Professional Documents

Culture Documents

4.5 kV-Fast-Diodes With Expanded SOA Using A Multi-Energy Proton Lifetime Control Technique

Uploaded by

HappyJoeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4.5 kV-Fast-Diodes With Expanded SOA Using A Multi-Energy Proton Lifetime Control Technique

Uploaded by

HappyJoeCopyright:

Available Formats

4.

5 kV-Fast-Diodes with Expanded SOA Using a Multi-Energy

Proton Lifetime Control Technique

O. Humbel, N. Galster, F. Bauer, W. Fichtner

ISPSD, May 1999, Toronto, Canada

Copyright [1999] IEEE. Reprinted from the International Symposium on

Power Semiconductor Devices and ICs.

This material is posted here with permission of the IEEE. Such permission of the

IEEE does not in any way imply IEEE endorsement of any of ABB Switzerland Ltd,

Semiconductors's products or services. Internal or personal use of this material is

permitted. However, permission to reprint/republish this material for advertising or

promotional purposes or for creating new collective works for resale or redistribution

must be obtained from the IEEE by writing to pubs-permissions@ieee.org.

ABB Semiconductors AG & ISL 4.5 kV-Fast-Diodes with Expanded SOA Using a Multi-Energy Proton Lifetime Control Technique

ISPSD Page 1 of 5 Toronto, 1999

4.5 kV-Fast-Diodes with Expanded SOA Using a Multi-Energy Proton Lifetime

Control Technique

O. Humbel !, N. Galster ", F. Bauer ", W. Fichtner !

" ABB Semiconductors Lenzburg, Switzerland

Phone: +41/62 888 63 79; Fax: +41/62 888 63 05; E-Mail: galster@abbsem.ch

! Integrated Systems Laboratory, ETH Zrich, Switzerland

Phone: +41/632 60 95; Fax: +41/632 11 94; E-Mail: humbel@iis.ee.ethz.ch

Abstract: This paper presents a 4.5 kV diode fabricated using

a new ion irradiation technique whereby electrons are

replaced by protons in a second irradiation step. The second

proton peak is located close to the middle of the n-base.

Compared to the combined ion-electron irradiation, diodes

with a double proton peak show a smaller maximum reverse-

recovery current and a much smoother tail current behavior.

The new device has an excellent ruggedness, being able to

withstand a peak power of 1 MW/cm

2

.

I. INTRODUCTION

With increasing demands for higher switching frequencies,

new power switches such as the Hard Driven GTO [1] - or

IGCT - and the IGBT require improved diode concepts.

Snubberless conditions in these applications are gaining

ground, imposing switching transients at very high di/dt

and dv/dt values. This leads to new challenges in diode

development. Besides the standard criteria of low static and

dynamic losses, soft recovery under all application

conditions (in particular at low current density and high

line voltage) and low reverse-recovery current, the need for

a large SOA (Safe Operating Area) has become most

important. The optimum diode design depends on the

specific application conditions.

In the following, the new 4.5 kV diode is investigated in

two different applications (clamped inductive and resistive

switching), computer simulations employing lifetime

profiles will be compared to the test results.

II. COMMUTATION CONDITIONS

In order to optimize the behavior of diodes during turn-off,

the circuit needs to be taken into consideration in particular

with respect to inductive and resistive switching.

Fig. 1 shows a clamped inductive circuit with a perfect

switch, which results in a linear di/dt determined by the

external inductance L. This differs essentially from the

resistive mode of commutation (Fig. 2). Here the turn-off is

controlled by an active switch, which switches

progressively over a defined period of time. This means

that the di/dt is determined by R (time-dependant)

resistance of the switch) rather than by the stray inductance

L

s

. This type of circuit is realized for Undeland snubbers

where the active switch

L

L

S

V

R

R

Charge

D

Clamp

DUT

F

C

Clamp

Fig. 1 Snubberless, clamped inductive switching circuit

L

S

V

R

DUT

F

R

Fig. 2 Snubberless Undeland/Mc Murray snubber diode,

resistive switching circuit

is typically a GTO or in freewheeling diodes circuits where

the active switch is an IGBT. The differences in the

stress that the diode experiences will be explained in

chapter IV.

III. MULTI-ENERGY PROTON LIFETIME CONTROL

The design concepts for diode optimization include

basically the variation of emitter efficiency and lifetime

control. Local lifetime control has proven to be very

successful and is realized by either heavy metal doping or

by exposure to ion beams (protons or particles), in

addition to electron irradiation [2,5]. Ion irradiation is

intended to reduce anode emitter efficiency and hence the

plasma density close to the anode thus leading to lower

maximum reverse current and a softer recovery behavior.

Due to the carrier lifetime reduction both in the n-base and

ABB Semiconductors AG & ISL 4.5 kV-Fast-Diodes with Expanded SOA Using a Multi-Energy Proton Lifetime Control Technique

ISPSD Page 2 of 5 Toronto, 1999

cathode area of the diode, electron irradiation yields a tail-

current phase free from heavy impact ionization caused by

dynamic avalanche, but the possibilities of further tailoring

the plasma distribution in the diode are very limited [3].

