Professional Documents

Culture Documents

Absorption Costing For Decision-Making

Uploaded by

userhappy0 ratings0% found this document useful (0 votes)

59 views8 pagesAbsorption Costing for Decision-making

Original Title

Absorption Costing for Decision-making

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentAbsorption Costing for Decision-making

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

59 views8 pagesAbsorption Costing For Decision-Making

Uploaded by

userhappyAbsorption Costing for Decision-making

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 8

ABSORPTION COSTING FOR DECISION-MAKING

Mike Lucas, of the University of Buckingham, describes how absorbing

certain fixed overhead costs into unit product costs can complement

Kaplan and Coopers approach to !BC, to improve the "uality of planning

and decision making

#eceived wisdom has it that absorption costs should not be used for

decisionmaking, i$e$ non%volume related costs should not be allocated to

the product unit level$ &f such costs are allocated down to the product unit

level, the resultant unit cost will be a function of production volume$ 'ake,

for example, the cost of performing a machine set%up$ 'his will be

independent of the number of units to be produced$ Conse"uently, if the

si(e of a production run is halved, the per unit cost of a machine set%up is

doubled)

*uch a cost is therefore only valid for one particular volume of output,

whereas most planning or decision%making deliberations involve potential

changes in volume$

'he supposed raison detre of !BC is to improve the "uality of planning

and decision%making+ an !BC unit cost is therefore of little value$

'his principle is recognised by Kaplan and Cooper in their advocacy of !BC

for planning and decision%making purposes$,-. &t is also acknowledged by

/rury in his fourth edition,,0. in which he describes Kaplan and Coopers

approach to !BC$ 'he principle is still largely disregarded by a number of

textbook writers, who continue to present !BC as primarily a product

costing system%%a more sophisticated absorption costing system, using a

number of absorption bases 1cost drivers2, rather than 3ust one volume

related basis such as labour hours$

Kaplan and Gooper's approach to ABC

Kaplan and Cooper, in their exposition of !BC, explicitly condemn the

practice of allocating nonvolume related costs to the product unit level$

Conse"uently, their conception of !BC is as a more sophisticated marginal

costing system%%employing contribution analysis at several different

levels$

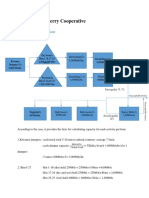

&n their approach to !BC, the firm is envisaged as a hierarchy of costs

with each level representing a different type of cost variability%%as shown

in 4igure -$ 'he lowest three levels in the hierarchy are concerned with

product related costs$ Unit level costs are short term variable costs such

as direct material, direct labour and so on$ 'hese costs vary in direct

proportion to the number of units produced$

Many product related costs are not, however, driven by the number of

units produced per se, but by the number of batches5production runs

undertaken$ !n obvious example of such batch level costs is machine

set%ups$

'he third category of product sustaining costs relates to activities which

are necessary to maintain the product in the firms product range$ 4or

each product, a firm must maintain a bill of materials, a routing sheet,

tooling and so on$ *uch product sustaining activities will increase as

more products 1or product variants2 are added to the product range$ *uch

costs, however, will be independent of the number of units produced in a

particular period$

&n addition to the various product related costs, there are some expenses

which do not relate to individual products, but to particular customers,

e$g$ order processing and distribution costs$ 4inally, there are certain

general overheads which do not relate to any particular product or

customer, such as the chief executives salary$

6ith Kaplans approach to cost analysis there is no need 1or 3ustification2

for any allocation downwards from a higher level, of non%volume related

costs 1in 4igure -2 to the product unit level$ #ather, contribution should be

rolled upward when considering a particular decision$ ! unit%level

operating margin for individual products can be calculated by subtracting

unit%level costs from sales revenue$ 4rom this unit%level margin can be

subtracted batch%related and product%sustaining expenses to arrive at a

product%level margin$ *uch a margin can be calculated for each product in

the range and from this can be deducted any customer related expenses

to determine the profitability of a particular sales order$

'his approach can give managers better insights into the nature of their

costs and thus facilitate better informed decisions when bidding for 3obs or

deciding which orders to accept$ 'he method can also be applied in

determining the profitability of a product over a period of time%%not by

calculating a full unit cost to compare with the selling price, but by

identifying the demands the product puts on service and support

activities$ 'he estimated cost of these activities is then added to the

short%run variable costs of producing the units sold and this total cost is

then compared with the total revenue earned by the product$ 'hus, for

example, it may be revealed that low volume products are unprofitable

because of the disproportionate demands placed on batch level activities%%

a machine set%up is necessary whether one unit or one thousand units are

being manufactured)

