Professional Documents

Culture Documents

Resume of Qualifications

Uploaded by

DON0 ratings0% found this document useful (0 votes)

200 views3 pagesExperienced manufacturing professional seeks challenging environment where background and experience can be applied to the efficient satisfaction of the production objective. 1 / 08 - 9 / 09 BBK Performance, Corona and Temecula, California Director of Manufacturing Responsible for Manufacturing Operations. NGK was TS-16949, QS 9002 and ISO 14000 certified.

Original Description:

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentExperienced manufacturing professional seeks challenging environment where background and experience can be applied to the efficient satisfaction of the production objective. 1 / 08 - 9 / 09 BBK Performance, Corona and Temecula, California Director of Manufacturing Responsible for Manufacturing Operations. NGK was TS-16949, QS 9002 and ISO 14000 certified.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

200 views3 pagesResume of Qualifications

Uploaded by

DONExperienced manufacturing professional seeks challenging environment where background and experience can be applied to the efficient satisfaction of the production objective. 1 / 08 - 9 / 09 BBK Performance, Corona and Temecula, California Director of Manufacturing Responsible for Manufacturing Operations. NGK was TS-16949, QS 9002 and ISO 14000 certified.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 3

RESUME OF QUALIFICATIONS

OBJECTIVE

Experienced manufacturing professional seeks challenging environment where background and

experience can be applied to the efficient satisfaction of the production objective.

SUMMARY OF QUALIFICATIONS

Manufacturing Manager 10 years

Logistics Manager 8 years

Safety and Health Manager 4 years

Managed Quality 10 Years

Procurement Manager 4 years

Implementation Manager TS16949

Highly skilled and knowledgeable regarding Automation and Robotics

Experience with automotive OEM supply chain managers

Participated in OEM supplier symposiums, and product launch

Production planning, cost control, supplier performance

Innovative and creative in problem solving and cost reduction

Knowledgeable OSHA regulations / compliance

Excellent organization, follow-up, analytical, and communication skills

Knowledgeable on Quality Systems TS-16949, QS-9001, ISO14001, ISO9001/2000

EXPERIENCE

1/08 – 9/09 BBK Performance, Corona & Temecula, California

Director of Manufacturing

Responsible for Manufacturing Operations. As the Director of Manufacturing my responsibilities

included overseeing Quality, Logistics, Production Planning. Responsible for cost control, vendor

performance, outside processing, inventory accuracy, Safety, and OSHA compliance. Temecula

(Headquarter) location managed full CNC machine shop and R&D. The Corona location was

primarily utilized for welded products, such as Stainless Steel Performance Headers, and undercar

Exhaust and Suspension products. Corona was also the Packaging and Distribution center.

02/03 - 1/08 Magnaflow Performance Exhaust, Rancho Santa Margarita, California

Sr. Manufacturing Manager / Plant Manager

Responsible for Manufacturing in 3 facilities. Equipment planning, Logistics, capital expenditures,

resource planning, OSHA compliance / safety, continuous improvement, Mfg planning, production

throughput, inventory, P&L, cost control, and quality. Four managers, six supervisors and 170

direct employees were my responsibility.

10/1999 – 02/03 NGK Spark Plugs, Irvine California

Manufacturing Manager promoted to General Manager

As General Manager I was responsible for operations in the plant. Duties include Logistics,

resource management, facility safety, production planning, security, quality and quantity of

production, Administration/HR duties, cost control, profitability, and training. NGK was TS-16949,

QS 9002 and ISO 14000 certified. Five department managers, reported directly to me, we

employed approximately 200 factory associates.

06/1996 – 10/1999 Smittybilt Inc, Corona, California

Robotic Supervisor promoted to Plant Manager

At Smittybilt, I was responsible for all production-related matters. Managed a

crew of, five department supervisors, ten leaders and two hundred production workers. My daily

duties included, establishing clear production goals, creating production schedules, estimating

product backlogs, and monitoring quality. Controlled, determined and monitored resource levels.

Was involved with R&D in the design and fabrication of welding jigs and fixtures. Was responsible

for purchasing raw materials, production supplies and consumables.

