might have a slight inuence on the

activation energy value. Finally, the high polarity of dimethyl sulf-

oxide and its corresponding afnity towards the resin, where it is

expected to adsorb strongly, might be leading to the hindering of

some of the available active sites of the catalyst, decreasing the

overall reaction rate. The direct comparison between the adsorption

constant values here reported and those for the solvent free system

is not allowed. The two models have different considerations over

the non-ideality of the mixture and the values estimated for these

constants are affected by them. However, it is important to mention

that, as expected due to the well-known high afnity of water to-

wards ion exchange resins, as Amberlyst-15, a higher adsorption

capacity was estimated for water than for dimethyl sulfoxide. Nev-

ertheless, it is important to underline that no direct measurement

of the adsorption constants was performed. Instead, the values pre-

sented were obtained through the tting of kinetic data. In any case,

it is intended that those values are coherent between them and, if

not accurate, at least they should have some physical meaning.

The simulation of the concentration proles along the catalyst

particles radius allowed the determination of the reaction effec-

tiveness factor, for which a value of 57% was obtained when eval-

uated at 343 K (the highest temperature assessed, at which higher

inuence of the mass transfer resistances is expected) and consid-

ering the average particle diameter of commercial Amberlyst-15,

685 lm.

4. Conclusions

Although solvent selection methodologies for different applica-

tions have been the aim of several research works, the authors of

Fig. 4. Effect of the temperature on the reaction rate (P = 8.0 bar; r

acet/gly

= 1.0;

x

solv

= 0.5 (n/n); stirring speed of 500 rpm). The full lines represent the conversion

estimated by the model.

Fig. 5. Effect of the reactants molar ratio on the reaction rate (P = 8.0 bar; T = 323 K;

x

solv

= 0.5 (n/n); stirring speed of 500 rpm). The full lines represent the conversion

estimated by the model. The full lines represent the conversion estimated by the

model.

Fig. 6. Effect of the solvents molar fraction on the reaction rate (P = 8.0 bar;

T = 323 K; r

acet/gly

= 1.0; stirring speed of 500 rpm). The full lines represent the

conversion estimated by the model.

R.P.V. Faria et al. / Chemical Engineering Journal 233 (2013) 159167 165

this study have perceived that for integrated reactiveadsorptive

processes as SMBR, the information on this topic was scarce and

therefore there was a need to develop a concise and prompt meth-

odology for this purpose. The methodology suggested in this paper

comprises a two stage screening. First, an extensive list of the most

commonly used solvents in chemical processes is reduced based on

their properties, reported in the literature. Then, experimental

tests are performed with the solvents selected from the previous

screening step. When the methodology developed was applied to

the synthesis of GEA, through the acetalization of glycerol, cata-

lyzed by Amberlyst-15, dimethyl sulfoxide has demonstrated to

be the most suitable solvent for this reaction, presenting top per-

formances on almost every topic. It proved to be unreactive and

miscible with the reaction medium and most importantly, it pre-

sented an adsorption capacity for the catalyst/adsorbent of the pro-

cess that can predictably reduce the solvent consumption on a

future SMBR unit. Moreover, its use has low health and environ-

mental impact.

Finally, a detailed study of the kinetic of the acetalization of

glycerol was conducted. The mathematical model developed was

able to predict with high accuracy the effect on the reaction rate

promoted by changes in the design variables, with a correlation

coefcient of 0.980. The kinetic law was described by the Lang-

muirHinshelwoodHougenWatson method. A value of

77.7 kJ mol

1

was estimated for its activation energy. When com-

pared with the solvent free reaction, the presence of dimethyl sulf-

oxide appears to have some impact on the reaction performance,

consequence of the dilution factor and the reduction of available

catalyst active sites due to its adsorption.

Acknowledgments

The research leading to these results received funding from the

European Union Seventh Framework Programme (FP7/2007-2013)

under Grant Agreement 241718 EuroBioRef. This work was also

nancially supported by Fundao para a Cincia e a Tecnologia,

Project Grant PTDC/EQU-EQU/100564/2008. C.P. gratefully

acknowledges nancial support from Fundao para a Cincia e a

Tecnologia, Postdoctoral Research Fellowship SFRH/BPD/71358/

2010.

References

[1] G. Sorda, M. Banse, C. Kemfert, An overview of biofuel policies across the

world, Energy Policy 38 (2010) 69776988.

[2] A. Behr, J. Eilting, K. Irawadi, J. Leschinski, F. Lindner, Improved utilisation of

renewable resources: new important derivatives of glycerol, Green Chem. 10

(2008) 1330.