!n important implication of Kaplans analysis is that the non%volume

related costs included in any decision analysis are not short%term

incremental costs, but proxies for long%run incremental cost%based

typically on existing average activity costs$ 'hus, for example, the total

cost of machine setups is divided by the number of set%ups performed to

arrive at average cost per set%up$ 'his is then used as an estimate of the

long%term incremental cost that will arise by performing machine set%ups$

Kaplan and Cooper argue the superiority of this approach on two grounds$

4irst, they contend that it is probably not feasible to identify all the actual

incremental costs of each decision in a complex, multi%product

environment$ *econd, they argue that, during a particular period,

numerous decisions are made independently of each other but the

collective impact can be to drive up fixed costs over time, even though

these longer%term cost increases are not incremental 1and hence relevant2

to$ any one particular decision$

'he argument is that, if only actual incremental costs are considered when

looking at a particular decision, a positive contribution is likely to lead

decision%makers to embark upon actions 1e$g$ accepting marginal

business2 which place demands on service and support functions$ 7ver

time this consumption of service5support activities will start to drive up

costs$ 'he current actual cost of support activities can be viewed as acting

as a proxy for these long%run incremental costs$ 'he !BC approach is

essentially a long%term one aimed at curbing the excesses which can

result from traditional marginal costing%%which ignores potential long term

increases in cost$

'hus, although Kaplan and Cooper assert that !BC is not a decision%

making tool 1but an attention directing one2, it is difficult to escape the

conclusion that it is) &t is nearer to the truth to say that !BC is a tool for

planning5decision%making, but one which uses proxies for long%term

incremental cost rather than strictly decision%relevant incremental costs$

The role o cost allocat!on

'he 8immerman approach

'he Kaplan and Cooper approach is based on the received wisdom that

non%volume related costs should not be allocated to the product unit level$

'here is, however, a school of thought in favour of such allocations,

suggesting that cost allocations have an important role to play in

motivating and controlling managers$

8immerman,,9. for example, suggested that there are certain

service5support costs which are fixed with respect to short%run changes in

production volume, but which are related, in the longer term, to the level

of primary inputs 1e$g$ labour2$ *uch costs would typically be classified

under the general overhead category in 4igure -$ !n example would be a

works canteen$

:very additional worker employed places additional demands on the

canteen$ !lthough actual cost of the canteen may be fixed in the short%

term, opportunity costs arise in the form of delays and5or degradation of

service to other users$ !s time goes by, management will tend to ad3ust

the actual level of service provided, in order to reduce delays5degradation

of service, and hence costs rise$

8immerman argues that these opportunity costs and conse"uent long%

term incremental actual costs should be taken into account by individual

managers when deploying labour resources$ *uch costs are hard to

observe5measure, but allocating current average cost can serve to proxy

them$

'hus, for example, a production manager deciding on the optimal mix of

factor inputs will be induced to take into account the additional costs of

using labour%%in terms of the demands it places on the works canteen%%if

labour hours are made to carry the burden of recovering this overhead

cost$

'he resultant factor input mix, it is argued, will be closer to the optimal

one than would be the case if such costs were ignored$

'his principle can be illustrated by 4igure 0, which shows how the

selection of input factors 1in this example, capital and labour2, to produce

a given output, depends on the relative prices of those factors$

'he iso"uant shows all the possible combinations which could be used to

produce a particular output$ !ll points assume technical efficiency 1i$e$ no

waste2+ the optimal combination 1i$e$ that producing the lowest unit

product cost2 will depend on the slope of the isocost line which represents

the relative prices of input factors$ &socost line - represents relative prices

if the demands placed by labour on service departments such as the

canteen are ignored and only the actual cost of labour itself is taken into

account$ 'he true cost of using labour resource is understated and in

conse"uence more labour hours are used than would otherwise be the

case$ 'he manager is, in effect, basing his decision on false price

information$

&f the true cost of using labour is proxied by means of charging labour

hours with service department overhead, the relative price of labour

increases, as shown by isocost line 0, and less of it should be used$ 'he

resultant input mix 1point 02 is closer to the real optimum, because the

hidden costs of using labour are recognised$ By charging labour hours with

fixed overhead burden, overhead is factored into the unit product cost$ &f

a unit re"uires one labour hour, a corresponding amount of overhead will

be included in the unit cost$ !ccording to the logic of 8immermans

argument, this is 3ustified since, in the longer term, actual costs of the

service resource will tend to rise in relation to the number of labour hours

worked and the allocated fixed cost is a proxy for these additional costs,

i$e$ one labour hour gives rise to x canteen cost$

'he "uestion naturally arises as to which costs should be classified as

long%run volume%related costs and thus allocated to the product unit level%

after all, virtually all costs change if volume is increased enough) 6hat

about, for example, rent; 8immermans argument appears to relate to

those areas where there is additional consumption of resources as a result

of an increase in a primary input such as labour$ !s a conse"uence of this

consumption of resources, delays5degradation of service to other users

occurs$ 'hese opportunity costs give rise to additional actual costs in the

longer term as management ad3usts the level of service provision$ 'his is

unlikely to apply to rent, unless a huge increase in labour force was being

contemplated%necessitating a new factory)

