Professional Documents

Culture Documents

Mix Design Method of SCC

Uploaded by

Shraddha ShaduOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mix Design Method of SCC

Uploaded by

Shraddha ShaduCopyright:

Available Formats

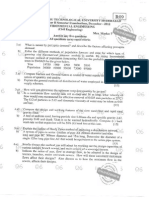

Testing and Mix Design Method of Self-

Compacting Concrete

Hardik Upadhyay

*1

, Pankaj Shah

*2

, Elizabeth George

#3

*

PG Students, Dept. of Structure Engg., BVM Engg. College, Gujarat Technological University

Gujarat, India.

1

hpupadhyay88@yahoo.in

2

shah2pankaj@yahoo.com

#

Professor, Dept. of Structure Engg., BVM Engg. College, Gujarat Technological University

Gujarat, India.

3

pmgeorge02@yahoo.com

Abstract Self compacting concrete is a highly flowable, yet

stable concrete that can spread readily into place and fill the

formwork without any consolidation and without undergoing any

significant separation. In general, SCC results in reduced

construction times and reduced noise pollution. This paper deals

with the history of SCC development and its basic principle,

different testing methods to test high-flowability, resistance

against segregation, and passibility. Different mix design

methods using a variety of materials has been discussed in this

paper, as the characteristics of materials and the mix proportion

influences self-compactability to a great extent.

KeywordsSelf-compactingconcrete,Mixdesign,Superplasticizer,

Water-powder ratio, Flowability.

I. INTRODUCTION

In Japan, in early eighties, premature deterioration of

concrete structures were detected almost everywhere in the

country. The main cause of the deterioration was recognized

as inadequate compaction. In addition, the gradual reduction

in the number of skilled workers in Japans construction

industry led to a reduction in the quality of construction work.

As a solution for these social and technical requirements, the

concept of SCC was proposed by Prof Okamura

1

at Tokyo

University in 1988. He gave the first prototype of SCC using

materials already in the market. Later studies to develop SCC,

including a fundamental study on the workability of concrete,

were carried out by Ozawa and Maekawa

2

. SCC has now been

taken up with enthusiasm across Europe and other parts of the

world, in both site and precast concrete work. Practical

application has been backed up by research on its physical and

mechanical characteristics of SCC.Early SCC relied on very

high contents of cementitious paste, the mixes required

specialized and well-controlled placing methods to avoid

segregation, but the high contents of cement paste made them

prone to shrinkage and high heat generation. The overall costs

were very high and applications therefore remained very

limited. After series of advancements it is no longer a material

consisting of cement, aggregates, water and admixtures. As

already mentioned it is now an engineered material with

several constituents.

A. Basic Principle

The SCC is that which gets compacted due to its self-

weight and is deaerated (no entrapped air) almost completely

while flowing in the form work. In densely reinforced

structural members, it fills completely all the voids and gaps

and maintains nearly horizontal concrete level after it is

placed. With regard to its composition, SCC consists of the

same components as conventionally vibrated normal concrete,

ie, cement, aggregates, water, additives or admixtures.

However, the high dosage of super-plasticizer used for

reduction of the liquid limit and for better workability, the

high powder content as lubricant for the coarse aggregates,

as well as the use of viscosity-agents to increase the viscosity

of the concrete have to be taken into account.

Superplasticizer enhances deformability and with the

reduction of water/powder segregation resistance is increased.

High deformability and high segregation resistance is obtained

by limiting the amount of coarse aggregate. These two

properties of mortar and concrete in turn lead to self-

compactability limitation of coarse aggregate content. Figure

1 shows the basic principles for the production of SCC.

Fig. 1.Basic principles for production of self-compacting

concrete

3

II. TESTINGOF SCC

At the stage before solidification, self-compacting

concrete is required to have three qualities: high-flowability,

resistance against segregation and passibility, ie, ability that is

necessary to pass the space between reinforcing bars. Other

additional properties, such as, washout resistance and

National Conference on Recent Trends in Engineering & Technology

13-14 May 2011 B.V.M. Engineering College, V.V.Nagar,Gujarat,India

finishability, may be significant and specified for individual

projects/applications. Therefore, it is important to test whether

the concrete is selfcompactable or not and also to evaluate

deformability or viscosity for estimating proper mix

proportioning if the concrete does not have sufficient self-

compactability. The existing procedures for self-compacting

characteristics are those, which measure height differences at

different points under free flow and also resistance against

blocking. The common tests currently used, although not

standardized for assessment of fresh SCC, are described here.