[3] C.J.A. Mota, C.X.A.d. Silva, V.L.C. Gonalves, Gliceroqumica: novos produtos e

processos a partir da glicerina de produo de biodiesel, Quim. Nova 32 (2009)

639648.

[4] C.H. Zhou, J.N. Beltramini, Y.X. Fan, G.Q. Lu, Chemoselective catalytic

conversion of glycerol as a biorenewable source to valuable commodity

chemicals, Chem. Soc. Rev. 37 (2008) 527549.

[5] H. Seram, I.M. Fonseca, A.M. Ramos, J. Vital, J.E. Castanheiro, Valorization of

glycerol into fuel additives over zeolites as catalysts, Chem. Eng. J. 178 (2011)

291296.

[6] I. Agirre, I. Garca, J. Requies, V.L. Barrio, M.B. Gemez, J.F. Cambra, P.L. Arias,

Glycerol acetals, kinetic study of the reaction between glycerol and

formaldehyde, Biomass Bioenergy 35 (2011) 36363642.

[7] A. Jaecker-Voirol, I. Durand, G. Hillion, B. Delfort, X. Montagne, Glycerin for

new biodiesel formulation, Oil Gas Sci. Technol. 63 (2008) 395404.

[8] B. Delfort, I. Durand, A. Jaecker-Voirol, T. Lacome, X. Montagne, F. Paille, Diesel

Fuel Compounds Containing Glycerol Acetals; US 2003/0163949, in, 2003.

[9] G.W. Mushrush, S.C. Basak, J.E. Slone, E.J. Beal, S. Basu, W.M. Stalick, D.R. Hardy,

Computational study of the environmental fate of selected aircraft fuel system

deicing compounds, J. Environ. Sci. Health Part A Toxic/Hazard. Substances

Environ. Eng. 32 (1997) 22012211.

[10] G.W. Mushrush, E.J. Beal, D.R. Hardy, J.M. Hughes, J.C. Cummings, Jet fuel

system icing inhibitors: synthesis and characterization, Ind. Eng. Chem. Res. 38

(1999) 24972502.

[11] G.W. Mushrush, E.J. Beal, D.R. Hardy, W.M. Stalick, S. Basu, D. Grosjean, J.

Cummings, Jet fuel system icing inhibitors: synthesis and stability, ACS Div.

Fuel Chem., Preprints 43 (1998) 6062.

[12] G.W. Mushrush, W.M. Stalick, E.J. Beal, S.C. Basu, J. Eric Slone, J. Cummings, The

synthesis of acetals and ketals of the reduced sugar mannose as fuel system

icing inhibitors, Pet. Sci. Technol. 15 (1997) 237244.

[13] E. Garca, M. Laca, E. Prez, A. Garrido, J. Peinado, New class of acetal derived

from glycerin as a biodiesel fuel component, Energy Fuels 22 (2008) 4274

4280.

[14] S.D. Varfolomeev, G.A. Nikiforov, V.B. Volieva, G.G. Makarov, L.I. Trusov, Agent

for Increasing the Octane Number of a Gasoline Automotible Fuel; WO/2009/

145674, 2009.

[15] J.M. Delgado Puche, Procedure to obtain biodiesel fuel with improved

properties at low temperature; US 7 637 969, Industrial Management S.A.,

Madrid, 2009.

[16] G.H. Hillion, B.P. Delfort, I.R.M. Durand, Method For Producing Biofuels,

Transforming Triglycerides Into At Least Two Biofuel Families: Fatty Acid

Monoesters And Ethers and/or Soluble Glycerol Acetals; US 2007/0283619 A1,

2007.

[17] T. Harnitzky, N. Menschutkine, Ueber die Verbindungen des Glycerins mit den

Aldehyden, Justus Liebigs Annalen der Chemie 136 (1865) 4.

[18] J.U. Nef, Dissociationsvorgnge in der Glycol-Glycerinreihe, Justus Liebigs

Annalen der Chemie 335 (1904) 191245.

[19] H.S. Hill, H. Hibbert, Studies on reactions relating to carbohydrates and

polysaccharides V. The use of acetylene for the synthesis of cyclic acetals, J.

Am. Chem. Soc. 45 (1923) 31083116.

[20] H.S. Hill, A.C. Hill, H. Hibbert, Studies on the reactinos relating to

carbohydrates and polysaccharides. XVI. Separation and Identication of the

isomeric ethylidene glycerols, J. Am. Chem. Soc. 50 (1928) 22422249.

[21] M. Martin Maglio, C.A. Burger, Condensation reactions: a laboratory

preparation of ethylidene glycerol, J. Chem. Educ. 23 (1946) 174175.

