Professional Documents

Culture Documents

Dead See Final Soil Report

Uploaded by

Obada Al HarastaniOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dead See Final Soil Report

Uploaded by

Obada Al HarastaniCopyright:

Available Formats

SITE INVESTIGATION

AND GEOTECHNICAL EVALUATION FOR

PROPOSED JORDANIAN DEVELOPMENT AREA PROJECT

PLOT 21, BASIN 2 AL SAHEL AL SHEMALI AL SHRQI

DEAD SEA JORDAN

S12000003

PREPARED FOR

TAHAN & BUSHNAQ CONSULTANTS

AMMAN, JORDAN

MARCH 2012

Geot. Eng. M.M / S12000003

2 of 33

TABLE OF CONTENTS

Page

LETTER OF TRANSMITTAL 1

TABLE OF CONTENTS 2-3

1.0 INTRODUCTION............................................................................................................. 4

1.1 Purpose of Study:.............................................................................................................. 4

1.2 Scope of Work:.................................................................................................................. 4

2.0 PROJECT AND SITE DESCRIPTION......................................................................... 5

3.0 GENERAL GEOLOGY................................................................................................5

4.0 SEISMICITY AND EARTHQUAKES......................................................................10

5.0 FIELD EXPLORATION AND LABORATORY TESTING..................................10

5.1 Field Exploration: ........................................................................................................... 10

5.1.1 Drilling and Sampling: ................................................................................................ 10

5.2 Laboratory Testing:........................................................................................................ 13

6.0 SURFACE AND SUBSURFACE CONDITIONS..................................................... 14

6.1 Ground Materials: ....................................................................................................... 14

6.2 In-Situ Test Results: ....................................................................................................... 15

6.2.1 Standard Penetration Test (SPT):................................................................................ 15

6.3 Groundwater and Cavities:............................................................................................ 20

6.4 Material Chemical Properties..................................................................................... 20

6.4.1 Sulphate Content ...................................................................................................... 20

6.4.2 Chloride Content in Ground Materials.................................................................. 21

7.0 CONCLUSIONS AND RECOMMENDATIONS.....................................................23

7.1 Foundation Depth and Type ....................................................................................... 23

7.2 Allowable Bearing Pressure........................................................................................ 26

7.3 Foundation Settlement: ............................................................................................... 28

7.4 Subgrade Reaction:...................................................................................................... 29

7.5 Excavation Methods: ................................................................................................... 29

7.6 Excavation of Side Slopes:........................................................................................... 29

7.7 Drainage: ...................................................................................................................... 30

7.8 Backfill Materials, Selected Engineered Fill and Compaction Criteria: ................ 30

7.9 Earth Pressure.............................................................................................................. 31

7.10 Foundation Excavation Inspection: ........................................................................... 32

8.0 STANDARD OF CARE ..............................................................................................32

Geot. Eng. M.M / S12000003

3 of 33

Page

APPENDICES 33

Appendix A Logs of Boreholes and Test Pits ..

Appendix B Generalized Subsurface Profiles ..

Appendix C Laboratory Test Results ...

Appendix D Chemical Analysis and Standard Figures and Tables

Appendix E Geology, Seismicity and Earthquake Maps .

LIST OF FIGURES

Figure No. 1 General Site Plan..................................................... 7

Figure No. 2 Photos of the proposed site. 8 & 9

LIST OF TABLES

Table No. 1 Building Names, Number of Floors, Floors Areas and F.F.Ls .. 5

Table No. 2 Borehole Numbers, Locations, Elevations, F.F.Ls and Depths ... 11 & 12

Table No. 3 Test Pits Numbers, locations, F.F.Ls and Depths 12

Table No. 4 SPT Results .. 16

Table No. 5 Laboratory Test Results of Boreholes . 17

Table No. 6 Laboratory Test Results of Test Pits 18

Table No. 7 Materials Types and Properties ... 19

Table No. 8 Chemical Test Results................................................................ 21

Table No. 9 Structures, FFL, Depth and Type of footings. ... 25

Table No. 10 Design SPT Values..................................................................... 27

Table No. 11 Structures and Net Allowable Bearing Pressure........................ 27

Table No. 12 Settlement values.. 28

Table No. 13 Material Properties used in stability analysis... 32

Geot. Eng. M.M / S12000003

4 of 33

1.0 INTRODUCTION

This report presents the results of the site investigation and geotechnical evaluation for the

proposed Jordanian Development Area project to be constructed at the eastern Dead Sea shore

- Jordan. This report presents the summary of field, laboratory testing and engineering

analysis for the proposed project site.

1.1 Purpose of Study:

The purpose of this study is to determine the surface and subsurface conditions at the

project site along with the physical, mechanical and chemical properties of the foundation

ground in order to provide recommendations for design and construction of the

foundations of the proposed project. This study is also aimed to provide recommendation

on side slopes during constructers' excavation.

1.2 Scope of Work:

The scope of work consisted of the following:

1. Collecting information and maps particular to the project site such as public services,

site plan and land use maps.

2. Making visits to the site to collect information about present land use, surface

topography, geological features and surface drainage.

3. Drilling and sampling of twenty five (25) borings.

4. Excavation of six (6) test pits.

5. Carrying out the necessary laboratory tests.

6. Performing engineering analyses based on field and laboratory findings.

7. Providing conclusions and recommendations for foundation design and construction.

Geot. Eng. M.M / S12000003

5 of 33

2.0 PROJECT AND SITE DESCRIPTION

Based on the provided information received from the client, it is understood that the proposed

project will consist of several buildings with approximate foot print areas, number of floors

and finish floor levels (F.F.L) as indicated in the following table:

Table 1: Building Names, Number of Floors, Floor Areas and F.F.L.s

The site located on the eastern shore of the Dead Sea / J ordan. The site is boarded by an

existing paved road from the north-east, the Dead Sea from the south-west, the existing

"Holiday Inn" hotel from the north-west side and by unutilized plots from south-east side. The

site slopes down toward the Dead Sea direction with an average slope of about 10%. It is

crossed by deeply incised, steep sided and relatively wide wadi.

A general site plan showing the location of the project and both drilled boreholes and

excavated test pits is presented in Figure No. 1. Figure No.2 shows some of the project site

photos.

3.0 GENERAL GEOLOGY

Based on the geological map of the area (Al Karama 3153-IV), the project area belongs to

Lisan Formation of J ordan Valley Group of Quaternary Period and Pleistocene Epoch. This

formation consists predominantly of millimeter-to-centimeter-laminated, very weak, friable,

low density, white, calcareous mudstone with alternating white marl, greenish brown clay and

evaporates. In the water saturated state they behave as soft clays. Micro-faults and controlled

laminations are typical. This formation was formed in brackish water of the Lisan Lake which

occupied the Dead Sea basin during the Late Pleistocene.

Sandy gravel lenses are common within the Lisan Marl. The thickness of these lenses may

vary form few centimeters to more than one meter.

Building Name

F.F.L

(m)

Max Foot

Print Area

(m2)

Max. No.

of Floors

Main Building 7

Second Basement -406.15 3159

First Basement -401.95 5139

Building A -409.35 758.0 2

Building B, C & D -412.67 1378 3

Geot. Eng. M.M / S12000003

6 of 33

At the project site, the lisan Marl Materials are unconformably overlain by recent yellow soil

consist of yellow-brown to gray brown humus-rich silty clay to clayey silt and alluvial fan

(ALF) sediments composed of boulder, cobbles and gravel of sandstone and limestone in

clayey-silty sand matrix.

No faults or other special geological features were observed on the geological map or during

our site inspections. However, the site is structurally controlled by Red Sea-Dead Sea rift fault

system. Geological Map is present in Appendix E.

Geot. Eng. M.M / S12000003

8 of 33

Geot. Eng. M.M / S12000003

9 of 33

Figure No.2 Photos of the proposed site

Geot. Eng. M.M / S12000003

10 of 33

4.0 SEISMICITY AND EARTHQUAKES

According to the Jordanian seismic code (published by the ministry of public works and

housing in October 2005), the site lies within Zone (3), with a seismic zone factor of Z=0.30.

The formations are classified as (S

D

) type. The seismic factors related to the acceleration

Ca=0.36; whereas, the seismic factor related to the velocity C

V

=0.54. These factors should be

used in the design of the proposed project.

5.0 FIELD EXPLORATION AND LABORATORY TESTING

5.1 Field Exploration:

The field exploration consisted of borehole drilling; test pits excavation and field density

testing.

