Professional Documents

Culture Documents

SOM Lecture 02

Uploaded by

tvkbhanuprakash100%(1)100% found this document useful (1 vote)

48 views31 pagesIntroduction to Stress

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentIntroduction to Stress

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

48 views31 pagesSOM Lecture 02

Uploaded by

tvkbhanuprakashIntroduction to Stress

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 31

Shear Forces on Bolts

Bolted connection in a steel frame

The bolts must withstand the shear forces

imposed on them by the members of the frame.

14062014 2/25 StrengthofMaterials I(Introduction)

Equilibrium and FBDs Equilibrium and FBDs

Equilibrium analysis will determine the

force P, but not the strength or

the rigidity of the bar. g y

14062014 3 StrengthofMaterials I(Introduction)

Freebody diagram for determining the

internal force system acting on section

External forces acting on

a body.

Resolving the internal force

R i t th i l f P d R into the axial force P and

the shear force V.

14062014 4 StrengthofMaterials I(Introduction)

Deformations Deformations

Deformations produced by the components of internal forces and

couples

14062014 5 StrengthofMaterials I(Introduction)

Normal and Shear Stress NormalandShearStress

If the stress is uniformly distributed, we get

Otherwise we call it average stress

14062014 6 StrengthofMaterials I(Introduction)

Axially Loaded Bars Axially Loaded Bars

when the loading is uniform, its resultant

th h th t id f th l d d passes through the centroid of the loaded area

Statics

A bar loaded axially by A bar loaded axially by

(a) uniformly distributed load of intensity p

(b) a statically equivalent centroidal force P = pA

14062014 7 StrengthofMaterials I(Introduction)

Normal stress distribution in a

strip caused by a concentrated load.

14062014 8 StrengthofMaterials I(Introduction)

Saint Venants Principle p

The difference between the effects of two different but statically equivalent

loads becomes very small at suffiently large distances fromthe load loads becomes very small at suffiently large distances from the load.

1. Most analysis in mechanics of materials is based on simplifications that can

be justified with Saint Venants principle.

2. We often replace loads (including support reactions) by their resultants

and ignore the effects of holes, grooves, and fillets on stresses and

deformations.

3. Many of the simplifications are not only justified but necessary.

4. Without simplifying assumptions, analysis would be exceedingly difficult.

5. However, we must always keep in mind the approximations that were

d d k ll f h i h fi l d i made, and make allowances for them in the final design.

14062014 9 StrengthofMaterials I(Introduction)

Normal stress distribution in a

grooved bar

14062014 10 StrengthofMaterials I(Introduction)

Stresses on Inclined Planes

14062014 11 StrengthofMaterials I(Introduction)

1. Maximum normal stress is P/A, and it acts on the cross

section of the bar (that is on the plane = 0) section of the bar (that is, on the plane = 0).

2. The shear stress is zero when = 0, as would be expected.

3. The maximum shear stress is P/2A, which acts on the

planes inclined at = 45

o

to the cross section.

In summary, an axial load causes not only normal stress but also

h h d f b h d d h shear stress. The magnitudes of both stresses depend on the

orientation of the plane on which they act.

14062014 12 StrengthofMaterials I(Introduction)

Stresses acting on two mutually

di l i li d ti f b perpendicular inclined sections of a bar.

By Substituting =+90

o

we get By Substituting =+90 , we get

stresses on a plane perpendicular to q

plane

Stresses acting on mutually perpendicular, or complementary

planes, they are called complementary stresses.

14062014 13 StrengthofMaterials I(Introduction)

The shear stresses that act on complementary planes

h th it d b t it have the same magnitude but opposite sense.

1 The design of axially loaded bars is usually based on the maximum normal 1. The design of axially loaded bars is usually based on the maximum normal

stress in the bar.

2 This stress is commonly called simply the normal stress and denoted by 2. This stress is commonly called simply the normal stress and denoted by .

3. The design criterion thus is that = P/A must not exceed the working stress

of the material from which the bar is to be fabricated. o t e ate a o w c t e ba s to be ab cated

4. The working stress, also called the allowable stress, is the largest value of

stress that can be safely carried by the material. y y

5. Working stress, denoted by

w

, will be discussed more fully later

14062014 14 StrengthofMaterials I(Introduction)

Procedure for Stress Analysis

I l th t l i f i ll l d d b f t t In general, the stress analysis of an axially loaded member of a structure

involves the following steps.

1. EquilibriumAnalysis

If necessary, find the external reactions using a freebody diagram

(FBD) of the entire structure.

