Professional Documents

Culture Documents

Valve Sheet

Uploaded by

Aris KancilCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Valve Sheet

Uploaded by

Aris KancilCopyright:

Available Formats

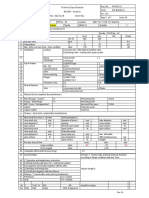

CJ

SURYA CIPTA

CNG STATION PROJECT

DATA SHEET

PIPING DATA SHEET FOR VALVE

~ ~ .

rI

1 07/01/10 Issued for Bid DMS/BPN TSJ SJD

0 22106/09 Issued for Bid DMS/BPN TSJ SJD

Rev Date Description By Chkd Appvd

f

PT. Perusahaan Gas Negara (Persero) Tbk.

GtlsNegarll

Document No.: SCS-01-L-DS-002-A4

Revision: 1

f

Document Code Rev:

DATA SHEET 1

PT. Perusahaan Gas Negara (Persero) Tbk.

Gas Negara Title

PIPING DATA SHEET FOR Page 2 0122

VALVE

PIPING DATA SHEET FOR VALVE

TABLE OF CONTENTS

GATE VALVE DATA SHEET 316 SS 20

PLUG VALVE DATA SHEET - CARBON STEEL 22

- .

GATE VALVE DATA SHEET CARBON STEEL 17

TABLE OF CONTENTS 2

BALL VALVE DATA SHEET CARBON STEEL 3

BALL VALVE DATA SHEET 316 SS 7

CHECK VALVE DATA SHEET CARBON STEEL 10

GLOBE VALVE DATA SHEET 316 SS 15

1.

2.

C)

3.

4.

5.

6.

7.

o

Group: Discipline: Project Title:

Engineering - PDJB Piping SURYA CIPTA CNG STATION PROJECT

Date: FileName Document Number:

07/01/2010

SCS01-LDS-002A4 Piping

SCS-01-L-DS-002-A4

Data Sheet for Valve Rev 1

PT. PERUSAHAAN GAS NEGARA (Persero) Tbk

BALL VALVE DATA SHEET

CARBON STEEL

I CLASS 150

G N_g_r.

Rev Date Description

ENGPDJB

SURYACIPTAeNG STATION PROJECT

By Chk App

Doc. No. SCS.Q1-lDS.Q02-A4

Revision 1 1 07/01/2010 Issued forBid DMS/BPN TSJ SJD

COMMON REQUIREMENTS

Thefollowing technical requirements apply toall valve tagnosmentioned below.

DESIGN & CONSTRUCTION MATERIALS

Valvetype Ball Valve Body/Bonnet/Ends ASTMA105 (')

Design code API6D Ball ASTM A105 with 3 mil ENP

r>

ASME B16.34 Stem ASTM A105 with 3 mil ENP (")

Endconnections RFflanged ends tocomply with ASME816.5 Stempacking Graphite (')

Face-to-face dimensions ASME B16.10 Seat Ring Insert -

Body construction Welded DRing PTFEBased orViton

r>

Firesafe design &test API Sid 6D7or API Spec 6FA Ball Seat PTFEBased (')

Anti static design Yes Bolts ASTM A193 Gr. B7 (')

Anti blow-out stem Yes Nuts ASTM A194 Gr. 2H (')

NACE MR-0175 requirement No

painting Refer to Doc. No. SCS-01-l-SP.Q06-A4

Inspection &testing API6D DESIGN CONDITION

_ \ Marking MSS SP-25 Design Pressure (psig) 160

) Certiflcatlon BS EN 10204 Design Temp.

(oF)

150

Design Life (years) 20

Service Line Refer toDoc. No. SCS-01-L-DS-001A4

"Piping Class DataSheet"

SPECIFIC INDIVIDUAL REQUIREMENTS

Valvetag no. A1CR4

Size range 2"uptoincl. 8"

Pressure rating Class 150

Boreopening Fullbore

Ball mounting Trunnion mounted

Bodycontruction Welded

Leveroperator For2"uptoincl. 6"

Manualgearbox operator For8"& above

Drainconnection (3/4" NPT) Mfr. Std

",

!

NOTES:

1. Trunnion mounted valveshall be provided withthe injectionof sealantequippedwith checkvalve.

2. (/r) Equivalent or Higher

3. Valve shall besuitableto the design conditions

IPage 3 of 22

L

'YPT. PERUSAHAAN GAS NEGARA (Persero) Tbk

BAll VALVE DATA SHEET

I

CARBONSTEEL

I CLASS300

O NIIgllrll

Rev Date Description

ENGPDJB PDJB

SURYA CIPTA eNG STATION PROJECT

By Chk App App

Doc. No. SCS-Ql-L-DS002-A4

Revision 1 1 07/0112010 Issued for Bid DMS/BPN TSJ

COMMONREQUIREMENTS

The following technical requirements apply to all valve tag nos mentioned below.

DESIGN & CONSTRUCTION MATERIALS

Valve type Ball Valve Body/BonneVEnds ASTMA105 (')

Design code API 60 Ball ASTMA105 wilh 3 mil ENP r)

ASME B16.34 Stem ASTMAl05 wilh 3 mil ENP (')

End connections RF flanged ends to complywith ASME 816.5 Stempacking Graphite (')

Face-to-face dimensions ASME B16.10 Seat ring insert Nylon (')

Body construction Welded o ring PTFE based or Viton (')

Fire safe design & test API Sid 607 or API Spec 6FA. Ball Seat ASTMA105 wilh 3 mil ENP (')

Anti static design Yes Bolts ASTM A193 Gr. B7 (')

Anti blow-out stem Yes Nuts ASTMA194 Gr. 2H (')

NACE MR-Q175 requirement No

Painting Refer to Doc. No. SCS-01-L-SP-006-A4

.

Inspection & testing API 60 DESIGNCONDITION

Marking MSS SP-25 Design Pressure (psig) 720

J''';ertification BS EN 10204 Design Temp.

(oF)

150

Design Life (years) 20

Service Line Refer to Doc. No. SCS-01-L-DS-001A4

"Piping Class Data Sheet"

..

,

-

SPECIFICINDIVIDUAL REQUIREMENTS

Valve tag no. B1CR4

Size range 2" up to incl. 8"

Pressure rating Class 300

Bore opening Full Bore

Ball mounting Trunnion mounted

Body contructlon Double Block & Bleed

Lever operator For 2" up to incl. 6"

Manual gearbox operator For 8" & above

Drain connection (3/4" NPT) Yes

"

NOTES:

1. Trunnion mounted valve shall be provided with the Injection of sealant equipped with check valve.

2. (*) Equivalent or Higher

3. Valve shall be suitable to the design conditions

IPage 4 of 22

(

j> PT. PERUSAHAAN GAS NEGARA (Persero) Tbk

BALLVALVE DATASHEET

I

CARBON STEEL

I

CLASS BOO

C;"'. N_II_rl"

Rev Date Description

ENGPDJB PDJB

SURYACIPTAeNG STATION PROJECT

By Chk App App

Doc. No. SCS-01-L-DS-002-A4

Revision 1 1 07/0112010 Issued forBid DMS/BPN TSJ

COMMON REQUIREMENTS

Thefollowing technical requirements apply toallvalve tagnosmentioned below.

DESIGN & CONSTRUCTION MATERIALS

Valvetype BaJlValve Body/Bonnet/Ends ASTM A105 (')

Design code API6D Ball ASTM A105 with3 mil ENP r)

ASME B16.34 Stem ASTM A105 with3 mil ENP (')

Endconnections Socket weld or screwed endstoASME 816.11 StemPacking Graphite (')

Female NPToutlet connection toASME 81.20.1 Seat ring insert

-

Face-to-face dimensions Manufacturer's standard Orin9 PTFEbased orViton (')

Body construction Split bolted body ( 2 or 3 Pes) Ball Seat PTFEbased (')

Replaceable ball &seats Bolts ASTM A193 Gr. B7 (')

Firesafedesign &test API Std 607 or API Spec 6FA Nuts ASTM A194 Gr. 2H (')

Antistaticdesign Yes

Anti blow-out stem Yes

NACEMR-0175requirement No DESIGN CONDITION

Painting RefertoDoc. No. SCS-01-L-SP-006-A4 Design Pressure (psig) 1150

\

tnspectlon &testing

.