In this paper we present the results of a new irradiation

technique where electron irradiation is replaced by proton

irradiation in a second step. The second proton peak is

located close to the middle of the n-base (Fig. 3). This

results in a favorable carrier distribution with lower

concentration at the anode and higher concentration at the

cathode side as compared to a device with combined proton

and electron irradiation. (Fig. 4).

electron+proton

double proton

Fig. 3. Doping (dot dashed) and lifetime profiles of the

combined p

+

/e

-

(solid) and the double-proton irradiated

(dashed) diode

electron+proton

double proton

Fig. 4. Doping profile (dot dashed) and on-state plasma

distributions of the conventionally (solid) and the double-

proton irradiated (dashed) diode

IV. DEVICE SIMULATION

For the two different applications mentioned above, a 1-

dimensional computer simulation employing lifetime

profiles will be compared to the test results (Fig. 6 and Fig.

13 are used to explain the physical processes).

An initial trap distribution and related capture cross-

sections were taken from work carried out previously [7]

and the resulting excess carrier lifetime was calculated and

implemented into the device simulator DESSIS [4].

A linear approximation for different proton doses and

energies turned out to be acceptable. The physical models

of the simulator were optimized for good agreement

between the measurements under resistive, snubberless

conditions and the simulations (Fig. 6).

The virtual devices obtained by this procedure (e.g. same

doping- and lifetime profiles and same physical models)

were then implemented in the clamped inductive topology

(Fig. 2) and showed good agreement with the measured

data without further calibration (Fig. 13).

V. MEASURED AND SIMULATED REVERSE-

RECOVERY CHARACTERISTICS

A. Resistive, Snubberless Condition

In this mode the commutation di/dt is controlled by the

active switch, which in our case is a GTO, and typically is

in the range of 50 to 100 A/ scm

-2

at zero current crossing,

accelerating towards the max. reverse current I

RR

[2]. Snap-

off of the diode current is most likely to occur at low

forward current densities (1A/cm

2

3 A/cm

2

) and high

DC-voltages and is more likely to impose problems on the

neighboring circuitry than on the device itself. Dynamic

avalanche, on the contrary occurs at high forward current

and high voltage and may result in the destruction of the

device itself. The maximum power a diode can withstand

during turn off gives us a measure of the ruggedness (SOA)

of the device.

In Fig. 5, the reverse-recovery waveforms of two diodes

with the same on-state voltage drop of 7.1V but different

lifetime profiles are compared at 420 A/cm

2

.

The double-proton irradiated diode has a soft recovery, i.e.

a smooth decay of the diode current without abrupt

changes, even at forward currents as low as 1A/cm

2

and at

a line voltage as high as 3.6 kV. This diode also has a

smaller maximum reverse-recovery current and

consequently a lower maximum peak power density. The

conventional diode with combined e

-

/p

+

irradiation by

contrast shows a greater reverse peak current and

significant snap-off.

To understand the physical processes of the reverse-

recovery of devices with different lifetime profiles, the

simulation described in chapter IV was employed.

The charge carriers in a diode are extracted through the anode

and cathode immediately after the voltage is reversed. As a

consequence, in the device with combined electron and proton

irradiation, a space charge region is formed not only across the

pn-junction, but also across the n

+

/n

-

-junction under the

applied recovery conditions.

3

0

-3

-6

2 0 4 6 8

[ s]

0

-1

-2

-3

Fig. 5. Reverse-recovery waveforms of the double-proton

irradiated (dashed) diode compared to the waveform of a

combined p

+

/e

-

-irradiated diode.

ABB Semiconductors AG & ISL 4.5 kV-Fast-Diodes with Expanded SOA Using a Multi-Energy Proton Lifetime Control Technique

ISPSD Page 3 of 5 Toronto, 1999

30

0

-30

-60

2 0 4 1 3

1

0

-1

-2

-3

-4

[ s]

Fig. 6. Simulated and measured reverse-recovery

characteristics of a double-proton irradiated (dashed) and

p

+

/e

-

-irradiated (solid) device.

This results in a virtual reduction of the usable base-region

(Fig. 7) and to snap-off of the reverse current at the moment

when the two space-charge regions meet at voltages lower

than the static punch-through voltage. Due to the lower

recombination rate and consequently stronger diffusion of

holes into the base-region of the device with profiled lifetime

as obtained by double-energy proton irradiation, the slope of

the electric field is steeper compared to that of the device with

a lifetime profile as obtained by single-energy proton

irradiation combined with electron irradiation. This in turn

delays also the "punch through" of the space-charge region

towards the cathode stopping layer and therefore supports

"soft recovery" even up to voltages beyond the static punch-

through voltage.

To increase the applied voltage of a proper device, the

behavior of the electric field and the carrier distribution

during recovery are of fundamental interest.

Fig. 7 illustrates the simulated electrical field of the double-

p

+

irradiated diode compared to that of the p

+

& e

-

irradiated

device. Fig.9 compares the hole distributions during

reverse-recovery as shown in Fig. 8.

For the comparably snappy recovery of the p

+

& e

-

-

irradiated diode, one can see an additional electric field on

the cathode side.