5.1.1 Drilling and Sampling:

Twenty five (25) boreholes were drilled between February 5

th

and March 5

th

, 2012.

The boreholes were drilled to approximate depths ranging from 10 to 23m below the

existing ground level. The locations of these borings are indicated in Figure No. 1.

The borehole information is presented in Tables No. 2.

The locations of the boreholes were selected and marked in the field by the staff of

ACES. Table No. 2 shows the borings names, locations (coordinates), elevations,

F.F.L's, and exploration depths. The elevations at the top of boreholes were estimated

according to the topographic map provided by the client and should be considered

approximate. Samples were visually examined and described by ACES staff

according to ASTM D2488-09a.

The drilling was executed with "Edeco (36/1) rotary rig, mounted on Mercedes

truck 1417, capacity 400m " and "Toho 2P rotary rig, mounted on Mercedes truck

LK608, capacity 800m" using the rotary air flush percussion drilling technique .

Standard Penetration Tests (SPT) was performed at various depths in the drilled

boreholes to obtain the approximate dynamic resistance of the ground materials. The

tests were performed in accordance with ASTM D 1586-08a (Standard Test Method

for Standard Penetration Test (SPT) and Split-Barrel Sampling of Soils).

The SPT blow counts at different depths are presented on logs of borings (Appendix

A). The definition of Standard Penetration Test (SPT) and useful SPT correlations are

Geot. Eng. M.M / S12000003

11 of 33

presented in the legend of borings logs (also in Appendix A). Further discussion on

the results obtained from SPT is presented in Section 6.4.

Disturbed but representative soil samples were retrieved from inside the split spoon

samplers used in the SPT test. The recovered samples were placed in air-tight plastic

bags to maintain the moisture content.

Percussion (down-the-whole hammering) drilling techniques were used at other

intervals where no SPT sampling was performed.

Table No. 2

Borehole Numbers, Locations, Elevations, F.F.Ls and Depths

Coordinates

No.

Elevation

(m)

F.F.L

(m)

Depth

(m)

Easting Northing

BH1 -403.0 -412.67 16 206067 128529

BH2 -400.0 -412.67 19 206085 128543

BH3 -398.8 -412.67 23 206104 128553

BH4 -397.0 -412.67 22 206116 128572

BH5 -407.5 -412.67 14 206108 128595

BH6 -407.0 -412.67 12 206093 128592

BH7 -407.0 -412.67 15 206094 128611

BH9 -403.5 -409.35 15 206024 128640

BH10 -403.5 -409.35 12 206013 128640

BH11 -403.5 -406.15 15 205997 128653

BH12 -402.5 -406.15 14 206019 128662

BH13 -401.2 -406.15 17 206027 128673

BH14 -400.5 -406.15 20 206049 128657

BH15 -399.5 -406.15 17 206067 128668

BH16 -399.3 -406.15 17 206054 128682

BH17 -397.5 -406.15 23 206055 128702

BH18 -396.5 -406.15 20 206081 128706

BH19 -397.5 -406.15 19 206074 128694

BH20 -397.7 -406.15 22 206081 128681

BH22 -397.4 -401.95 22 206097 128676

Geot. Eng. M.M / S12000003

12 of 33

Table No. 2 Cont

Borehole Numbers, Locations, Elevations, F.F.Ls and Depths

Coordinates

No.

Elevation

(m)

F.F.L

(m)

Depth

(m)

Easting Northing

BH24 -406.0 -401.95 14 206130 128649

BH25 -406.2 -401.95 10 206120 128641

BH26 -403.0 -401.95 10 206141 128635

BH27 -395.5 -401.95 20 206158 128612

BH28 -400.5 -406.15 16 206042 128670

5.1.2 Excavation of Test Pits:

Six (6) test pits were excavated between February 3

rd

and February 27

th

, 2012. The test

pits were excavated to a depth of 1m deep for recommendation of proposed culvert and

buildings where the drilling with rig was not possible due to accessibility. The

numbers, locations (coordinates) and depths of each test pit are listed in Table No. 3.

The locations of the excavated test pits are also shown on the site plan in Figure No. 1.

Test pit logs are presented in Appendix A while test pit photos are presented in

Appendix E.

Bulk samples were obtained from the test pits for laboratory testing (e.g., natural

moisture content, direct shear test, unconfined compressive test, sieve analysis and

Atterberg limits). The results of these tests are summarized in Table No. 8.

Table No. 3

Test Pits Numbers, Locations, F.F.L's and Depths

Coordinates

No.

Elevation

(m)

Depth

(m)

Easting Northing

TP1 -413.0 1.0 206070 128617

TP2 -415.0 1.0 206090 128631

TP3 -401.0 1.0 206143 128619

TP4 -415.0 1.0 206050 128635

TP5 -415.0 1.0 206037 128625

TP6 -407.0 1.0 206122 128654

Geot. Eng. M.M / S12000003

13 of 33

5.2 Laboratory Testing:

In order to determine the physical and mechanical properties of the ground materials, the

following tests were performed according to American Society for Testing and Materials

(ASTM) Standards:

ASTM D2216-05, Standard Test Method for Laboratory Determination of

Water (Moisture) Content of Soil, Rock and Soil Aggregate Mixtures.

ASTM D 422-63(2007), Standard Test Method for Particle-Size Analysis of

Soils.

ASTM D 4318-10, "Standard Test Methods for Liquid Limit, Plastic Limit, and

Plasticity Index of Soils."

ASTM D 3080-04, "Standard Test Method for Direct Shear Test of Soils under

Consolidated Drained Conditions."

ASTM D 2166-06, "Standard Test Method for Unconfined Compressive Strength

of Cohesive Soil."

Chemical Tests According to the procedures outlined in British standard B.S.

1377:1990

The results of these tests are summarized in Table No. 6 whereas the test sheets are

presented in Appendix C.

The encountered materials are described in the logs of test pits (see Appendix A).

Geot. Eng. M.M / S12000003

14 of 33

6.0 SURFACE AND SUBSURFACE CONDITIONS

6.1 Ground Materials:

From Boreholes

The drilled boreholes generally encountered the following materials:

Fill material composed of loose fine coarse grain sand and gravel and cobbles

of sandstone, limestone, chert and basalt with few asphalt and concrete

fragments. This material was encountered in all boreholes except : BH1, BH2,

BH3 and BH4. It extends from the surface level to an approximate depth

ranging from 0.5m to 6.0m below the existing ground surface.

Alluvial deposits composed of alternated to intercalated lenses of brownish

yellow gravely sand to sandy gravel with silty to marly clay. This material was

encountered at the surface of BH1, BH2, BH3 and BH4 or below the fill

material of BH5 and BH6 and extended to depth ranging from 1.5m to 13.0m

below the existing ground surface.

Alluvial (wadi) material composed of varicolored gravel and cobbles of

sandstone, limestone, chert and basalt with coarse grained sand. This material

was encountered below the fill material in boreholes BH9, BH10, BH12, BH15,

BH16, BH18, BH19, BH20, BH22, BH24, BH25, BH26 and BH28 and

extended to depth ranging from 5.0m to 10.0m or to the end of this boreholes.

Grayish off white fine to medium grained sand alternated with thin silty sand

and some coarse sandy gravel. This material was encountered below the fill or

alluvial material in boreholes BH9, BH10, BH11, BH12, BH13, BH14, BH15,

BH18, BH22, BH25, BH26 and BH27 and extended to the end of these

boreholes.

Grayish yellow to greenish gray firm to stiff marly clay (lisan marl)

intercalated with white aragonite gravely sand. This material was encountered

below the alluvial or fill material in boreholes BH1, BH2,BH3, BH4, BH5,

BH6, BH7, BH18, BH20, BH24, BH27 and BH28 and extended to the end of

these boreholes.

Generalized subsurface profiles are presented in Appendix B. More information about the

encountered materials can be obtained from the logs of borings (Appendix A).

Geot. Eng. M.M / S12000003

15 of 33

Note that the grain size analyses performed on the fill and alluvial materials in boreholes

are not representative of the formation as it was performed on the disturbed samples

obtained during drilling where all the gravels, cobbles and boulders were broken into

pieces. On the other hand, the grain size analyses performed on the materials from tests

pits are more representative.

From Test Pits

The encountered material in test pits TP1, TP3 and TP5 were Lisan marl materials

composed of soft to very stiff, thinly laminated bands of greenish gray clay and white

aragonite marl, with some fine grained sand lenses. The material encountered in test pit

TP2 and TP4 was grayish yellow highly weathered disintegrated clayey silt and TP6 was

Alluvial deposits composed of gravel and cobbles of sandstone, limestone and chert with

coarse grained sand and some silty sand.