APl6D Design Temp. ('F) 270

\

./

Marking

.

MSSSP-25 Design ure (years) 20

Certification BS EN 10204

-

Service Line RefertoDoc. No. SCS..Q1-L-DS-001-A4

"Piping Class DataSheet"

- -

SPECIFIC INDtVIDUAL REQUIREMENTS

Valve tag.no. D1CX1 D1CS1

Size range 1/2"uptoincl. 1 1/2" 1/2"uptoincl. 1 1/2"

Pressure rating Class 800 Class800

Endconnections Nipple (75mm) x NPTF Nipple both ends (75mm)

Boreopening Reduced bore Reduced bore

Ball mounting Floating ball Floating ball

Body ccntruction

- -

Leveroperator Forall sizes inrange Forall sizes inrange

Manual gearbox operator -

-

) Orain connection (3/4"NPT) Mfr. Std Mfr. Std

- _NippleThickness SCHaD SCH ao

.

NOTES:

1. (*) Equivalent or Higher

2. Valve shall be suitableto the designconditions

IPage 5 of 22

c

c

PT. PERUSAHAAN GAS NEGARA (Persero) Tbk

BALL VALVEDATASHEET

I

CARBON STEEL

I

CLASS 2500

......H.II'

Rev Date Description

ENGPDJB PDJB

SURYACIPTAeNG STATION PROJECT

By Chk App App

Doc. No. SCS-DlLDS-D02A4

Revision 1 1 07/0112010 Issued forBid DMSIBPN TSJ

COMMON REQUIREMENTS

Thefollowing technical requirements apply toall valve tagnosmentioned below.

DESIGN & CONSTRUCTION MATERIALS

Valvetype Ball Valve Body/BonneUEnds ASTM Al05 (')

Design code API6D Ball ASTMA105wilh 3 mil ENP r)

ASME B16.34 Stem ASTM A105with 3 mil ENP (')

Endconnections RF flanged endstocomply withASME816.5 Stempacking Graphite (')

Face-to-face dimensions ASME B16.10 Seat Ring Insert RPTFE (')

Body construction Welded o Ring PTFE BasedorVlton (')

Firesafedesign &test API Sid 607 or API Spec 6FA Ball Seat ASTM Al05with 3 mil ENP (')

Anti static design Yes Barts ASTM A193 Gr. B7 (')

Anti blow-out stem Yes Nuts ASTM A194 Gr. 2H (')

NACE MR-0175 requirement No

Painting Refer to Doc. No.

Inspection &testing API6D DESIGN CONDITION

Marking MSS SP25 Design Pressure (psig) 4020

} Certlficatlon BS EN 10204 Design Temp. ("F) 350

. -

Design life (years) 20

Service line Refer to Doc. No.

"Piping ClassData Sheet"

.

SPECIFIC INDIVIDUAL REQUIREMENTS

Valve tag no. G1CR5

Size range 2" upto incl. 4"

Pressure rating Class2500

BoreOpening Fullbore

Ball mounting Trunnion mounted

Body contruction DoubleBlock & Bleed

Leveroperator For 2" upto tncl. 4"

Drainconnection (3/4"NPT) Yes

. ,

)

NOTES:

1. Trunnion mountedvalve shall be providedwith the injectionof sealant equippedwith check valve.

2. (*) Equivalent or Higher

3. Valve shall be suitable to the design conditions

(Page 6 of 22

(

c

j> PT. PERUSAHAANGASNEGARA(Persero) Tbk

BALLVALVEDATASHEET

I

CARBON STEEL

I

CLASS2500

..... N __r.

Rev Date Description

ENGPDJB PDJB

SURYACIPTAeNG STATION PROJECT

By Chk App App

Doc. No. SCS-Q1LDS-002-A4

Revision 1 1 07/01/2010 Issued for Bid DMS/BPN TSJ

COMMONREQUIREMENTS

The following technical requirements apply toaU valvetagnosmentioned below.

DESIGN& CONSTRUCTION MATERIALS

Valve type Ball Valve Body/BonneVEnds ASTMA105 (')

Designcode API6D Ball ASTMA105with 3 mil ENP (')

ASMEB16.34 Stem ASTMA105 with 3 mil ENP (')

Endconnections Socket weldor screwed endstoASME 816.11 StemPacking Graphite (')

Female NPToutlet connection toASME B1.20.1 Seat ring insert

.

Face-to-face dimensions Manufacturer's standard o ring PTFE basedor Viton (')

Bodyconstruction ' Split boltedbody ( 2 or 3 Pes) BallSeat PTFE based (').

Replaceable balf & seats Bolts ASTMA193Gr. B7 (')

Firesafe design &test API std 607 or API Spec6FA Nuts ASTMA194Gr. 2H

o

Anti staticdesign Yes

Anti blow-out stem Yes

NACE MR-0175 requirement No DESIGN CONDITION

Painting RefertoDoc. No. Design Pressure (pSi9) 4020

)

1nspection &testing API6D Design Temp. ("F) 350

.

Marking MSSSP-25 Design life (years) 20

Certification BSEN10204 ServiceLine Referto Doc. No. SCS-01-L-OS-OO1-A4

"Piping ClassData Sheet"

-

SPECIFIC INDIVIDUALREQUIREMENTS

Valve tag no. G1CX1

Size range 1/2" up tolncl. 1 1/2"

Pressurerating Class2500

Endconnections Nipple(75mm)x NPTF

Boreopening Reduced bore

Ball mounting Floating ball

Bodycontruction

-

.

Leveroperator Forall sizesinrange

Manual gearbox operator

.

-

) '}rain connection (3/4"NPn Mfr. Std

, l\lipple Thickness SCH80

NOTES:

1. (*) Equivalent or Higher

2. Valve shall be suitable to the design conditions

IPage 7 of 22

c

ey PT. PERUSAHAAN GAS NEGARA (Persero) Tbk

BALL VALVE DATA SHEET

I

31655

I

CLASS 150

.... N_",..n.

Rev Date Description

ENGPDJB PDJB

SURYACIPTAeNG STATION PROJECT

By Chk App App

Doc. No. SCS-Q1LDS-Q02A4

Revision 1 1 07/0112010 Issued forBid DMS/BPN TSJ

COMMON REQUIREMENTS

The following technical reauirements apply toallvalve tagnosmentioned below.

DESIGN & CONSTRUCTION MATERIALS

Valve type Ball Valve Body/BonneUEnds ASTM A351 CF8M (')

Designcode API6D Ball ASTM A182 Gr. F316

n

ASME B16.34 Stem ASTM A276-316 (')

Endconnections RF flanged endsto comply withASME816.5 Stem packing Graphite (')

Face-to-face dimensions ASME 816.10 Seat ring insert

-

Body construction Welded . 0 ring PTFEbased or Viton (')

Fire safedesign &test API Sid 607 or API Spec 6FA Ball Seat PTFEbased (')

Anti static design Yes Bolts ASTM A193 Gr. B8 (')

Antiblow-out stem Yes Nuts ASTM A194 Gr. B8M (')

NACE MR0175 requirement No

Painting Refer to Doc. No. SCS-01-L-SP-006-A4

Inspection &testing API6D DESIGN CONDITION

) Marking

MSSSP-25 Design Pressure (psig) 160

_:erlification BS EN 10204 Design Temp. ('F) 130

Design Life (years) 20

Service Line Referto Doc. No. SCS-01-L-DS-001-A4

"Piping ClassDataSheet"

.