Compute the axial force P in the member using the method of sections.

This method introduces an imaginary cutting plane that isolates a

segment of the structure.

The cutting plane must include the cross section of the member of

interest.

The axial force acting in the member can then be found from the FBD of

the isolated segment because it now appears as an external force on the the isolated segment because it now appears as an external force on the

FBD.

14062014 15 StrengthofMaterials I(Introduction)

1. Computation of Stress

1. After the axial force has been found by equilibrium analysis, the y q y ,

average normal stress in the member can be obtained from s=P/A,

where A is the crosssectional area of the member at the cutting where A is the cross sectional area of the member at the cutting

plane.

2 In slender bars s=P/A is the normal stress if the section is sufficiently 2. In slender bars, s=P/A is the normal stress if the section is sufficiently

far from applied loads and abrupt changes in the cross section (Saint

V i i l ) Venants principle).

14062014 16 StrengthofMaterials I(Introduction)

Design Considerations

For purposes of design, the computed stress

1. must be compared with the allowable stress, also called the working stress.

2. The working stress, which we denote by

w

, is discussed in detail in the next

chapter.

3. To prevent failure of the member, the computed stress must be less than the

working stress.

4 N h A l i f T Th l i d i h l i f 4. Note on the Analysis of Trusses The usual assumptions made in the analysis of

trusses are: (1) weights of the members are negligible compared to the applied

loads (2) joints beha e as smooth pins and (3) all loads are applied at the joints loads; (2) joints behave as smooth pins; and (3) all loads are applied at the joints.

Under these assumptions, each member of the truss is an axially loaded bar.

5 The internal forces in the bars can be obtained by the method of sections or the 5. The internal forces in the bars can be obtained by the method of sections or the

method of joints (utilizing the freebody diagrams of the joints).

14062014 17 StrengthofMaterials I(Introduction)

Determine the normal force, shear force, and moment

at a section through point C. Take P = 8 kN.

14062014 StrengthofMaterials I(Introduction) 18

14062014 StrengthofMaterials I(Introduction) 19

The floor crane is used to lift a 600kg concrete pipe. Determine the

resultant internal loadings acting on the cross section at H resultant internal loadings acting on the cross section at H.

14062014 StrengthofMaterials I(Introduction) 20

14062014 StrengthofMaterials I(Introduction) 21

14062014 StrengthofMaterials I(Introduction) 22

Examples

Sample Problem #1

The bar ABCD consists of three cylindrical steel segments with different lengths

and crosssectional areas. Axial loads are applied as shown. Calculate the normal

stress in each segment.

14062014 23 StrengthofMaterials I(Introduction)

14062014 24 StrengthofMaterials I(Introduction)

Observe that the lengths of the segments do not affect the calculations of the

stresses. Also, the fact that the bar is made of steel is irrelevant; the stresses in

the segments would be as calculated, regardless of the materials from which

the segments of the bar are fabricated.

14062014 25 StrengthofMaterials I(Introduction)

The two members used in the construction of an aircraft

fuselage are joined together using a 30 fish mouth weld fuselage are joined together using a 30 fishmouth weld.

Determine the average normal and average shear stress on the

plane of each weld. Assume each inclined plane supports a

h i l f f 400 lb horizontal force of 400 lb.

14062014 Strength of Materials I (Introduction) 26

14062014 StrengthofMaterials I(Introduction) 27

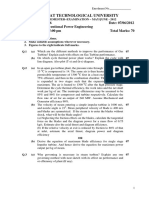

For the truss shown in calculate the normal stresses in (1) member

AC; and (2) member BD. The crosssectional area of each member is ( )

900 mm

2

.

14062014 28 StrengthofMaterials I(Introduction)

14062014 29 StrengthofMaterials I(Introduction)

14062014 30 StrengthofMaterials I(Introduction)

The rectangular wood panel is formed by gluing together two boards along the

30

o

seamas shown in the figure Determine the largest axial force P that can be 30 seamas shown in the figure. Determine the largest axial force P that can be

carried safely by the panel if the working stress for the wood is 1120 psi, and the

normal and shear stresses in the glue are limited to 700 psi and 450 psi, normal and shear stresses in the glue are limited to 700 psi and 450 psi,

respectively.