More information about the encountered materials can be obtained from the logs of test

pits (Appendix A).

6.2 In-Situ Test Results:

The in-situ testing mainly composed of two types: SPT within the drilled borehole and

field density on the excavated test pits.

6.2.1 Standard Penetration Test (SPT):

Standard Penetration Test (SPT) was performed at various depths in the fill, alluvial

deposits, sand and lisan marl materials to obtain approximate dynamic resistance of

the ground materials. Several empirical correlations have been established to relate the

SPT blow count (N) with relative density and friction angle for granular materials.

Table No. 4 presents the SPT depth in each borehole, the materials at that depth, SPT

blow counts and the corresponding SPT N values. The definition of SPT and useful

SPT correlations for granular soils are presented in the legend to boring logs

(Appendix A). The SPT (N) value ranged: from 16 to refusal in fill materials; from 25

to refusal in the alluvial and sand materials and from 18 to refusal in lisan marl

materials. The measured blow counts (N) classify the alluvial, sandy and lisan marl

materials as " medium dense to very dense". However, the relatively high N value may

have resulted from the presence of gravel and cobbles within the soil matrix.

Geot. Eng. M.M / S12000003

16 of 33

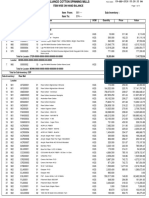

Table No. 4

SPT Results

N-value is the sum of the second and third number of blows.

6.3 Materials Physical and Mechanical Properties:

The laboratory test results of boreholes and test pits are summarized in Table No. 5 and

6. Further information about the materials encountered, geological description and their

physical properties can be obtained from Table No. 7.

BH No.

Depth

(m)

Encountered

Material

SPT blows

N-

Value

8.0

Lisan marl

50 in 5cm. >50

BH-01

9.5

Lisan marl

11/12/22 34

11.0

Lisan marl

11/9/9 18

BH-02

12.5

Lisan marl

10/10/9 19

13.0

Lisan marl

8/10/11 21

BH-04

14.5

Lisan marl

10/10/12 22

5.0 Alluvial 21/33/50 in 10cm >50

BH-09

7.0 Alluvial 38/50 in 8cm >50

2.0

Fill

11/13/15 28

BH-10

4.0

Fill

9/14/17 31

1.5

Fill

8/9/13 22

BH-11

3

Fill

14/17/21 38

3

Fill

7/8/9 17

BH-12

6

Alluvial

8/15/10 25

5.5

Sand

13/17/20 37

BH-13

7.5

Sand

16/19/25 44

6.0

Alluvial

22/50 in 6cm >50

BH-22

8.0

Alluvial

50 in 9cm >50

2

Alluvial

12/15/24 39

BH-24

7

Alluvial

9/17/22 39

2.5

Fill

7/9/8 17

BH-25

5.0

Alluvial

50 in 11cm. >50

3.0

Fill

37/50 in 12cm. >50

BH-26

6.0

Sand

21/32/50 in 8cm >50

5.5

Fill

4/7/9 16

BH-27

7.0

Sand

50 in 50cm. >50

Geot. Eng. M.M / S12000003

17 of 33

Table No. 5

Laboratory Test Results of Boreholes

Atterberg Limits Grain Size Distribution

BH

No.

Depth

(m)

M.C

(%)

Specific

Gravity

LL

(%)

PL

(%)

PI

(%)

G

(%)

S

(%)

M

(%)

C

(%)

Material

1 10.0-11.0 10.48 17 13 4 0 75 20 5 Lisan Marl

12.0-13.0 8.09 0 79 16 5 Lisan Marl

2

15.0-17.0 4.94 0 79 16 5 Lisan Marl

14.0-15.0 9.80 - 0 74 20 6 Lisan Marl

4

9.0-10.0 5.82 Alluvial

5 6.0-7.0 7.26 - 0 65 27 8 Alluvial

3.0-4.0 - 22 73 4 1 Alluvial

6

8.0-9.0 2.01 - 0 82 14 4 Alluvial

4.0-5.0 8.85 - 10 63 21 6 Lisan Marl

7

7.0-8.0 5.91 - 2 79 15 4 Lisan marl

11 6.0-8.0 0.39 - 2 91 6 1 Sand

6.0-7.5 0.67 - 32 61 5 2 Alluvial

12

9.0-12.0 0.33 - 5 89 5 1 Sand

9.0-10.0 3.71 - 0 88 10 2 Sand

13

13.0-14.0 1.80 - 0 90 8 2 Sand

7.0-8.0 1.92 - 7 82 9 2 Alluvial

22

11.0-12.0 1.38 - 0 86 11 3 Sand

7.0-8.0 28.03 Alluvial

24

9.0-1.0 16.22 - 5 55 31 9 Alluvial

4.0-5.0 2.15 - 12 78 8 2 Alluvial

25

5.0-6.0 6.78 - 4 72 17 7 Alluvial

7.0-8.0 2.32 - 0 81 15 4 Sand

27

13.0.14.0 7.23 - 2 74 18 6 Lisan Marl

M.C: Moisture Content

G: Gravel S: Sand M: Silt C: Clay

L.L: Liquid Limit P.L: Plastic Limit P.I: Plasticity Index

Geot. Eng. M.M / S12000003

18 of 33

Table No. 6

Laboratory Test Results of Test Pits

M.C: Moisture Content

G: Gravel S: Sand M: Silt C: Clay

L.L: Liquid Limit P.L: Plastic Limit P.I: Plasticity Index

C: Cohesion : Angle of Internal Friction

Direct shear

Test Results

Atterberg Limits Grain Size Distribution

Material

TP

No.

Depth

(m)

M.C

(%)

C

(KPa)

(Degree)

LL

(%)

PL

(%)

PI

(%)

G

(%)

S

(%)

M

(%)

C

(%)

qu

(kg/cm

2

)

1 0.0-1.0 11.91

38.6 21.3 17.3 0 2.2 53.9 43.9 2.51

Lisan marl

2 0.0-1.0 14.67

42.4 22.8 19.6 1.5 7.6 46.4 44.5 Clayey silt

3 0.0-1.0 17.41 5.70 31.14 36.3 22.3 14 0 1.4 51.0 47.6 3.62 Lisan marl

5 0.0-1.0 24.53 34.0 20.0 14.0 0.0 7.0 73.0 20.0 Lisan marl

6 0.0-1.0 1.96 48.0 49.0 3.0 0.0 Alluvial

Geot. Eng. M.M / S12000003

19 of 33

Table No. 7

Materials Types and Properties

Approximate

Depths

(m)

Geological Description

Summary of Tests

Results

Plasticity/

Expansiveness

See logs of borings,

(Appendix A).

Fill material composed of loose fine

coarse grain sand and gravel and

cobbles of sandstone, limestone, chert

and basalt with few asphalt and

concrete fragments.

- -

See logs of borings,

(Appendix A).

Alluvial deposits composed of

alternated to intercalated lenses of

brownish yellow gravely sand to

sandy gravel with silty to marly clay.

M/C : 0.67-28.03%

G : 0.0-32%

S : 55-82%

M : 4-31%

C : 1-9%

P : N.P

See logs of borings,

(Appendix A).

Alluvial (wadi) material composed

of varicolored gravel and cobbles of

sandstone, limestone, chert and basalt

with coarse grained sand.

See logs of borings,

(Appendix A).

Grayish off white fine to medium

grained sand alternated with thin silty

sand and some coarse sandy gravel.

M/C : 0.33-2.32%

G : 0-5%

S : 81-90%

M : 6-15%

C : 1-4%

P : N.P

See logs of borings,

(Appendix A).

Grayish yellow to greenish gray firm

to stiff marly clay (lisan marl)

intercalated with white aragonite

gravely sand.

M/C : 4.94-10.48%

G : 0-10%

S : 63-79%

M : 15-21%

C : 4-6%

LL : 17%

PL : 13%

PI : 4%

P: Low

PE: Low

M.C: Moisture Content

G: Gravel S: Sand M: Silt C: Clay

L.L: Liquid Limit P.L: Plastic Limit P.I: Plasticity Index

PE : Potential of Expansiveness P: Plasticity

Geot. Eng. M.M / S12000003

20 of 33

6.3 Groundwater and Cavities:

No free ground water or cavities were encountered in any of the boreholes to the drilled

depths during or after the completion of drilling activities. However, the surface hydrology

is outside the scope of this study.