'herefore an assumption about the likely volume level over the planning

hori(on is re"uired in deciding whether to allocate or not to allocate$ &f,

over the anticipated volume range, significant delays5 degradation of

service%%as a result of increasing primary inputs%%are considered a realistic

possibility, then there is a good case for cost allocation$ 6here, over the

anticipated volume range, it is considered unlikely that delays5degradation

of service to other users will result%%as a conse"uence of increasing

primary inputs%%there is not a good case for cost allocation$

!pplying this criterion, it may be appropriate to allocate works canteen,

payroll and personnel costs, for example+ it will probably not be

appropriate to allocate rent and so on$

'he <apanese approach

! slightly different rationale for cost allocation is that apparently adopted

by a number of <apanese manufacturing firms; 'hese firms load labour

hours with overhead burden%%not because they believe this will result in

an optimal mix of inputs, but to encourage the substitution of capital for

labour as part of their advanced manufacturing technology 1!M'2

strategy$ !ll production overhead%%including non%volume related costs 1i$e$

batch level, product%sustaining level costs etc2 are allocated using labour

hours$ Conse"uently, the resultant unit costs are of little use for either

longterm or short%term decisions%%since they are neither the short%term

nor long%term incremental costs of

producing a unit) <apanese managers do not believe that the resultant

product costs are a reasonable proxy for long run incremental costs+

rather, they believe that the behavioral benefits accruing from cost

allocation outweigh the disadvantages, namely inaccurate product costs

and possible erroneous decisions) <apanese companies tend to use

estimated product costs produced outside the management accounting

system and based on managers past experience or intuition$,=. &t

appears that the primary purpose of management accounting in <apan is

to influence behaviour rather than to provide accurate product costs$ &t is

not clear that the 6est is ready to sacrifice its penchant for accurate

product cost information, which has been the cornerstone of western

management accounting since its beginning$

Concl"s!on

Kaplan and Cooper argue that if higher%level, nonvolume related costs

such as batch level costs etc are allocated to the product unit level the

resultant unit cost will be largely meaningless$ Clearly, their approach to

!BC cannot be reconciled to that of the <apanese companies$ 'here is,

however, no necessary contradiction between the Kaplan5Cooper approach

and that of 8immerman$ 8immerman merely introduces a category of

long%run volume related costs which are effectively ignored in Kaplan and

Coopers analysis$

'he only necessary difference is that, with 8immerman, the unit level cost

would include a proxy for the hidden costs of using labour that arise in

the longer term$ 'here would appear to be a good case, therefore, for

including 8immerman type allocations in a Kaplan and Cooper style !BC

system$

/&!>#!M? 4igure -? 'he firms cost structure 1adapted from Kaplan and

Cooper,l.2

>#!@A? 4igure 0? 'he selection of the optimal mix of input factors @oint -

shows the least cost combination of inputs when no account is taken of