Fig. 7. The simulated field distribution of a double-proton

irradiated (dashed) diode compared to a conventionally

irradiated (solid) device during turn-off.

1

2

3

4

0 2 1

3

1

0

-1

-2

-3

30

0

-30

-60

[ s]

Fig. 8. Simulated reverse-recovery characteristics of a

double proton irradiated (dashed) and p

+

/e

-

-irradiated

(solid) device I

F

=16A/cm

2

, U

DC

=4kV (same as in Fig.6).

1

2

3

4

10

12

10

14

10

16

0 200 400

[ m]

Fig. 9. Simulated hole distribution at 4 points of time

during the reverse-recovery shown in Fig. 8

There is almost no voltage drop possible across this second

space-charge region because of the majority-carrier

influenced electric field. In contrast, the field on the anode

side is governed by the minority carriers.

The voltage rise over the double-irradiated device leads to a

comparatively lower maximum electric field and to a faster

propagation of the depletion region into the n-base up until

point 2 (Fig. 9) as compared to the p

+

& e

-

-irradiated diode.

Towards the end of the recovery phase the situation

however changes.

The different speeds at which the depletion region is built

up are also illustrated in Fig. 9. Here the depletion speed at

low voltage is much higher (Fig. 9, Points 1 & 2) in the

double-proton irradiated device than in the electron/proton

irradiated diode which results in a reduced I

rr

. However, at

high voltage, toward the end of the recovery phase (Fig. 9,

Points 3 &4), the space-charge region moves more slowly

in the double-irradiated diode, resulting in a softer

recovery. This is a result of the higher amount of carriers

close to the cathode in the double-p

+

irradiated device.

The improved peak power handling capability of the

double-proton irradiated diode is illustrated in Fig. 10.This

shows the diode turn-off waveforms of a double-proton

irradiated diode at a forward current of 90 A/cm

2

and a

reverse supply-voltage of 3.2 kV which results in a peak

power dissipation of 1MW/cm

2

without destruction of the

device.

ABB Semiconductors AG & ISL 4.5 kV-Fast-Diodes with Expanded SOA Using a Multi-Energy Proton Lifetime Control Technique

ISPSD Page 4 of 5 Toronto, 1999

This is a significantly improved capability as compared to

previously tested devices with either electron or combined

p

+

/e

-

-irradiation, where the destruction was observed at

peak power levels between 150 and 250 kW/cm

2

[2].

1 2 3 4 5

0

1

2

3

4

time in s

0

70

-140

-280

Fig. 10.Reverse-recovery of a double-proton irradiated

diode: I

F

= 90A/cm

2

; U

DC

= 3.2 kV; 125 C which leads to a

peak power of 1MW/cm

2

(I

rr

270 A/cm

2

and U

max

4 kV)

B. Clamped Inductive Commutation

This type of operation is of growing importance in Voltage

Source Inverters (VSI) where snubberless IGCTs demand

equally unsnubbered FWDs and Neutral Point Clamping

(NPC) diodes (multi-level inverters). The voltage across

the diode increases to its maximal value while the full

reverse current flows. Diode current I

RR

from current

source L (Fig. 1) cannot decline until V

cl

= V

R

is reached.

Once the clamp becomes effective, the recovery current

declines while the diode voltage remains constant [2].

Fig. 11 shows the waveforms of p

+

& e

-

-irradiated diode

during clamped, inductive turn-off at 2.8 kV supply

voltage. The diode exhibits snappy behavior at a forward

current of 6 A/cm

2

. In contrast the diode with double-

proton irradiation (Fig.12) shows the on-set of snap-off at a

clamp voltage of between 3,8 and 4 kV for the same

forward current. This is an increase of more than 1000 V

for a 4.5 kV diode.

The peak power dissipated by the diode during turn-off

under such conditions may be approximated by multiplying

peak reverse-recovery current with clamp voltage: V

R

*I

RR

90 kW/cm

2

.

The circuit as depicted in Fig.2 was implemented in the

device simulator and the same virtual device structure as

investigated under resistive, snubberless conditions was

compared to the measured waveforms (Fig.13).

For both simulation and measurement, the conditions are:

I

F

= 6 A/cm

2

, L = 1000 H and V

R

= 2900 V, di/dt = 50

A/ s cm

-2

. The test and simulation circuit is shown in

Fig. 1. The simulation result can be seen to be in excellent

agreement with the measurement.

C. Comparison of Commutation Modes

With the help of numerical device investigations, the

physical stresses on the DUT, especially the differences

between those of inductive, clamped and resistive

commutation were analyzed.

Fig. 14 shows the different recovery processes for a

double-proton irradiated device with an initial current

density of 6 A/cm

2

and a clamp-voltage of 3kV.

An obvious difference between commutation modes lies in

the value of the voltage occurring at the peak of reverse-

recovery current. For inductive, clamped commutation,

maximum reverse-recovery current and maximum voltage

occur simultaneously. The peak power under comparable

switching conditions is always higher as compared to the

resistive-switching mode.