6.4 Material Chemical Properties

6.4.1 Sulphate Content

Sulphate content (expressed as [SO

3

]) for the tested soil samples are shown in

Table No. 8.

Sulphate attack to concrete is well documented phenomena and is caused by the

presence of high sulphate content either by the ingress of the sulphate of the

surrounding environment, such as foundations soils, or by the presence of sulphate

in the concrete ingredients, such as sand or aggregate, or both.

The attack results in a considerable internal expansion which may lead to cracking

and disintegration of the concrete.

Based on the sulphate content present in the foundations soils; this site can be

classified within class 3 as categorized in BS 5328:Part 1 (see Appendix D). The

requirements of BS 5328:Part 1 for class (3) are to use ordinary portland cement,

sulphate resisting portland cement, or blast furnace portland cement or super

sulphated cement with minimum cement content of 320 and 340 kg/m3 and

maximum free water to cement ratio of 0.5 and 0.5, respectively.

Taking into consideration the characteristics of the proposed project, its function

and the presence of ground water, it is recommended that the overall site be treated

as class (3) which presents the severe conditions.

Geot. Eng. M.M / S12000003

21 of 33

6.4.2 Chloride Content in Ground Materials

The chloride content for the tested soil samples are also presented in Table No. 8.

There is no widely accepted view on the concentration which chlorides become

significant in soil or ground water, but limited experience in the region suggests it

may be as low as 0.05%, particularly in situations where alternate wetting and

drying or capillary rise affect the concrete (CIRIA Guide, 1983).

As shown in Table No. 8, the chloride content in the tested soil samples is more

than 0.05% and is considered significant.

Table No. 8

Chemical Test Results

BH-No

Depth

(m)

Encountered

Material

Sulphate

Content

SO3 (%)

Chloride

Content

Cl (%)

Carbonate

Content

CaCO

3

(%)

pH

Value

BH 4 14.0-15.0 Lisan marl 0.249 0.298 42.47 8.18

BH 13 9.0-10.0 Sand 0.427 0.149 53.44 8.64

BH 22 7.0-8.0 Alluvial 0.160 0.213 52.43 8.82

6.4.3 pH Value

Soil pH is one of the most common soil chemical measurements. It provides the

investigator with information about the solubility of various soil compounds, the

adsorption behavior of ions to soil surface and the microbial activity of soil

system. The measured pH values listed in Table No. 9 indicate that the tested

samples are alkaline, with values ranging from 8.18-8.82. These values are

considered not detrimental to steel.

6.4.4 Carbonate Content

Carbonate content in the tested samples is considered slightly high (i.e., more than

40%), which is normal due to the nature of alluvial material.

Geot. Eng. M.M / S12000003

22 of 33

6.4.5 General Recommendations

Where resistance is needed against both sulphates and chlorides, it is highly

recommended to protect the concrete from the soil and groundwater with

waterproofing membrane or tanking, and a compromise has to be made on

the type of cement used. Generally, cement containing at least 3.5% but not more

than 9% C3A is preferred. Each situation should be considered on its merits.

It is advisable that the designer shall consult CIRIA Guide to Concrete

Construction in the Gulf Region, once the exposure conditions of the designed

structures are finally determined, in order to determine, more accurately, the

cement type (Figure 6 -Appendix D) and range of specifications limits

requirements for minimum cement content, maximum water cement ratio and

minimum cover for reinforcement (Table 13 Appendix D).

Geot. Eng. M.M / S12000003

23 of 33

7.0 CONCLUSIONS AND RECOMMENDATIONS

According to the field and laboratory investigation, subsurface conditions, engineering

analysis and practical experience, we believe that the proposed project can be satisfactorily

supported by the ground at the site, provided that the following recommendations are

considered:

7.1 Foundation Depth and Type

Main Building (Block C).

Foundation of the Main building are to be constructed at an approximate elevation

of -407.0m and -403.0m. The investigation indicated that part of the main building site

(adjacent to Holiday Inn Hotel site) is covered by dumped fill reaching 6m in thickness.

Most of these fill materials will be removed to reach the design level of foundation.

However, if any dumped fill will remain below the design level, it should be either

completely removed or excavated to a minimum depth of 1.5m and replaced by selected

fill materials, as described herein later.

The investigation indicated that ground materials encountered at the expected foundation

level of the main building are alluvial deposits, lisan marl, and/or engineered fill

material (due to difference in elevations and especially, above the proposed culvert),

which are characterized by large variations in properties and strength parameters in both

vertical and horizontal extends. Therefore, foundations may be subjected to significant

differential settlement and differential movement may cause damage to the foundations

and structures. Accordingly, raft foundations are essential to support the 6-7 story main

building.

However, if the client chooses not to adopt this solution and assuming that occurrence of

some minor cracks (especially within the partition walls, in the plaster, in the interface

between different structural elements, along water and electrical installations, etc.) is

acceptable, the following alternative may be adopted.

a. Unify foundation ground by Excavating of minimum of 1.5m below foundation

levels

b. Backfill the over excavations with selected fill up to a height of 1.2m. The

selected fill shall be a soil or soil rock mixture, which is free from organic

matter or other deleterious substances. It shall not contain rocks or lumps over

15 cm in greatest dimension, and not more than 15 percent larger than 7 cm.

Geot. Eng. M.M / S12000003

24 of 33

The fine materials (passing sieve 200) shall not exceed 35 percent (materials

classified as A-1-a, A1-b and/or A-2-4 according to AASHTO Classification

are considered suitable for this purpose). Selected fill shall be spread in lifts

not exceeding 20 cm in uncompacted thickness, moisture conditioned to its

optimum moisture content, and compacted to a dry density not less than 95 %

of the maximum dry density as obtained by modified proctor compaction test

(ASTM D 1557).

c. The remaining top 30cm of the over excavation shall be backfilled either with

cyclopean concrete (plain concrete with approximately 40% stones) or with

engineered fill.

If engineered fill is used, it should be spread into two lifts and each lift shall be

compacted to a dry density not less than 97 percent of the maximum density as

obtained by modified proctor compaction test (ASTM D 1557-09). The

plasticity index for the base course material shall not be more than 6 percent. It

shall be composed of graded crushed stone satisfying all the requirements of

base course materials according to the Standard Specifications for the

Construction of Roads and Bridges, Ministry of Public Works, Jordan.

d. Foundations system with sufficient rigidity (i.e, strip foundation and/or isolated

footing with tie beam constructed at foundation level) can be erected on the

foundation ground prepared as described above.

e. Foundations constructed as described herein shall be designed using a net

allowable bearing pressure value of 1.5 kg/cm

2

.

Building A

Foundation of the building A are to be constructed at an approximate elevation of -

410.5m. Ground materials encountered at the above elevation are alluvial deposits,

and/or fill material. These deposits are characterized by large variations in properties

and strength parameters in both vertical and horizontal extends. Therefore, foundations

may be subjected to significant differential settlement and differential movement may

cause damage to the foundations and structures. Accordingly, shallow foundations

system with sufficient rigidity is recommended to support the two (2) story building. In

order to enhance the rigidity of the foundation systems, foundations shall be tied

together with ground tie beams constructed at the foundation level.

Differential settlement may also be reduced by reduction of the transmitted pressure,

which, in turn, can be achieved by separating the foundations from the foundation

ground by a 30 cm thick cyclopean concrete layer (i.e., plain concrete with

approximately 40% stones).

Geot. Eng. M.M / S12000003

25 of 33

Building B, C & D

Foundation of the building B, C & D are to be constructed at an approximate elevation

of -413.5m. Ground materials encountered at the above elevation are lisan marl.

Although, these materials are relatively homogeneous, significant variations in strength

parameters in both vertical and horizontal extend may take place as a result of the

possible local water submergence. Accordingly, shallow foundation systems with

sufficient rigidity are recommended to support the 3 story building. In order to enhance

the rigidity of the foundation systems, foundations shall be tied together with ground tie

beams constructed at the foundation level.

Differential settlement may also be reduced by reduction of the transmitted pressure,

which, in turn, can be achieved by separating the foundations from the foundation

ground by a 30 cm thick cyclopean concrete layer (i.e., plain concrete with

approximately 40% stones).

Based on the above mentioned analysis for the proposed structures, finish floor levels

(F.F.L), bearing materials, depth of foundations and foundations types are provided in

Table No.9:

Table No.9: Structures, Finish Floor Levels, Depth and Type of Foundations.

Structure Name BH No.