SPECIFIC INOIVIDUAL REQUIREMENTS

Valve tag no. A1SR4

Size range 2" uptoincl. 6"

.

Pressure rating Class150

Boreopening Full bore

Ball mounting Trunnion mounted

Bodycontruction

-

Leveroperator Forall sizesinrange

Manual gearbox operator

-

.

Drainconnection (3/4"NPT) Mfr. Std

(j

NOTES:

1. Trunnion mountedvalve shall be providedwith the injectionof sealant equippedwith check valve.

2. (*) Equivalent or Higher

3. Valve shall be suitable to the design conditions

IPage a of 22

j> PT. PERUSAHAANGASNEGARA (Persero) Tbk

BALL VALVE DATA SHEET

I

316 SS

I CLASS800

G rv.g.r

Rev Date Description

ENGPDJB

SURYA CIPTA eNG STATION PROJECT

By Chk App

Doc. No. SCS-01LDS-002A4

Revision 1 1 07/0112010 Issuedfor Bid BPN/DMS 18J SJD

COMMONREQUIREMENTS

The following technical requirements apply to all valvetag nos mentionedbelow.

DESIGN& CONSTRUCTION MATERIALS

Valve type Ball Valve Body/Bonnet/Ends ASTMA182 Gr. F316L (')

Design code API6D Ball ASTMA182 Gr. F316 r)

ASME B16.34 Stem ASTMA276-316 (')

End connections Socket weld or screwedendsto ASME 816.11 Stempacking Graphite (')

FemaleNPToutlet connectionto ASME 81.20.1 Seat ring insert

-

Face-to-face dimensions Manufacturer'sstandard o ring PTFEbased or Viton (')

Body construction Split boltedbody ( zor 3 Pes) Ball Seat PTFEbased (')

Replaceable ball & seat's Bolts ASTMA193 Gr. B8 (')

Fire safe design& test API Std 607 or API SpecBFA Nuts ASTMA194 Gr. B8M (')

Anti static design Yes

Anti blow-out stem Yes

NACE MR-0175requirement No DESIGNCONDITION

'\ Painting Refer to Doc. No. SCS-Q1-L-SP..o06-M Design Pressure (psig) 160

j nspection & testing API6D DesignTemp. ('F) 130

Marking MSSSP-25 Design Life (years) 20

Certification BS EN 10204 Service Line Refer to Doc. No. SCS-01-L-DS-001-M

"PipingClass DataSheer'

SPECIFICINDIVIDUAL REQUIREMENTS

Valve tag no. D1SX1 D1SS1

Size range 112" up to inel. 1 1/2" 1/2" up to incl. 1 1/2"

Pressure rating Class 800 Class 800

End connections Nipple (75mm)x NPTF Nippleboth ends (75mm)

Bore opening Reducedbore Reducedbore

Ball mounting Floatingball Floatingball

Body contruction

-

-

Lever operator For all sizes in range For all sizes in range

Manual gearboxoperator -

-

Drain connection (3/4" NPn Mfr.Std Mfr. Std

0'"

l ~ i p l l Thickness SCHAOS SCH.40S

,.

-

NOTES:

1. (*) Equivalent or Higher

2. Valve shall be suitable to the design conditions

IPage 9 of 22

c

o

()

c(j' PT. PERUSAHAANGAS NEGARA(Persero) Tbk

CHECK VALVE DATA SHEET

I

CARBONSTEEL

I CLASS150

G ,.."....

Rev Date Description

ENGPDJB POJB

SURYACIPTACNGSTATIONPROJECT

By Chk App App

Doc. No. SCS-G1L-DSOO2A4

Revision 1 1 07/01/2010 Issuedfor Bid OMS/BPN

TSJ

COMMONREQUIREMENTS

The followingtechnical requirementsapplyto all valve tag nos mentionedbelow.

DESIGN& CONSTRUCTION MATERIALS

Valve type Dual PlateCheckValve Body/Bonnet/Ends ASTMA216 Gr. WeB

(0)

Design code API Std 594 Plate/Disc ASTMA216 Gr. WeB

(0)

End connections RF Flanged endsto comply withASME 816.5 Trim/HingePin ASTMA182 Gr. F316 (1

Face-to-face dimensions API Std 594 Seats 31655 (Replaceable)

(0)

Body construction Wafer Spring Inconel)(750 (1

Anti static design No

Antiblow-out stem No DESIGNCONDITiON

NACE MR-0175 requirement No Design Pressure (psig) 160

Painting Refer to Doc. No. SCS-01-L-SpOO6-A4 Design Temp.

(oF)

160

Inspection & testing API Std 598 Design Life (years) 20

Ma'rking MSS SP-25 Service Line Refer to Doc. No.

Certification asEN 10204 "Piping Class Data Sheet"

-

.

SPECIFIC INDIVIDUAL REQUIREMENTS

Valve tag no. A2CR1

Size range 2" up to incl. B"

Pressure rating Class 150

Body construction Wafer type

NOTES:

1. Equivalent or HIgher

2. Valve shall be suitable to the design conditions

IPage 10 of 22

o

o

PT. PERUSAHAANGASNEGARA(Persero) Tbk

CHECK VALVE DATA SHEET

I

CARBONSTEEL

I CLASS150

__No>_,.

Rev Date Description

ENGPDJB PDJB

SURYACIPTACNGSTATIONPROJECT By Chk App App

Doc. No.

Revision 1 1 07101/2010 Issuedfor Bid DMSI8PN TSJ

COMMONREQUIREMENTS

The followingtechnical requirements applyto all valve tag nos mentionedbelow.

DESIGN& CONSTRUCTION MATERIALS

Valve type SWINGTYPECheck Valve Body.cover ASTMA216 Gr.WeB (,

Design code ASME816.34 PlateJOisc ASTMA216 Gr.WCB

(0)

End connections RF Flanged ends to complywithASME 816.5 Hinge Pin ASTM A182 Gr.316 (,

Body I Bonnetconstruction Bolted Cover Arm ASTMA216 Gr.WCB

(0)

pace-to-face dimensions ASME 816.10 EodySeat Ring ASTM A105 Stejte No.6

(0)

Disc Type SwingType Disc seating surface 13%ChromiumSteel

(0)

NACE MR01-75requirement No Bonnet gasket ManufactureStandard

(0)

painting Refer to Doc. No. SCS-01-L-5P-006-A4

Bo"

ASTMA193 Gr. B7

(0)

Inspection & testing API Std 598 Not ASTMA194Gr. 2H

n

Marking MSS SP-25

Certification BSEN 10204 DESIGNCONDITION

Design Pressure (pslg) 160

DesignTemp.

(OF)

150

Design Life (years) 20

Service Line Referto Doc. No. SCS-01-L-OS-OO1-A4

"piping Class Data Sheet"

SPECIFICINDIVIDUAL REQUIREMENTS

Valve tag no. A2CR4

Size range 2" up to incl. 8"

Pressure rating Class 150

Body construction SwingType

NOTES:

1. (*) Equivalent or Higher

2. Valve shall be suitable to the design conditions

IPage 11 of 22

cf.i' PT. PERUSAHAANGAS NEGARA(Persera) Tbk

CHECK VALVE DATA SHEET

I

CARBON STEEL

I CLAS$300

N_.,..

Rev Date Description

ENGPOJB POJB

SURYACIPTACNGSTATION pROJECT

By Chk App App

Doc. No. SCS-D1LDSOO2A4

Revision 1 1 07/0112010 Issuedfor bid DMS/BPN TSJ

COMMON REQUIREMENTS

The followingtechnical requirements applyto all valve tag nos mentionedbelow.