In this situation, the full clamp voltage is applied over a

reduced space-charge region. Due to this lower field-

expansion into the base-region of the device, the slope of

the electric field is steeper as compared to that of the

resistive circuit conditions.

The different field distributions are shown in Fig. 15 for

both commutation modes, at the points where voltage starts

to rise (point 1), where DC-voltage is reached (point 2) and

at zero current (point 3).

Additionally the extension of the space-charge region

during the recovery phase is plotted (Fig.14).

Concerning the snappiness criteria, the design rules are

similar to the those for the resistive mode. The increased

excess carrier concentration at the cathode prevents the

formation of a second electric there, which results in a

smooth reverse-recovery current.

0

-1

-2

-3

0 2 4 6 8

14

0

-28

-56

[ s]

Fig. 11. Measured reverse-recovery of a conventional

irradiated device in a clamped, inductive switching mode

with a snappy recovery at U

clamp

= 2.8 kV, I

F

= 6 A/cm

2

0

-1

-2

-3

-4

0 2 4 6 8

14

0

-28

-56

[ s]

Fig. 12. Measured reverse-recovery of a double-proton

irradiated device in a clamped, inductive switching mode

(U

clamp

= 3.8 and 3.9 kV, I

F

= 6 A/cm

2

)

ABB Semiconductors AG & ISL 4.5 kV-Fast-Diodes with Expanded SOA Using a Multi-Energy Proton Lifetime Control Technique

ISPSD Page 5 of 5 Toronto, 1999

1

0

-1

-2

-3

0 2 4 6

14

0

-14

-28

-42

[ s]

Fig. 13. Measured (dotted) and simulated (solid) reverse-

recovery characteristic of a double-proton irradiated device

in a clamped inductive switching mode (U

clamp

= 2.9 kV, I

F

= 6 A/cm

2

)

1

2

3

0 2 4 6

1

0

-1

-2

-3

200

0

400

600

800

[ s]

Fig. 14. Recovery of a double-proton irradiated diode in

resistive (dashed) and inductive, clamped (solid) circuit

(U

DC

/U

clamp

= 3 kV, I

F

= 6 A/cm

2

) and the corresponding

width of the space charge region

0 200 400

200

150

100

50

0

[ m]

2

3

1

Fig. 15. Electric field during the recovery of a double-

proton irradiated diode in a resistive (dashed) and an

inductive clamped (solid) circuit at the 3 points mentioned

V. CONCLUSION

It has been verified by testing that multiple-proton

irradiation techniques applied to diodes as already

suggested in [2] brings a significantly improved diode

performance with respect to snappiness under both resistive

and inductive switching conditions in comparison to

combined electron and proton irradiation.

In addition, the SOA of the double-proton irradiated device

shows an increase - by a factor of 2 to 4 - in power

handling capability as compared to devices with combined

e

-

-p

+

-irradiation.

We have shown that a 1-dimensional computer simulation

employing lifetime profiles can be used to model device

performance and to explain the physical processes of a

diode undergoing turn-off. The excellent agreement of

simulated and tested turn-off characteristics allows reliable

prediction of device performance and avoids laborious

experimentation.

ACKNOWLEDGMENT

The authors wish to thank Stefan Mller and Kurt Haas of

the Q&R department and Mark Frecker and Hans Vetsch of

the Production Test department of ABB Semiconductors

for their help in device testing.

REFERENCES

[1] H. Grning, B. Oedegard, J. Rees, A. Weber, E. Carroll

and S. Eicher, High-power hard-driven GTO module for

4.5 kV/3 kA snubberless operation, PCIM 96 Europe,

p.169-183, 1996

[2] N. Galster, M. Frecker, E. Carroll, J. Vobecky and P.

Hazdra, Application-Specific Fast-Recovery Diode:

Design and Performance, Proc. PCIM, Tokyo 98, p. 69,

1997

[3] J. Vobecky, and P. Hazdra, Future Trends in Local

Lifetime Control, Proc. ISPSD 96, p.161, 1996

[4] R. Escoffier, W. Fichtner, D. Fokkema, E. Lyumkis, O.

Penzin, B. Polsky, A. Schenk and B. Schmithsen,

DESSIS 5.0 Manual, ISE Integrated Systems

Engineering AG, CH - Zrich, 1996

[5] J. Vobecky, P. Hazdra, N. Galster, E. Carroll, Free-

wheeling diodes with improved reverse-recovery by

combined electron and proton irradiation, Proc. PEMC98,

pp.1-22 - 1-25

[6] J. Vobecky and P. Hazdra, Simulation of power

diodes, Internal Report, Praque 1996

You might also like

- Balancing Circuit For A 5-KV 50-Ns Pulsed-Power Switch Based On SiC-JFET Super CascodeDocument7 pagesBalancing Circuit For A 5-KV 50-Ns Pulsed-Power Switch Based On SiC-JFET Super Cascodemohsen feiziNo ratings yet

- A New High-Efficiency Single-Phase Transformerless PV Inverter TopologyDocument8 pagesA New High-Efficiency Single-Phase Transformerless PV Inverter TopologyMohamed SaidNo ratings yet