3/1995 – 5/1996 Gary Steel, Long Beach, California

Night Shift Manager

Night Shift Facility Manager. Was responsible for a crew of two, leadmen and thirty steel workers.

Gary Steel was the largest supplier of steel plate on the West Coast. Was responsible for the

efficient operation of seven gantry type NC Gas and Plasma cutting machines. Responsible for all

Night Shift operations, shipping, receiving, administration, and quality.

11/1988 -3/1996 Komatsu Forklift MFG, Buena Park, California

Welding Leadman promoted to Plant Manager

My normal duties included supervising a crew of five lead men and sixty workers. Responsible for

production planning, created work schedules, product quantity and quality. Responsible for the

Machine Shop Production. Purchased shop equipment, consumable supplies, and welding products.

Was also the safety director and hazardous material coordinator. While employed at Komatsu, I

was sent to Japan were I received a certification for Management, Inventory Control, Kaizen, JIT,

and Advanced Robotic Programming.

EDUCATION

1969/1972: Wilson High School: Long Beach, California

1972/1974: Long Beach City College, California, (Industrial Major)

1980: Modern Shipbuilding and Management Techniques

1990: Attended multiple Management Seminars, attained certifications

1991: Computer Training: Lotus 123 Qpro, and WordStar

1995: Advanced computer training: PowerPoint, Excel, Word

2000: Completed training course titled, Tools for Corrective Action

2001: Completed training course titled, Visual Factory Management

2001: Certified in, Advanced Microsoft Access

2001: Certified by General Motors Corp. in Lean Manufacturing Concepts

2003: Completed OSHA certified Hazwoper Training, certified as a Level 3 Responder

2005: Fanuc Robot Training

2007: Completed 20 weeks Manager Training (received certification)

ACHIEVEMENTS

Project Implementation Manager ISO 9001/2000

Managed Purchasing, Logistics, and Warehouse functions

Implemented Continuous Improvement program

Introduced (LEAN) operations

Systemized R&D process

Created process mapping for R&D and production

Project Implementation Manager for Automation and Robotics

Participated in meetings with OEM customers, represented operations during visits/audits

Won General Motors Supplier of the Year (three consecutive years)

Dispatched to Japan (twice) for Management, Five S, and Lean Mfg. Training

First local staff (non Japanese transferee) at NGK to achieve General Manage title

Promoted to Plant Manager at Smittybilt

Member of American Welding Society since 1987

References

Salary History

Available upon request

You might also like

- Cycle Count.1Document1 pageCycle Count.1DONNo ratings yet

- Line Shift ReportDocument1,300 pagesLine Shift ReportDONNo ratings yet

- Manufacturing Guide To World ClassDocument15 pagesManufacturing Guide To World ClassDONNo ratings yet

- Luxfer Riverside Video PresentationDocument16 pagesLuxfer Riverside Video PresentationDONNo ratings yet

- Work RequestDocument2 pagesWork RequestDONNo ratings yet

- Interview Techniques and Guidance: Preparation 1. Research The CompanyDocument4 pagesInterview Techniques and Guidance: Preparation 1. Research The CompanyDON100% (1)

- Five S Implementation: SORT (Clearing Up Space) OrganizationDocument8 pagesFive S Implementation: SORT (Clearing Up Space) OrganizationDONNo ratings yet

- 5S Check SheetDocument8 pages5S Check SheetDONNo ratings yet

- 11/17/2009 Dear Sirs: I Am Writing This Letter To BeDocument1 page11/17/2009 Dear Sirs: I Am Writing This Letter To BeDONNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

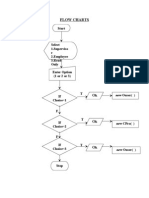

- Flow Charts Option: StartDocument13 pagesFlow Charts Option: StartbalabooksNo ratings yet

- WWW - Incar.tw-Kobelco SK 75 Service ManualDocument5 pagesWWW - Incar.tw-Kobelco SK 75 Service Manualpurnomo0% (1)