DESIGN& CONSTRUCTION MATERIALS

Valve type Dual plate checkvalve BodylBonneUEnds ASTMA216Gr. WeB (1

Design code APIStd. 594 Plate/Disc ASTM A216 Gr. WeB

(0)

End connections RF Flanged ends to complywith ASME816.5 TrimlHinge Pin ASTM A182 Gr. 316 r)

Body construction Wafer Seats 31658 (Replaceable) (1

Face-to-face dimensions API Std 594 Spring Inconel X750 (1

Anti static design No

Anti blow-out stem No

NACE M R ~ 1 7 5 requirement No

Painting Refer to Doc. No. SCS.01L-SP-006A4

Inspection & testing API Std 598

Marking MSS SP25 DESIGNCONDITION

Certification BS EN 10204 Design Pressure (pslg) 720

DesignTemp. ('F) 150

Design Ufe (years) 20

Service Une Refer to Doc. No. SCS-01L-DS-001-A4

"Piping Class Data Sheet"

SPECIFICINDIVIDUALREQUIREMENTS

Valve tag no. 82CR3

Size range 2" up to lncl. 4"

Pressure rating Class 300

Body construction Wafer type

NOTES:

1. (-) Equivalent or Higher

2. Valve shall be suitable to the design conditions

[Peqe 12 of 22

CJ

c(j' PT. PERUSAHAANGAS NEGARA(Persero) Tbk

CHECK VALVE DATA SHEET

I

CARBON STEEL

I

CLASS2500

G H."""

Rev Dale Description

ENG PDJB POJB

SURYACIPTACNG STATION PROJECT

By Chk App App

Doc. No. SCS-01L-DSOO2A4

Revision 1 1 07/01/2010 Issuedfor Bid DMSIBPN TSJ

COMMON REQUIREMENTS

The following technical requirements applyto all valvetag nos mentionedbelow.

DESIGN& CONSTRUCTION MATERIALS

Valve type SwingDisc Check Valve Body A$TMA352-LCB (API 60) (.)

Design code API 60 Trim ASTMA352-LCB (API 60) (.)

Endconnections RF Flangedends to complywith ASME816.5 SeatsI seat ring RTFEbased r)

eace-tc-rece dimensions API 60, ASME 816.10 Pin 31658 (Replaceable 1 (.)

Body construction Boltedcover Spring lnccnet X750

o

Renewableseat

Bo'

ASTMA193 Gr. B7 (1

Anti static design No Nut ASTM A194 Gr. 2H (.)

Anti blow-cut stem No

NACE MR-0175 requirement No

.

Painting Refer to Doc. No. SCS-01-L-SP-006-A4 DESIGN CONDITION

Inspection & testing API Std 598 Design Pressure (psig) 4020

Marking MSSSP-25 Design Temp. rFJ

350

Certification BS EN 10204 Design Life (years) 20

Service Line Refer to Doc. No. SCS01-L-D5-001-A4

"Piping Class Data Sheet"

-

SPECIFIC INDIVIDUAL REQUIREMENTS

Valve tag no. G2CR4

Size range 2" up to inel. 4"

Pressure rating Class 2500

Body construction Swing type

Bore Full bore

NOTES:

1. rJEquivalent or Higher

2. Valve shall be suitable to the design conditions

Page 13 of 22

()

o

o

j' PT. PERUSAHAAN GASNEGARA(Persero) Tbk

CHECK VALVE DATA SHEET

I

CARBON STEEL

I

CLASS2500

_.N_.....

Rev Date Description

ENGPOJ8 POJB

SURYACIPTAeNG STATION PROJECT

By Chk App App

Doc. No. SCS-01-L-DS-002A4

Revision 1 1 07101/2010 Issuedfor Bid OMS/BPN TS'

COMMON REQUIREMENTS

The followingtechnical requirements applyto aU valvetag nos mentionedbelow.

DESIGN& CONSTRUCTION MATERIALS

Valve type Non-SlamType Body/BonneUEnds ASTMA216 Gr. WeB (0)

Design code ASME816.34 Plate/Disc Duplex (0)

End connections RF Flangedendsto complywilh ASME816.5 Trim/Hinge Pin ASTMA182 Gr.316

(0)

sace-to-tece dimensions Mfr. Std Seats 31655

(0)

Body construction

-

Seatsinsert PTFEBased(Replaceable)

(0)

Anti static design No Spring loconelX750

(0)

Anti blow-outstem No

Tight shut- off Yes DESIGN CONDITiON

NACE MR0175 requirement No Design Pressure (psig) 4020

Painting Refer to Doc. No. SCS-01-LSP-006-A4 Design Temp. ('F) 350

Inspection & testing API Std 598 Design Life (years) 20

Marking MSS SP25 Service Line Referto Doc. No. SCS-01-L-D$-001-A4

Certification BS EN 10204 "Piping Class Data Sheet"

Design Life (years) 20

SPECIFIC INDIVIDUAL REQUIREMENTS

Valve tag no. G2CR8

Size range 2"' up to incl. 4"

Pressure rating Class 2500

Facing RF flanged ends

NOTES:

1. (*) Equivalent or Higher

2. Valve shall be suitable to the design conditions

3. Contractor shall calculate operating condition at valve inlet and actual flow rate.

[Pace 14 of 22

c)

o

~ PT. PERUSAHAANGAS NEGARA(Persero) Tbk

GLOBE VALVE DATA SHEET

I

31655

I ClASS 150

G N ......

Rev Date Description

ENG PDJB PDJB

SURYA CIPTA eNG STATION PROJECT

By Chk App App

Doc. No. $CS01-L-DS-002-A4

Revision 1 1 07/01/2010 Issued for Bid DMS/BPN TSJ

COMMON REQUIREMENTS

The following technical requirementsapply to all valvetag nos mentioned below.

DESIGN& CONSTRUCTION MATERIALS

vatve type Globe Valve Body/Bonnet ASTM A3S1 CFBM

11

Designcode ASME 816.34 Disc ASTM A3S1 CFBM (1

End connections RF Flanged ends to comply with ASME B16.5 Stem ASTM A276 - 316

11

Construction Bolted bonnet Body seat ring ASTM A182 Gr. F316

(0)

Outside screw& yoke Gland packing Graphite

(0)

Disc Plug disc type Bonnet gasket Manufacturer's standard

Face-to-facedimensions ASME 816.10 Bolts ASTM A193 ~ 88

11

Anti static design No Nuts ASTM A194 Gr. 88M

I')

Anti blow-out stem No DESIGNCON'DIT1ON

NACE MR0175 requirement No Design Pressure (psig) 160

Painting Refer to Doc. No. SCS01-L-SP-00SA4 Design Temp. ("F) 130

Inspection & testing API Std 598 Design Life (years) 20

.

Marking MSS SP-2S Service Line Refer to Doc. No. SCS-01-L-DS-001-A4

Certification asEN 10204 "Piping Class Data Sheet"

..

-

SPECIFIC INDIVIDUAL REQUIREMENTS

Valve tag no. A3SR1

Size range 2" up to incl. 4"

Pressure rating Class 150

End connection Raised Face

Handwheel operator For 2" up to incl. 4"

.

NOTES:

1. (*) Equivalent or Higher

2. Valve shall be suitable to the design conditions

[Paqe 15 of 22

o

o

PT. PERUSAHAANGAS NEGARA (Persero) Tbk

GLOBE VALVE DATA SHEET

I

316SS

CLASSBOO

<; ... N._,.

Rev Date Description

ENG PDJB PDJB

SURYACIPTAeNG STATIONPROJECT

By Chk App App

Doc. No. SCS-01-L-DS-002A4

Revision 1 1 07/0112010 Issuedfor Bid OMSIBPN TSJ

COMMONREQUIREMENTS

The following technical requirementsapply to all valve tag nos mentioned below.