- 2007 - Sam Mandegaran - ABreakdownVoltageMultiplierforHighVoltageSwingDriv (Retrieved-2015-08-30)Document11 pages2007 - Sam Mandegaran - ABreakdownVoltageMultiplierforHighVoltageSwingDriv (Retrieved-2015-08-30)Miguel D. Diaz H.No ratings yet

- Light Triggering Thyristor For HVDC and Other Applications.Document6 pagesLight Triggering Thyristor For HVDC and Other Applications.IDESNo ratings yet

- High Voltage Pulser With A Fast Fall-Time For Plasma Immersion Ion ImplantationDocument4 pagesHigh Voltage Pulser With A Fast Fall-Time For Plasma Immersion Ion ImplantationAnonymous u5128WZ1KNo ratings yet

- Fast Recovery Diode Generates Nanosecond PulsesDocument4 pagesFast Recovery Diode Generates Nanosecond Pulsessebastian.gonczarekNo ratings yet

- Full Bridge ConverterDocument10 pagesFull Bridge ConvertermuqeetmmaNo ratings yet

- Electronics 08 01137 v2Document14 pagesElectronics 08 01137 v2sigit kurniawanNo ratings yet

- Battery Charging PDFDocument15 pagesBattery Charging PDFTamjid KabirNo ratings yet

- Oc Lab ManualDocument29 pagesOc Lab ManualmanojmuthyalaNo ratings yet

- An On-Line Monitoring System For A Micro Electrical Discharge Machining (micro-EDM) ProcessDocument9 pagesAn On-Line Monitoring System For A Micro Electrical Discharge Machining (micro-EDM) ProcessAnang KatyayanNo ratings yet

- Wireless Power Transmission 2Document6 pagesWireless Power Transmission 2St. Anne's CET (EEE Department)No ratings yet

- High-speed voltage follower designDocument2 pagesHigh-speed voltage follower designfatyfroisNo ratings yet

- 5716 4791 1 PB PDFDocument8 pages5716 4791 1 PB PDFJunika Purnama ZulkifliNo ratings yet

- Dual-Frequency Modified C/V Technique: 150 125 100 7 5 1 50 25 / I 15MW/600nmDocument2 pagesDual-Frequency Modified C/V Technique: 150 125 100 7 5 1 50 25 / I 15MW/600nmkurabyqldNo ratings yet

- Ultra Step-Up DC-DC Converter With Reduced Switch StressDocument10 pagesUltra Step-Up DC-DC Converter With Reduced Switch StressnimasalimNo ratings yet

- Lallart 2008Document9 pagesLallart 2008Minh Le VanNo ratings yet

- Transformer Less Voltage Quadrupler Based DC-DC Converter With Coupled Inductor and PI Filter For Increased Voltage Gain and EfficiencyDocument8 pagesTransformer Less Voltage Quadrupler Based DC-DC Converter With Coupled Inductor and PI Filter For Increased Voltage Gain and EfficiencywelsyaNo ratings yet

- A Low-Cost Solar Micro-Inverter With Soft-SwitchingDocument6 pagesA Low-Cost Solar Micro-Inverter With Soft-Switchingmohamed parvezNo ratings yet

- AC Performance of NanoelectronicsDocument23 pagesAC Performance of Nanoelectronicspraveenpv7No ratings yet

- Coping W Poor Dynamic Performance of Super-Junction MOSFET Body Diodes PDFDocument6 pagesCoping W Poor Dynamic Performance of Super-Junction MOSFET Body Diodes PDFefremofeNo ratings yet

- Piezo Electric Energy HarvestingDocument16 pagesPiezo Electric Energy HarvestingjcvmanalelNo ratings yet

- Design and Implementation of A 100 KW Sic Filter-Less PV Inverter With 5 KW/KG Power Density and 99.2% Cec EfficiencyDocument6 pagesDesign and Implementation of A 100 KW Sic Filter-Less PV Inverter With 5 KW/KG Power Density and 99.2% Cec EfficiencyadnantanNo ratings yet

- High Step-Up Resonant DC/DC Converter With Balanced Capacitor Voltage For Distributed Generation SystemsDocument13 pagesHigh Step-Up Resonant DC/DC Converter With Balanced Capacitor Voltage For Distributed Generation SystemsAbdelaziz IsmealNo ratings yet

- Design and Characterization of High-Current Optical Darlington Transistor For Pulsed-Power ApplicationsDocument11 pagesDesign and Characterization of High-Current Optical Darlington Transistor For Pulsed-Power ApplicationsNUR ASYIQIN BINTI AZAHARNo ratings yet

- Proposal of A Soft-Switching Single-PhaseDocument7 pagesProposal of A Soft-Switching Single-Phaseayie55No ratings yet

- Proceedieee2004 RadanDocument14 pagesProceedieee2004 RadanTimothy BriggsNo ratings yet

- Review of The H-Bridge Three-Phase Low Power Dissipation Connected Micro-Grid NetworkDocument12 pagesReview of The H-Bridge Three-Phase Low Power Dissipation Connected Micro-Grid NetworkDika AdiNo ratings yet