F.F.L

(m)

Bearing

Material

Depth of

foundations

(m)

Type of

foundations

(m)

Main Building

BH11, BH12, BH13,BH14, BH15,

BH16, BH17, BH18, BH19, BH20,

BH22, BH24, BH25, BH26, BH27,

BH28, TP2, TP3 & TP6

-406.15

&

-401.95

Alluvial &

Lisan marl

1.5

Raft/

Isolated/Strip

Building A BH8, BH10, TP4 & TP5 -409.35 Alluvial 1.5 Isolated/Strip

Building B,C &D

BH1, BH2, BH3, BH4, BH5, BH6

& BH7

-412.67 Lisan marl 2.0 Isolated/Strip

Culvert TP1, TP2 & TP3 Lisan marl 1.0 Raft

Geot. Eng. M.M / S12000003

26 of 33

7.2 Allowable Bearing Pressure

Allowable bearing pressure was calculated based on settlement consideration as

proposed by Meyerhofs theory, for 25.4 mm (1 in.) of estimated maximum settlement,

q

net.all

(kN/m

2

) = 7.99 NC

N

2

28 . 3

1 28 . 3

+

B

B

F

d

; (for B > 1.22m)

Since Meyerhof proposed his original correlation, researchers have observed that its

results are rather conservative. Later, Meyerhof (1965) suggested that the net allowable

bearing pressure should be increased by about 50%. Bowles (1977) proposed that the

modified form of the bearing pressure equation be expressed as

q

net.all

(kN/m

2

) = 11.98 NC

N

2

28 . 3

1 28 . 3

+

B

B

F

d

4 . 25

, mm S

; (for B > 1.22m)

Where:

NC

N

: corrected standard penetration number,

NC

N

: N x 9.78 ( )

2

,

/ / 1 m kN

N

N : measured standard penetration test N value.

N

: effective overburden pressure.

As mentioned earlier, there is a large variation in the soil strength in both horizontal

and vertical extends as indicated from the SPT test results. Therefore, second lowest

values below foundation influence are taken into consideration in bearing capacity

computing, as presented below.

Many authors do not consider correction to N values of SPT for depth shallower than 5.0

m. Other correction factor is considered based on used hammer energy. The correction

factor of this type the used in the investigation hammer is 0.75. Accordingly, the

adopted corrected number of blows for shallow foundations are as follows:

Geot. Eng. M.M / S12000003

27 of 33

Table No. 10

Design SPT Values

Structure Name SPT N blows

Corrected

N value

(design value)

Main Building 18 13

Building A 17 12

Building B, C & D 22 16

Culvert 17 12

B = Foundation Width,

F

d

= Foundation Depth Factor; Fd =

+

B

D

f

33 . 0 1 1.33,

S = tolerable settlement in mm.

For large width, B, e.g. mat foundations, the preceding equation can be approximated

(assuming

+

B

B

8 . 32

1 8 . 32

1) as

q

net.all

(kN/m

2

) 11.98 NC

N

F

d

4 . 25

, mm S

; or

q

net.all

(kN/m

2

) 11.98NC

N

+

4 . 25

,

33 . 0 1

mm S

B

D

f

15.93 NC

N

4 . 25

, mm S

.

Based on the above, the following net allowable bearing pressure values are

recommended.

Table No. 11

Structure Name and Net Allowable Bearing Pressure

Net allowable bearing pressure

kg/cm

2

Structure Name

Raft Isolated/Strip

Main Building 2.3 1.5

Building A 1.4

Building B, C & D 1.9

Culvert 2.1

Geot. Eng. M.M / S12000003

28 of 33

7.3 Foundation Settlement:

The consolidation settlement for the alluvial materials is expected to be insignificant

(negligible). The elastic (immediate) settlement of the materials can be calculated using

the following equation based on the theory of elasticity [e.g, Timoshenko and Goodier

(1951)]:

s = qa xB (1-

2

) I

Es

Where:

s: settlement of the corner of a rectangular base (mm).

qa: net allowable bearing pressure

B: the width of the foundation, approximately equal to 1.0m for isolated (square strip and

raft) footings

I: combined depth, roughness and bedrock thickness influence factor, which is equal to:

0.88 for square footing

2.1 for strip & raft footing (L/B=10)

: the Poisson's ratio of the materials; is generally about 0.3 for soils.

E: Youngs modulus of soil

E= 7000 N

0.5

Therefore, the estimated foundation settlement is:

Table No.12: Settlement values:

Since the fill materials is erratic and does not have uniform engineering properties,

settlements could not be predicted using conventional settlement calculations. However, if

construction was performed according to the recommendations above, settlements are

expected to be within allowable limits.

Settlement

cm per meter width

Structure

qa

Kg/cm

2

E

Kg/cm

2

Square

0.88

Strip

2.10

Raft

2.10

Main Building (Raft) 2.3 0.3 300 0.61 1.46 1.46

Main Building (Isolated) 1.5 0.3 300 0.40 0.96 -

Building A 1.4 0.3 290 0.39 0.92 -

Building B, C & D 1.9 0.3 330 0.46 1.10 -

Culvert 2.1 0.3 290 1.38

Geot. Eng. M.M / S12000003

29 of 33

7.4 Subgrade Reaction:

For the design of raft foundations on these layers, the conservative value of the modulus

of sub-grade reaction is calculated using the allowable bearing pressure (1.5 Kg/cm

2

) as

follow:

For design of culvert and main building raft foundations, the following modulus of

subgrade reaction may be calculated from the standard penetration number of blows (N

value):

K

0.3

= 1.8 Ncor (MN/m

3

) (Scott 1981),

K

0.3

(for base diameter of 0.3m)

Accordingly, the (K

0.3

) value will be : (1.8*13=23.4 MN/m

3

( 2.3kg/cm

3

))

For Main Building ( 2.3kg/cm

3

)

For Culvert ( 2.1kg/cm

3

)

For foundation size correction:

K

s

= K

0.3

2

2

3 . 0

+

B

B

assuming that foundation ground behave as granular soil.

Where (B) is foundation width.

7.5 Excavation Methods:

It is expected that the excavation will be carried out through the fill, lisan marl and alluvial

materials. Therefore, pneumatic equipment such as jackhammer will be needed in addition

to the conventional excavation equipment such as loaders and dozers for excavation work

at the site.

7.6 Excavation of Side Slopes:

To minimize the stability problems, the temporary excavation sides should be cut at a face

inclination not steeper than one horizontal to one vertical (1H: 1V) for the fill and

alluvial materials.

If these side slopes can not be achieved for insufficient lateral distance or for any other

reason, temporary lateral support (shoring) system may be necessary and should be

considered.

Geot. Eng. M.M / S12000003

30 of 33

7.7 Drainage:

It is recommended to protect the foundation ground and excavation from surface water

both during and after construction by providing proper drainage and protection system and

maintaining the sewer and water system of the buildings continuously. The rain water and

surface water (if any) which is collected from the rain water ducts and from ground

surface should be directed away from the buildings.

Proper drainage should also be provided at all retaining walls (if any) in the form of either

perforated drain pipes or weep holes across the wall. A filter/drainage blanket or layer

approximately 50 cm wide should be backfilled against all retaining walls consisting of

open graded filter materials (single size gravel may also be used). Gradation requirements

for filter material are outlined in the following paragraph.

7.8 Backfill Materials, Selected Engineered Fill and Compaction Criteria:

The existing fill materials are considered suitable for backfilling purposes.

Backfill Materials:

The materials to be used for backfilling purposes under bottom slab and behind

underground walls shall be a soil or soil-rock mixture, which is free from organic matter

or other deleterious substances. It shall not contain rocks or lumps over 15 cm in greatest

dimension, and not more than 15 percent larger than 7 cm. The fine materials (passing

sieve 200) shall not exceed 35 percent. The plasticity index for the backfill material shall

not be more than 10 percent. It shall be spread in lifts not exceeding 20cm in uncompacted

thickness, moisture conditioned to its optimum moisture content, and compacted to

density not less than 95 percent of the maximum dry density as obtained by modified

proctor compaction test (ASTM D 1557-09).

Selected Engineered Fill:

The engineered fill materials shall be composed of well graded granular material. It shall

be spread in lifts not exceeding 20cm in uncompacted thickness, moisture conditioned to

its optimum moisture content and compacted to a dry density not less than 97 percent of

the maximum density as obtained by modified proctor compaction test (ASTM D 1557-

09). The plasticity index for the selected fill material shall not be more than 6 percent.