[22] A.S. Shevchuk, V.A. Podgornova, E.G. Piskaikina, Features of synthesis of 4-

hydroxymethyl-1,3-dioxolanes from glycerol and aldehydes, Russ. J. Appl.

Chem. 72 (1999) 853856.

[23] A.C. Da Silva Ferreira, J.C. Barbe, A. Bertrand, Heterocyclic acetals from glycerol

and acetaldehyde in port wines: evolution with aging, J. Agric. Food. Chem. 50

(2002) 25602564.

[24] R.P.V. Faria, C.S.M. Pereira, V.M.T.M. Silva, J.M. Loureiro, A.E. Rodrigues,

Glycerol valorization as biofuel: thermodynamic and kinetic study of the

acetalization of glycerol with acetaldehyde, Ind. Eng. Chem. Res. 52 (2013)

15381547.

[25] D.J. Miller, L. Peereboom, A.K. Kolah, N.S. Asthana, C.T. Lira, Process for

production of a composition useful as a fuel; US2006/0199970 A1, United

States, 2008.

[26] X. Hong, O. McGiveron, C.T. Lira, A. Orjuela, L. Peereboom, D.J. Miller, A reactive

distillation process to produce 5-hydroxy-2-methyl-1,3-dioxane from mixed

glycerol acetal isomers, Org. Process Res. Dev (2011).

[27] X. Hong, O. McGiveron, A.K. Kolah, A. Orjuela, L. Peereboom, C.T. Lira, D.J.

Miller, Reaction kinetics of glycerol acetal formation via transacetalization

with 1,1-diethoxyethane, Chem. Eng. J. 222 (2013) 374381.

[28] X. Hong, A.K. Kolah, C.T. Lira, D.J. Miller, An improved approach for cyclic

acetals from glycerol, Nashville, TN, 2009.

[29] A.E. Rodrigues, C.S.M. Pereira, J.C. Santos, Chromatographic reactors, Chem.

Eng. Technol. 35 (2012) 11711183.

[30] C.S.M. Pereira, P.S. Gomes, G.K. Gandi, V.M.T.M. Silva, A.E. Rodrigues,

Multifunctional reactor for the synthesis of dimethylacetal, Ind. Eng. Chem.

Res. 47 (2008) 35153524.

[31] A.E. Rodrigues, V.M.M.D. Silva, Industrial Process for Acetals Production in a

Simulated Moving Bed Reactor; WO/2005/11347, 2005.

[32] V.M.T.M. Silva, A.E. Rodrigues, Novel process for diethylacetal synthesis, AlChE

J. 51 (2005) 27522768.

[33] N.S. Graa, L.S. Pais, V.M.T.M. Silva, A.E. Rodrigues, Analysis of the synthesis of

1,1-dibutoxyethane in a simulated moving-bed adsorptive reactor, Chem. Eng.

Process.: Process Intensication 50 (2011) 12141225.

[34] S. Luo, J.L. Falconer, Acetone and acetaldehyde oligomerization on TiO

2

surfaces, J. Catal. 185 (1999) 393407.

[35] R. Gani, C. Jimnez-Gonzlez, D.J.C. Constable, Method for selection of solvents

for promotion of organic reactions, Comput. Chem. Eng. 29 (2005) 16611676.

[36] M. Folic , R. Gani, C. Jimnez-Gonzlez, D.J.C. Constable, Systematic selection of

green solvents for organic reacting systems, Chin. J. Chem. Eng. 16 (2008) 376

383.

[37] S. Perez-Vega, E. Ortega-Rivas, I. Salmeron-Ochoa, P.N. Sharratt, A system view

of solvent selection in the pharmaceutical industry: towards a sustainable

choice, Environ. Dev. Sustain. 15 (2013) 121.

[38] A.I. Papadopoulos, P. Linke, Integrated solvent and process selection for

separation and reactive separation systems, Chem. Eng. Process.: Process

Intensication 48 (2009) 10471060.

[39] J.P. Taygerly, L.M. Miller, A. Yee, E.A. Peterson, A convenient guide to help

select replacement solvents for dichloromethane in chromatography, Green

Chem. 14 (2012) 30203025.

[40] R. Hu, Y. Pan, Recent trends in counter-current chromatography, TrAC Trends

Anal. Chem. 40 (2012) 1527.

[41] C. Jimnez-Gonzalez, A.D. Curzons, D.J.C. Constable, V.L. Cunningham,

Expanding GSKs Solvent selection guide application of life cycle

assessment to enhance solvent selections, Clean Technol. Environ. Policy 7

(2004) 4250.