the demands placed on a service function by the employment of labour$ !t

this point, L- of labour will be used in con3unction with C- of capital$ &f

labour is charged with the burden of service cost recovery, the least cost

combination shifts to point 0$ !t this point, less labour will be employed%%

L0, and more capital%%C0

-$ K!@L!B, #$? Contribution margin analysis? no longer relevant

*trategic cost management? the new paradigm, from a paper

presented at annual meeting of 'he !merican !ccounting

!ssociation$ <ournal of Management !ccounting #esearch, 0, 4all

-CCD$

0$ /#U#E, C$? Management and Cost !ccounting 1Fth ed2$ 'hompson

Business @ress, -CCG$

9$ 8&MM:#M!B, <$L$? H'he costs and benefits of cost allocations, 'he

!ccounting #eview, L&I, 9, <uly -CJC$

F$ M!K&/7, '$? #ecent trends in <apans cost management practices

in <apanese Management !ccounting, edited by M7B/:B, E$ and

*!KU#!&, M$ @roductivity @ress, Cambridge, Mass, -CKC$

=$ E7*A&K!6!, '$? Characteristics and practical applications of

<apanese cost accounting systems in <apanese Management

!ccounting edited by M7B/:B, E$ and *!KU#!&, M$ @roductivity

@ress, Cambridge, Mass, -CKC$

Copyright of Management !ccounting? Maga(ine for Chartered

Management !ccountants is the property of Caspian @ublishing and its

content may not be copied or emailed to multiple sites or posted to a

listserv without the copyright holders express written permission$

Aowever, users may print, download, or email articles for individual use$

Bac#

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- National Cranberry Case SolutionDocument4 pagesNational Cranberry Case SolutionAli Umer MughalNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- PepsiCo Changchun Joint Venture Helpful HintsDocument2 pagesPepsiCo Changchun Joint Venture Helpful HintsLeung Hiu Yeung50% (2)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Market & Competitor Analysis Template inDocument25 pagesMarket & Competitor Analysis Template inSlidebooks Consulting87% (31)

- Background of PadiniDocument2 pagesBackground of PadiniThoh Ying Qian63% (8)

- Financial Management - Lecture Notes, Study Material and Important Questions, AnswersDocument5 pagesFinancial Management - Lecture Notes, Study Material and Important Questions, AnswersM.V. TV67% (3)

- Wells Fargo Preferred CheckingDocument3 pagesWells Fargo Preferred CheckingAarón CantúNo ratings yet

- Study TExtDocument22 pagesStudy TExtuserhappyNo ratings yet

- FRSvsIFRS 31dec09Document0 pagesFRSvsIFRS 31dec09userhappyNo ratings yet

- Influential Factors of Country Accounting System DeveDocument12 pagesInfluential Factors of Country Accounting System DeveJoEst KaraNgNo ratings yet

- Avoiding Price WarsDocument2 pagesAvoiding Price WarsuserhappyNo ratings yet

- Avoiding Price WarsDocument2 pagesAvoiding Price WarsuserhappyNo ratings yet

- 79369489Document5 pages79369489userhappyNo ratings yet

- Corporate Governance and Firm Value - Evidence From The Korean Financial CrisisDocument49 pagesCorporate Governance and Firm Value - Evidence From The Korean Financial CrisisuserhappyNo ratings yet

- Corporate Governance and Firm Value - Evidence From The Korean Financial CrisisDocument49 pagesCorporate Governance and Firm Value - Evidence From The Korean Financial CrisisuserhappyNo ratings yet