- Engineering QuotesDocument10 pagesEngineering QuotesGendakenNo ratings yet

- How To Sputter Thin Films of Metal Onto GlassDocument5 pagesHow To Sputter Thin Films of Metal Onto Glassfred_m_48601No ratings yet

- Wrf736sdam14 - Tech - Sheet - W10811276 - Rev - B Otro Modelo de La Nevera de Oliva OcoaDocument5 pagesWrf736sdam14 - Tech - Sheet - W10811276 - Rev - B Otro Modelo de La Nevera de Oliva OcoaEdison EspinalNo ratings yet

- Quick Union Reference Tables: Pressure Control EquipmentDocument1 pageQuick Union Reference Tables: Pressure Control EquipmentMiguel FNo ratings yet

- HVCB Timing ApplicationDocument52 pagesHVCB Timing Applicationbhuban mohanNo ratings yet

- Sensotronic Brake ControlDocument20 pagesSensotronic Brake ControlShubhankar Banerjee100% (1)

- Freezing pipes-FPSDocument2 pagesFreezing pipes-FPSBinu SulochananNo ratings yet

- Standardization of Welding ElectrodesDocument8 pagesStandardization of Welding ElectrodesAqsa BanoNo ratings yet

- Vista 128BPT Program ManualDocument72 pagesVista 128BPT Program ManualyalmanzaNo ratings yet

- Standard For Safety UL ADocument49 pagesStandard For Safety UL ANhất NgônNo ratings yet

- 61 35 122 Removing and Installing - Replacing General ModuleDocument2 pages61 35 122 Removing and Installing - Replacing General ModuleTung NguyenNo ratings yet

- Address Book in JAVADocument18 pagesAddress Book in JAVAmelyfony100% (1)

- High Build Epoxy Coating for Hulls and Ballast TanksDocument3 pagesHigh Build Epoxy Coating for Hulls and Ballast Tankskasosei0% (1)

- Checklist of Requirements in The Application For Mechanical Installation/s of Industrial FacilitiesDocument1 pageChecklist of Requirements in The Application For Mechanical Installation/s of Industrial FacilitiesoliciakimNo ratings yet

- Next Gen Ford Ranger Digital BrochureDocument10 pagesNext Gen Ford Ranger Digital BrochureTri BureauNo ratings yet

- ATS1801 - Interface PC - ImpDocument8 pagesATS1801 - Interface PC - ImpluismantonioNo ratings yet

- LMS Adaptive FiltersDocument14 pagesLMS Adaptive FiltersalialibabaNo ratings yet

- Thermostats and Dial Thermometers PDFDocument252 pagesThermostats and Dial Thermometers PDFAsep MustopaNo ratings yet

- CRCM Manual 2 9 16Document33 pagesCRCM Manual 2 9 16Kamagara Roland AndrewNo ratings yet

- Environmental Quality Control of Emission From Diesel Engines Regulations 1996 - P.U.a 429-96Document22 pagesEnvironmental Quality Control of Emission From Diesel Engines Regulations 1996 - P.U.a 429-96scribdledeeNo ratings yet

- QlassicDocument31 pagesQlassicQila HusinNo ratings yet

- Joy Global SolutionsDocument18 pagesJoy Global Solutionsjvr001100% (1)

- FD FX Brochure Update 072020Document9 pagesFD FX Brochure Update 072020Alex PomaNo ratings yet

- A Practical Introductory Guide On Using Satellite Technology For CommunicationsDocument15 pagesA Practical Introductory Guide On Using Satellite Technology For CommunicationsJohan PrinslooNo ratings yet

- Core 3Document2 pagesCore 3RidhiNo ratings yet

- Introduction to Generators, Protection Schemes, Relays and MaintenanceDocument44 pagesIntroduction to Generators, Protection Schemes, Relays and MaintenancerahulNrana100% (1)

- Power Tool Switches: Catalog 1308650 Issued 1-01Document18 pagesPower Tool Switches: Catalog 1308650 Issued 1-01Gamal AhmadNo ratings yet

- A ProcessDocument41 pagesA ProcessjulioNo ratings yet