166 R.P.V. Faria et al. / Chemical Engineering Journal 233 (2013) 159167

[42] K. Alfonsi, J. Colberg, P.J. Dunn, T. Fevig, S. Jennings, T.A. Johnson, H.P. Kleine, C.

Knight, M.A. Nagy, D.A. Perry, M. Stefaniak, Green chemistry tools to inuence

a medicinal chemistry and research chemistry based organisation, Green

Chem. 10 (2008) 3136.

[43] P.G. Jessop, Searching for green solvents, Green Chem. 13 (2011) 13911398.

[44] C.L. Yaws, Yaws Handbook of Physical Properties for Hydrocarbons and

Chemicals, 2008.

[45] G. Wypych, Handbook of Solvents, ChemTec Publishing, 2001.

[46] R.M. Quinta Ferreira, C.A. Almeida-Costa, A.E. Rodrigues, Heterogeneous

models of tubular reactors packed with ion-exchange resins: simulation of

the MTBE synthesis, Ind. Eng. Chem. Res. 35 (1996) 38273841.

[47] S.-K. Ihm, J.-H. Ahn, Y.-D. Jo, Interaction of Reaction and Mass Transfer in Ion-

Exchange Resin Catalysts, Ind. Eng. Chem. Res. 35 (1996) 29462954.

[48] T. Dogu, E. Aydin, N. Boz, K. Murtezaoglu, G. Dogu, Diffusion resistances and

contribution of surface diffusion in TAME and TAEE production using

Amberlyst-15, Int. J. Chem. React. Eng. 1 (2003).

[49] K. Sundmacher, R.-S. Zhang, U. Hoffmann, Mass transfer effects on kinetics of

nonideal liquid phase ethyl tert-butyl ether formation, Chem. Eng. Technol. 18

(1995) 269277.

[50] V.M.T.M. Silva, A.E. Rodrigues, Kinetic studies in a batch reactor using ion

exchange resin catalysts for oxygenates production: role of mass transfer

mechanisms, Chem. Eng. Sci. 61 (2006) 316331.

[51] G.K. Gandi, V.M.T.M. Silva, A.E. Rodrigues, Process development for

dimethylacetal synthesis: thermodynamics and reaction kinetics, Ind. Eng.

Chem. Res. 44 (2005) 72877297.

[52] V.M.T.M. Silva, A.r.E. Rodrigues, Synthesis of diethylacetal: thermodynamic

and kinetic studies, Chem. Eng. Sci. 56 (2001) 12551263.

[53] N.S. Graa, L.S. Pais, V.M.T.M. Silva, A.E. Rodrigues, Oxygenated biofuels from

butanol for diesel blends: synthesis of the acetal 1,1-dibutoxyethane catalyzed

by amberlyst-15 ion-exchange resin, Ind. Eng. Chem. Res. 49 (2010) 6763

6771.

[54] R.G. Miller, The jackknife: a review, Biometrika 61 (1974) 115.

[55] C.S.M. Pereira, M. Zabka, V.M.T.M. Silva, A.E. Rodrigues, A novel process for the

ethyl lactate synthesis in a simulated moving bed reactor, Chem. Eng. Sci. 64

(2009).

[56] F. Lode, M. Houmard, C. Migliorini, M. Mazzotti, M. Morbidelli, Continuous

reactive chromatography, Chem. Eng. Sci. 56 (2001) 269291.

R.P.V. Faria et al. / Chemical Engineering Journal 233 (2013) 159167 167

You might also like

- HLLDocument40 pagesHLLClinton ThomsonNo ratings yet

- An Accelerator Free Peroxide Vulcanization TechniqueDocument17 pagesAn Accelerator Free Peroxide Vulcanization TechniqueClinton ThomsonNo ratings yet

- KSWCFC Application 2Document2 pagesKSWCFC Application 2Clinton ThomsonNo ratings yet

- Us 2975151Document4 pagesUs 2975151Clinton ThomsonNo ratings yet

- Catalytic ReactorsDocument40 pagesCatalytic ReactorsClinton Thomson100% (1)

- University of Kerala: Time Table For The Sixth Semester B.Tech Degree ExaminationDocument2 pagesUniversity of Kerala: Time Table For The Sixth Semester B.Tech Degree ExaminationClinton ThomsonNo ratings yet

- Photocatalytic Water Treatment Using Tio: Clinton Thomson Guided by 7614 Saibi.RDocument1 pagePhotocatalytic Water Treatment Using Tio: Clinton Thomson Guided by 7614 Saibi.RClinton ThomsonNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Critical Care NursingDocument46 pagesCritical Care Nursingraquel_racoNo ratings yet