DESIGN& CONSTRUCTION MATERIALS

Valve type Globe Valve Body/Bonnet ASTM A182 Gr. F316L (")

Design code ASME 816.34 Disc ASTMA182 Gr. F316 (")

End connections Socket Weld or Screwed Ends to comply with Stem ASTMA276 - 316 (')

ASME 816.11 BodySeat Ring ASTMA182 Gr. F316 (')

Construction Bolted bonnet Gland Packing Graphite (')

Outside screw & yoke Bonnet Gasket Manufacturer's standard

Disc Plug disc type Bolt ASTM A193 Gr. 88

o

Face-to-face dimensions ASME 816.10 .Nut ASTM A194 Gr. 8aM r)

Anti static design No DESIGN CONDITION

Anti blow-out stem No Design Pressure (psig) 160

NACE MR01-75 requirement No Design Temp. (F) 130

Painting Refer to Doc. No. SCS-01-L-SpOO6-A4 Design Life (years) 20

Inspection & testing API Std 598 Service Line Refer to Doc. No. SCS-01L-D$-001-A4

Marking MSSSP-25 "Piping Class Data Sheer'

Certification BS EN 10204

. .

SPECIFIC INDIVIDUAL REQUIREMENTS

Valve tag no.

,

D3SS1

Size range 1/2" up to lnct. 1 1/2"

Pressure rating Class 800

End connections Socketweld

Handwheel operator For all sizes in range

.

NOTES:

1. f") Equivalent or Higher

2. Valve shall be suitable to the design conditions

[Paqe 16 of 22

c(j' PT. PERUSAHAANGAS NEGARA(Persero) Tbk

GATE VALVE DATA SHEET

I

CARBON STEEL

I

CLASS150

c He"e'"

Rev Date Description

ENGPDJB PDJB

SURYA CIPTA eNG STATION PROJECT By Chk App App

Doc. No. SCS-01LDS-o02A4

Revision 1 1 07/01/2010 Issued for Bid DMS/BPN TSJ

COMMONREQUIREMENTS

The following technical requirements apply to all valve tag nos mentioned below.

GENERAL MATERIALS

Valve type Gate Valve Body, bonnet, yoke ASTMA216 Gr. WCB

(.)

Design code API 600 Disc ASTMA216 Gr. WeB r)

End connections RF flanged ends to comptywith ASME 816.5 Disc seat surface/stem 13%Chromium Steel

(.)

Bodylbonnet construction Bolted bonnet Body seat ring ASTMA10SSielite No.6 (.)

Outside screw & yoke Gland packing Graphite

(0)

Wedge type Solid wedge type Bonnet gasket ManufactureStandard

Pace-to-racedimensions ASME 816.10 Bolt ASTM A193 Gr. B7

o

Anti static design

.

No Nut ASTM A194 Gr. 2H (.)

Anti blow-out stem No DESIGNCONDITION

NACE MR01-75 requirement No Design Pressure (psig) 160

Painting Refer to Doc. No. SCS-01-L-SP-006-A4 Design Temp. ('F) 150

Marking' MSS S P ~ 5 Design Life (years) 20

Inspection & testing API Std 598 Service Line Refer to Doc. No. SCS-01-L-D$-OO1-A4

Certification asEN 10204 "Piping Class Data Sheet"

.

SPECIFIC INDIVIDUAL REQUIREMENTS

Valve tag no. A4CR1

Size range 2" up to lncl. 4"

Pressure rating Class 150

End connections Raised face

Handwheet operator For ~ up 10incl. 4"

)

NOTES:

1. (*) Equivalent or Higher

2. Valve shall be suitable to the design conditions

IPage 17 Of 22

c

o

ti

GATEVALVE DATASHEET

I

CARBON STEEL

. PT. PERUSAHAANGAS NEGARA(Persero) Tbk

I

CLASS800

",H_,,_n.

Rev Date Description

ENGPDJB PDJB

SURYA CIPTAeNG STATION PROJECT

By Chk App App

Doc. No. SCSOlL.DS-002A4

Revision 1 1 07/0112010 Issued for Bid DMS/BPN TSJ

COMMON REQUIREMENTS

The following technical requirements apply to all valve tag nos mentioned below.

DESIGN& CONSTRUCTION MATERIALS

Valve type Gate Valve Body/Bonnet ASTMA10S

(0)

Design code API 602 Disc ASTMA10S (")

End connections Socket weld or Screwed ends to Disc seat surface/Stem 13%Chromium Steel

(0)

ASME 816.11 Body Seat Ring ASTMA105 Stelile No.6

(0)

Construction Bolted Gland Packing Graphite (0)

Outside screw & yoke Bonnet Gasket Manufacturer's standard

Disc Solid Wedge type Bolt ASTMA193 Gr. 87 (0)

Face-to-face dimensions Mfr. Std Nul ASTMA194 Gr. 2H

(0)

Anti static design No ~ S I N CONDITION

Anti blow-cut stem No Design Pressure (psig) 1150

NACE MR01-75 requirement No DesignTemp.

rFJ

270

Painting Refer to Doc. No. $CS-01-L-$P-006-A4 Design life (years) 20

Inspection & testing API $td 598 Service line Refer to Doc. No. SCS-01-L-OS-OO1-A4

:

Marking MSS SP-25 "Piping Class Data Sheet"

. Certification asEN 10204

SPECIFIC INDIVIDUAL REQUIREMENTS

Valve tag no. D4CS1 D4CX1

Size range 1/2" up to incl. 1 1/2" 1/2" up to incl. 1 1/2"

Pressure rating Class BOO Class 800

End connections Socketweld Socketweldx NPT

Handwheet operator For all sizes in range For al! sizes in range

)

NOTES:

1. (") Equivalent or Higher

2. Valve shall be suitable to the design conditions

IPage 18 of 22

c

c

c(j' PT. PERUSAHAANGASNEGARA (Persero) Tbk

GATEVALVE DATASHEET

I

CARBONSTEEL

I

CLASS2500

t; _I1...

Rev Date Description

ENGPDJB PDJB

SURYACIPTAeNGSTATION PROJECT

By Chk App App

Doc. No. SCS-01-L-DS-002-A4

Revision 1 1 07/01/2010 Issued for Bid DMS/BPN TSJ

COMMON REQUIREMENTS

The following technical requirements apply to aU valve tag nos mentIoned below.

DESIGN& CONSTRUCTION MATERIALS

Valve type 0

Gate Valve Body/Bonnet ASTMA10S (0)

Design code API 602 . Disc ASTMA105 (1

End connections Socket weld or Screwedends to Discseat surfaceJStem 13% Chromium Steel (")

ASME 816.11 Body Seat Ring ASTM A105 $telite NO.6

r)

Construction Bolted Gland Packing Graphite

(0)

Outside screw & yoke Bonnet Gasket Manufacturers standard

Disc Solid Wedge type Bolt ASTM A193 Gr. B7

(0)

Face-to-face dimensions Mfr. Std Nul ASTM A194 Gr. 2H

(0)

Anti static design No DESIGN CONDITION

Anti blow-out stem No Design Pressure (psig) 4020

NACE requirement No Design Temp. 350

Painting Refer to Doc. No. Design Life (years) 20

Inspection & testing API Std 598 Service Line Refer to Doc. No.

!

Marking MSSSP-25 "Piping Class Data Sheet"

Certification as EN 10204

.