- Analysis of Very Fast Transient Over Voltages in 400kv GIS Transformers Using WaveletDocument6 pagesAnalysis of Very Fast Transient Over Voltages in 400kv GIS Transformers Using WaveletFelipe BittarNo ratings yet

- DocumentsDAB EfficiencyDocument6 pagesDocumentsDAB EfficiencyPiyush MenghaniNo ratings yet

- Zulu James Lab 1 4157Document7 pagesZulu James Lab 1 4157James Jimmy JahNo ratings yet

- A Study On The Effect of Pulse Rising and Falling Time On Amorphous Oxide Semiconductor Transistors in Driver CircuitsDocument4 pagesA Study On The Effect of Pulse Rising and Falling Time On Amorphous Oxide Semiconductor Transistors in Driver CircuitsKunal JoshiNo ratings yet

- Class E amplifier achieves 96% efficiency at 3.9 MHzDocument9 pagesClass E amplifier achieves 96% efficiency at 3.9 MHzjrmciNo ratings yet

- Stacked High Voltage Switch Based S I C Vjfets: ISPSD 2003, April 14-17, UKDocument4 pagesStacked High Voltage Switch Based S I C Vjfets: ISPSD 2003, April 14-17, UKМилан ЛукићNo ratings yet

- Trans Ind Electr 2007 - 2Document8 pagesTrans Ind Electr 2007 - 2Indra PratamaNo ratings yet

- Technical Development On Partial Discharge Measurement and Electrical Insulation Techniques For Low Voltage Motors Driven by Voltage InverterDocument15 pagesTechnical Development On Partial Discharge Measurement and Electrical Insulation Techniques For Low Voltage Motors Driven by Voltage InverterBraulio VillaNo ratings yet

- 1) A Three-Phase Soft-Switched High-Power-Density DC-DC ConverterDocument11 pages1) A Three-Phase Soft-Switched High-Power-Density DC-DC Converteralberfilba2No ratings yet

- Xlecture 1 - Introduction To Power ElectronicsDocument17 pagesXlecture 1 - Introduction To Power ElectronicsমোঃওমরফারুকNo ratings yet

- P Nur Mohammad CUET01Document11 pagesP Nur Mohammad CUET01Sushmitha NagarajuNo ratings yet

- A Simple Energy Recovery Circuit For High-Power Inverters With Complete Turn-On and Turn-Off SnubbersDocument8 pagesA Simple Energy Recovery Circuit For High-Power Inverters With Complete Turn-On and Turn-Off Snubberss_shweta15No ratings yet

- Ge 1961 Tunnel Diode ManualDocument99 pagesGe 1961 Tunnel Diode Manualb_winklerNo ratings yet

- Gaas Pin Photodiode: Created in Comsol Multiphysics 5.5Document20 pagesGaas Pin Photodiode: Created in Comsol Multiphysics 5.5Gerson P.No ratings yet

- Laboratory Manual: Dr. Oday Ali AhmedDocument7 pagesLaboratory Manual: Dr. Oday Ali AhmedEsraa YahyaNo ratings yet

- Optimized DiodeDocument6 pagesOptimized DiodeEla HawesNo ratings yet

- Cao 2021Document5 pagesCao 2021blackyNo ratings yet

- Design and Simulation of A Grid Tied Single PhaseDocument10 pagesDesign and Simulation of A Grid Tied Single PhaseERICK SANTIAGO ACOSTA HERNANDEZNo ratings yet

- Senkottai Village, Madurai - Sivagangai Main Road, Madurai - 625 020. (An ISO 9001:2008 Certified Institution)Document23 pagesSenkottai Village, Madurai - Sivagangai Main Road, Madurai - 625 020. (An ISO 9001:2008 Certified Institution)Raji SharmiNo ratings yet

- Wideband Resistive Voltage Divider For A Standard Wattmeter: Journal of Physics: Conference SeriesDocument8 pagesWideband Resistive Voltage Divider For A Standard Wattmeter: Journal of Physics: Conference SeriesAngel SamanthaNo ratings yet

- Design Modification of Rogowski Coil For Current MDocument7 pagesDesign Modification of Rogowski Coil For Current MLeandro AriasNo ratings yet

- A Solar Powered Reconfigurable Inverter Topology For Ac/Dc Home With Fuzzy Logic ControllerDocument6 pagesA Solar Powered Reconfigurable Inverter Topology For Ac/Dc Home With Fuzzy Logic ControllerTushar MukherjeeNo ratings yet

- Vibrational energy harvesting using MEMS piezoelectric generatorsDocument17 pagesVibrational energy harvesting using MEMS piezoelectric generatorsLuis Gustavo ReisNo ratings yet

- Design of Buck DC-DC Converter Space ApplicationDocument7 pagesDesign of Buck DC-DC Converter Space ApplicationIJRASETPublicationsNo ratings yet

- nano-HIGH POWER SUBNANOSECONDDocument5 pagesnano-HIGH POWER SUBNANOSECONDSergei_V_7521No ratings yet