- Kurukku PadaiDocument4 pagesKurukku PadaisimranNo ratings yet

- Quarter 3 Week 6Document4 pagesQuarter 3 Week 6Ivy Joy San PedroNo ratings yet

- SATURDAY - FIRST - PDF (1)Document3 pagesSATURDAY - FIRST - PDF (1)Manuel Perez GastelumNo ratings yet

- CRM - Final Project GuidelinesDocument7 pagesCRM - Final Project Guidelinesapi-283320904No ratings yet

- 576 1 1179 1 10 20181220Document15 pages576 1 1179 1 10 20181220Sana MuzaffarNo ratings yet

- Is 13779 1999 PDFDocument46 pagesIs 13779 1999 PDFchandranmuthuswamyNo ratings yet

- Nursing Care Plan: Pt.'s Data Nursing Diagnosis GoalsDocument1 pageNursing Care Plan: Pt.'s Data Nursing Diagnosis GoalsKiran Ali100% (3)

- ID2b8b72671-2013 Apush Exam Answer KeyDocument2 pagesID2b8b72671-2013 Apush Exam Answer KeyAnonymous ajlhvocNo ratings yet

- #6 Decision Control InstructionDocument9 pages#6 Decision Control InstructionTimothy King LincolnNo ratings yet

- Lead Workplace CommunicationDocument55 pagesLead Workplace CommunicationAbu Huzheyfa Bin100% (1)

- Fire Art Case StudyDocument15 pagesFire Art Case StudyKimberlyHerring100% (1)

- Feline Neonatal IsoerythrolysisDocument18 pagesFeline Neonatal IsoerythrolysisPaunas JoshiNo ratings yet

- Syllabus/Course Specifics - Fall 2009: TLT 480: Curricular Design and InnovationDocument12 pagesSyllabus/Course Specifics - Fall 2009: TLT 480: Curricular Design and InnovationJonel BarrugaNo ratings yet

- E1979017519 PDFDocument7 pagesE1979017519 PDFAnant HatkamkarNo ratings yet

- GB BioDocument3 pagesGB BiolskerponfblaNo ratings yet

- UT & TE Planner - AY 2023-24 - Phase-01Document1 pageUT & TE Planner - AY 2023-24 - Phase-01Atharv KumarNo ratings yet

- The Recipe For Oleander Sou1Document4 pagesThe Recipe For Oleander Sou1Anthony SullivanNo ratings yet

- A Photograph (Q and Poetic Devices)Document2 pagesA Photograph (Q and Poetic Devices)Sanya SadanaNo ratings yet

- Paediatrica Indonesiana: Sumadiono, Cahya Dewi Satria, Nurul Mardhiah, Grace Iva SusantiDocument6 pagesPaediatrica Indonesiana: Sumadiono, Cahya Dewi Satria, Nurul Mardhiah, Grace Iva SusantiharnizaNo ratings yet

- Blunders and How To Avoid Them Dunnington PDFDocument147 pagesBlunders and How To Avoid Them Dunnington PDFrajveer404100% (2)

- The Berenstain Bears and Baby Makes FiveDocument33 pagesThe Berenstain Bears and Baby Makes Fivezhuqiming87% (54)

- A Guide To Effective Project ManagementDocument102 pagesA Guide To Effective Project ManagementThanveerNo ratings yet

- Diploma Pendidikan Awal Kanak-Kanak: Diploma in Early Childhood EducationDocument8 pagesDiploma Pendidikan Awal Kanak-Kanak: Diploma in Early Childhood Educationsiti aisyahNo ratings yet

- 9m.2-L.5@i Have A Dream & Literary DevicesDocument2 pages9m.2-L.5@i Have A Dream & Literary DevicesMaria BuizonNo ratings yet

- Trump's Fake ElectorsDocument10 pagesTrump's Fake ElectorssiesmannNo ratings yet

- The Training Toolbox: Forced Reps - The Real Strength SenseiDocument7 pagesThe Training Toolbox: Forced Reps - The Real Strength SenseiSean DrewNo ratings yet

- Clinincal Decision Support SystemDocument10 pagesClinincal Decision Support Systemم. سهير عبد داؤد عسىNo ratings yet

- Your Free Buyer Persona TemplateDocument8 pagesYour Free Buyer Persona Templateel_nakdjoNo ratings yet

- Acts 1 Bible StudyDocument4 pagesActs 1 Bible StudyPastor Jeanne100% (1)