SPECIFIC INDIVIDUAL REQUIREMENTS

Valve tag no. G4CS1 G4CX1

Size range 112"up to incl. 1 1/2" 1/2" up to incl. 1 112"

Pressure rating Class 2500 Class 2500

End connections Socketweld Socketweld x NPT

Handwheel operator For all sizes in range For all sizes in range

NOTES:

1. (.) Equivalent or Higher

2. Valve shall be suitable to the design conditions

IPage 19 of 22

o

c

<& PT. PERUSAHAANGAS NEGARA(Persero) Tbk

GATE VALVEDATASHEET

I

316 SS

I

CLASS150

....."'fI"'"

Rev Date Description

ENGPOJB POJB

SURYA CIPTA eNG STATION PROJECT

By Chk App App

Doc. No. SCS-01-LDS-o02A4

Revision 1 1 07/01/2010 Issued for Bid OMS/BPN TSJ

COMMONREQUIREMENTS

The following technical requirements apply to all valve tag nos mentioned below.

GENERAL MATERIALS

Valve type Gate Valve Body, bonnet, yoke ASTM A351 CF8M

(0)

Design code API 600 Disc ASTM A351 CFBM (0)

End connections RF flanged ends to comply with ASME B16.5 Stem ASTMA276 - 316 (0)

Body/bonnet construction Boiled bonnet Bodyseat ring ASTM A182 Gr. F316

(0)

Outside screw & yoke Grandpacking Graphite (0)

Wedge type Flexiblewedge type Bonnet gasket ManufactureStandard

Pace-to-race dimensions ASME 816.10 Bolt ASTMA193 Gr. B8

(0)

Anti static design No Nut ASTMA194 Gr. 88M (')

Anti blow-out stem No DESIGNCONDITION

NACE M R ~ 7 5 requirement No Design Pressure (psig) 160

Painting Refer to Doc. No. SCS.01-L-SP-006-A4 DesignTemp. m

130

Marking MSSSP-25 Design Life (years) 20

Inspection & testing API Std 598 Service line Refer to Doc. No. SCS-01-L-O&.OO1-A4

Certification B$ EN 10204 "Piping Class Dala Sheef

,

SPECIFIC INDIVIDUAL REQUIREMENTS

Valve tag no. A4SR2

Size range 2" up to Incl. 4"

Pressure rating Class 150

End connections Raised face

Handwheeloperator For 2" up to incl. 4"

"

)

I

.

NOTES:

1. (*) Equivalent or Higher

2. Each valve with nominal diameters of 10" and above shall be fitted with lifting Jugs

3. Valve shall be suitable to the design conditions

IPage 20 of 22

c

c

:.r. pERUSAHAANGASNEGARA(Persero) Tbk

GATEVALVEDATASHEET

I 31658

I CLASS 800

G ... Nep..-

Rev Date Description

ENGPDJB PDJB

SURYACIPTAeNG STATION PROJECT By Chk App App

Doc. No. SCS-ol-L-DS-002-A4

Revision 1 1 0710112010 Issuedfor Bid DMSIBPN TSJ

COMMONREQUIREMENTS

The following technical requirementsapply to all valve tag nos mentionedbelow.

DESIGN & CONSTRUCTION MATERIALS

Valve type Gate Valve BodylBonnet ASTMA182 Gr. F316L (")

Design code API 602 Disc ASTMA182 Gr. F316 (")

End connections Socket weld or Screwed ends to ASME 816.11 Stem ASTMA276 - 316 (1

Construction Bolted BodySeat Ring ASTMA182 Gr. F316

(0)

Outside screw& yoke Gland Packing Graphite

(0)

Disc Solid Wedge type Bonnet Gasket Manufacturer'sstandard

Face-to-face dimensions Mfr. Std Bolt ASTMA193 Gr. 88

(0)

Anti static design No

"

Nul ASTMA194 Gr. 88M

(0)

Anti blow-out stem No DESIGNCONDITION

NACE MR01-75 requirement No Design Pressure (psig) 160

Painting Refer to Doc. No. SCS-01-L-SP-006-A4 Design Temp. rF) 130

Inspection & testing . API SId 598 Design Life (years) 20

Marking MSS SP-25 Service Line Refer to Doc. No. SCS-01-L-OS-OO1-A4

i

Certification as EN 10204 "Piping Class Data Sheer'

.

-

SPECIFIC INDIVIDUAL REQUIREMENTS

Valve tag no. 04SS1 D4SX1

Size range 1/2" up to incl. 1 1/2" 1/2" up to incl. 1 1/2"

Pressure rating Class Class BOO

End connections Socketweld Socketweld x NPT

Handwheeloperator For all sizes in range For all sizes in range

\

.

.

)

NOTES:

1. (.) Equivalent or Higher

2. Valve shall be suitable to the design conditions

IPage 21 of 22

c

c

c(j' PT. PERUSAHAAN GAS NEGARA (Persero) Tbk

PLUG VALVE DATA SHEET

I

CARBON STEEL

I

CLASS 2500

G N.g..

Re Date Description

ENG PDJB PDJB

SURYACIPTAeNGSTATIONPROJECT

By Chk App App

Doc. No. SCS-01-L-DS-o02-A4

Revision 1 1 07/01/2010 Issuedfor Bid DMS/BPN

TSJ

COMMON REQUIREMENTS

The followingtechnical requirements applyto all valvetag nos mentioned below.

GENERAL MATERIALS

Valve type Plug Valve Body/BonneUEnds ASTMA105 {"I

Design code API Spac6D Plug ASTMA105with 3 mit EN? (")

Endconnections RF flanged endsto complywithASME 816.5 Stem 13%Chromium Steel

("I

Body/bonnet construction TaperedPlugType Stempacking Graphite

(0)

Plug type lubricated Plug Seats Metal based

Face-to-facedimensions ASME B16.10 Seals PTFE based

(0)

Fire safe design & test API Std 607 or API Spec BFA Bolts ASTM A193 Gr. B7 (0)

Antistatic design Yes Nuts ASTM A194 Gr. 2H (0)

Anti blow-out stem Yes

Sealant Injection Yes DESIGN CONDITION

NACE MR0175 requirement No Design Pressure (psig) 4020

Painting Refer to Doc. No. SCS-01L-SpOO6-A4 DesignTemp. ('F) 350

Marking MSS SP-25 Design Ufe (years) 20

\

.lnspectlon & testing API Sid 598 Service Line Refer to Doc. No. SCS01-L-DS-001-M

Certification BS EN 10204 "PipingClass Data Sheet"

-

-

SPECIFIC INDIVIDUAL REQUIREMENTS

Valve tag-no. G8CR4

Size range 2" up to incl. 4"

Pressure rating Class 2500

End connections Raised face

Lever operator For 2" up to inel. 4"

-,

)

.

NOTES:

1. Each valve shall be provided with the injection of sealant equipped with check valve.

2. (*) Equivalent or Higher

3. Valve shall be suitable to the design conditions

!Page 22 of 22

c

c

You might also like

- Valve Data Sheet: BCXS302TDocument1 pageValve Data Sheet: BCXS302TRoo FaNo ratings yet

- VDS (Valve Data Sheet)Document1 pageVDS (Valve Data Sheet)Shandi Hasnul Farizal0% (1)

- Data Sheet For Globe ValveDocument4 pagesData Sheet For Globe ValveShaaban Noaman100% (1)

- MR For Ball ValvesDocument12 pagesMR For Ball Valvesengr_umer_01100% (1)

- NTF in DS LG 001 Data Sheet Level GaugeDocument4 pagesNTF in DS LG 001 Data Sheet Level GaugeRicardo NapitupuluNo ratings yet

- Piping ClassDocument15 pagesPiping ClassCatalina BlancoNo ratings yet

- Ball Valve Data Sheet: Item Requirement NotesDocument1 pageBall Valve Data Sheet: Item Requirement NotesVivi OktaviantiNo ratings yet

- PIP - Piping Material Specifications Collection - IHSDocument3 pagesPIP - Piping Material Specifications Collection - IHSmontanovillarroelfabiolalourdeNo ratings yet

- Data Sheet Sight GlassDocument5 pagesData Sheet Sight GlassAdhya RazanNo ratings yet