- A High-Efficiency 6.78-Mhz Full Active Rectifier With Adaptive Time Delay Control For Wireless Power TransmissionDocument10 pagesA High-Efficiency 6.78-Mhz Full Active Rectifier With Adaptive Time Delay Control For Wireless Power Transmissionfelix_007_villedaNo ratings yet

- Rogowski Coil 1Document4 pagesRogowski Coil 1sanjaybmscseNo ratings yet

- Microwave Avalanche Diodes: Simon M. Sze, Robert RyderDocument16 pagesMicrowave Avalanche Diodes: Simon M. Sze, Robert RyderMohd Azlishah OthmanNo ratings yet

- Static Induction TransistorDocument7 pagesStatic Induction TransistorEnrique Gamez Cardenas50% (2)

- High Gain GaN-AlGaN Heterojunction Phototransistor - APL - 1998-Wei Yang PDFDocument4 pagesHigh Gain GaN-AlGaN Heterojunction Phototransistor - APL - 1998-Wei Yang PDFVenkata Surya NagarajuNo ratings yet

- It Is Quite Another Electricity: Transmitting by One Wire and Without GroundingFrom EverandIt Is Quite Another Electricity: Transmitting by One Wire and Without GroundingNo ratings yet

- Impedance Spectroscopy: Theory, Experiment, and ApplicationsFrom EverandImpedance Spectroscopy: Theory, Experiment, and ApplicationsEvgenij BarsoukovNo ratings yet

- Rylwy ManualDocument5 pagesRylwy ManualHappyJoeNo ratings yet

- QEG QuestionsAnswersQEG4!4!2014 BDocument3 pagesQEG QuestionsAnswersQEG4!4!2014 BHappyJoeNo ratings yet

- Patent WO8706402A1 - Jim MurrayDocument44 pagesPatent WO8706402A1 - Jim MurrayHappyJoeNo ratings yet

- Where Does Humanity GoDocument6 pagesWhere Does Humanity Gojc200312127869No ratings yet

- Behringer Ep2500 Power Amplifier SchematicDocument1 pageBehringer Ep2500 Power Amplifier SchematicIonut CaldararuNo ratings yet

- Intelli Vu PLUSDocument2 pagesIntelli Vu PLUSHappyJoeNo ratings yet

- Relay Basics TYCO - PDF - (1 - 1)Document32 pagesRelay Basics TYCO - PDF - (1 - 1)Jan PranNo ratings yet

- Prof - Van Overmeire (VUB)Document1 pageProf - Van Overmeire (VUB)Dédaluz SupertrampNo ratings yet

- Tariel Kapanadze Patent WO2008103130A1Document12 pagesTariel Kapanadze Patent WO2008103130A1HappyJoeNo ratings yet

- A Simple Approach To YIG OscilDocument8 pagesA Simple Approach To YIG OscilGiao NguyenNo ratings yet

- UFOs Are Real - C E Stone01Document55 pagesUFOs Are Real - C E Stone01anon-94675790% (10)

- Keter - 8 X 11 Shed - 163887 - AssemblyinstructionsDocument52 pagesKeter - 8 X 11 Shed - 163887 - AssemblyinstructionsHappyJoeNo ratings yet

- Resonance Phenomena in Non-Linear and Parametric CircuitsDocument12 pagesResonance Phenomena in Non-Linear and Parametric CircuitsharishkumarsinghNo ratings yet

- Patent US2787755 - Magnetic Frequency DividerDocument3 pagesPatent US2787755 - Magnetic Frequency DividerHappyJoeNo ratings yet

- George Green Message For The Ground CrewDocument17 pagesGeorge Green Message For The Ground CrewDelwayne MillsNo ratings yet

- Reading 34: Frequency Modulation What Is Frequency Modulation?Document15 pagesReading 34: Frequency Modulation What Is Frequency Modulation?Mustafa IbrahimNo ratings yet

- 2N3904 BJTDocument7 pages2N3904 BJTsuperkan619No ratings yet

- 4.5 kV-Fast-Diodes With Expanded SOA Using A Multi-Energy Proton Lifetime Control TechniqueDocument6 pages4.5 kV-Fast-Diodes With Expanded SOA Using A Multi-Energy Proton Lifetime Control TechniqueHappyJoeNo ratings yet

- List of Dead Scientists Assassinated - World TruthDocument90 pagesList of Dead Scientists Assassinated - World TruthHappyJoeNo ratings yet

- Racal Dana LCR 9343mDocument50 pagesRacal Dana LCR 9343mHappyJoeNo ratings yet

- MFJ-854 RF MeterDocument5 pagesMFJ-854 RF MeterHappyJoeNo ratings yet

- Keshe - Harvard Using His Tech - News - A Magnetic Cure Against Viruses Like EbolaDocument4 pagesKeshe - Harvard Using His Tech - News - A Magnetic Cure Against Viruses Like EbolaHappyJoeNo ratings yet

- Proposed Studies On The Implication of Peaceful Space Activities For Human AffairsDocument219 pagesProposed Studies On The Implication of Peaceful Space Activities For Human Affairsmauro.pennacchiettiNo ratings yet

- Hands On HealingDocument5 pagesHands On HealingHappyJoe100% (4)