- Historical Vs Current CostDocument4 pagesHistorical Vs Current Costuserhappy0% (1)

- Corporate Governance and Firm Value - Evidence From The Korean Financial CrisisDocument49 pagesCorporate Governance and Firm Value - Evidence From The Korean Financial CrisisuserhappyNo ratings yet

- Lessons From East Asia's Crisis and RecoveryDocument21 pagesLessons From East Asia's Crisis and RecoveryuserhappyNo ratings yet

- Cost Based Measures AssetsDocument64 pagesCost Based Measures AssetsuserhappyNo ratings yet

- How Things Work.Document1 pageHow Things Work.userhappyNo ratings yet

- Datasheet BUK7508-55Document9 pagesDatasheet BUK7508-55Luis PerezNo ratings yet

- Marathon Sponser ProposalDocument9 pagesMarathon Sponser ProposalPrabahar RajaNo ratings yet

- Return, Risk, and The Security Market LineDocument45 pagesReturn, Risk, and The Security Market Lineotaku himeNo ratings yet

- SR05 - Amruth Pavan Davuluri - How Competitive Forces Shape StrategyDocument14 pagesSR05 - Amruth Pavan Davuluri - How Competitive Forces Shape Strategyamruthpavan09No ratings yet

- ATM BrochuresDocument5 pagesATM Brochuresगुंजन सिन्हाNo ratings yet

- CRM Case Study PresentationDocument20 pagesCRM Case Study PresentationAnonymous QVBtzHYmxC100% (1)

- Industry Multiples in India: March 2019 - Seventh EditionDocument47 pagesIndustry Multiples in India: March 2019 - Seventh EditionharishNo ratings yet

- REPORT - Economic and Steel Market Outlook - Quarter 4, 2018Document24 pagesREPORT - Economic and Steel Market Outlook - Quarter 4, 2018Camelia ZlotaNo ratings yet

- Build, Operate and TransferDocument11 pagesBuild, Operate and TransferChloe OberlinNo ratings yet

- Interweave Knits Sum13Document124 pagesInterweave Knits Sum13Michelle Arroyave-Mizzi100% (25)

- Key Drivers For Modern Procurement 1Document22 pagesKey Drivers For Modern Procurement 1setushroffNo ratings yet

- 1 .Operating Ratio: Year HUL Nestle Britannia MaricoDocument17 pages1 .Operating Ratio: Year HUL Nestle Britannia MaricoSumith ThomasNo ratings yet

- Fund Management User ManuualDocument35 pagesFund Management User ManuualPradip Shelar100% (3)

- James Montier WhatGoesUpDocument8 pagesJames Montier WhatGoesUpdtpalfiniNo ratings yet

- Employees PF Scheme 1952Document100 pagesEmployees PF Scheme 1952P VenkatesanNo ratings yet

- 5Document15 pages5balwantNo ratings yet

- Chapter-1: 1.1 Categorization of PostsDocument15 pagesChapter-1: 1.1 Categorization of PostsJyothi PrasadNo ratings yet

- Presented by DR Jey at BIRD LucknowDocument16 pagesPresented by DR Jey at BIRD LucknowvijayjeyaseelanNo ratings yet

- Money Growth and InflationDocument52 pagesMoney Growth and InflationMica Ella GutierrezNo ratings yet

- DaburDocument12 pagesDaburAshish Anand0% (1)

- Ch7 HW AnswersDocument31 pagesCh7 HW Answerscourtdubs78% (9)

- Unilever Case StudyDocument17 pagesUnilever Case StudyRosas ErmitañoNo ratings yet

- Introduction To Financial Accounting Session 1 PDFDocument53 pagesIntroduction To Financial Accounting Session 1 PDFdivya kalyaniNo ratings yet

- Bir Form No. 1914Document1 pageBir Form No. 1914Mark Lord Morales BumagatNo ratings yet

- Prospects and Challenges of The Emerging Oil and Gas Industry in GhanaDocument8 pagesProspects and Challenges of The Emerging Oil and Gas Industry in GhanaEsther AdutwumwaaNo ratings yet