Geot. Eng. M.M / S12000003

31 of 33

Retaining Walls:

The backfill materials immediately behind the retaining walls (if any) shall consist of

filter/drainage materials composed of clean coarse sand and gravel or crushed stone

conforming to the following gradation requirements:

Sieve Size Percentage Passing by Weight

2 1/2" 100

1 1/2" 80-100

3/4" 60-95

No. 4 35-65

No. 8 25-50

No. 30 5-25

No. 200 0-3

(Single size gravel may also be used as an alternative to the above filter materials).

These materials shall extend vertically from the bottom of the walls to a level of

approximately 1m below the finished ground level behind the walls. The top 1m shall be

backfilled with relatively impervious materials.

7.9 Earth Pressure

Assuming that there are no sustained surcharges, no back slope and no hydrostatic

pressure conditions, the following soil parameters may be used in the design (based on our

experience with similar materials).

Table No. 13 Material Properties used in stability analysis

* For earth pressure calculation, cohesion should be considered zero due to tension cracks.

Material Types

Unit

Weight

(g/cm

3

)

Cohesion

( C )

(kg/cm

2

)

Angle of

Internal

Friction

()

(Degree)

Coef. of

Active

Earth

Pressure

Ka

Coef. of

Passive

Earth

Pressure

Kp

Coef. of

Earth

Pressure

at rest

Ko

Fill materials 1.8 2.0 30 0.33 3.00 0.5

Alluvial materials 2.0 5.0 35 0.27 3.69 0.42

Lisan Marl materials

1.6 0.2 12 0.65 1.54 0.79

Selected fill

materials

2.0 0.1 30 0.33 3.00 0.50

Filter materials 2.0 0.0 34 0.28 3.54 0.44

Geot. Eng. M.M / S12000003

32 of 33

7.10 Foundation Excavation Inspection:

The recommendations given in this report are based on the assumption that the subsurface

materials and conditions do not deviate appreciably from those disclosed in the borings.

Our office should be notified, in writing, immediately after all foundation excavations and

before foundation construction to inspect the excavations and confirm that the required

ground is reached and all the undesirable and loose materials are removed.

8.0 STANDARD OF CARE

Arab Center for Engineering Studies has endeavored to provide their services in a manner that

features appropriate professional practice and the level of care and skill ordinarily exercised

by members of the profession. No other representation, expressed or implied, is included or

intended in this document.

It should be noted that the boreholes show subsurface conditions at the locations, dates, and

depths indicated and it is not warranted that they are strictly representative of the materials

and conditions at other locations, times, and greater depths than indicated.

Geot. Eng. M.M / S12000003

33 of 33

APPENDICES

APPENDIX A

LOGS OF BORINGS & TEST PITS

LEGEND TO BORING LOGS

SYMBOLS FOR COMMON SOIL AND ROCK TYPES

CLAY

SILT SAND

GRAVEL

COBBLES & BOULDERS

PEAT

FILL

CHALK MARL

LIMESTONE

CHERT

CLAYSTONE

SILTSTONE

SANDSTONE

SHALE

BASALT

PHOSPHATE

SAMPLER TYPE

Sample

Disturbance

HAMMER

Disturbed

CORE BARREL

Relatively

Undisturbed

AUGER

Disturbed

SHELBY TUBE

Undisturbed

DRIVE CYLENDER

(Manual)

Relatively

Undisturbed

DRIVE BARREL

Relatively

Undisturbed

DRIVE SPLIT SPOON

(S.P.T.)

Disturbed

S.P.T. (Blows/30cm) : The number of blows, in the Standard Penetration test, required to drive a five centimeter diameter split tube

sampler a distance of thirty centimeters using sixty three and half kilograms weight falling seventy six centimeters

Fine Grained Soils Coarse Grained Soils

S.P.T

(Blows

/30cm)

Consistency Field Identification

Unconfined

Compressive

Strength

(kg/cm

2

)

S.P.T

(Blows/

30cm)

Density Field Identification

Relative

Density

(%)

0-2 Very Soft

Easily penetrated several cms

with fist.

<0.25 0-4 Very Loose

Easily indented with finger

, thumb, or fist.

0-20

2-4 Soft

Easily penetrated several cms

with thumb

0.25-0.5 4-10 Loose

Less easily indented with

fist but easily shoveled.

20-40

4-8 Firm

Penetrated several cms by

thumb with moderate effort.

0.5-1.0 10-30

Medium

Dense

Shoveled with difficulty. 40-60

8-15 Stiff

Readily indented by thumb

but penetrated only with great

effort.

1.0-2.0 30-50 Dense

Requires pick to loosen for

shoveling by hand.

60-80

15-30 Very Stiff

Readily indented by thumb

nail.

2.0-4.0 >50 Very Dense

Requires blasting or heavy

equipment to loosen.

80-100

>30 Hard

Indented with difficulty by

thumb nail.

>4.0

Recovery : The percentage of length of core recovered in each run to the total length of the core run.

R.Q.D. : The Rock Quality Designation is the percentage of the sum of lengths of intact core pieces ten centimeters or longer to the

total length of the core run.

Point Load Strength and Unconfined Compressive Strength: In the point load test, a rock core is loaded between two steel cones

and failure occurs by tensile splitting. A point load strength index, Is, is calculated as the ratio of the applied load, P, at rupture to the

square of the distance, H, between the loading points: Is =P / H

2

.

A correlation that is commonly used between the point load index and the unconfined compressive strength, qu, of a cylinder with a

length to diameter ratio of 2 to 1 is: qu =24 Is

(50).

.

Where Is

(50)

is the point load strength corrected to a diameter of 50mm (Brock and Franklin, 1972).

Rock Quality Rock Strength

Rock Quality Designation,

RQD (%)

Rock Quality

Description

Description Uniaxial Compressive Strength

(MPa)

0 - 25 Very Poor Extremely Weak 0.3-1.0

25 - 50 Poor Very Weak 1.0-5.0

50 - 70 Fair Weak 5.0-30.0

70 - 90 Good Medium Strong 30.0-50.0

90 - 100 Excellent Strong 50.0-100.0

Very Strong 100.0-250.0

Extremely Strong >250.0

ARAB CENTER FOR ENGINEERING STUDIES

Logged By : Melena M.

*From (8.0-16.0)m; Increase of sand

-404.50

50 in 5cm.

11

T

C

R

(

%

)

Field Records

Grayish yellow to greenish gray firm to stiff marly clay

(lisan marl) intercalated with white aragonite gravely

sand.

SAMPLE KEY

Alluvial deposits composed of alternated to intercalated

lenses of brownish yellow gravely sand to sandy gravel

with silty to marly clay.

Sheet 1 of 2

E

l

e

v

a

t

i

o

n

(

m

)

Description

S

y

m

b

o

l

D

e

p

t

h

(

m

)

S

a

m

p

l

e

T

y

p

e

Core Recovery

12 22

>50

*From (1.5-8.0)m; Increase of clayey marl (lisan marl).

34

S

C

R

(

%

)

Checked By : Mustafa B.

0-15

cm

15-30

cm

30-45

cm R

Q

D

(

%

)

Ground Water Table

Total Core Recovery

Solid Core Recovery

Rock Quality Designation

N

Blows

Percussion

Standard Penetration

Test

Rock Core

Total Depth (m): 16

Ground Level (m): -403.0

Coordinates: N=128,529.00 E=206,067.00

0

1

2

3

4

5

6

7

8

9

10

11

12

13

REMARKS:

SPT Records

TCR:

SCR:

RQD:

Appendix

Drilling Method : Rotary Percussive

Boring Started : 06-02-2012 Rig : Toho2

Boring Completed : 07-02-2012 Driller : MA

Project : Jordanian Development Area

Project Ref. No. : S12000003

Location : Dead Sea, Jordan

Client : Tahan & Bushnaq Consultants

Borehole No.

BH-01

Page 1 /

Core Dia (mm):

Casing Depth (m) : -

Drilling Medium : Air Flush

Boring Dia (mm) : 99.2

Casing Dia (mm): 122.5

Total Depth (m): 16

Ground Level (m): -403.0

Coordinates: N=128,529.00 E=206,067.00

Core Recovery

Logged By : Melena M.