- Halfaya Project Surface Facility Piping SpecificationDocument77 pagesHalfaya Project Surface Facility Piping SpecificationVignesh Panchabakesan67% (3)

- Piping Class CS1 300 4Document3 pagesPiping Class CS1 300 4rakicbg100% (1)

- Check ValveDocument1 pageCheck ValveRoshanKuckianNo ratings yet

- BE-WI-248-01-F19 Datasheet Breather ValveDocument3 pagesBE-WI-248-01-F19 Datasheet Breather Valvemika cabelloNo ratings yet

- Face-To-Face Valve Dimensions - EN-558-1: DN Basic SeriessDocument3 pagesFace-To-Face Valve Dimensions - EN-558-1: DN Basic Seriessdona_001No ratings yet

- Piping Engineering CourseDocument2 pagesPiping Engineering CourseprasannaNo ratings yet

- PUMP PIPING DESIGN MANUALDocument21 pagesPUMP PIPING DESIGN MANUALSlobodan AnticNo ratings yet

- List of StandardsDocument3 pagesList of Standardssumant.c.singh1694No ratings yet

- Cs Ball Valve 600#Document4 pagesCs Ball Valve 600#Vijay GaikwadNo ratings yet

- OMV Pipe ClassDocument160 pagesOMV Pipe Classliviu_dovaNo ratings yet

- 01SA0S02Document5 pages01SA0S02raobabar21No ratings yet

- Class 1CB2S01 (Pip PN01CB2S01 - 2005)Document6 pagesClass 1CB2S01 (Pip PN01CB2S01 - 2005)Zvonko BešlićNo ratings yet

- Check Valve Data SheetDocument1 pageCheck Valve Data SheetJèfrì PìnémNo ratings yet

- DWS 2510 Valve SpecificationDocument7 pagesDWS 2510 Valve SpecificationsudjonoNo ratings yet

- 03CA2SAE: Specification Piping Material ClassDocument7 pages03CA2SAE: Specification Piping Material Classabhishek186186No ratings yet

- Utility Gate Valve Data SheetsDocument9 pagesUtility Gate Valve Data SheetsArunkumarNo ratings yet

- Datasheet For Strainer.Document7 pagesDatasheet For Strainer.venka07No ratings yet

- 2002000-Piping Material SpecificationsDocument63 pages2002000-Piping Material SpecificationsRaju NaiduNo ratings yet

- Y-Strainer Technical SpecificationDocument7 pagesY-Strainer Technical SpecificationKailas NimbalkarNo ratings yet

- Piping Valve Data SheetsDocument415 pagesPiping Valve Data SheetsMaffone NumerounoNo ratings yet

- ET de TubulacaoDocument214 pagesET de TubulacaoClarisse MendoncaNo ratings yet

- Flexible Hose DatasheetDocument7 pagesFlexible Hose DatasheetchintanNo ratings yet

- EGP3-03.20 Technical Requirements For Piping ComponentsDocument31 pagesEGP3-03.20 Technical Requirements For Piping ComponentsMathias OnosemuodeNo ratings yet

- Restriction Orifice Final CalculationDocument1 pageRestriction Orifice Final CalculationJasperTanNo ratings yet

- Velan Forged Steel Gate Globe Checks PDFDocument25 pagesVelan Forged Steel Gate Globe Checks PDFsunil kumarNo ratings yet

- EIL Spec - 1Document5 pagesEIL Spec - 1Mohammed TariqNo ratings yet

- Actuated Ball Valve 357 D - BDKDocument4 pagesActuated Ball Valve 357 D - BDKfarhanakhtar ansariNo ratings yet

- Pig ValvesDocument3 pagesPig ValvesteacgNo ratings yet

- Motor Operated Valve List and DrawingsDocument50 pagesMotor Operated Valve List and DrawingsJuan ShunaNo ratings yet

- Dokumen - Tips Gas Filtration Products Absolute 2015-09-04 Gas Filtration ProductsDocument28 pagesDokumen - Tips Gas Filtration Products Absolute 2015-09-04 Gas Filtration ProductsCorne SalcedoNo ratings yet

- Strainer Open Area RatioDocument1 pageStrainer Open Area Rationeurolepsia3790100% (1)

- Valve Material Specification for Hindustan Petroleum CorpDocument17 pagesValve Material Specification for Hindustan Petroleum Corpzaldy1985No ratings yet

- Datasheet PSV PDPDEDocument8 pagesDatasheet PSV PDPDERicardo NapitupuluNo ratings yet

- Basic valve datasheets for inquiryDocument21 pagesBasic valve datasheets for inquirymainur mechanical engineerNo ratings yet

- Duplex StrainersDocument1 pageDuplex StrainersBossman Instruments TechnologyNo ratings yet

- List of Valve StandardsDocument8 pagesList of Valve StandardsMuthu BalamuruganNo ratings yet

- Ga Drawing of Gate, Ball, Check, Butterfly Valve & T Type Stainer P.O. No. - Pl17100130 W.O. No. - 100181 r1Document7 pagesGa Drawing of Gate, Ball, Check, Butterfly Valve & T Type Stainer P.O. No. - Pl17100130 W.O. No. - 100181 r1siva8000No ratings yet

- Gas supply pig launcher datasheetDocument9 pagesGas supply pig launcher datasheetOlusayoNo ratings yet

- 48" X 15' Three Phase Test SeparatorDocument2 pages48" X 15' Three Phase Test Separatorpraash bhattNo ratings yet

- Ioi Og Qoc 200810Document20 pagesIoi Og Qoc 200810andhucaosNo ratings yet

- Piping Material Class for Oman SRIP ProjectDocument1,507 pagesPiping Material Class for Oman SRIP ProjectMidhun K ChandraboseNo ratings yet

- Actuated Ball Valve 357 D - BDKDocument5 pagesActuated Ball Valve 357 D - BDKfarhanakhtar ansariNo ratings yet

- Iit MumbaiDocument243 pagesIit MumbaiYogesh JagdaleNo ratings yet

- API602 Forged Steel Gate & Globe ValvesDocument4 pagesAPI602 Forged Steel Gate & Globe ValvesThomasFrenchNo ratings yet

- Flame ArresterDocument16 pagesFlame Arresteriran1362No ratings yet

- Mitered BendsDocument1 pageMitered BendsTsouki TsoukiNo ratings yet

- Suppliers of Y Type StrainerDocument17 pagesSuppliers of Y Type StrainertriveniequipmentsNo ratings yet

- Wedge and Slab Gate ValvesDocument8 pagesWedge and Slab Gate Valvesgad30No ratings yet

- PCSE-100-ET-C-024:: Perú Camisea Second Expansion (Pcse)Document6 pagesPCSE-100-ET-C-024:: Perú Camisea Second Expansion (Pcse)Moises Alvarez LeandroNo ratings yet

- STD Spec - Pig TrapsDocument10 pagesSTD Spec - Pig TrapsArun MishraNo ratings yet

- Process & Piping Design Section Plug Valves Technical SpecificationDocument14 pagesProcess & Piping Design Section Plug Valves Technical Specificationashish.mathur1100% (1)

- Segmen Jatingaleh Bawen-3of3Document1 pageSegmen Jatingaleh Bawen-3of3Aris KancilNo ratings yet

- Cng-000-El-011 Voltage Drop Calculation (MS) r1Document6 pagesCng-000-El-011 Voltage Drop Calculation (MS) r1Aris KancilNo ratings yet

- Energi Indonesia 2012Document29 pagesEnergi Indonesia 2012Aris KancilNo ratings yet

- Claude Frederic BastiatDocument3 pagesClaude Frederic Bastiatapi-26172897No ratings yet

- Gas Line Sizing - SPBG PalembangDocument24 pagesGas Line Sizing - SPBG PalembangAris KancilNo ratings yet