- Keshe - CO2KitInstructionsDocument3 pagesKeshe - CO2KitInstructionsHappyJoeNo ratings yet

- Martin Tajmar Et Al - Measurement of Gravitomagnetic and Acceleration Fields Around Rotating SuperconductorsDocument12 pagesMartin Tajmar Et Al - Measurement of Gravitomagnetic and Acceleration Fields Around Rotating SuperconductorsOlmnopNo ratings yet

- Turnigy Accucel 6 ManualDocument21 pagesTurnigy Accucel 6 Manualkupoo_999No ratings yet

- Patent - Paul BabcockDocument25 pagesPatent - Paul BabcockHappyJoeNo ratings yet

- Mfj-269c User ManualDocument40 pagesMfj-269c User ManualHappyJoeNo ratings yet

- W201 Wiring DiagramDocument290 pagesW201 Wiring Diagramilikemyfishbigandblue86% (44)

- BD139Document3 pagesBD139Christina Tio TrisnasariNo ratings yet

- Pines Shield Multifuncion PDFDocument3 pagesPines Shield Multifuncion PDFGustavo Portilla MartinezNo ratings yet

- November 2019 Chint Electric Price List Firefly Electric & Lighting CorpDocument6 pagesNovember 2019 Chint Electric Price List Firefly Electric & Lighting Corpmas zak danielNo ratings yet

- ARCODE Gearless SP-16 CPC-T.enDocument36 pagesARCODE Gearless SP-16 CPC-T.enOsama Odeh100% (1)

- Current Differential Relay ManualDocument4 pagesCurrent Differential Relay Manualppraveenkumar79No ratings yet

- CT PartsDocument13 pagesCT PartsJose Aldrin Climacosa SerranoNo ratings yet

- Hho ManualDocument23 pagesHho ManualtononoinkNo ratings yet

- Simple Machines ExercisesDocument3 pagesSimple Machines Exercisesyensy morel ureñaNo ratings yet

- Industrial Gigabit Ethernet PHY Reference DesignDocument19 pagesIndustrial Gigabit Ethernet PHY Reference DesignNguyễn Hữu TàiNo ratings yet

- 40XMH'11 40XW'11: (67TL) (67TK)Document50 pages40XMH'11 40XW'11: (67TL) (67TK)Carlos NetoNo ratings yet

- BobcatDocument3 pagesBobcatJorge CabreraNo ratings yet

- Rectifier Diodes BYW29 Series Ultrafast: General Description Quick Reference DataDocument6 pagesRectifier Diodes BYW29 Series Ultrafast: General Description Quick Reference DataEddy Santiago Neira SisaNo ratings yet

- ZPA PogonDocument57 pagesZPA PogonMacakafkaNo ratings yet

- Ca and CH Series: Product SpecificationsDocument12 pagesCa and CH Series: Product SpecificationsMark ThomasNo ratings yet

- User Manual: EV1000 Series General Purpose Variable Speed DriveDocument159 pagesUser Manual: EV1000 Series General Purpose Variable Speed DriveEngenharia SematexNo ratings yet

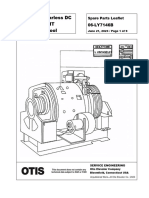

- 06 Ly7146bDocument9 pages06 Ly7146bm.omeracarNo ratings yet

- BDS Maschinen MABasicDocument4 pagesBDS Maschinen MABasicJOAQUINNo ratings yet

- AKAI GX Reel To Reel RecorderDocument11 pagesAKAI GX Reel To Reel RecorderRoger CalvertNo ratings yet

- 1MRB520308-BEN D en Distributed Busbar Protection REB500Document58 pages1MRB520308-BEN D en Distributed Busbar Protection REB500locomaniacoNo ratings yet

- Wellcome To Our PresentationDocument16 pagesWellcome To Our PresentationnordianashahuddinNo ratings yet

- First Summative Test in CSS 1Document3 pagesFirst Summative Test in CSS 1Ricky Rom MonteNo ratings yet

- HST-2 Expansion Anchor Technical DatasheetDocument11 pagesHST-2 Expansion Anchor Technical DatasheetThe KeymasterNo ratings yet

- HD44780 CommandsDocument3 pagesHD44780 CommandsPhani ChakravarthiNo ratings yet

- Cmos Implementation of Logic Blocks and Sequential ElementsDocument18 pagesCmos Implementation of Logic Blocks and Sequential ElementsShovon BhowmickNo ratings yet

- 2SA1568Document13 pages2SA1568raquelNo ratings yet

- Machinists Screw JackDocument3 pagesMachinists Screw Jackmauri_ros100% (1)

- DLT 300 Lo SeriesDocument2 pagesDLT 300 Lo SeriesKhurram ShahzadNo ratings yet

- Opto-Isolated I/O Board: VCC Is 5 VDC, +V Is 5 VDC (VCC and +V Are Isolated For Each Other)Document2 pagesOpto-Isolated I/O Board: VCC Is 5 VDC, +V Is 5 VDC (VCC and +V Are Isolated For Each Other)Miklós GordosNo ratings yet