1. Slump Flow Test for Measuring Flowability:

The basic equipment used is the same as for the

conventional Slump test

4

(Figure 2). The test method differs

from the conventional one in the way that the concrete sample

placed into the mould has no reinforcement rod and when the

slump cone is removed the sample collapses. The diameter of

the spread of the sample is measured, ie, a horizontal distance

is measured as against the vertical slump measured in the

conventional test. While measuring the diameter of the spread,

the time that the sample takes to reach a diameter of 500 mm

(T50) is also sometimes measured. The Slump Flow test can

give an indication about the filling ability of SCC and an

experienced operator can also detect an extreme susceptibility

of the mix to segregation. However, this information cannot

be obtained from numerical results alone, a substantial

previous experience in using the test and carrying out

construction in SCC is essential.

Fig. 2 Slump flow test

2. V-funnel Test:

The V-funnel test was developed in Japan and used

by Ozawa, et al

5

. The equipment consists of a V-shaped

funnel, shown in Figure 3. The funnel is filled with concrete

and the time taken by it to flow through the apparatus

measured. This test gives account of the filling capacity

(flowability). The inverted cone shape shows any possibility

of the concrete to block is reflected in the result.

Fig. 3 V-funnel

3. L-box Test:

The L-box test method uses a test apparatus

comprising a vertical section and a horizontal trough into

which the concrete is allowed to flow on the release of a trap

door from the vertical section passing through reinforcing bars

placed at the intersection of the two areas of the apparatus

(Figure 4)

6.

The concrete ends of the apparatus H1 and H2

measure the height of the concrete at both ends. The L-box

test can give an indication as to the filling ability and passing

ability.

Fig. 4 L-box test

TABLE.I RECOMMENDED LIMITS FOR DIFFERENT FRESH

PROPERTIES OF SCC BY EFNARC

Typical range of

values

Sr

No

Method Unit

Min. Max.

1

Slump flow by abram's

cone Mm 650 800

2 T

50cm

Slump flow Sec 2 5

3 V-Funnel Sec 6 12

4 T

5

minutes V-Funnel Sec 0 3

5 L-Box h

2

/h

1

0.8 1

National Conference on Recent Trends in Engineering & Technology

13-14 May 2011 B.V.M. Engineering College, V.V.Nagar,Gujarat,India

III. MIX-DESIGN

The Japanese concept for design of SCC is based on a

method proposed by Okamura and Ozawa

7

. The authors have

proposed a simple mix-proportioning system assuming

general supply from ready-mixed concrete plants. The coarse

and fine aggregate contents are fixed so that self-

compactability can be achieved easily by adjusting the water

to powder volume ratio and superplasticizer dosage only. The

mixed design as proposed is:

Coarse aggregate content is fixed at 50% of the solid

volume;

Fine aggregate content is fixed at 40% of the mortar volume;

Water-powder ratio in volume is assumed as 0.9 to 1.0

depending on the properties of the powder; and

Superplasticizer dosage and the final water-powder ratio are

determined so as to ensure the self-compactability.

The value of water to powder volume ratio (Vw/Vp)

is optimized by mortar flow test and Mortar Funnel Test.

Takada

8

considered the slump flow value of 65030 mm and

the V-funnel time of 112 s as adequate value for the

workable SCC. Further to increase the viscosity and thereby

reduce the deformity an organic stabilizer welan gum

9

was

used. In organic stabilizer, there is a polymer formation of 3-

dimensional framework which increases the viscosity and

water adsorption.

IV. FUTURE OF SELF-COMPACTINGCONCRETE

Since the development of the prototype of SCC in 1988, its

use in actual structures has gradually increased worldwide.

SCC addresses many environmental issues; the main ones are

reduction in noise level in the factory as well as on site,

reduction in personal injuries from noise and manual

handling, reduction in electricity usage and reduction in the

overall maintenance costs of vibration equipment. A typical

application example of SCC is the two anchorages of Akashi-

Kaikyo (Straits) Bridge opened in April 1998, a suspension

bridge with the longest span (1991 m) in the world. The SCC

provides tangible opportunities to both designer and

contractor. It also has a future in the precast industry

providing durable concrete at a lower cost due to lower initial

investments of vibrating facilities and lower recurring costs

due to faster reusage of moulds. It improves the working

environment at plants and sites by eliminating noise of

vibration; it is possible for concrete product plants to be

located in the urban area.

V. CONCLUSION

Considering the economy and the durability of

conventional concrete structures, it is observed that the quality

and the density of the concrete, as well as the compaction of

the concrete are main parameters that cause deterioration. For

this, SCC offers new possibilities and prospects. For this, SCC

offers new possibilities and prospects. It can be a boon

considering improvement in concrete quality, significant

advances towards automation and concrete construction

processes, shortened construction time, lower construction

cost and much improvement in working conditions as it

reduces noise pollution.