- Water Flow Diagram Ver Feb 27022013Document1 pageWater Flow Diagram Ver Feb 27022013Aris KancilNo ratings yet

- PipeP PE2406 CharacteristicDocument3 pagesPipeP PE2406 CharacteristicAris KancilNo ratings yet

- Segmen Mjpahit Jatingaleh MjpahitDocument1 pageSegmen Mjpahit Jatingaleh MjpahitAris KancilNo ratings yet

- 01 DS Ball Valve CSDocument4 pages01 DS Ball Valve CSAris KancilNo ratings yet

- Flow Sheet Sago Rev Feb 2014 Flow ChartDocument1 pageFlow Sheet Sago Rev Feb 2014 Flow ChartAris KancilNo ratings yet

- SAGU EXTRACTION FLOW DIAGRAMDocument3 pagesSAGU EXTRACTION FLOW DIAGRAMAris KancilNo ratings yet

- Burlian Plot Plan Burlian - Okt 2012 2007 ModelDocument1 pageBurlian Plot Plan Burlian - Okt 2012 2007 ModelAris KancilNo ratings yet

- Power distribution concept for 3000 KVA steam turbine generator panelDocument1 pagePower distribution concept for 3000 KVA steam turbine generator panelAris KancilNo ratings yet

- Blok Diagram Ekstrasi Sagu Rev 1 April 2013Document4 pagesBlok Diagram Ekstrasi Sagu Rev 1 April 2013Aris KancilNo ratings yet

- SImulasi Mass Balance - 18april2013 - As (Version 1)Document7 pagesSImulasi Mass Balance - 18april2013 - As (Version 1)Aris KancilNo ratings yet

- Flow Sheet Layout3Document1 pageFlow Sheet Layout3Aris KancilNo ratings yet

- Gas Transmision CodeDocument59 pagesGas Transmision CodeAris KancilNo ratings yet

- 10.Cnb-dwg-p-006 Layout SPBG Jalan Ki MeroganDocument1 page10.Cnb-dwg-p-006 Layout SPBG Jalan Ki MeroganAris KancilNo ratings yet

- Risk Assestment Gas Terminal N PipelineDocument14 pagesRisk Assestment Gas Terminal N PipelineAris KancilNo ratings yet

- 01 DS Ball Valve CSDocument4 pages01 DS Ball Valve CSAris KancilNo ratings yet

- Pipe wall thickness calculation sheet for high pressure natural gas lineDocument1 pagePipe wall thickness calculation sheet for high pressure natural gas lineAris KancilNo ratings yet

- Risk ManajemenDocument4 pagesRisk ManajemenAris KancilNo ratings yet

- Spek PipaDocument7 pagesSpek PipaAris KancilNo ratings yet

- Instrument and Control Design BasisDocument3 pagesInstrument and Control Design BasisAris KancilNo ratings yet

- Fire and Gas Detection SpecificationDocument4 pagesFire and Gas Detection SpecificationAris KancilNo ratings yet

- Kalkulasi Studikasus KSDocument6 pagesKalkulasi Studikasus KSAris KancilNo ratings yet

- Spesifikasi Truc HyundayDocument32 pagesSpesifikasi Truc HyundayAris Kancil50% (4)

- Gas Technology Institute PresentationDocument14 pagesGas Technology Institute PresentationAris KancilNo ratings yet

- Biogas GuideDocument63 pagesBiogas GuideAris KancilNo ratings yet

- XAS 756Cd PDFDocument98 pagesXAS 756Cd PDFNicolásOCNo ratings yet

- MAKO Piping Library Catalogue - Rev CDocument28 pagesMAKO Piping Library Catalogue - Rev Celmfp7774676No ratings yet

- Hump Hydraulics CalculationsDocument13 pagesHump Hydraulics CalculationsrutujaNo ratings yet

- Pump CalculationsDocument9 pagesPump CalculationsMohamad TantawyNo ratings yet

- Work Equipment Structure and FunctionDocument42 pagesWork Equipment Structure and FunctionHai Van100% (2)

- Section 6.1: Implement Circuit - General SystemDocument22 pagesSection 6.1: Implement Circuit - General SystemYido AlvarzNo ratings yet

- Apro Introduction 2015Document20 pagesApro Introduction 2015urtzilegorburuNo ratings yet

- Artificial Lift Technology Quizzes Questions: Lecture # 1 Sept 3, 2020Document21 pagesArtificial Lift Technology Quizzes Questions: Lecture # 1 Sept 3, 2020Jhon Hery T.R. Harahap100% (2)

- Pressure Drop 6Document57 pagesPressure Drop 6twintwin91No ratings yet

- Belt Drive Type: 7,5kW - 45kW 22kW - 250kW 15kW - 250kW 10 - 500 HPDocument2 pagesBelt Drive Type: 7,5kW - 45kW 22kW - 250kW 15kW - 250kW 10 - 500 HPAriantoNo ratings yet

- Raleigh, Fanno FlowDocument11 pagesRaleigh, Fanno Flowapi-3709779100% (1)

- DLM142EDocument28 pagesDLM142Eseaqu3stNo ratings yet

- Compressibility Effects on Airfoil LiftDocument9 pagesCompressibility Effects on Airfoil LiftSahil JadiaNo ratings yet

- CMYK printer profile for sizing water piping systemsDocument18 pagesCMYK printer profile for sizing water piping systemsorganicspolybondNo ratings yet

- Contamination, Leakage and Use of Wrong FluidDocument43 pagesContamination, Leakage and Use of Wrong Fluidminingnova2100% (1)

- Priority Pipe ProcurementDocument17 pagesPriority Pipe ProcurementJahangir AlamNo ratings yet

- 1900 Series Multi-Stage Split Case Pumps Technical DataDocument8 pages1900 Series Multi-Stage Split Case Pumps Technical DataKenneth CastroNo ratings yet

- Fluid Mechanics Equation Sheet FullDocument5 pagesFluid Mechanics Equation Sheet FullZara ThomasNo ratings yet

- 09-6 Surge Control SystemDocument7 pages09-6 Surge Control SystemAbderrahmaneTemhachetNo ratings yet

- Fluid Machinery Syllabus PDFDocument3 pagesFluid Machinery Syllabus PDFBajajNo ratings yet

- Cla-Val On Offshore Fire Products BrochureDocument16 pagesCla-Val On Offshore Fire Products BrochureAngeloNo ratings yet

- Pressure LossDocument33 pagesPressure LossFreddy Mendoza CoronelNo ratings yet

- Pastite For Pipe Connection System Bul 4300 PTPDocument6 pagesPastite For Pipe Connection System Bul 4300 PTPanoop9079No ratings yet

- Fire Alarm Valve E3 ReliableDocument4 pagesFire Alarm Valve E3 ReliableMKOZERDEM100% (1)

- POS Code Qty. Dimensions Material Total Weight Detail AreaDocument1 pagePOS Code Qty. Dimensions Material Total Weight Detail AreaOrxan QulamhuseynovNo ratings yet

- Injector: Steam Injector, Eductor-Jet Pump or Thermocompressor Is A Type ofDocument6 pagesInjector: Steam Injector, Eductor-Jet Pump or Thermocompressor Is A Type ofgelosholNo ratings yet

- Presentation ConocoPhillips Gas SeparatorDocument24 pagesPresentation ConocoPhillips Gas SeparatorEnyerberht Castañeda BritoNo ratings yet

- Introduction to Hydraulics Open ChannelsDocument63 pagesIntroduction to Hydraulics Open ChannelsAchal I100% (2)

- What Is Control ValveDocument4 pagesWhat Is Control ValveshahzafNo ratings yet

- ITP LegendDocument4 pagesITP LegendRezaSohrabiNo ratings yet