14062014 31 StrengthofMaterials I(Introduction)

Design for Working Stress in Wood

D i f N l St i Gl Design for Normal Stress in Glue

Design for Shear Stress in Glue

Maximum Load that can be carried

14062014 32 StrengthofMaterials I(Introduction)

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- 120 Upanishads With Original Sanskrit TextsDocument679 pages120 Upanishads With Original Sanskrit TextsDr. Prashan Kumar Thakur100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Default passwords for 3COM network devicesDocument42 pagesDefault passwords for 3COM network devicesJamey ParkerNo ratings yet

- EML3500 CH 8 SlidesDocument134 pagesEML3500 CH 8 SlidesGanesh Dongre100% (1)

- Aligning HR Interventions With Business StrategiesDocument14 pagesAligning HR Interventions With Business StrategiesSunielNo ratings yet

- LightWave 3D 8 TexturingDocument505 pagesLightWave 3D 8 Texturingmanjeethlal80% (5)

- Model Test Towing TankDocument29 pagesModel Test Towing Tanktvkbhanuprakash100% (1)

- Electrolysis Cell Student ActivityDocument3 pagesElectrolysis Cell Student ActivityPersonnumberunoo0% (2)

- Sanet - ST Sanet - ST Proceedings of The 12th International Conference On Measurem PDFDocument342 pagesSanet - ST Sanet - ST Proceedings of The 12th International Conference On Measurem PDFmaracaverikNo ratings yet

- BBU - Maintenance User GuideDocument578 pagesBBU - Maintenance User GuideSibte Hassan100% (2)

- TVKB - Model Ship ExtrapolationDocument32 pagesTVKB - Model Ship ExtrapolationtvkbhanuprakashNo ratings yet

- Understanding Ship Resistance and Propulsion ComponentsDocument13 pagesUnderstanding Ship Resistance and Propulsion ComponentstvkbhanuprakashNo ratings yet

- Chapter 3 Propeller TheoryDocument37 pagesChapter 3 Propeller TheorytvkbhanuprakashNo ratings yet

- Understanding Ship Resistance and Propulsion ComponentsDocument13 pagesUnderstanding Ship Resistance and Propulsion ComponentstvkbhanuprakashNo ratings yet

- ProfTVKB - Transverse Wave InterferenceDocument15 pagesProfTVKB - Transverse Wave InterferencetvkbhanuprakashNo ratings yet

- Proftvkb HW 10 Chap 03 ADocument1 pageProftvkb HW 10 Chap 03 AtvkbhanuprakashNo ratings yet

- ProfTVKB Propulsion Lect 01Document39 pagesProfTVKB Propulsion Lect 01tvkbhanuprakashNo ratings yet

- ProfTVKB - Propeller Geometry HWDocument1 pageProfTVKB - Propeller Geometry HWtvkbhanuprakashNo ratings yet

- Propeller & Propulsion Terminology: 1. DiameterDocument18 pagesPropeller & Propulsion Terminology: 1. DiametertvkbhanuprakashNo ratings yet

- TVKB - Model Ship ExtrapolationDocument32 pagesTVKB - Model Ship ExtrapolationtvkbhanuprakashNo ratings yet

- Prof - TVKB Carlton Propeller 02Document26 pagesProf - TVKB Carlton Propeller 02tvkbhanuprakashNo ratings yet

- Propeller Geometry: Frames of ReferenceDocument14 pagesPropeller Geometry: Frames of ReferencetvkbhanuprakashNo ratings yet

- Fluid Mechanics: Dimensional Analysis, Similitude, and ModelingDocument42 pagesFluid Mechanics: Dimensional Analysis, Similitude, and ModelingtvkbhanuprakashNo ratings yet

- TVKB Memh 2 Dof Lect 2Document16 pagesTVKB Memh 2 Dof Lect 2tvkbhanuprakashNo ratings yet

- Q1) The Force Has A Magnitude of 5oon. Express F As A Vector in Terms of Unit Vectors I and J. Identify The X and Y Scalar Components of FDocument2 pagesQ1) The Force Has A Magnitude of 5oon. Express F As A Vector in Terms of Unit Vectors I and J. Identify The X and Y Scalar Components of FtvkbhanuprakashNo ratings yet

- Homework 6-7-2012Document4 pagesHomework 6-7-2012tvkbhanuprakashNo ratings yet

- TVKB R&P HM MethodDocument42 pagesTVKB R&P HM MethodtvkbhanuprakashNo ratings yet

- Ship History WoodDocument8 pagesShip History WoodtvkbhanuprakashNo ratings yet

- Solid MechanicsDocument25 pagesSolid MechanicstvkbhanuprakashNo ratings yet

- TVKB Rules of SraddhaDocument5 pagesTVKB Rules of SraddhatvkbhanuprakashNo ratings yet