REFERENCE

[1] H Okamura and M Ouchi. Self-compacting Concrete.

Development, Present use and Future. Proceedingd of the First

International RILEM Symposium on Self-Compacting Concrete.

Sweden, Proc 7, 1999, pp 3-14.

[2] K Ozawa, M Kunishima, K Maekawa and K Ozawa. Development of

High Performance Concrete Based on Durability Design of Concrete

Structures. Proceeding of East-Asai and Pacific Conference on

Structural Engineering and Construction (EASEC-2), vol 1, January

1989, pp 445-450.

[3] F Dehn, K Holschemacher, K and D Weibe. Self-Compacting

Concrete (SCC) Time Development of the Material Properties and

the Bond Behaviour. LACER No 5, 2000, pp 115-124.

[4] Specification and Guidelines for Self-Compacting Concrete.

EFNARC, Association House, 99 West Street, Farnham, Surrey GU9

7EN, UK, February 2002.

[5] K Ozawa, N Sakata and H Okamura. Evaluation of Self-

Compactibility of Fresh Concrete Using the Funnel Test. Concrete

Library of JSCE, vol 25, June 1995, pp 59-75. March 2-3, 1993, pp

183-190.

[6] Petersson, P Billberg and B K Van. A Model for Self-compacting

Concrete. Proceedings of International RILEM Conference on

Production Methods and Workability of Concrete, edited by P J M

Bartos, et al, Chapman & Hall/E & FN Spon, Paisley, 1996, pp 483-

490.

[7] H Okamura and K Ozawa. Mix Design for Self-Compacting

Concrete. Concrete Library of JSCE, no 25, June 1995, pp 107-120.

[8] K Takada, G I Pelova and J C W Walraven. Influence of Chemical

Admixtures and Mixing on the Mix Proportion of General Purpose

Self-Compacting Concrete. International Congress Creating with

Concrete, University of Dundee, UK, September 6-10, 1999.

[9] N Sakata, K Maruyama and K Minami. Basic Properties and Effects

of Welan Gum on Self-consolidating Concrete. Proceedings of the

International RILEM Conference on Production Methods and

Workability of Concrete, edited by P J M Bartos, D L Marrs and D J

Cleland, E & FN Spon, Paisley, Scotland, June 3-5, 1996, pp 237-253.

National Conference on Recent Trends in Engineering & Technology

13-14 May 2011 B.V.M. Engineering College, V.V.Nagar,Gujarat,India

National Conference on Recent Trends in Engineering & Technology

13-14 May 2011 B.V.M. Engineering College, V.V.Nagar,Gujarat,India

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Earthquakes PresentationDocument18 pagesEarthquakes PresentationDeepak Lalwani100% (1)

- Geology For Engineers: Planet EarthDocument28 pagesGeology For Engineers: Planet EarthShraddha ShaduNo ratings yet

- Self Compating High Streangth ConcreteDocument6 pagesSelf Compating High Streangth ConcreteSudhir JettiNo ratings yet

- Self Compating High Streangth ConcreteDocument6 pagesSelf Compating High Streangth ConcreteSudhir JettiNo ratings yet

- Introduction To Environmental GeologyDocument37 pagesIntroduction To Environmental GeologyShraddha ShaduNo ratings yet

- Design of Reinforced Concrete Structures Ed1st by S RamamruthamDocument1,474 pagesDesign of Reinforced Concrete Structures Ed1st by S RamamruthamShraddha Shadu80% (10)

- Environmental EngineeringDocument6 pagesEnvironmental EngineeringShraddha ShaduNo ratings yet

- Environmental EngineeringDocument6 pagesEnvironmental EngineeringShraddha ShaduNo ratings yet

- Introduction To Engineering Seismology: QuestionsDocument1 pageIntroduction To Engineering Seismology: QuestionsShraddha ShaduNo ratings yet

- Reinforced Concrete Design (Limit State) - by Varghese P.C.Document566 pagesReinforced Concrete Design (Limit State) - by Varghese P.C.Yuva Raj95% (37)

- Understanding Disaster Management in PracticeDocument90 pagesUnderstanding Disaster Management in PracticeShraddha ShaduNo ratings yet

- Disaster ManagementDocument65 pagesDisaster ManagementShraddha ShaduNo ratings yet

- Ushvinder Kaur - SSN PDFDocument48 pagesUshvinder Kaur - SSN PDFShraddha ShaduNo ratings yet

- Revised B.tech Academic CalenderdocxDocument2 pagesRevised B.tech Academic CalenderdocxShraddha ShaduNo ratings yet