SPT Records

REMARKS:

Drilling Medium : Air Flush

Boring Dia (mm) : 99.2

Casing Dia (mm): 122.5

S

y

m

b

o

l

Percussion

Standard Penetration

Test

Rock Core

TCR:

SCR:

RQD:

Sheet 2 of 2

SAMPLE KEY

Bottom of borehole

-419.00

T

C

R

(

%

)

S

a

m

p

l

e

T

y

p

e

D

e

p

t

h

(

m

)

R

Q

D

(

%

)

E

l

e

v

a

t

i

o

n

(

m

)

Description

Page 2 /

Field Records

Core Dia (mm):

Casing Depth (m) : -

13

14

15

16

15-30

cm

30-45

cm

Ground Water Table

Total Core Recovery

Solid Core Recovery

Rock Quality Designation

N

Blows

Project : Jordanian Development Area

Project Ref. No. : S12000003

Location : Dead Sea, Jordan

Client : Tahan & Bushnaq Consultants

Borehole No.

BH-01

0-15

cm

Drilling Method : Rotary Percussive

Boring Started : 06-02-2012 Rig : Toho2

Boring Completed : 07-02-2012 Driller : MA

Appendix

S

C

R

(

%

)

Checked By : Mustafa B.

Alluvial deposits composed of alternated to intercalated

lenses of brownish yellow gravely sand to sandy gravel

with silty to marly clay.

Grayish yellow to greenish gray firm to stiff marly clay

(lisan marl) intercalated with white aragonite gravely

sand.

*From (2.0-5.0)m; Increase of clayey marl (lisan marl).

*From (5.0-19)m; Increase of sand

-402.00

11

S

a

m

p

l

e

T

y

p

e

T

C

R

(

%

)

Sheet 1 of 2

R

Q

D

(

%

)

E

l

e

v

a

t

i

o

n

(

m

)

Description

S

y

m

b

o

l

D

e

p

t

h

(

m

)

10

9

10

9

9 19

SAMPLE KEY

18

S

C

R

(

%

)

Checked By : Mustafa B.

0-15

cm

Core Recovery

30-45

cm

Field Records

0

1

2

3

4

5

6

7

8

9

10

11

12

13

15-30

cm

Ground Water Table

Total Core Recovery

Solid Core Recovery

Rock Quality Designation

N

Blows

SPT Records

REMARKS:

Appendix

Logged By : Melena M.

Total Depth (m): 19

Ground Level (m): -400.0

Coordinates: N=128,543.00 E=206,085.00

Percussion

Standard Penetration

Test

Rock Core

Drilling Method : Rotary Percussive

Boring Started : 07-02-2012 Rig : Toho2

Boring Completed : 08-02-2012 Driller : MA

Project : Jordanian Development Area

Project Ref. No. : S12000003

Location : Dead Sea, Jordan

Client : Tahan & Bushnaq Consultants

Borehole No.

BH-02

TCR:

SCR:

RQD:

Core Dia (mm):

Casing Depth (m) : -

Drilling Medium : Air Flush

Boring Dia (mm) : 99.2

Casing Dia (mm): 122.5

Page 1 /

Total Depth (m): 19

Ground Level (m): -400.0

Coordinates: N=128,543.00 E=206,085.00

Core Recovery

Logged By : Melena M.

SPT Records

REMARKS:

Drilling Medium : Air Flush

Boring Dia (mm) : 99.2

Casing Dia (mm): 122.5

S

y

m

b

o

l

Percussion

Standard Penetration

Test

Rock Core

TCR:

SCR:

RQD:

Sheet 2 of 2

SAMPLE KEY

Bottom of borehole

-419.00

T

C

R

(

%

)

S

a

m

p

l

e

T

y

p

e

D

e

p

t

h

(

m

)

R

Q

D

(

%

)

E

l

e

v

a

t

i

o

n

(

m

)

Description

Page 2 /

Field Records

Core Dia (mm):

Casing Depth (m) : -

13

14

15

16

17

18

19

15-30

cm

30-45

cm

Ground Water Table

Total Core Recovery

Solid Core Recovery

Rock Quality Designation

N

Blows

Project : Jordanian Development Area

Project Ref. No. : S12000003

Location : Dead Sea, Jordan

Client : Tahan & Bushnaq Consultants

Borehole No.

BH-02

0-15

cm

Drilling Method : Rotary Percussive

Boring Started : 07-02-2012 Rig : Toho2

Boring Completed : 08-02-2012 Driller : MA

Appendix

S

C

R

(

%

)

Checked By : Mustafa B.

-410.80

Alluvial deposits composed of alternated to intercalated

lenses of brownish yellow gravely sand to sandy gravel

with silty to marly clay.

*From (0.0-2.0)m; Increase of yellow fine to medium

grained sand.

*From (2.0-4.0)m; Incrase of sand with thin bituminous

dark gray silty clay

*From (4.0-6.0)m; Incease of medium to coarse grained

sand

*From (6.0-7.0)m; Incease of sand with thin bituminous

dark gray silty clay

Grayish off white fine to medium grained sand alternated

with thin silty sand and some coarse sandy gravel.

*From (7.0-12.0)m; Increase of medium coarse grained

sand with few fine gravel.

Grayish yellow to greenish gray firm to stiff marly clay

(lisan marl) intercalated with white aragonite gravely

sand.

Sheet 1 of 2

9

13

T

C

R

(

%

)

Field Records

SAMPLE KEY

R

Q

D

(

%

)

>50

27

25

50 in 7cm>50

50 in 3cm.

Drilling Method : Rotary Percussive

Boring Started : 19-02-2012 Rig : Toho2

Boring Completed : 19-02-2012 Driller : MA

Appendix

S

C

R

(

%

)

Checked By : Mustafa B.

0-15

cm

E

l

e

v

a

t

i

o

n

(

m

)

Project : Jordanian Development Area

Project Ref. No. : S12000003

Location : Dead Sea, Jordan

Client : Tahan & Bushnaq Consultants

-405.80

15-30

cm

0

1

2

3

4

5

6

7

8

9

10

11

12

13

Ground Water Table

Total Core Recovery

Solid Core Recovery

Rock Quality Designation

N

Blows

30-45

cm

SPT Records

S

a

m

p

l

e

T

y

p

e

Borehole No.

BH-03

D

e

p

t

h

(

m

)

S

y

m

b

o

l

Core Recovery

Description

Logged By : Melena M.

REMARKS:

Total Depth (m): 23

Ground Level (m): -398.8

Coordinates: N=128,553.00 E=206,104.00

Core Dia (mm):

Casing Depth (m) : -

Drilling Medium : Air Flush

Boring Dia (mm) : 99.2

Casing Dia (mm): 122.5

Page 1 /

TCR:

SCR:

RQD:

Percussion

Standard Penetration

Test

Rock Core

Total Depth (m): 23

Ground Level (m): -398.8

Coordinates: N=128,553.00 E=206,104.00

Core Recovery

Logged By : Melena M.

SPT Records

REMARKS:

Drilling Medium : Air Flush

Boring Dia (mm) : 99.2

Casing Dia (mm): 122.5

S

y

m

b

o

l

Percussion

Standard Penetration

Test

Rock Core

TCR:

SCR:

RQD:

Sheet 2 of 2

SAMPLE KEY

Bottom of borehole

-421.80

T

C

R

(

%

)

S

a

m

p

l

e

T

y

p

e

D

e

p

t

h

(

m

)

R

Q

D

(

%

)

E

l

e

v

a

t

i

o

n

(

m

)

Description

Page 2 /

Field Records

Core Dia (mm):

Casing Depth (m) : -

13

14

15

16

17

18

19

20

21

22

23

15-30

cm

30-45

cm

Ground Water Table

Total Core Recovery

Solid Core Recovery

Rock Quality Designation

N

Blows

Project : Jordanian Development Area

Project Ref. No. : S12000003

Location : Dead Sea, Jordan

Client : Tahan & Bushnaq Consultants

Borehole No.

BH-03

0-15

cm

Drilling Method : Rotary Percussive

Boring Started : 19-02-2012 Rig : Toho2

Boring Completed : 19-02-2012 Driller : MA

Appendix

S

C

R

(

%

)

Checked By : Mustafa B.

Percussion

Standard Penetration

Test

Rock Core

E

l

e

v

a

t

i

o

n

(

m

)

Description

S

y

m

b

o

l

D

e

p

t

h

(

m

)

S

a

m

p

l

e

T

y

p

e

Core Recovery

Logged By : Melena M.

SPT Records

REMARKS:

Total Depth (m): 22

Ground Level (m): -397.0

Coordinates: N=128,572.00 E=206,116.00

Sheet 1 of 2

*From (4.0-11.0)m; Incrase of sandy gravel.

*From (1.0-4.0)m; Increase of highly weathered coarse

grained sand with gravel and some bituminous clay.

*From (11.0-13.0)m; alternated with some light gray

marl.