- Circulation TheoryDocument23 pagesCirculation TheorytvkbhanuprakashNo ratings yet

- TVKB Memh 2 Dof Lect 2Document16 pagesTVKB Memh 2 Dof Lect 2tvkbhanuprakashNo ratings yet

- Sri Bhagavad Git As 023394 MBPDocument237 pagesSri Bhagavad Git As 023394 MBPtvkbhanuprakashNo ratings yet

- Prof TVKB Propeller TheoryDocument26 pagesProf TVKB Propeller TheorytvkbhanuprakashNo ratings yet

- TVKB Memh 2 Dof Lect 1Document21 pagesTVKB Memh 2 Dof Lect 1tvkbhanuprakashNo ratings yet

- Engineering Mechanics DynamicsDocument39 pagesEngineering Mechanics Dynamicstvkbhanuprakash100% (1)

- Intro To TurbulenceDocument21 pagesIntro To TurbulencetvkbhanuprakashNo ratings yet

- Terra Point White PaperDocument10 pagesTerra Point White Paperobi SalamNo ratings yet

- MobisudDocument2 pagesMobisudNguyen Duy KhangNo ratings yet

- 1.1.3.4 Lab - Visualizing The Black HatsDocument3 pages1.1.3.4 Lab - Visualizing The Black HatsCordis CordisNo ratings yet

- Aiou Code 1423 Solved Assignment 1 Autumn 2017, Code 1423 PDFDocument4 pagesAiou Code 1423 Solved Assignment 1 Autumn 2017, Code 1423 PDFtelecom_numl82330% (2)

- Rilem TC 162-TDF PDFDocument17 pagesRilem TC 162-TDF PDFAref AbadelNo ratings yet

- TIMESHEETDocument5 pagesTIMESHEETWasKito AdyNo ratings yet

- Embraer Spec E175-E2Document1 pageEmbraer Spec E175-E2Ward DepoorterNo ratings yet

- Healthbox - Mairi Johnson - HANDI at EHI Live - Nov 2013Document18 pagesHealthbox - Mairi Johnson - HANDI at EHI Live - Nov 2013EwanDavisNo ratings yet

- PCBA MachineDocument62 pagesPCBA MachineSahara MalabananNo ratings yet

- The Netherlands: Vehicle Technology DivisionDocument24 pagesThe Netherlands: Vehicle Technology DivisionВасилий ТретьяковNo ratings yet

- Masterseal Plus CatalogueDocument8 pagesMasterseal Plus CataloguePeter ManNo ratings yet

- Flux Cored Wires (Elga) PDFDocument15 pagesFlux Cored Wires (Elga) PDFVladan TimotijevicNo ratings yet

- MiVoice Office 400 Products BR enDocument12 pagesMiVoice Office 400 Products BR enWalter MejiaNo ratings yet

- The Apparatus of RepressionDocument221 pagesThe Apparatus of RepressionAndrew Charles Hendricks100% (3)

- Mineral oil lifetime estimation using activation energyDocument5 pagesMineral oil lifetime estimation using activation energyvzimak2355No ratings yet

- Ideal Institute of Engineering: Industrial RoboticsDocument10 pagesIdeal Institute of Engineering: Industrial RoboticsSoumik DasNo ratings yet

- GTU BE- Vth SEMESTER Power Engineering ExamDocument2 pagesGTU BE- Vth SEMESTER Power Engineering ExamBHARAT parmarNo ratings yet

- Memory Performance Guidelines For Dell PowerEdge 12thDocument47 pagesMemory Performance Guidelines For Dell PowerEdge 12thHuỳnh Hữu ToànNo ratings yet

- Dune Supreme/ Dune Vector: WWW - Armstrong-Ceilings - Co.Uk WWW - Armstrong-Ceilings - IeDocument2 pagesDune Supreme/ Dune Vector: WWW - Armstrong-Ceilings - Co.Uk WWW - Armstrong-Ceilings - IeMuneer KonajeNo ratings yet

- Modules Test ReportDocument4 pagesModules Test ReportprojectsNo ratings yet

- Elektricna Sema KlimeDocument58 pagesElektricna Sema Klimefrostssss0% (1)

- Powercell PDX Brochure enDocument8 pagesPowercell PDX Brochure enFate Laskhar VhinrankNo ratings yet

- CTM CTP Stepper Catalog en-EN 2007 PDFDocument20 pagesCTM CTP Stepper Catalog en-EN 2007 PDFQUỐC Võ ĐìnhNo ratings yet