- Is 1343 1980 PDFDocument68 pagesIs 1343 1980 PDFpriyankaNo ratings yet

- SP16-Design Aid For RC To IS456-1978Document252 pagesSP16-Design Aid For RC To IS456-1978sateeshsingh90% (20)

- Environmental Engineering Dec-2012Document2 pagesEnvironmental Engineering Dec-2012Shraddha ShaduNo ratings yet

- Self-Compacting ConcreteDocument68 pagesSelf-Compacting ConcreteMisgun SamuelNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Types of Processors and RAM'sDocument26 pagesTypes of Processors and RAM'sSneha NairNo ratings yet

- Check List For Chilled Water Secondary Pump: Sl. No Description RemarksDocument2 pagesCheck List For Chilled Water Secondary Pump: Sl. No Description Remarkssiruslara6491No ratings yet

- EnglishDocument6 pagesEnglishThineswary Siva naiduNo ratings yet

- Muhammad Akif Naeem Open Ended Lab Signals and SystemDocument20 pagesMuhammad Akif Naeem Open Ended Lab Signals and SystemMuhammad Akif NaeemNo ratings yet

- Lec8 SecondOrder PDFDocument61 pagesLec8 SecondOrder PDFPhan Phuong NgocNo ratings yet

- A Simulation of Attempts To Influence Crowd Dynamics'Document6 pagesA Simulation of Attempts To Influence Crowd Dynamics'KhairulNo ratings yet

- ESPRIT Milling Tutorial 02Document11 pagesESPRIT Milling Tutorial 02Sandaruwan සුජීවNo ratings yet

- TDG11Document100 pagesTDG11Splycho GoranNo ratings yet

- B.tech Regular Examination Fee Registration FormDocument1 pageB.tech Regular Examination Fee Registration FormvishwasNo ratings yet

- Introduction To PaintDocument12 pagesIntroduction To PaintMiracle UzomaNo ratings yet

- BSM BWMP - D1 and D2Document34 pagesBSM BWMP - D1 and D2Adnan DjamalNo ratings yet

- Dji Phantom 4 RTK Book F-2Document18 pagesDji Phantom 4 RTK Book F-2Liu Purnomo100% (1)

- Different Type of ChillersDocument7 pagesDifferent Type of ChillersMAGDY KAMEL100% (3)

- Odi2-065r16m18s02-Q DS 0-0-0Document3 pagesOdi2-065r16m18s02-Q DS 0-0-0leolima trustitNo ratings yet

- Catapult Ref ManDocument372 pagesCatapult Ref ManBiplab RoyNo ratings yet

- Sandvik: 11/2019 PME F Additional Comments For Hydrabolt Option & HH200Document1 pageSandvik: 11/2019 PME F Additional Comments For Hydrabolt Option & HH200Elber Luis Chavez BarriosNo ratings yet

- Structural Concept - Helix StructureDocument6 pagesStructural Concept - Helix StructurebistsushantNo ratings yet

- Kuokuang Petrochemicals Executive SummaryDocument40 pagesKuokuang Petrochemicals Executive SummaryKhoh Kai ShengNo ratings yet

- Watergems - How To Design A Water Distribution SystemDocument3 pagesWatergems - How To Design A Water Distribution SystemhiyogsNo ratings yet

- CAG Report On Antrix-Devas DealDocument76 pagesCAG Report On Antrix-Devas DealCanary Trap100% (1)

- Nauticus 3D BeamDocument114 pagesNauticus 3D BeamMinca AndreiNo ratings yet

- Injection Molding TrainingDocument131 pagesInjection Molding TrainingNuria Varela100% (3)

- Asme eDocument41 pagesAsme eAnonymous wWOWz9UnWNo ratings yet

- TDA1517Document15 pagesTDA1517Dave ManakisNo ratings yet

- Hydrocracking Reactor Temperature Control For Increased Safety, Reliability and PerformanceDocument8 pagesHydrocracking Reactor Temperature Control For Increased Safety, Reliability and Performancekirandevi1981No ratings yet

- Binsar Margiyanto: ND RDDocument2 pagesBinsar Margiyanto: ND RDmoez ben youssefNo ratings yet

- Pre Check: 1. Vgrs System DescriptionDocument8 pagesPre Check: 1. Vgrs System DescriptionNickNo ratings yet

- Stereo Conversion Preamplifier: GeneralDocument2 pagesStereo Conversion Preamplifier: GeneralFRANK NIELE DE OLIVEIRANo ratings yet

- Centum VPDocument101 pagesCentum VPgopalNo ratings yet

- Chemistry, Intermediate II Year Model Question PapersDocument3 pagesChemistry, Intermediate II Year Model Question PapersAkshay PandeyNo ratings yet