T

C

R

(

%

)

Field Records

SAMPLE KEY

R

Q

D

(

%

)

Alluvial deposits composed of alternated to intercalated

lenses of brownish yellow gravely sand to sandy gravel

with silty to marly clay.

0-15

cm

30-45

cm

0

1

2

3

4

5

6

7

8

9

10

11

12

13

15-30

cm

Ground Water Table

Total Core Recovery

Solid Core Recovery

Rock Quality Designation

N

Blows

TCR:

SCR:

RQD:

Page 1 /

Drilling Medium : Air Flush

Boring Dia (mm) : 99.2

Casing Dia (mm): 122.5

Project : Jordanian Development Area

Project Ref. No. : S12000003

Location : Dead Sea, Jordan

Client : Tahan & Bushnaq Consultants

Drilling Method : Rotary Percussive

Boring Started : 15-02-2012 Rig : Toho2

Boring Completed : 15-02-2012 Driller : MA

Appendix

Checked By : Mustafa B.

Borehole No.

BH-04

S

C

R

(

%

)

Core Dia (mm):

Casing Depth (m) : -

R

Q

D

(

%

)

Logged By : Melena M.

-410.00

-419.00

8

10

T

C

R

(

%

)

Field Records

Bottom of borehole

SAMPLE KEY

Grayish yellow to greenish gray firm to stiff marly clay

(lisan marl) intercalated with white aragonite gravely

sand.

Sheet 2 of 2

Description

S

y

m

b

o

l

D

e

p

t

h

(

m

)

S

a

m

p

l

e

T

y

p

e

Core Recovery

10

10

11

12

21

E

l

e

v

a

t

i

o

n

(

m

)

22

S

C

R

(

%

)

Checked By : Mustafa B.

0-15

cm

30-45

cm

13

14

15

16

17

18

19

20

21

22

15-30

cm

Ground Water Table

Total Core Recovery

Solid Core Recovery

Rock Quality Designation

N

Blows

REMARKS:

SPT Records

Total Depth (m): 22

Ground Level (m): -397.0

Coordinates: N=128,572.00 E=206,116.00

Percussion

Standard Penetration

Test

Rock Core

TCR:

SCR:

RQD:

Page 2 /

Appendix

Drilling Method : Rotary Percussive

Boring Started : 15-02-2012 Rig : Toho2

Boring Completed : 15-02-2012 Driller : MA

Project : Jordanian Development Area

Project Ref. No. : S12000003

Location : Dead Sea, Jordan

Client : Tahan & Bushnaq Consultants

Borehole No.

BH-04

Drilling Medium : Air Flush

Boring Dia (mm) : 99.2

Casing Dia (mm): 122.5

Core Dia (mm):

Casing Depth (m) : -

Logged By : Melena M.

E

l

e

v

a

t

i

o

n

(

m

)

Description

S

y

m

b

o

l

D

e

p

t

h

(

m

)

S

a

m

p

l

e

T

y

p

e

SAMPLE KEY

SPT Records

REMARKS:

Total Depth (m): 14

Ground Level (m): -407.5

Coordinates: N=128,595.00 E=206,108.00

Sheet 1 of 2

Core Recovery

Fill material composed of loose fine coarse grain sand

and gravel and cobbles of sandstone, limestone, chert

and basalt with few asphalt and concrete fragments.

Alluvial materials composed of brown to light brown fine

to course grained sand and very fine frained sandy silt

with alternating sub-rounded to sub angular gravel,

cobbles and occasional boulders of limestone chert

sandstone.

Grayish yellow to greenish gray firm to stiff marly clay

(lisan marl) intercalated with white aragonite gravely

sand.

* From (5.0-9.0)m; Alternated clayey marl and fine to

medium sand with some dark gray bituminous silty clay

R

Q

D

(

%

)

-410.00

-413.00

T

C

R

(

%

)

Field Records

* From (9.0-14.0)m; Increase of light gray sand with gray

clayey silt intercalations.

Percussion

Standard Penetration

Test

Rock Core

0-15

cm

30-45

cm

0

1

2

3

4

5

6

7

8

9

10

11

12

13

Ground Water Table

Total Core Recovery

Solid Core Recovery

Rock Quality Designation

N

Blows

TCR:

SCR:

RQD:

Page 1 /

Drilling Medium : Air Flush

Boring Dia (mm) : 99.2

Casing Dia (mm): 122.5

Core Dia (mm):

Casing Depth (m) : -

15-30

cm

Checked By : Mustafa B.

Borehole No.

BH-05

Project : Jordanian Development Area

Project Ref. No. : S12000003

Location : Dead Sea, Jordan

Client : Tahan & Bushnaq Consultants

Drilling Method : Rotary Percussive

Boring Started : 12-02-2012 Rig : Toho2

Boring Completed : 12-02-2012 Driller : MA

Appendix

S

C

R

(

%

)

Total Depth (m): 14

Ground Level (m): -407.5

Coordinates: N=128,595.00 E=206,108.00

Core Recovery

Logged By : Melena M.

SPT Records

REMARKS:

Drilling Medium : Air Flush

Boring Dia (mm) : 99.2

Casing Dia (mm): 122.5

S

y

m

b

o

l

Percussion

Standard Penetration

Test

Rock Core

TCR:

SCR:

RQD:

Sheet 2 of 2

SAMPLE KEY

Bottom of borehole

-421.50

T

C

R

(

%

)

S

a

m

p

l

e

T

y

p

e

D

e

p

t

h

(

m

)

R

Q

D

(

%

)

E

l

e

v

a

t

i

o

n

(

m

)

Description

Page 2 /

Field Records

Core Dia (mm):

Casing Depth (m) : -

13

14

15-30

cm

30-45

cm

Ground Water Table

Total Core Recovery

Solid Core Recovery

Rock Quality Designation

N

Blows

Project : Jordanian Development Area

Project Ref. No. : S12000003

Location : Dead Sea, Jordan

Client : Tahan & Bushnaq Consultants

Borehole No.

BH-05

0-15

cm

Drilling Method : Rotary Percussive

Boring Started : 12-02-2012 Rig : Toho2

Boring Completed : 12-02-2012 Driller : MA

Appendix

S

C

R

(

%

)

Checked By : Mustafa B.

Sheet 1 of 2

Fill material composed of loose fine coarse grain sand

and gravel and cobbles of sandstone, limestone, chert

and basalt with few asphalt and concrete fragments.

Alluvial materials composed of brown to light brown fine

to course grained sand and very fine frained sandy silt

with alternating sub-rounded to sub angular gravel,

cobbles and occasional boulders of limestone chert

sandstone.

Grayish yellow to greenish gray firm to stiff marly clay

(lisan marl) intercalated with white aragonite gravely

sand.

* From (9.0-14.0)m; Increase of fine to medium grained

sand with some marl intercalations.

-409.00

-411.50

-419.00

9

12

11

T

C

R

(

%

)

Field Records

>50 15

50 in 6cm

20 50 in 4cm

>50

>50

36

Borehole No.

BH-06

Project : Jordanian Development Area

Project Ref. No. : S12000003

Location : Dead Sea, Jordan

Client : Tahan & Bushnaq Consultants

Drilling Method : Rotary Percussive

Boring Started : 13-02-2012 Rig : Toho2

Boring Completed : 13-02-2012 Driller : MA

Appendix

S

C

R

(

%

)

Checked By : Mustafa B.

0-15

cm

SAMPLE KEY

30-45

cm

* From (4.5-9.0)m; Alternated marl and fine sand.

0

1

2

3

4

5

6

7

8

9

10

11

12

Ground Water Table

Total Core Recovery

Solid Core Recovery

Rock Quality Designation

N

Blows

15-30

cm

Logged By : Melena M.

D

e

p

t

h

(

m

)

R

Q

D

(

%

)

SPT Records

S

a

m

p

l

e

T

y

p

e

Core Recovery

S

y

m

b

o

l

Description

E

l

e

v

a

t

i

o

n

(

m

)

Percussion

Standard Penetration

Test

Rock Core

Drilling Medium : Air Flush

Boring Dia (mm) : 99.2

Casing Dia (mm): 122.5

REMARKS:

TCR:

SCR:

RQD:

Core Dia (mm):

Casing Depth (m) : -

Page 1 /

Total Depth (m): 12

Ground Level (m): -407.0

Coordinates: N=128,592.00 E=206,093.00

Core Recovery

Drilling Medium : Air Flush

Boring Dia (mm) : 99.2

Casing Dia (mm): 122.5

Page 2 /

TCR:

SCR:

RQD: